Sludge dehydration curing agent and resource utilization method thereof

A curing agent and resource-based technology, applied in chemical instruments and methods, water/sludge/sewage treatment, applications, etc., can solve problems such as weakened water holding capacity, high freight costs, waste of resources, etc., and achieve reduced loss and texture Excellent, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

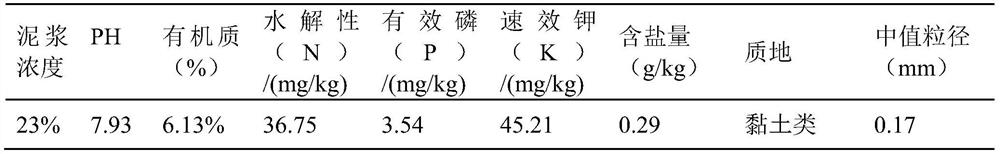

[0029] The research object is dredged mud from a lakeside area in Xizhou Town, Dali, Yunnan, and its basic physical properties are shown in Table 1.

[0030] Table 1 Basic physical properties of lakeside mud

[0031]

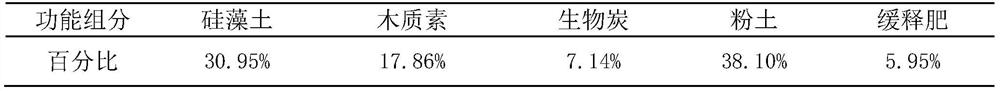

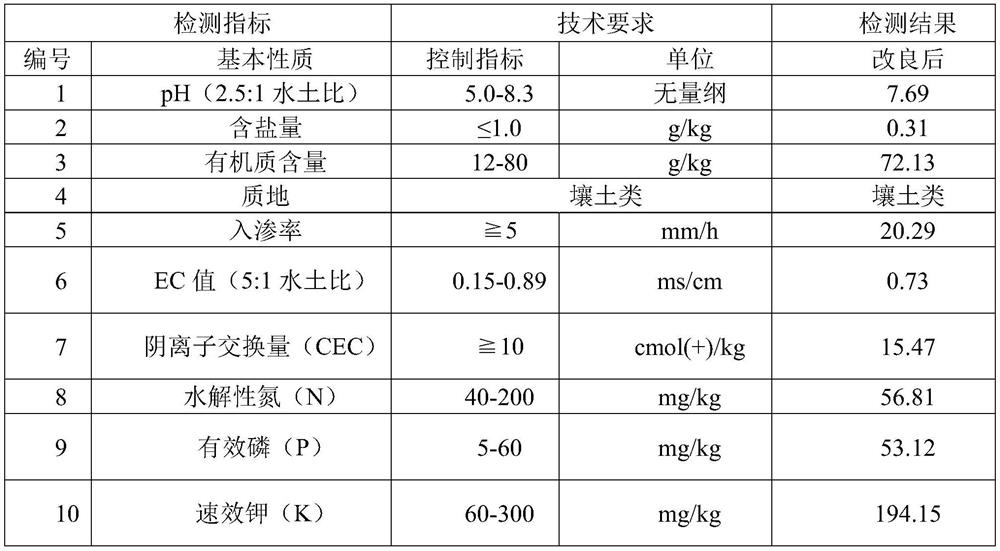

[0032] Take 26 parts of diatomite, 15 parts of lignin, 6 parts of biochar, 32 parts of silt, and 5 parts of slow-release fertilizer. The pores of diatomite are 485nm, the length of lignin fibers is 450um, and the fiber content is ≧85%. The carbon (C) content of the charcoal is 55.6%, the nitrogen content is 4.3%, the pH value is 8.5, the particle size of the slow-release fertilizer is between 0.6-0.8cm, the particle size of the silt is 0.075-0.005mm, and the silt content is 91%. , and there is no cohesion between the particles, and the clay content is 9%. The various components are fully mixed to obtain a lakeside mud dewatering and curing agent. According to the conversion of the number of parts, the mass percentage of each component is shown in Table 2. ...

Embodiment 2

[0040]The research object is dredged mud from a lakeside area in Shangguan, Dali, Yunnan, and its basic physical properties are shown in Table 4.

[0041] Table 4 Basic physical properties of lakeside mud

[0042]

[0043] Take 32 parts of diatomite, 18 parts of lignin, 7 parts of biochar, 41 parts of silt, and 4 parts of slow-release fertilizer. Among them, the pores of diatomite are 108-376nm, the length of lignin fiber is 412um, and the fiber content is ≧76.8% , the carbon (C) content of biochar is 48.7%, the nitrogen content is 3.2%, the pH value is 8.3, the particle size of slow-release fertilizer is between 0.56-0.79cm, the particle size of silt is 0.075-0.005mm, 92.3%, and no intergranular cohesion, clay content 7.7%. The various components are fully mixed to obtain a lakeside mud dewatering and curing agent. According to the conversion of the number of parts, the mass percentage of each component is shown in Table 5.

[0044] Table 5 Percentage of each component ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com