Automatic mud desanding and purification equipment

A purification equipment and mud technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of automatic control of mud, reduced efficiency of construction holes, and increased maintenance time, etc., to achieve Improve the operation of equipment, save manpower and material resources, and reduce the effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

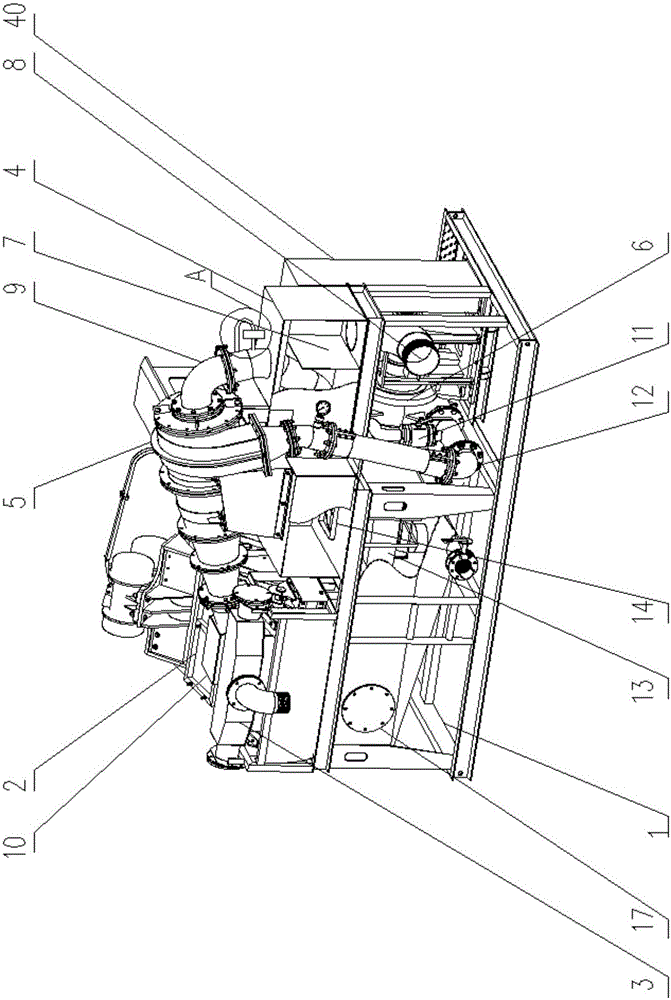

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

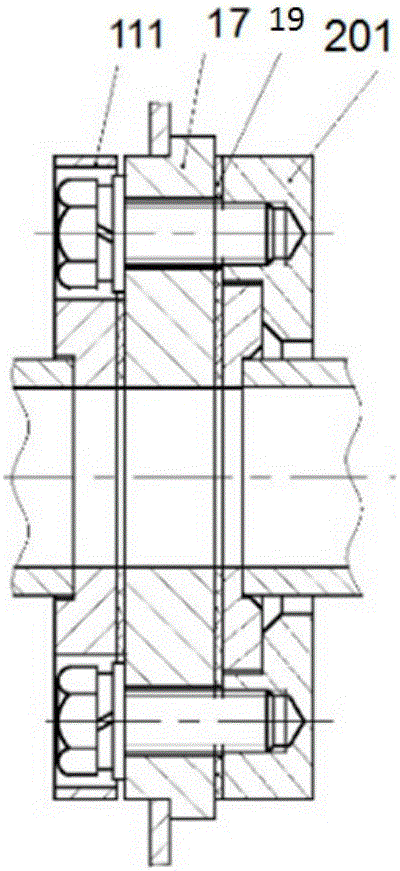

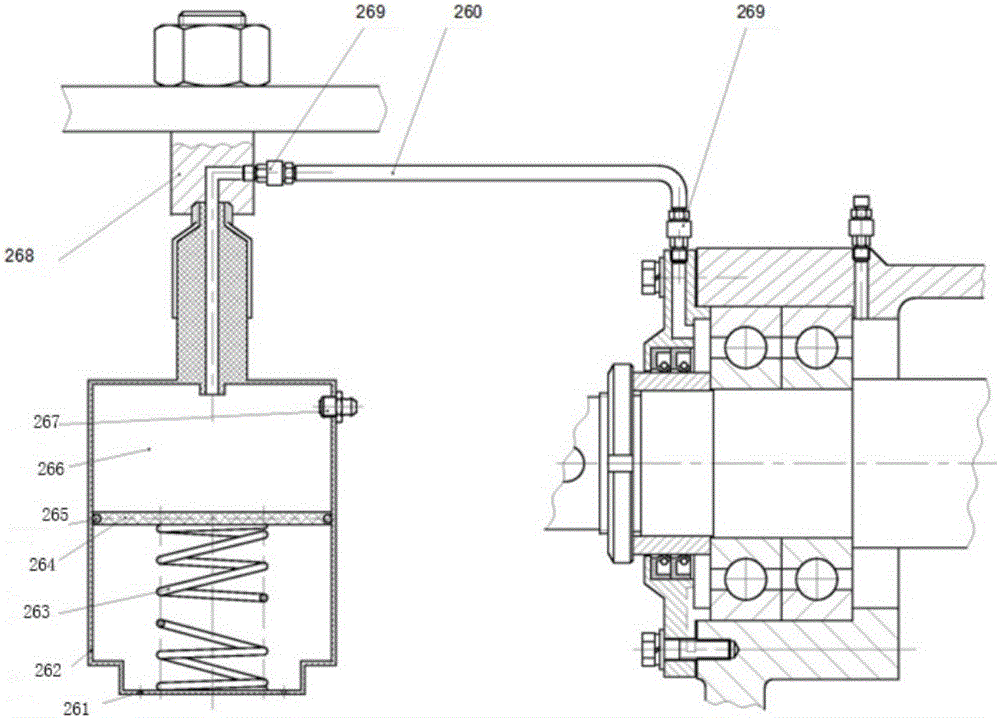

[0036]As shown in the figure, the present invention comprises, a feed port 3 is fixed on the frame 1 of a frame 1, and a vibrating coarse screen plate 22 is fixed at the lower end of the feed port 3, and the coarse screen plate 22 A slurry storage tank 17 is fixed at the lower end, and the slurry storage tank 17 communicates with the suction port of a slurry pump 6, and the discharge port of the slurry pump 6 is connected with a cyclone feed pipe 12 fixed on the machine. The feed port of the cyclone 5 on the frame 1 is connected, and the lower end of the bottom flow port 10 at one end of the cyclone 5 is fixed with a vibrating fine sieve plate 23, and the vibrating fine sieve plate 23 is located at the bottom of the slurry storage tank 17. The upper end is located above the vibrating coarse sieve plate 22; the upper end of the cyclone 5 has a cyclone overflow pipe 9,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com