Dehydrating method of washing equipment and washing equipment

A washing equipment and washing tub technology, which is applied to washing devices, control devices of washing machines, textiles and papermaking, etc., can solve the problems of difficulty in guaranteeing the overall dehydration efficiency of washing machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood by those skilled in the art that, in the description of the present invention, although the various steps of the control method of the present invention are described in a specific order in the application, these orders are not limiting, and the basic principles of the present invention Under the premise of the principles, those skilled in the art may perform the steps in different orders.

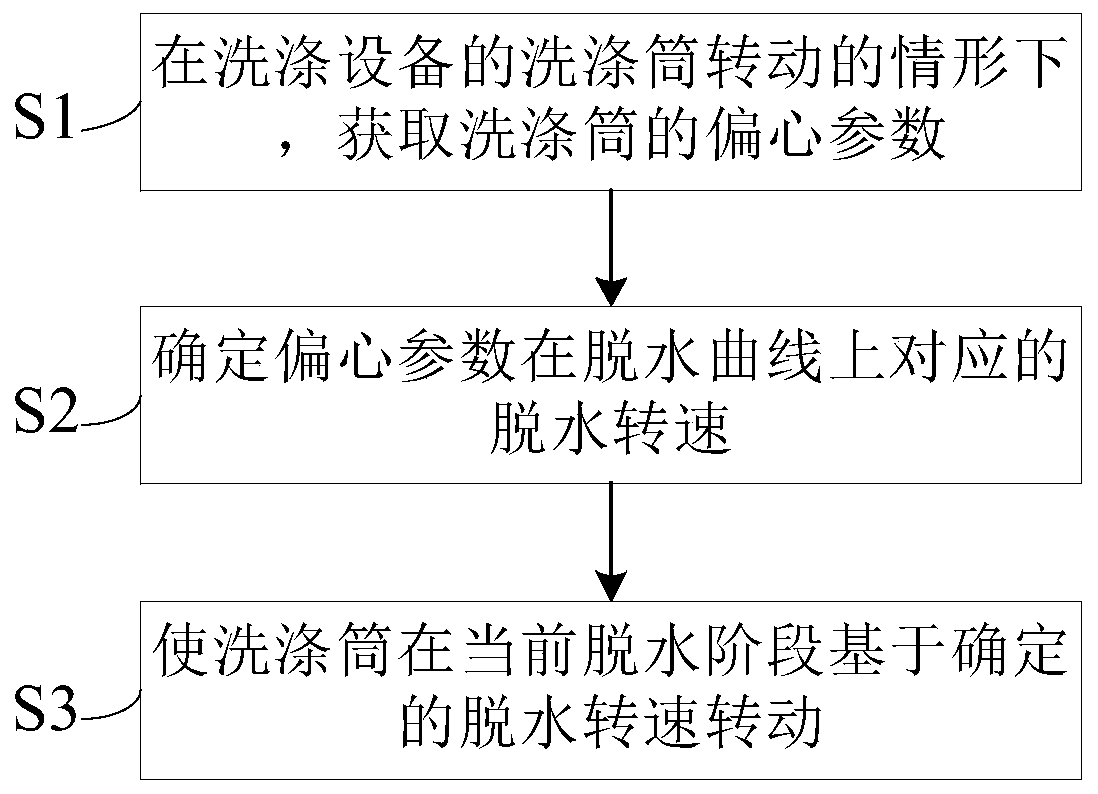

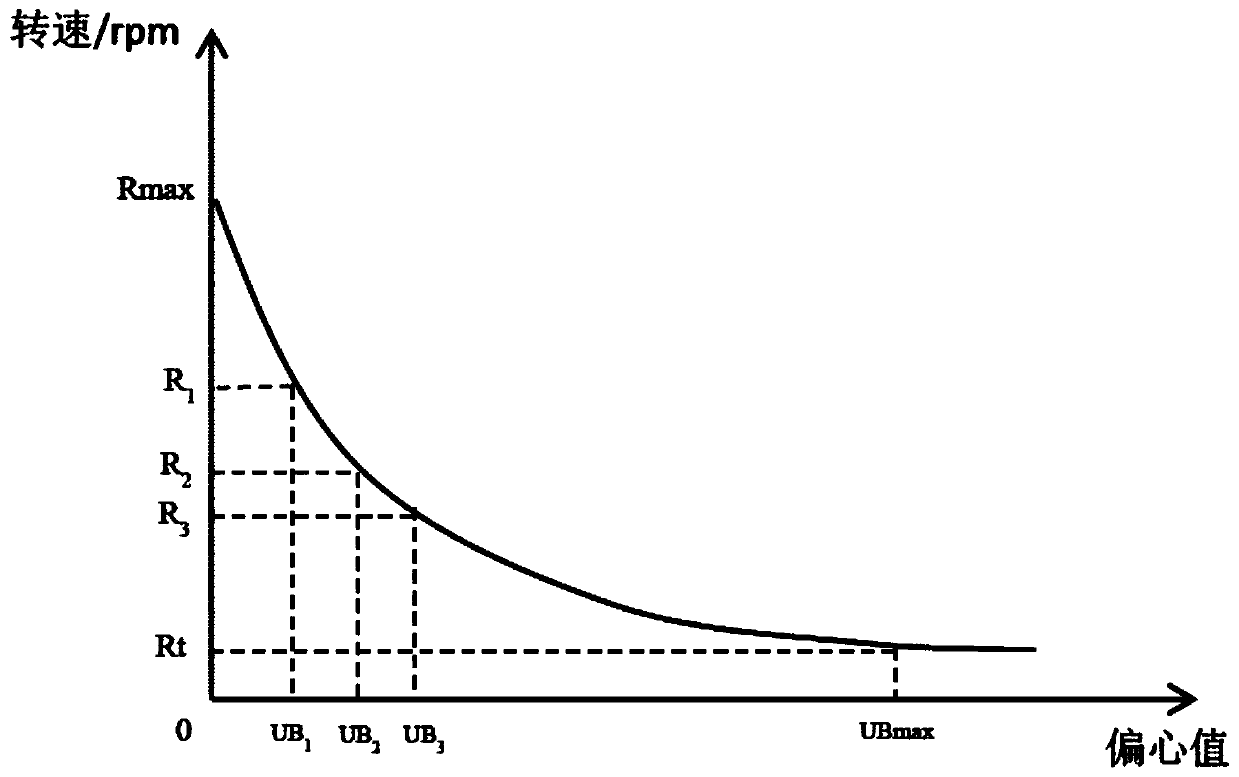

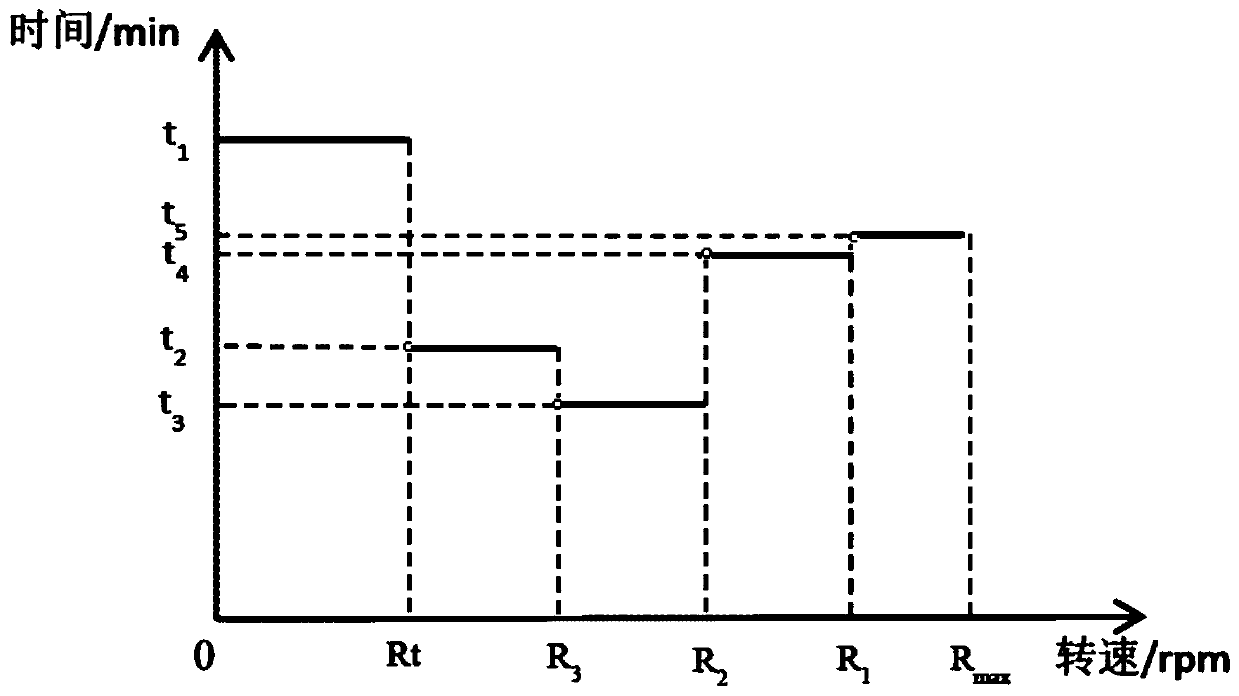

[0024] Based on the problems pointed out in the background technology that the existing washing machine may perform at least one laundry operation during the dehydration process, and the overall dehydration efficiency of the washing machine is difficult to guarantee, the present invention provides a dehydration method for washing equipment and washing equipment, aiming at making washing The device can perform dehydration operation without improving the current eccentricity of the washing drum, improve the dehydration efficiency of the washing device, and short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com