Ultrahigh-power ultrasonic dirty oil demulsification and dehydration plant

A super-high-power, dehydration device technology, applied in the petroleum industry, hydrocarbon oil treatment, multi-stage serial refining process treatment, etc., can solve the problems of poor treatment effect, unsuitable sewage treatment process, and affecting oilfield development effect, etc. Achieve the effects of reduced transportation, continuous and uninterrupted demulsification and dehydration, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

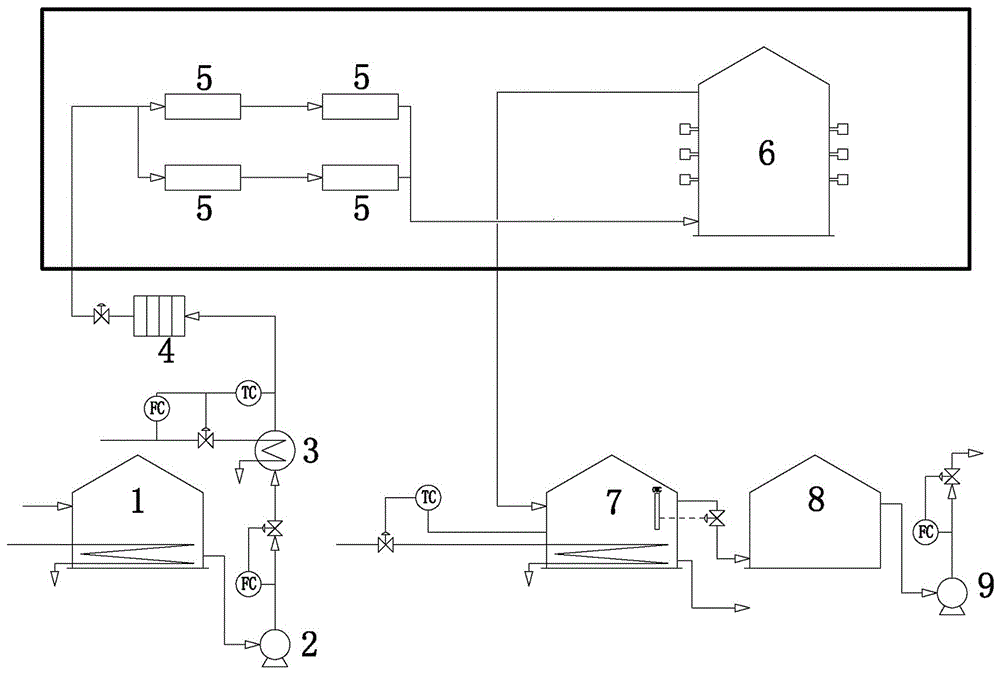

[0021] like figure 1 Shown: an ultra-high-power ultrasonic demulsification and dehydration device for dirty oil, including a dirty oil raw material tank 1, and the watery dirty oil in the dirty oil raw material tank 1 is sent to the ultrasonic effector 5 arranged in series through the watery dirty oil pump 2 for continuous ultrasonic Primary demulsification, the pipeline between the water-containing sewage oil pump 2 and the ultrasonic generator 5 is provided with a sewage oil heater 3 and an impurity filter 4 in sequence, and the water-containing sewage oil pump 2 boosts the pressure of the water-containing sewage oil and sends it to the sewage oil heater 3. Heating to 50°C-85°C, and filtering through the impurity filter 4 and then entering the ultrasonic effector 5 for continuous ultrasonic primary demulsification treatment; the outlet of the ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com