Patents

Literature

203 results about "High power ultrasound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

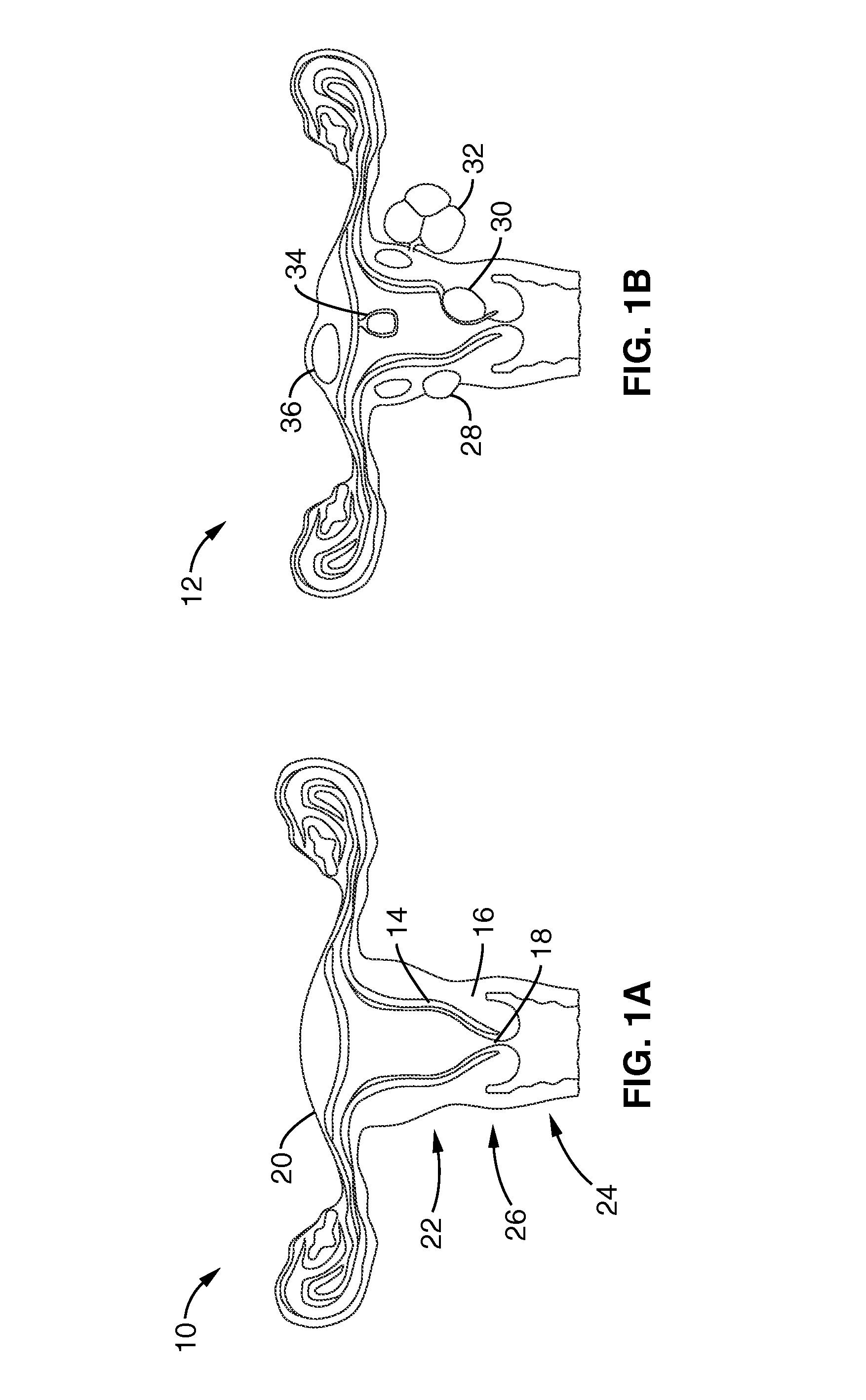

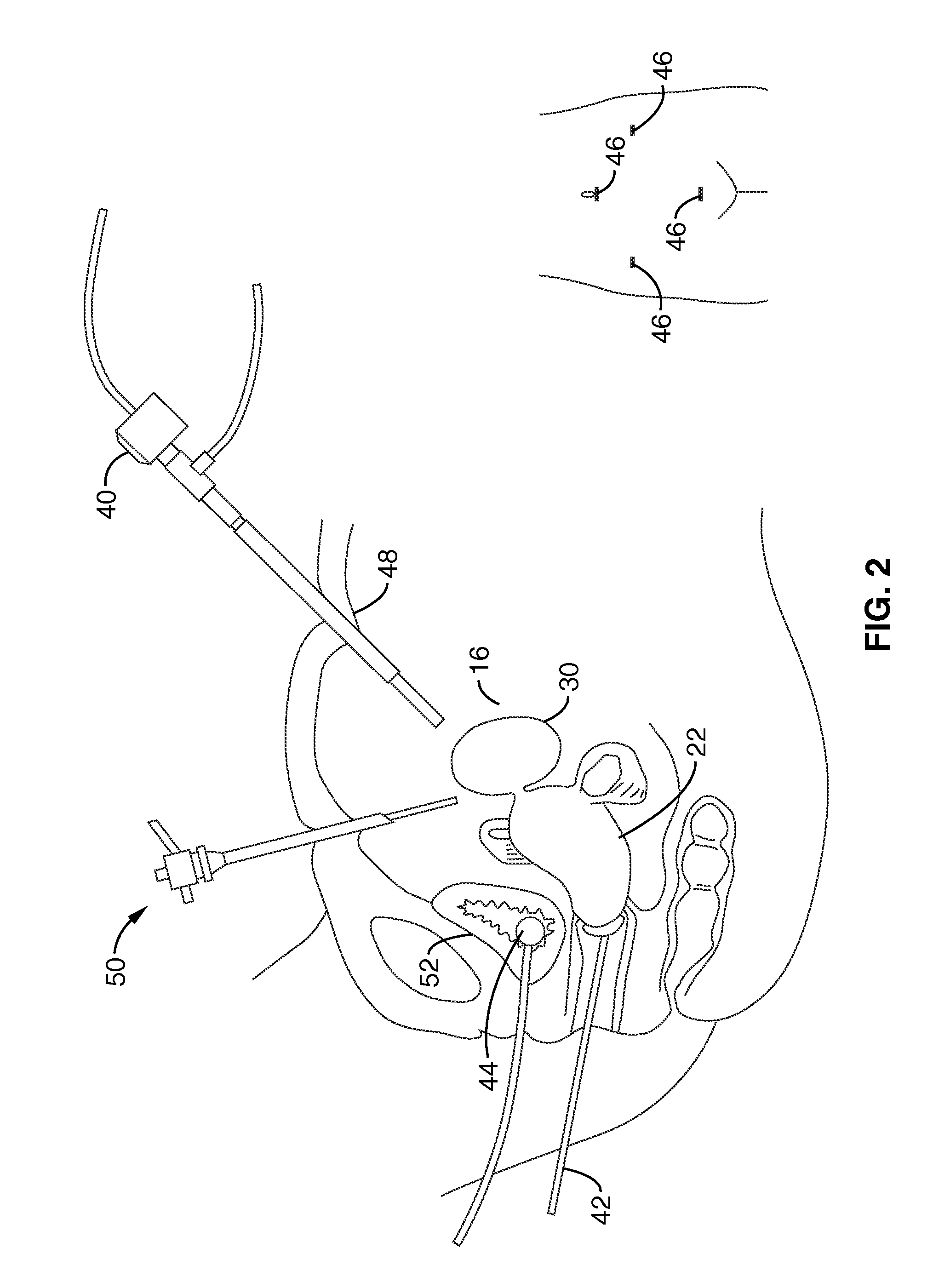

Method of thermal treatment of myolysis and destruction of benign uterine tumors

ActiveUS20070255267A1Shorten treatment timeIncrease opportunitiesUltrasound therapySurgical instruments for heatingHysteroscopic surgeryHigh intensity

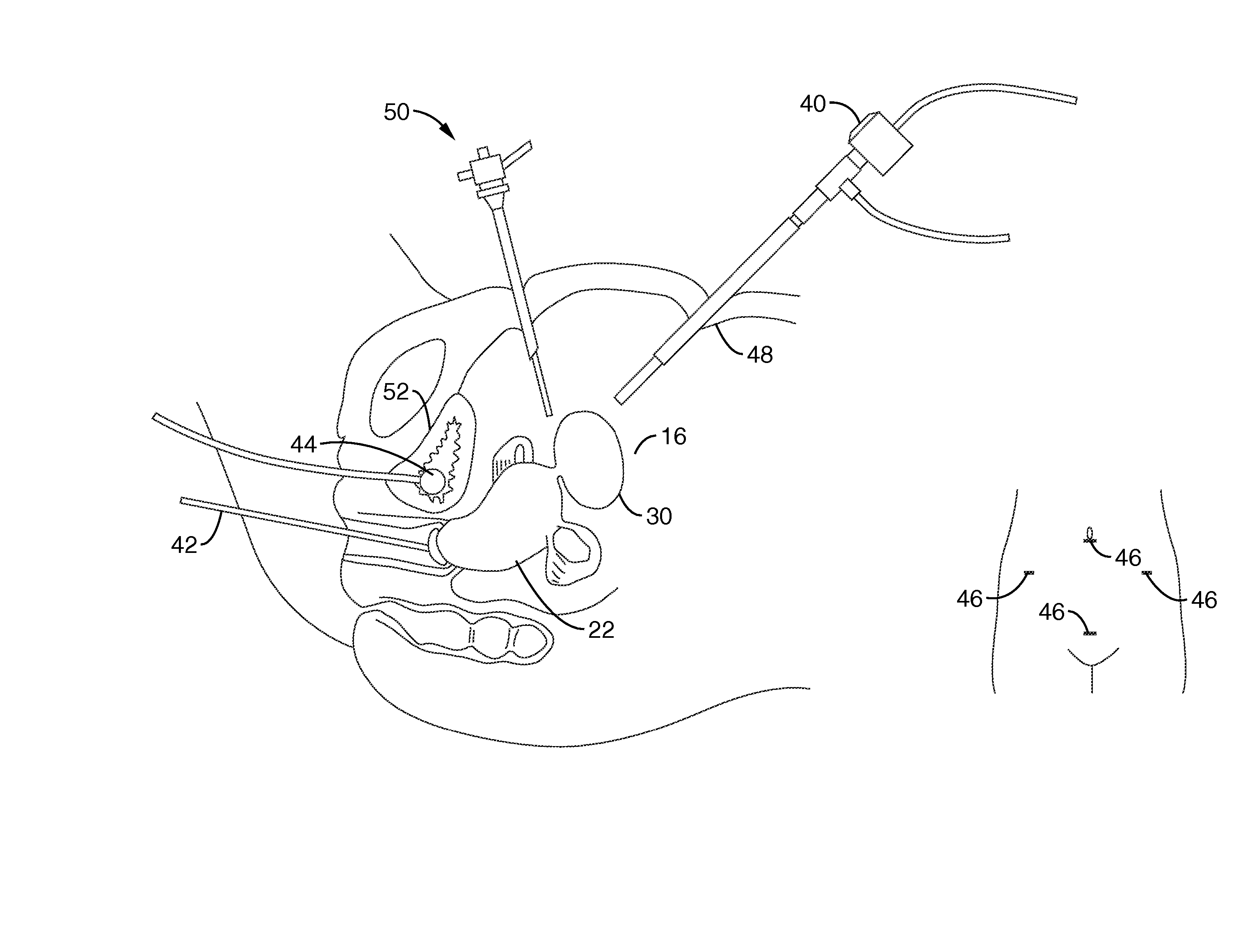

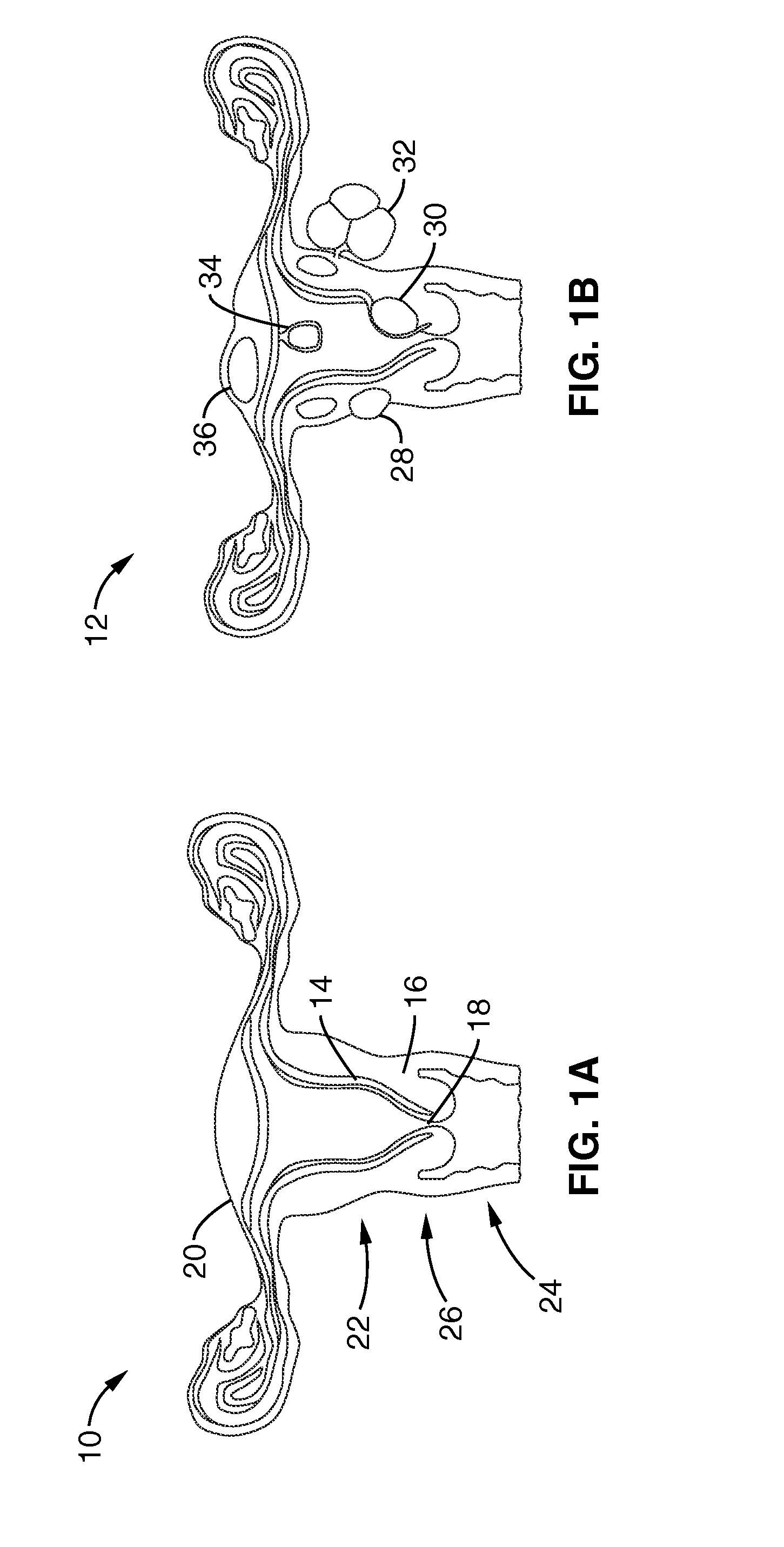

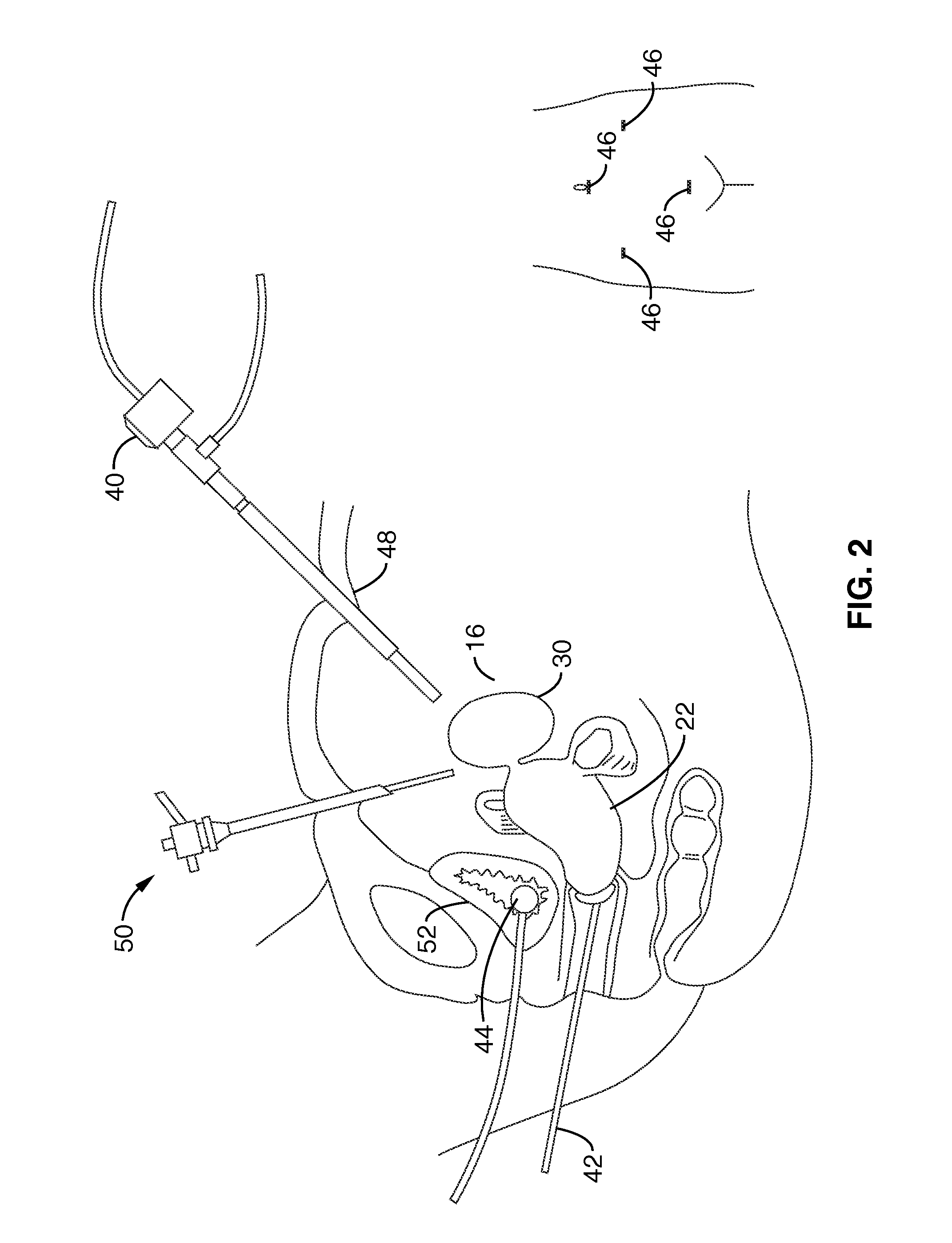

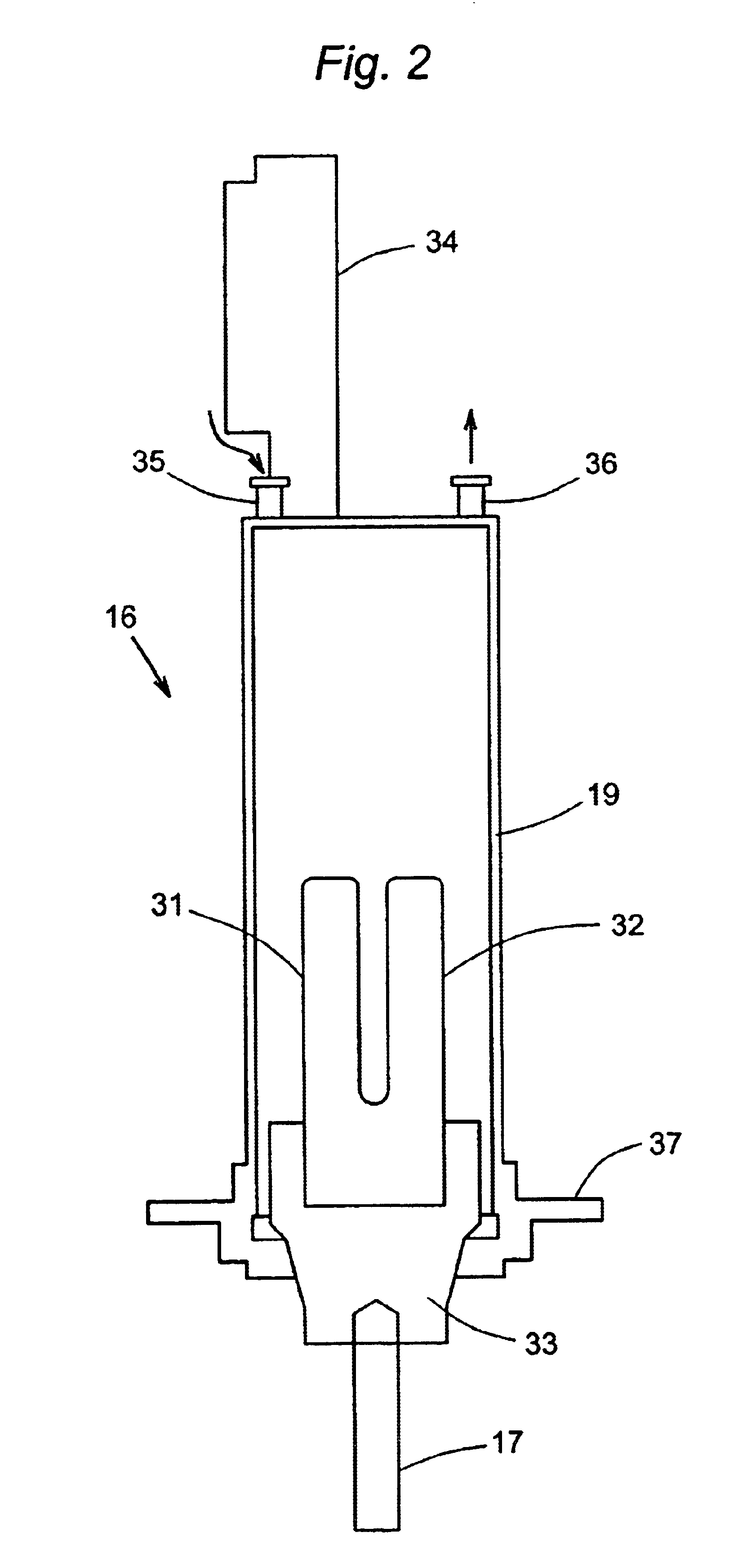

A high-power ultrasound heating applicator for minimally-invasive thermal treatment of uterine fibroids or myomas. High-intensity interstitial ultrasound, applied with minimally-invasive laparoscopic or hysteroscopic procedures, is used to effectively treat fibroids within the myometrium in lieu of major surgery. The applicators are configured with high-power capabilities and thermal penetration to treat large volumes of fibroid tissue (>70 cm3) in short treatment times (3-20 minutes), while maintaining three-dimensional control of energy delivery to thermally destroy the target volume.

Owner:RGT UNIV OF CALIFORNIA +1

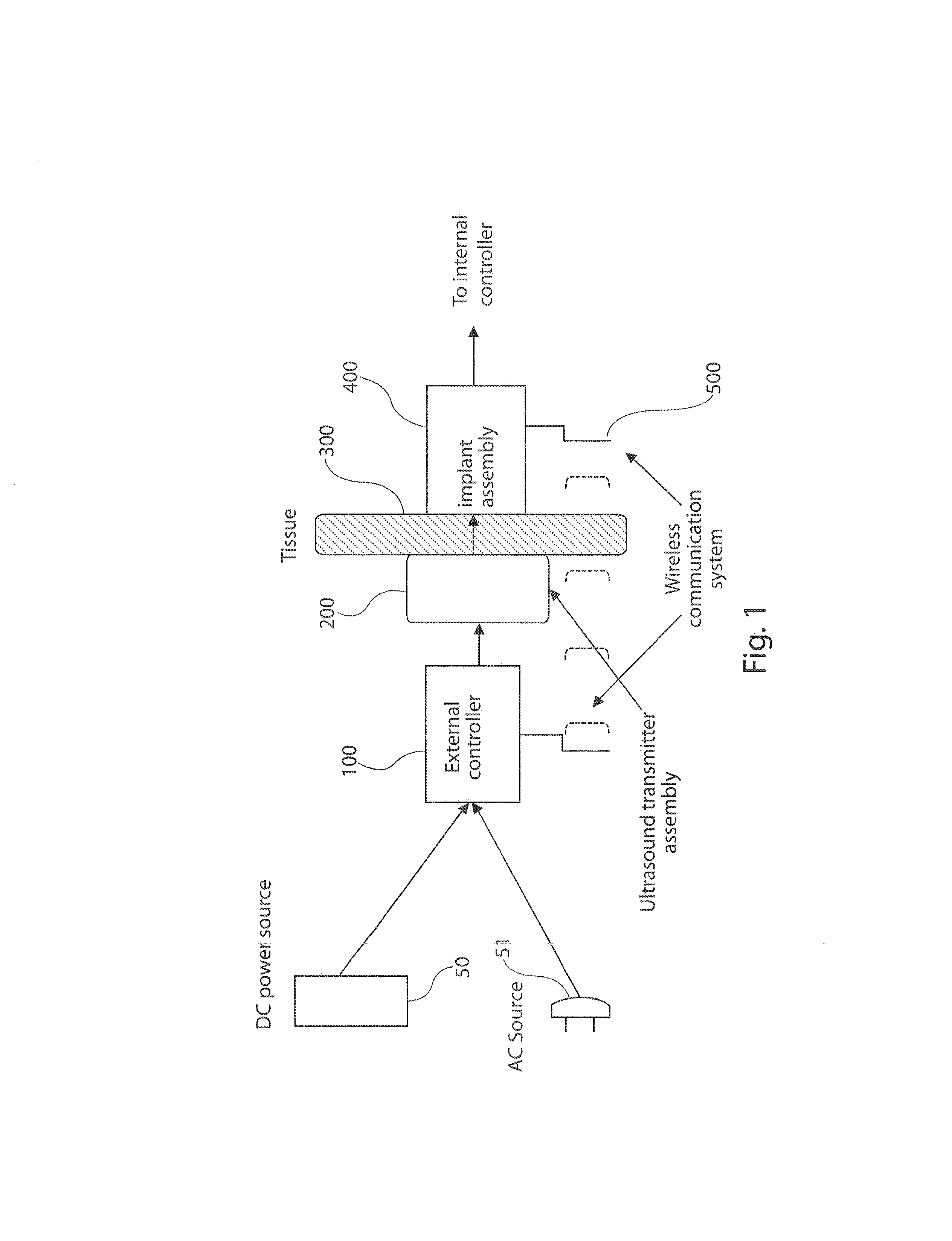

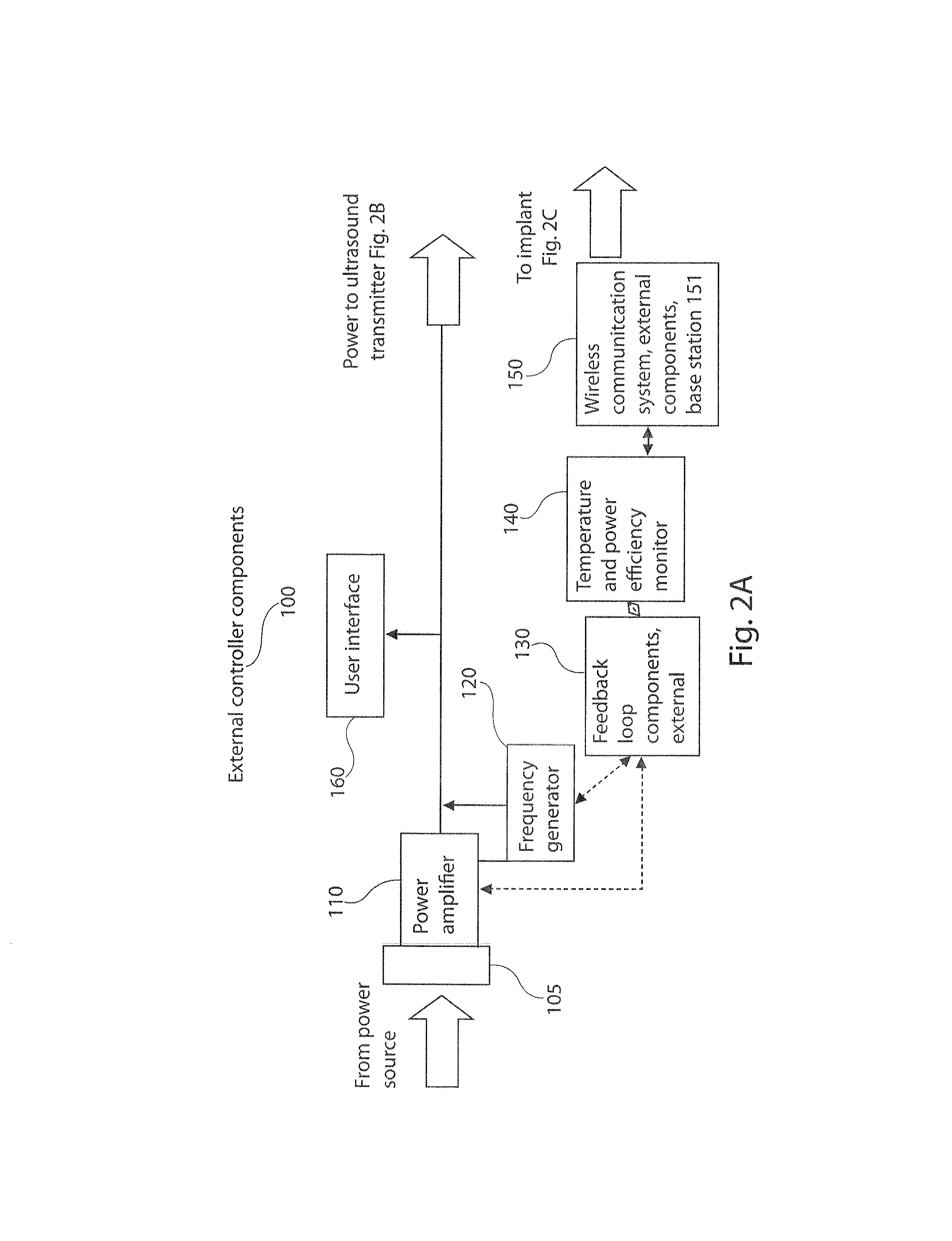

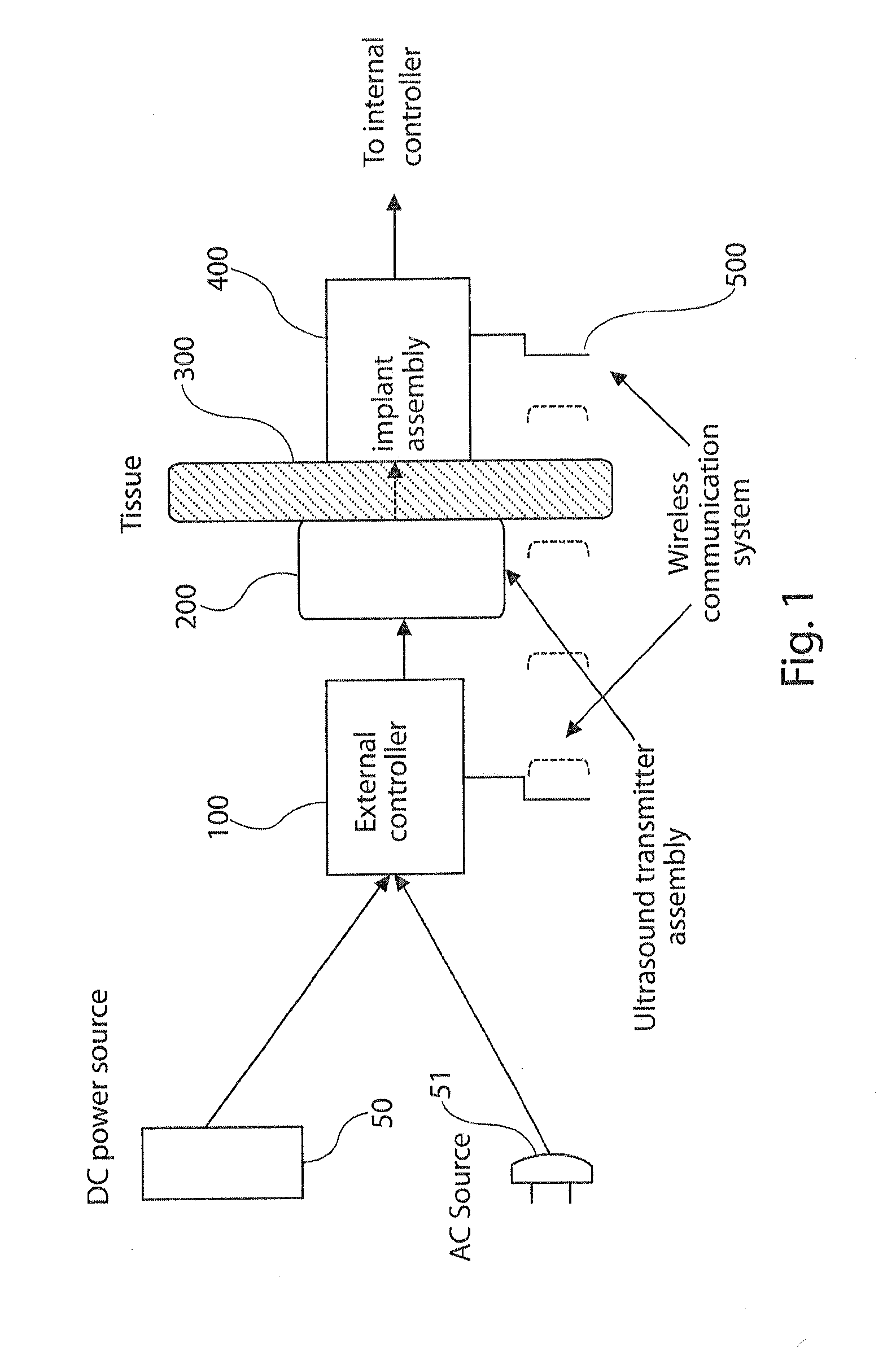

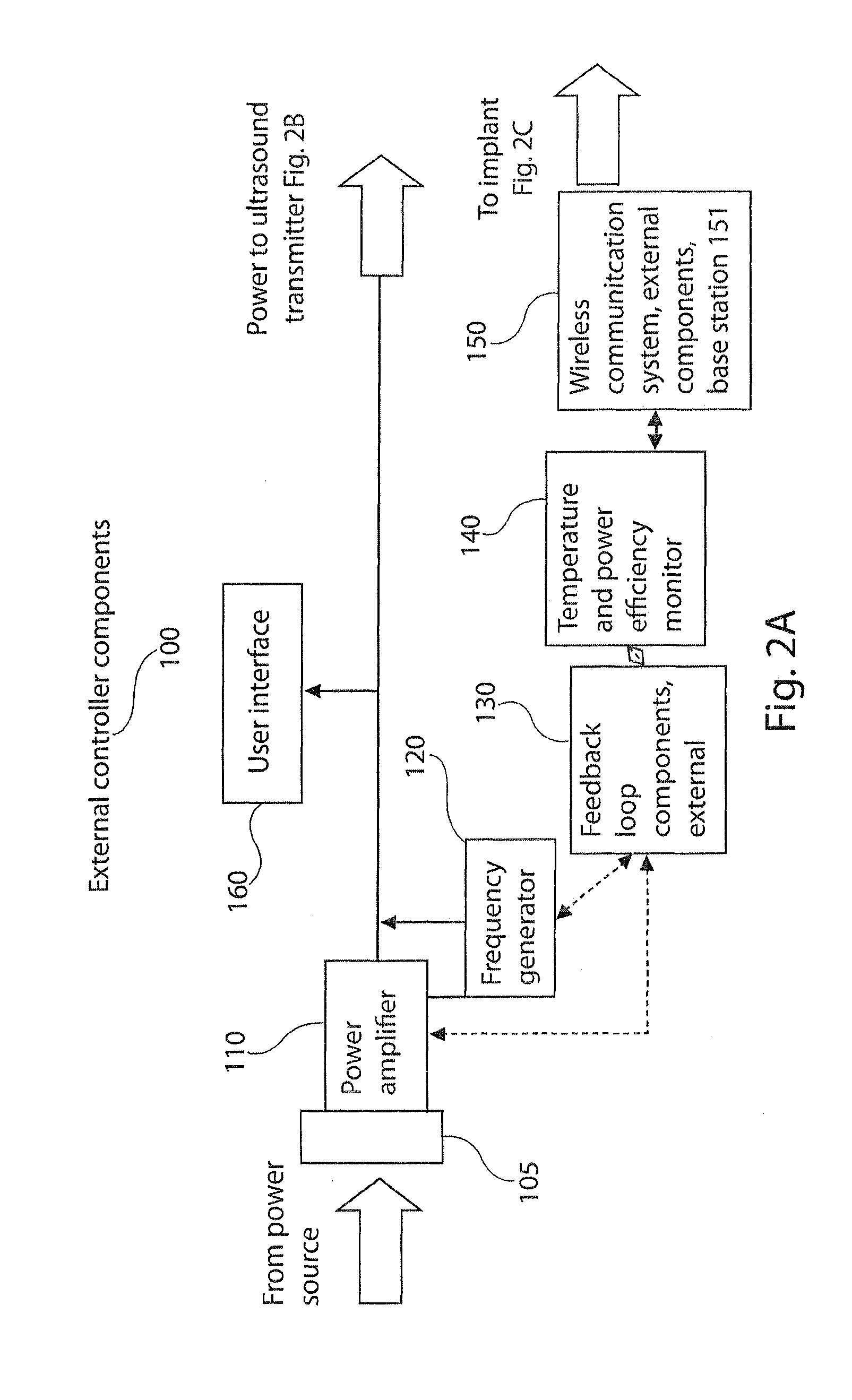

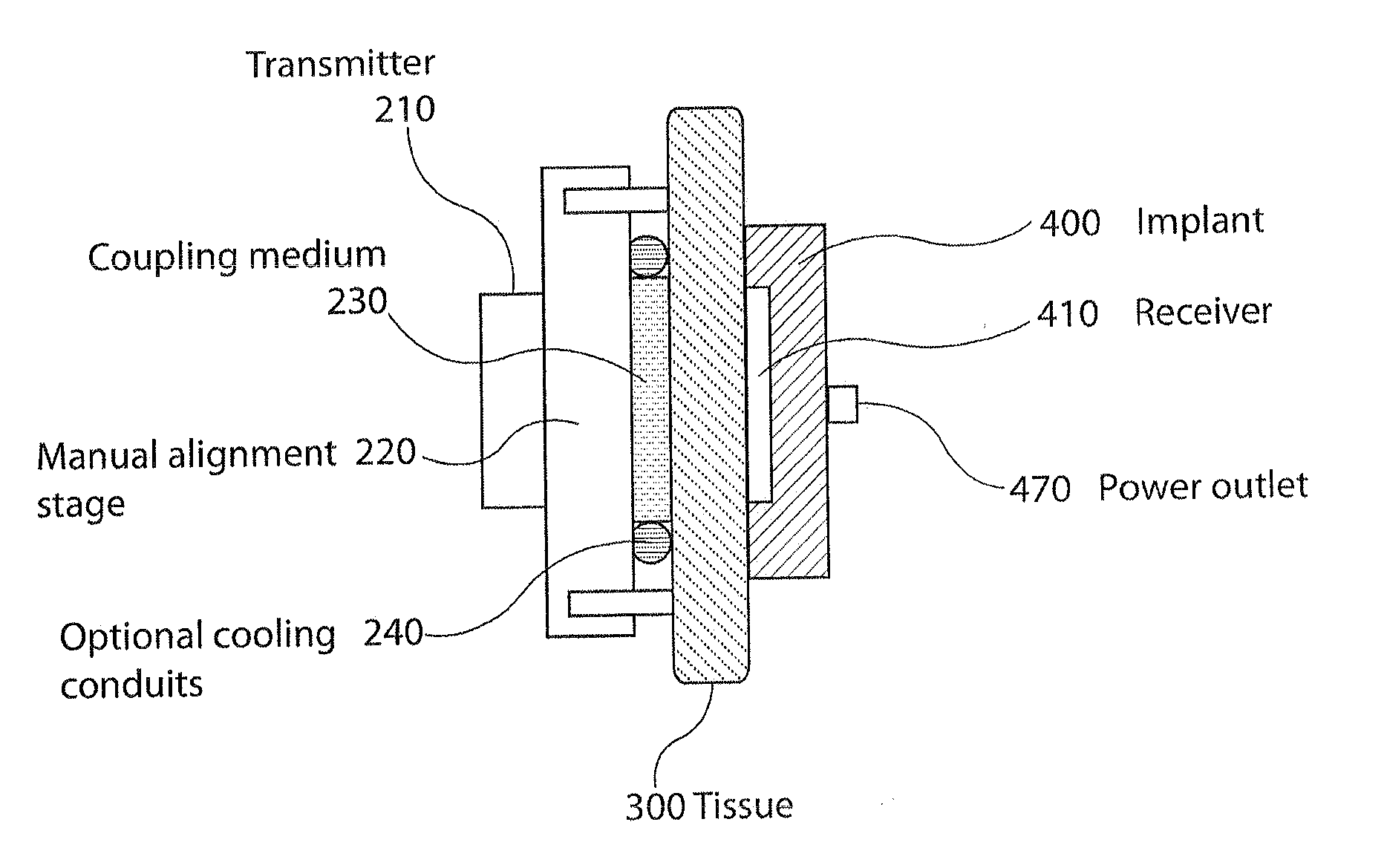

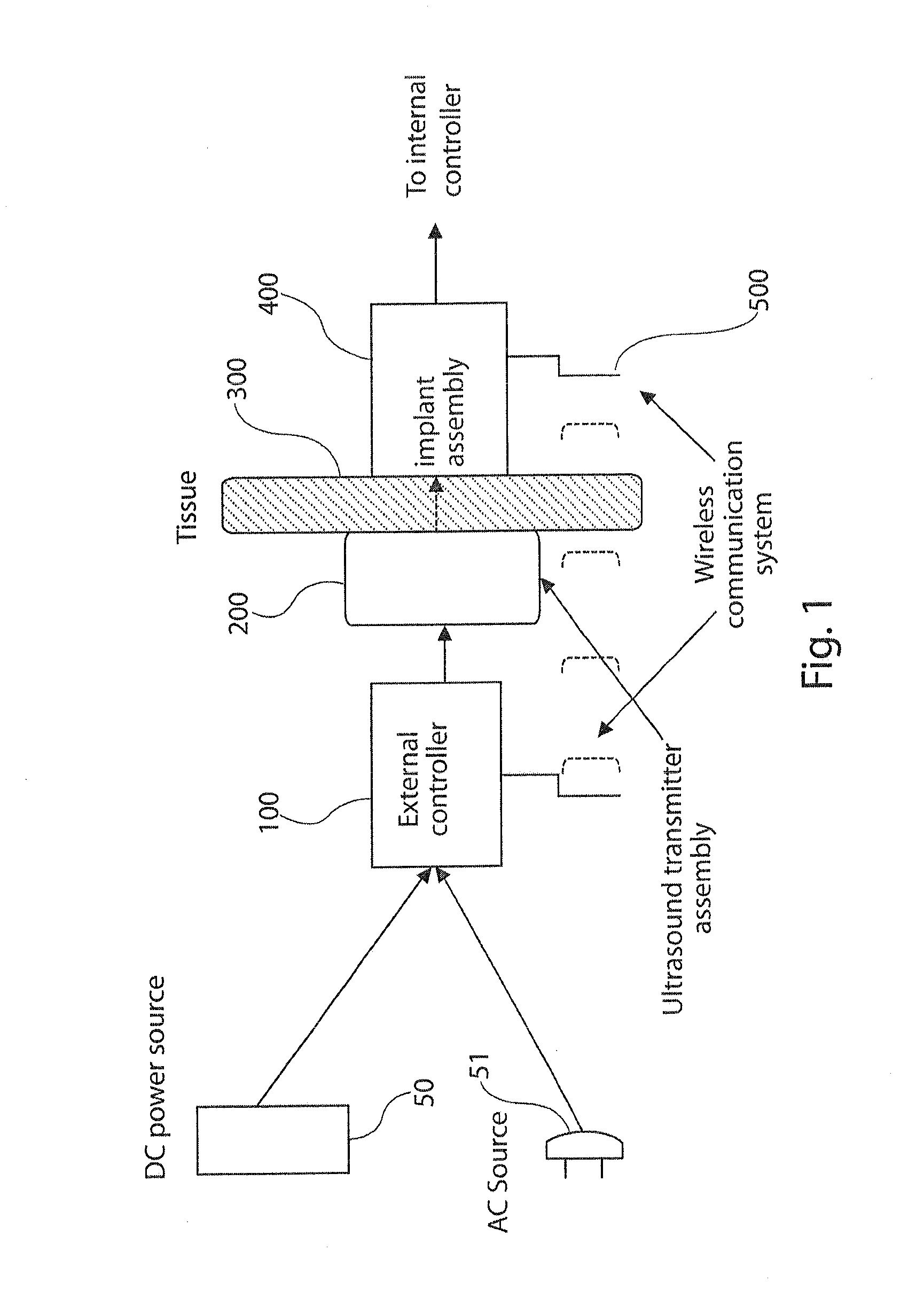

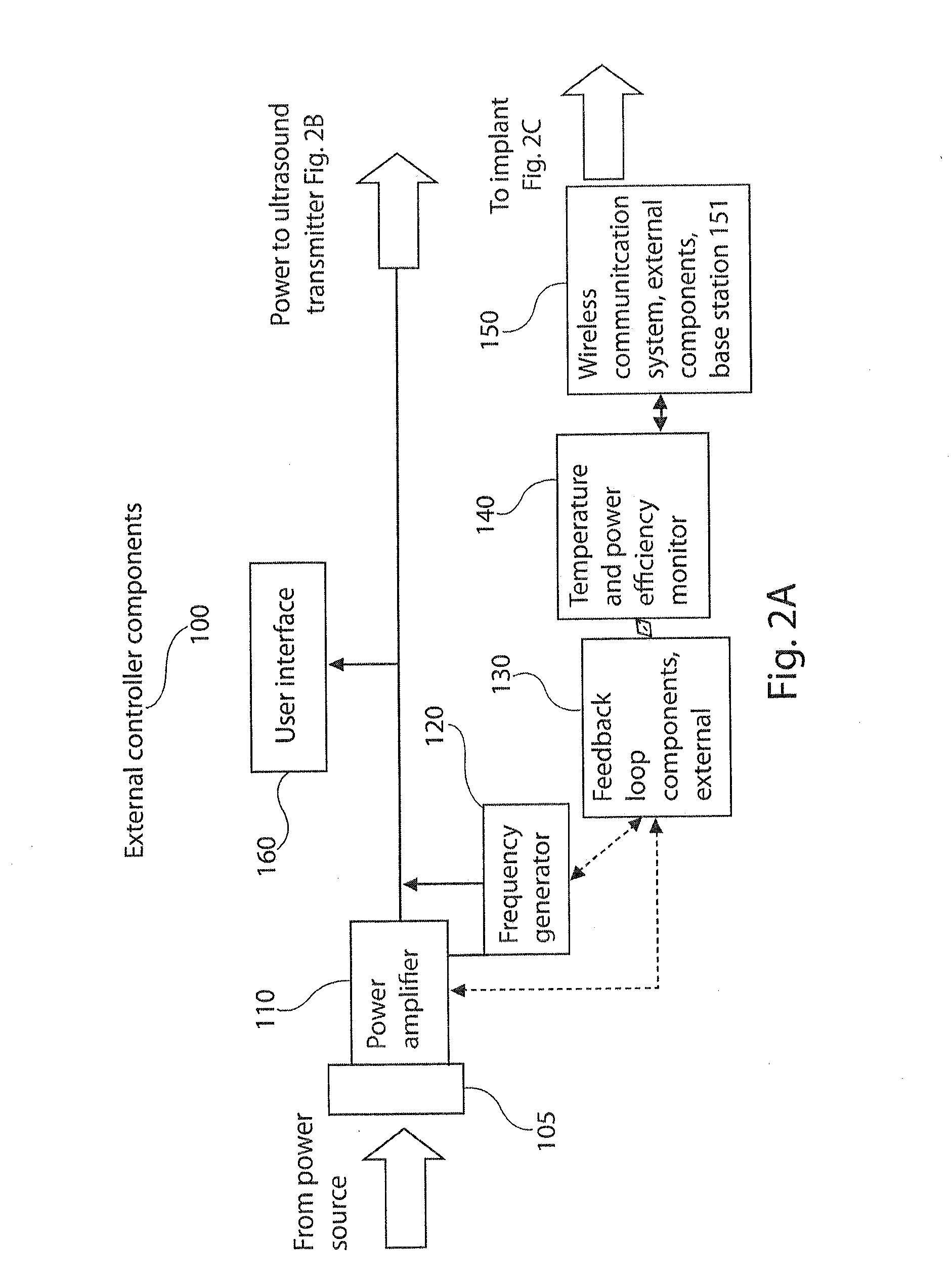

High power ultrasound wireless transcutaneous energy transfer (us-tet) source

InactiveUS20130178915A1Good effectOptimizes power transferElectrotherapyElectromagnetic wave systemEnergy transferElectricity

A bio-implantable energy capture and storage assembly is provided. The assembly includes an acoustic energy transmitter and an acoustic energy receiver. The acoustic energy receiver also functions as an energy converter for converting acoustic energy to electrical energy. An electrical energy storage device is connected to the energy converter, and is contained within a bio-compatible implant for implantation into tissue. The acoustic energy transmitter is separate from the implant, and comprises a substantially 2-dimensional array of transmitters.

Owner:PIEZO ENERGY TECH

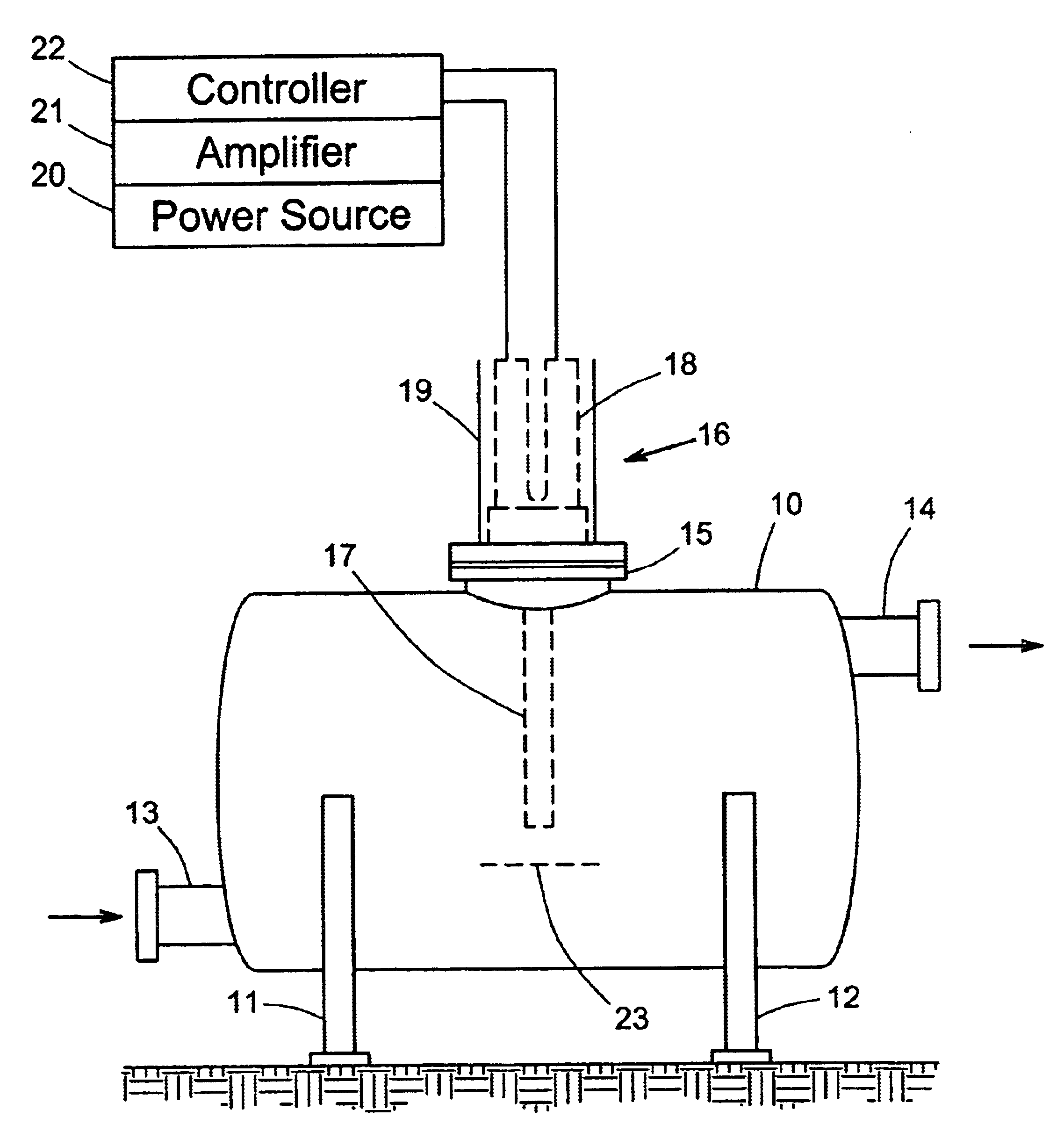

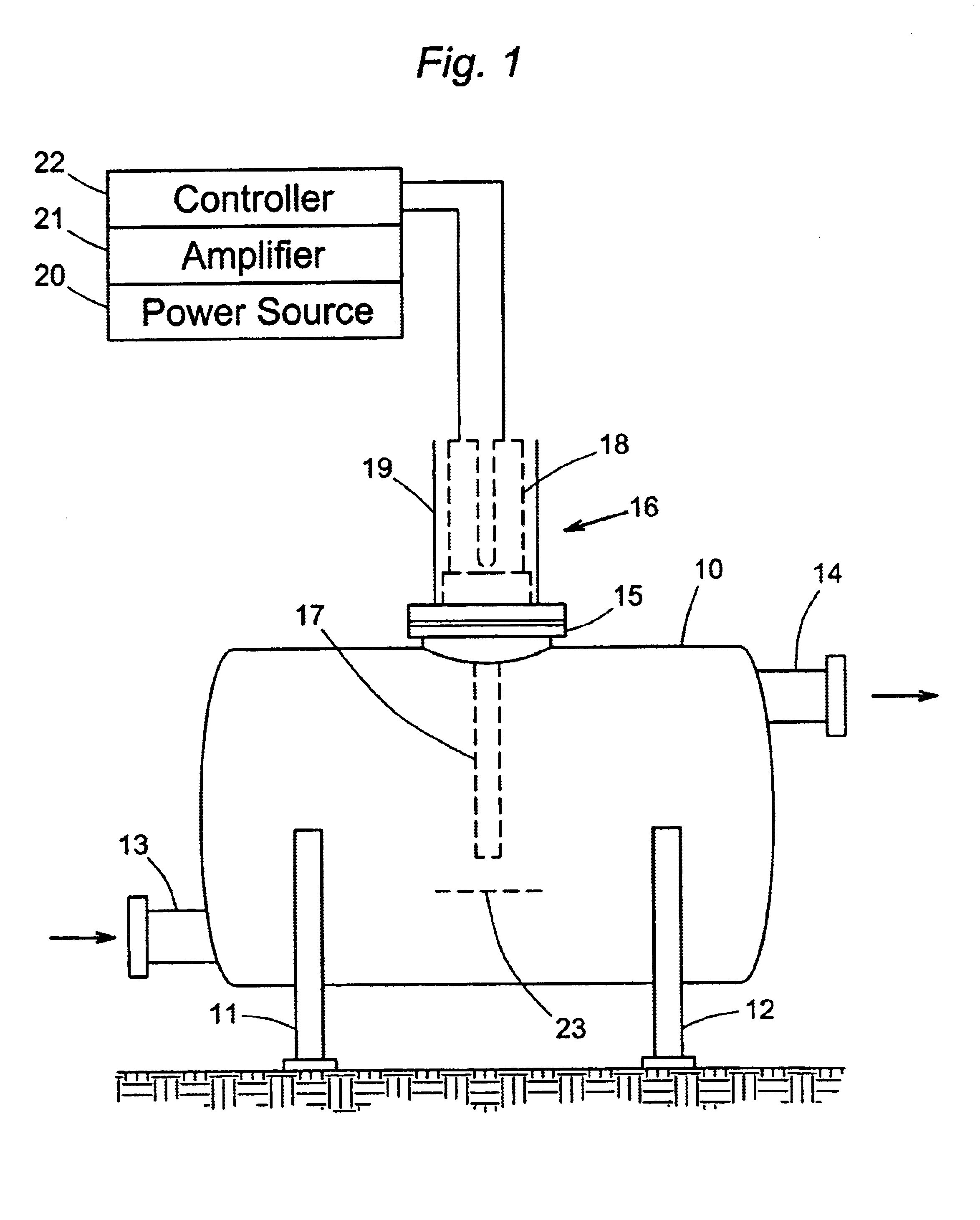

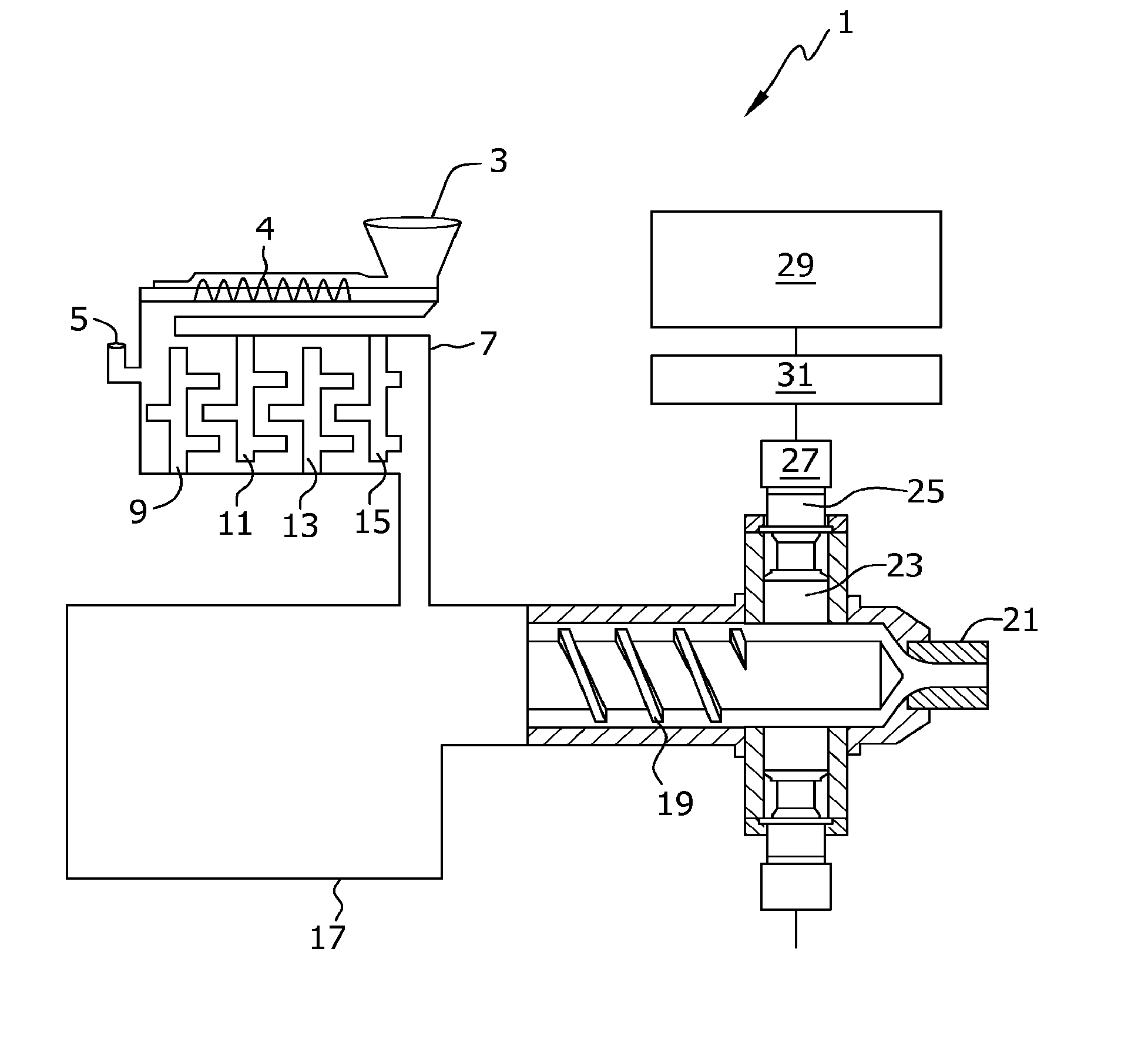

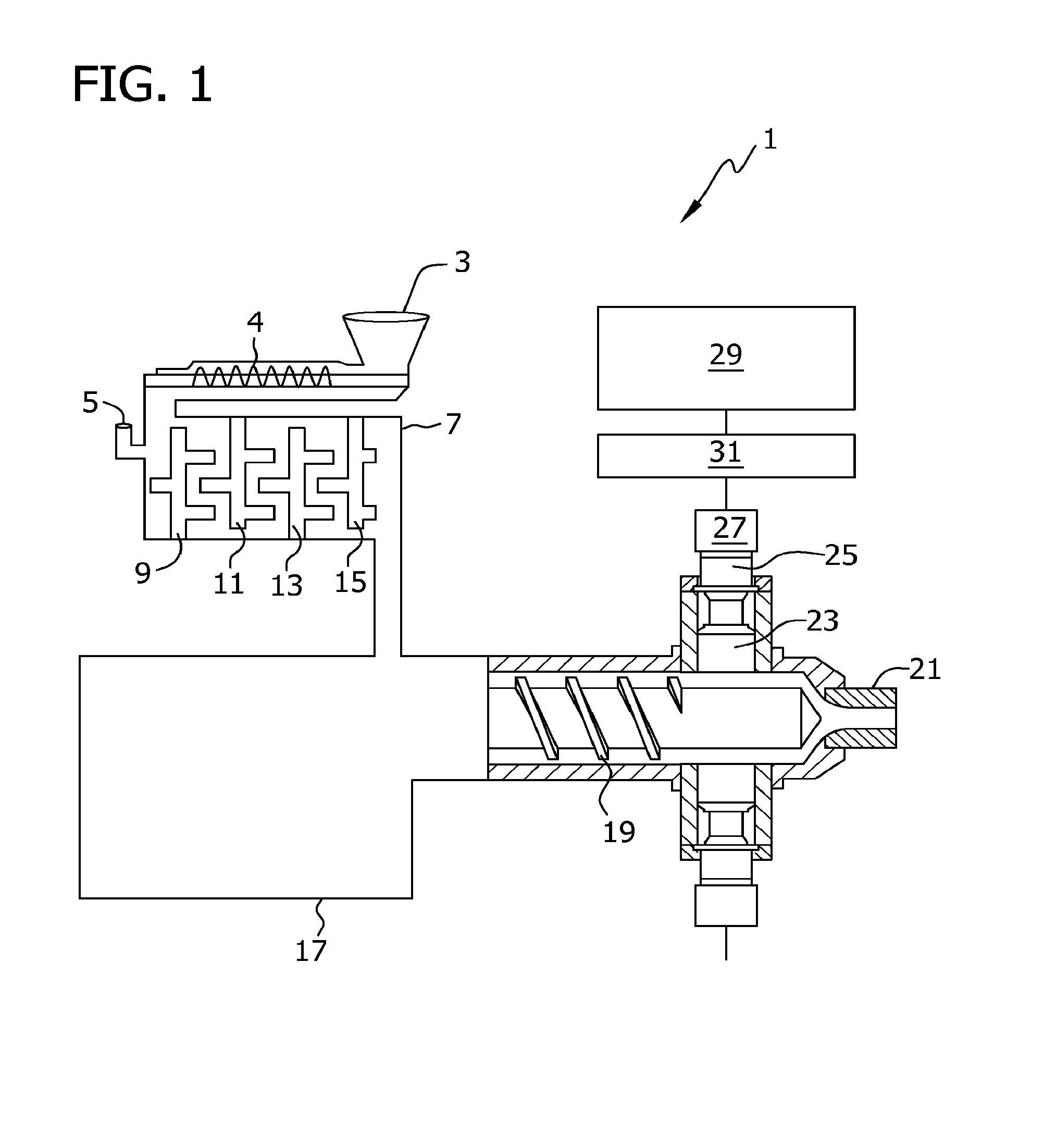

High-power ultrasound generator and use in chemical reactions

InactiveUS6897628B2Reaction be enhancedHigh yieldPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationChemical reactionEngineering

Ultrasound for use in promoting a chemical reaction is generated by an electromagnet formed from a pair of magnetostrictive prongs wound with coils that are oriented to produce an oscillating magnetostrictive force when an oscillating voltage is applied, in conjunction with a sensing electromagnet of magnetostrictive material that is arranged to receive the vibrations generated by the driving electromagnet and produce internal magnetic field changes due to the reverse magnetostrictive effect. These field changes generate voltages that are representative of the amplitude of the oscillating magnetostrictive force. The generated voltage is compared to a target value in a control circuit that adjusts the applied oscillating voltage accordingly. The oscillations in the prongs of the electromagnet are transmitted to an ultrasonic horn that is immersed in the reaction medium to provide direct contact with the reaction mixture.

Owner:NOKIA CORP +1

Production method of high-strength steel rope

InactiveCN103352381AMeet the standard requirementsUniform tissueFurnace typesQuenching agentsWater bathsQuenching

The invention provides a production method of a high-strength steel rope. The production method of the high-strength steel rope is characterized that low carbon is selected and used as raw materials of the steel rope, and the production technology comprises a first step of surface processing, wherein wire materials are placed on a pay-off rack, the diameter of the wire materials is 5.5mm, hot-rolled oxide-scale is eliminated through mechanical dephophorization equipment, high-power ultrasonic cleaning is conducted on the wire materials, the wire materials enter phosphating equipment, phosphating is conducted on the wire materials, the wire materials enter drying equipment and are dried finally, and preprocessed wire materials are obtained; a second step of drawing, wherein the preprocessed wire materials obtained from the first step are placed on a drawing machine, multi-pass drawing is conducted on the preprocessed wire materials, semi-finished wire materials are obtained, and winding up is conducted through a spool; a third step of water bath heat treatment and galvanization, wherein the semi-finished wire materials obtained in the second step are placed on the pay-off rack, the semi-finished wire materials are heated in a four-section form heat treatment furnace, quenching, drying, galvanization and cooling are conducted on the semi-finished wire materials, semi-finished wire materials are obtained, and winding up is conducted; a fourth step of wet type drawing, wherein the semi-finished wire materials obtained in the third step are placed on the drawing machine, multi-pass drawing is conducted on the semi-finished wire materials, the compression angle of a wire-drawing die of each pass is 13-14 degrees, dedicated lubricating agent is used as lubricating agent, the concentration of the dedicated lubricating agent is 2%-3%, finished wire materials are obtained, and winding up is conducted through a spool; a fifth step of stranding and rope forming, wherein the finished wire materials are placed on a stranding machine, stranding and laying-up are conducted, and the finished steel stranded rope is obtained.

Owner:ZHANGJIAGANG SHENGDA STEEL ROPE

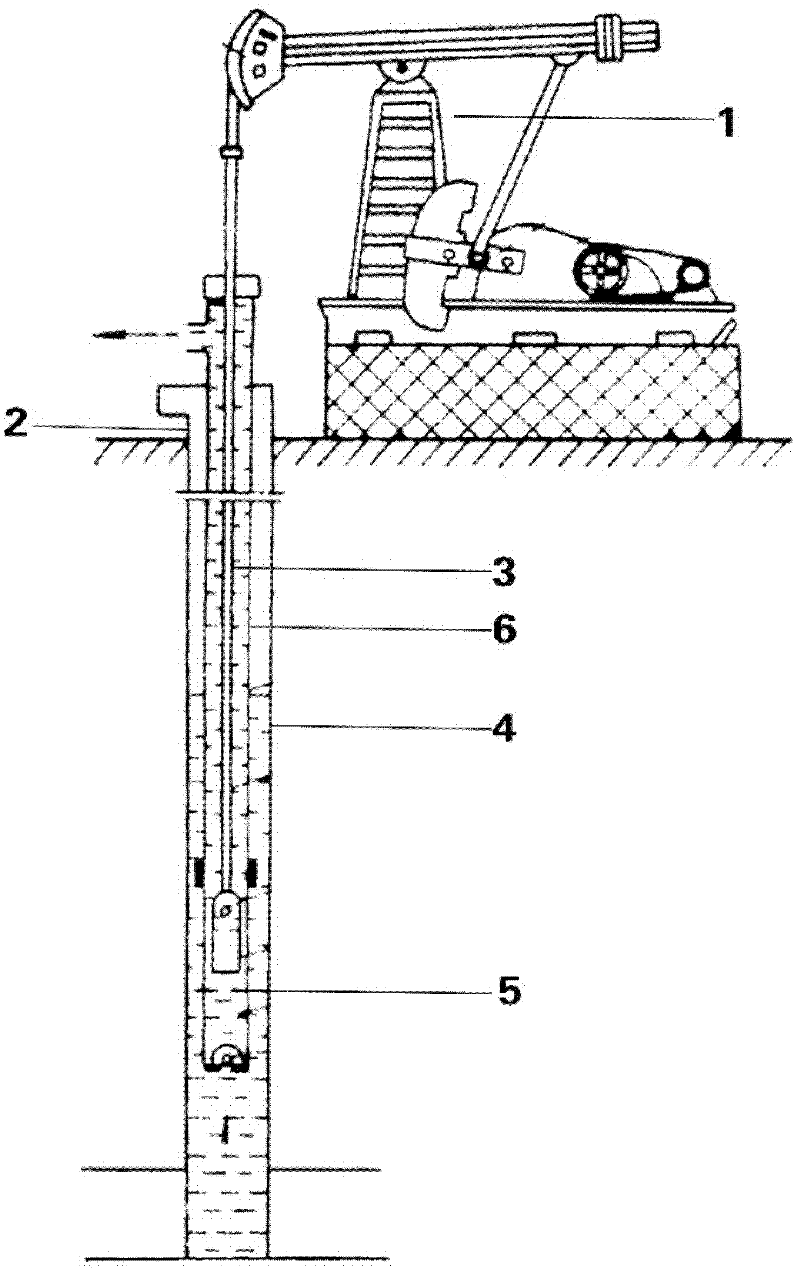

Underground ultrasonic yield-increasing pumping device for coalseam gas

InactiveCN102373908ALow flow resistanceReduce energy consumptionFluid removalSolenoid valveDesorption

The invention discloses an underground ultrasonic yield-increasing and atomized pumping device for coalseam gas. A reciprocating vacuum pump and an underground ultrasonic wave generator are connected by a control cabinet. The underground ultrasonic wave generator is connected to the ultrasonic yield-increasing and atomized pumping device. The reciprocating vacuum pump is connected to oil pipes. A casing pipe provided with an oil pipe is deeply inserted into a coalseam. An oil pipe opening is higher than a casting pipe opening. The ultrasonic yield-increasing and atomized pumping device is installed at the lower end in the oil pipe and used for sealing the oil pipe lower opening. The device includes: a high-power ultrasonic atomization transducer and a yield-increasing device ultrasonic transducer. The lower end of the high-power ultrasonic atomization transducer is connected to the yield-increasing device ultrasonic transducer, and is extended the lower end of the oil pipe opening. An inlet duct communicated with the casting pipe inner chamber is arranged in the oil pipe. A filter screen, a solenoid valve and a liquid level sensor are arranged in the inlet duct. The lower wall of the casting pipe is provided with eyeholes. A coalseam opening is arranged out of the casting pipe above the ground. According to the underground ultrasonic yield-increasing and atomized pumping device disclosed by the invention, the pumping operation for the coalseam gas can be completed, no mechanical motion occurs, and the advantages of saving energy, increasing the total desorption amount of the coalseam gas, reducing the cost and being simple in maintenance are achieved.

Owner:龚大建

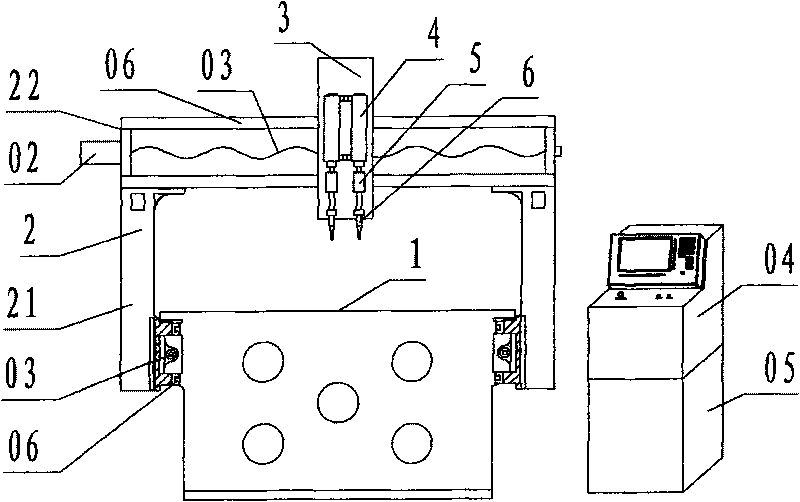

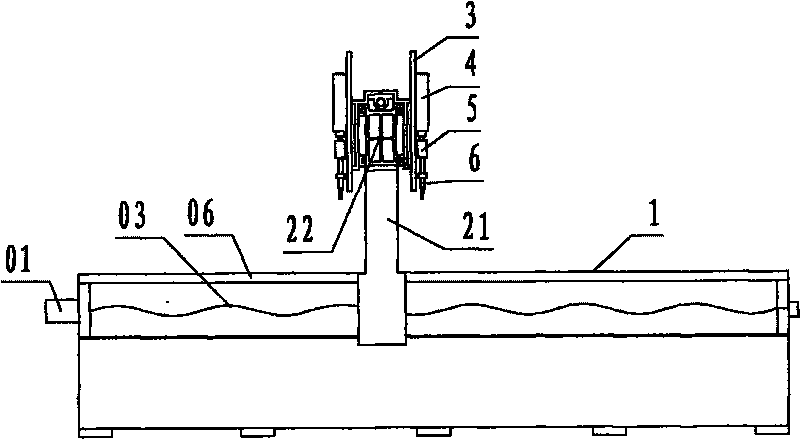

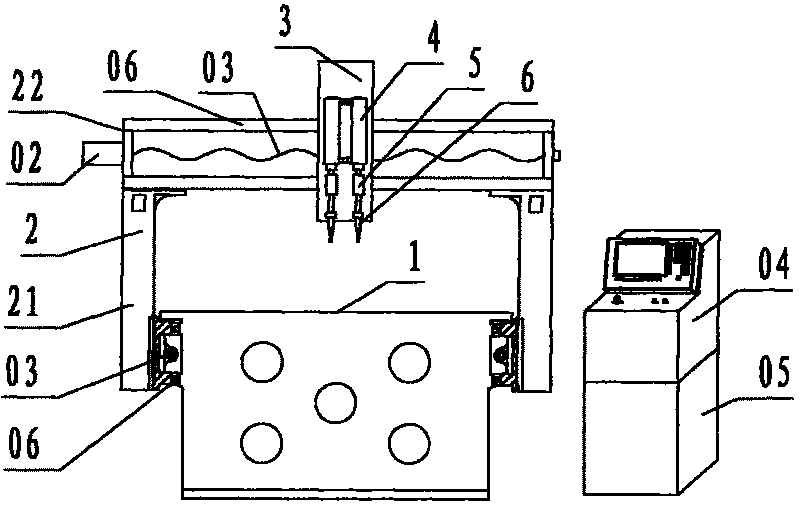

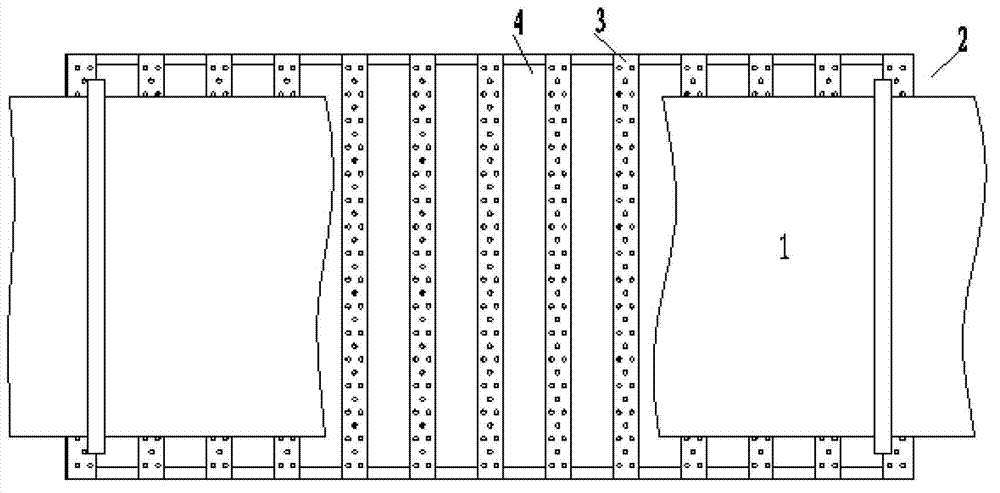

Portal frame movable type horizontal coordinate numerical control ultrasonic welding machine

ActiveCN101700602AOvercome costsOvercome deficienciesNon-electric welding apparatusUltrasonic weldingMovable type

The invention discloses a portal frame movable type horizontal coordinate numerical control ultrasonic welding machine, which is characterized by being special welding processing equipment integrated by an ultrasonic welding machine and a numerical control machine. In the invention, a box type fixed work bench and a movable portal frame are adopted in a machine structure, a controlled driving air cylinder, a high-power ultrasonic vibrator and a welding head are arranged on a transverse towing plate arranged on a portal frame beam; the high-power ultrasonic vibrator provides a vibration source, a numerical control system controls a servo motor and a screw rod system to drive the portal frame, the transverse towing plate and a horizontal coordinate target seeking according to a program, the up and down stretching of the air cylinder drives the high-power ultrasonic vibrator, and the welding head carries out welding and resetting. The invention overcomes the problems and defects of high cost, low efficiency, incomplete usage of the equipment and processing equipment resource waste; and by numerical control target seeking and automatic welding point to point and hop to hop at a variable time, the invention enables the numerical control and the automation of the ultrasonic welding of a more complex large work piece to achieve the purposes of low cost, high efficiency and high quality.

Owner:宁波市凯博数控机械有限公司

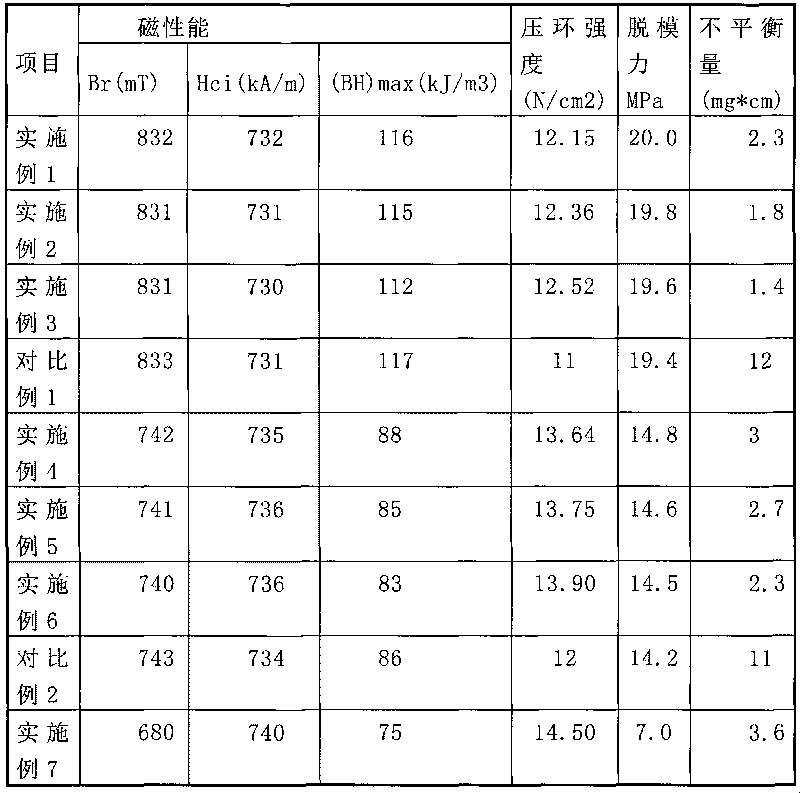

Boned neodymium iron boron permanent magnet and manufacturing method thereof

InactiveCN101710518AImprove density uniformityImprove unbalanced performanceTransportation and packagingMetal-working apparatusFirming agentNano al2o3

The invention relates to a boned neodymium iron boron permanent magnet and a manufacturing method thereof. The permanent magnet comprises NdFeB magnetic powder, thermosetting resin, a firming agent, a lubricant and a coupling agent, and also comprises nano-alumina powder of which the weight is 0.01 to 1 percent of that of the magnetic powder. The method comprises the following steps: uniformly mixing the thermosetting resin, the firming agent and acetone of which the weight is 1 to 4 times that of the resin; then performing surface treatment on the nano-alumina powder by utilizing the silane coupling agent KH-550; dispersing the nano-alumina powder by utilizing a high-power ultrasonic generator and drying the dispersed powder; mixing the thermosetting resin mixed with the nano-alumina powder after the drying with the magnetic powder uniformly by utilizing a large-scale mixer, and finally, adding the lubricant into the mixture for uniform mixing; and making the mixture into a green blank by a compression molding machine, and curing the green blank for 15 to 60 minutes at a temperature of between 150 and 220 DEG C to form a magnet. The boned neodymium iron boron permanent magnet improves the unbalanced performance of the magnet, ensures that the magnet has high stability and small vibration in a driver during high-speed rotation and better meets the technical requirements.

Owner:上海三环磁性材料有限公司 +1

High-power ultrasonic horn

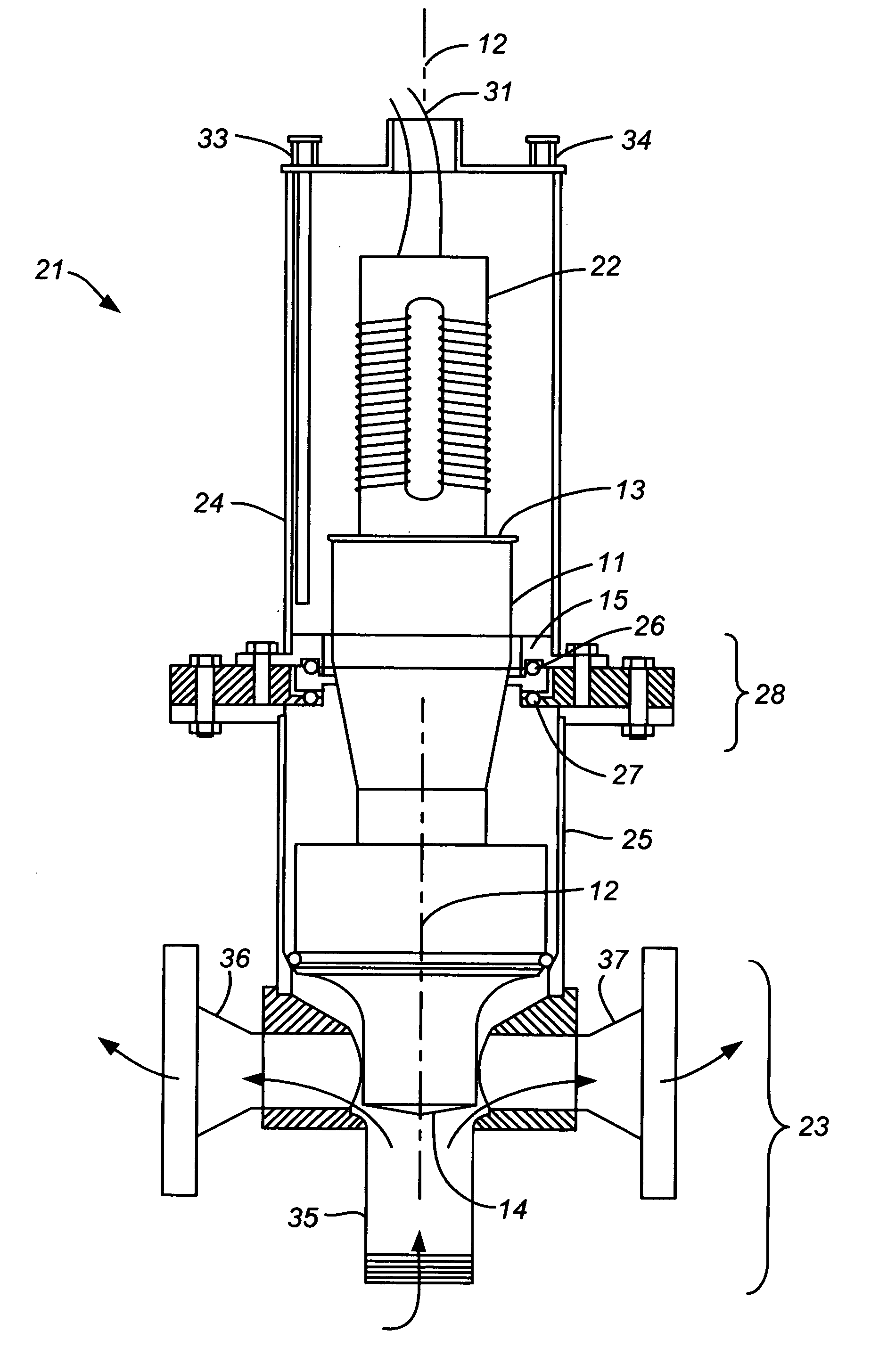

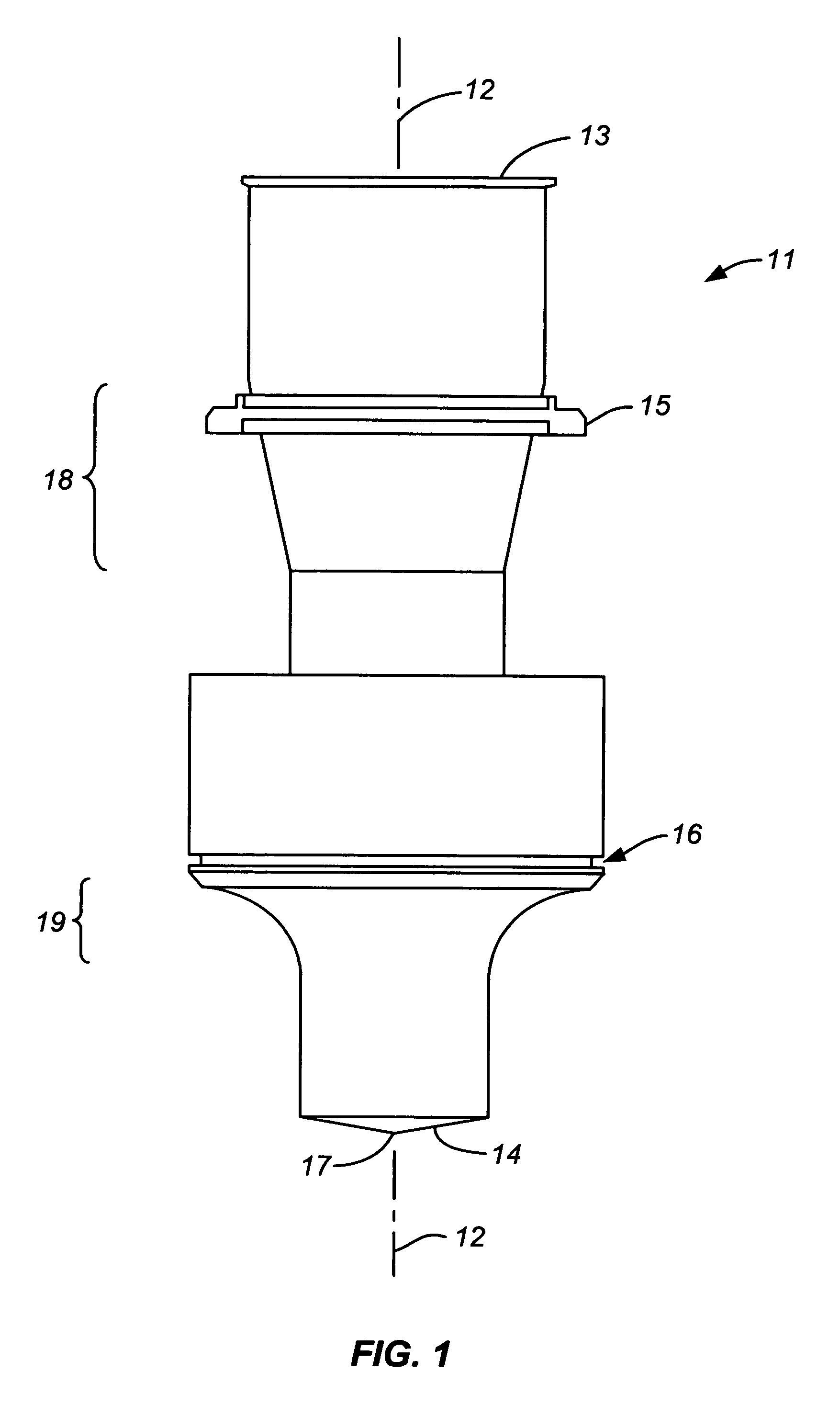

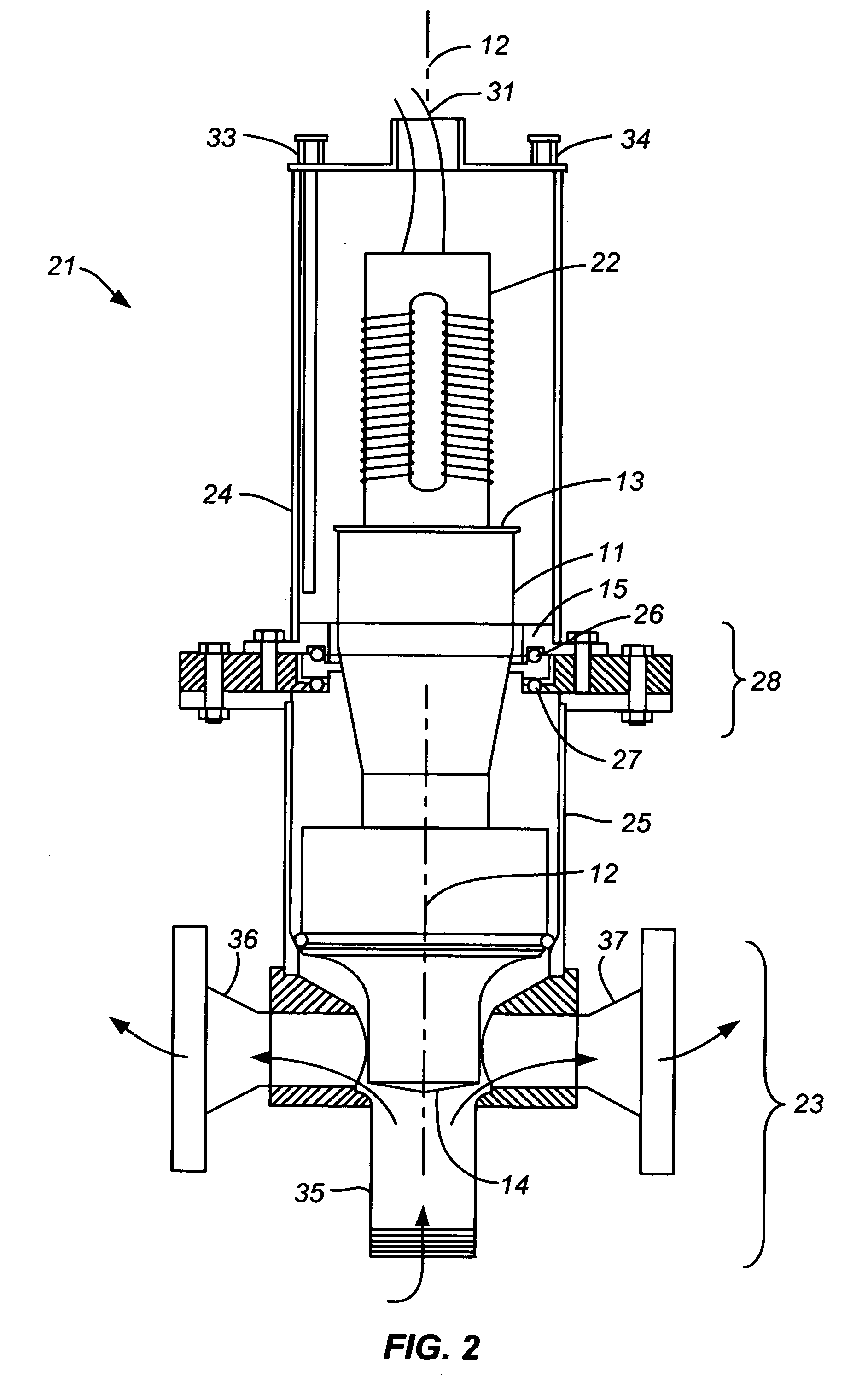

InactiveUS20060196915A1Improve permeabilityHigh stress of vibrationSoldering apparatusMechanical vibrations separationChemical reactorEngineering

An ultrasonic horn for use in a chemical reactor is formed as a unitary piece of material whose length is approximately equal to the wavelength of ultrasonic waves through the material at a selected ultrasonic frequency. The horn has a conically shaped distal end and a mounting surface at its proximal end, plus a mounting fixture between the proximal and distal ends for mounting the horn to a flow-through reactor with the distal end protruding into the reactor interior while the proximal end extends outside the reactor. The horn further contains a seal between the proximal and distal ends to seal the horn to the interior of a reaction vessel in a fluid-tight manner. With the unitary construction and the conical distal end, the horn is capable of transmitting high power ultrasonic waves to the reactor interior without damage to the horn or its mounting fixtures.

Owner:SULPHCO

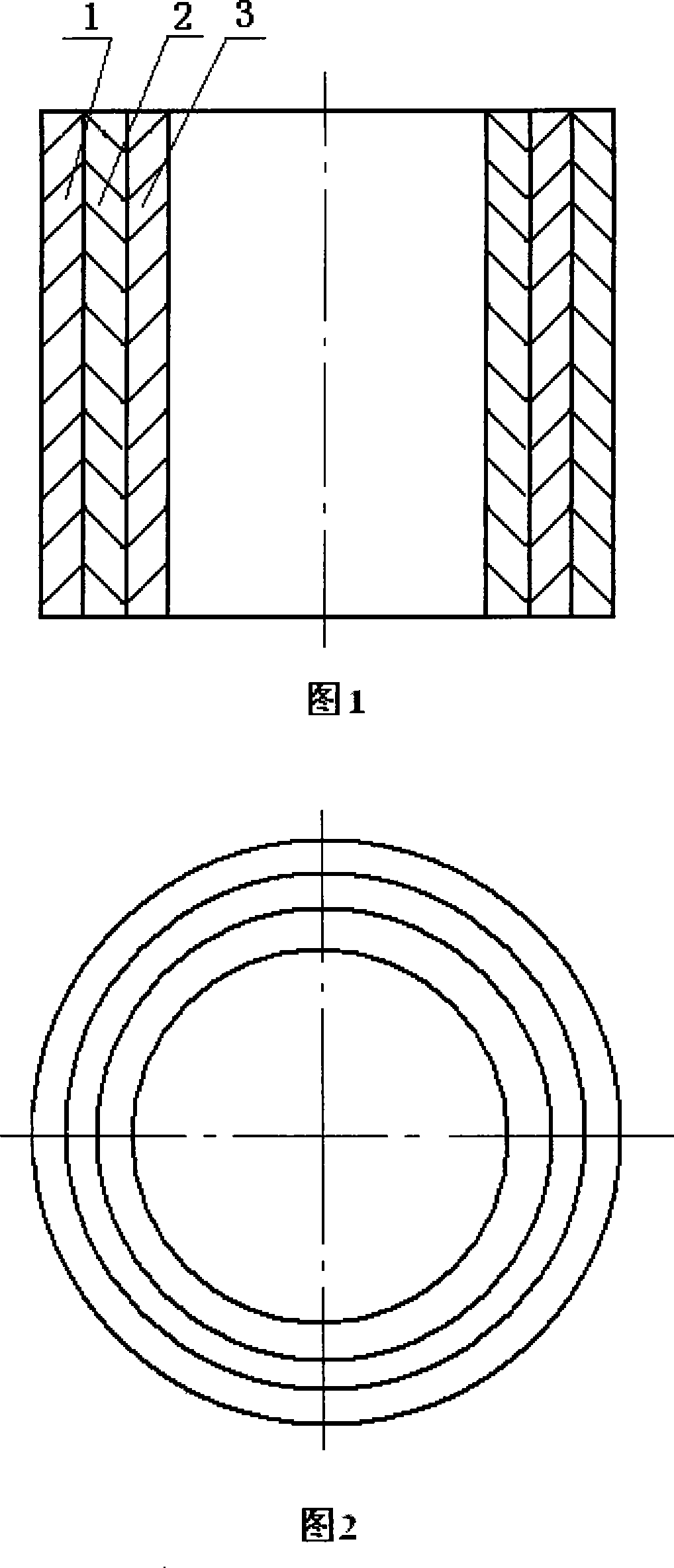

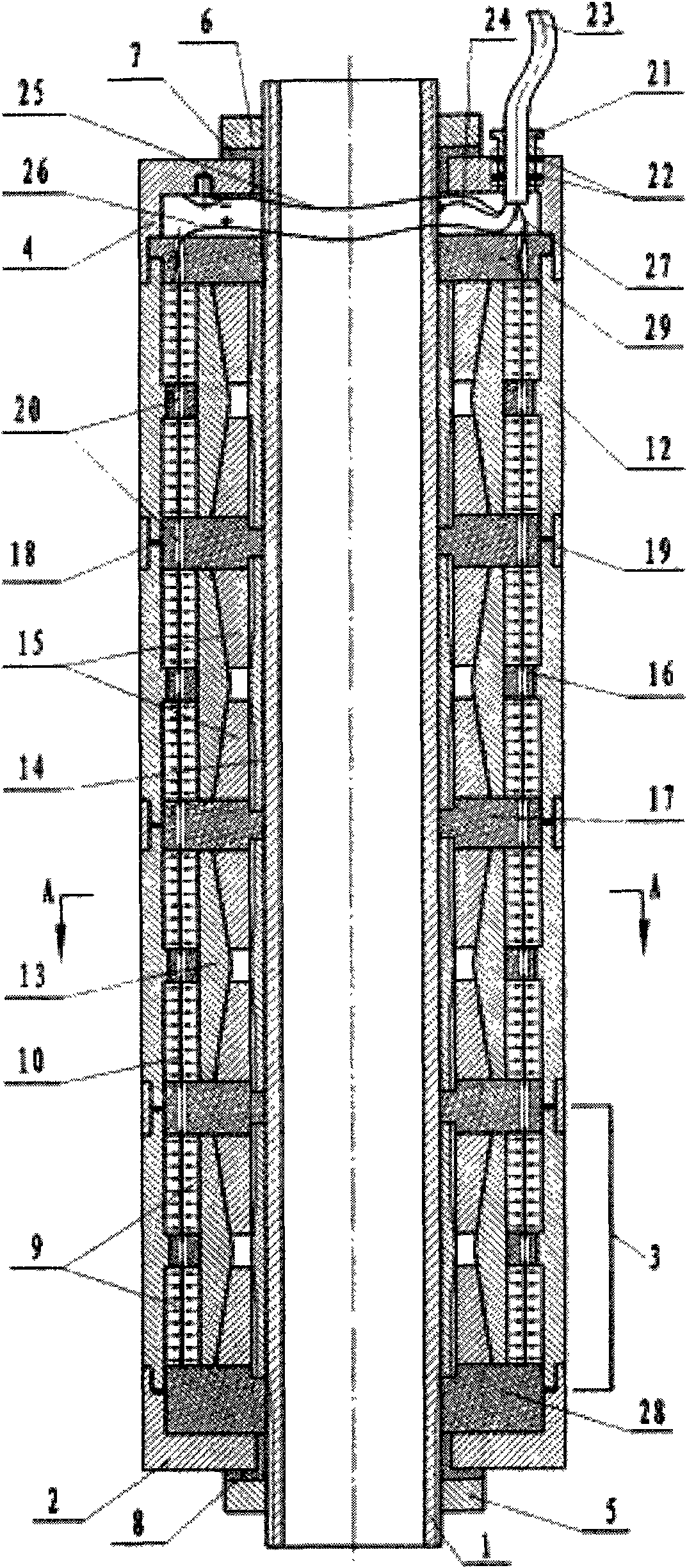

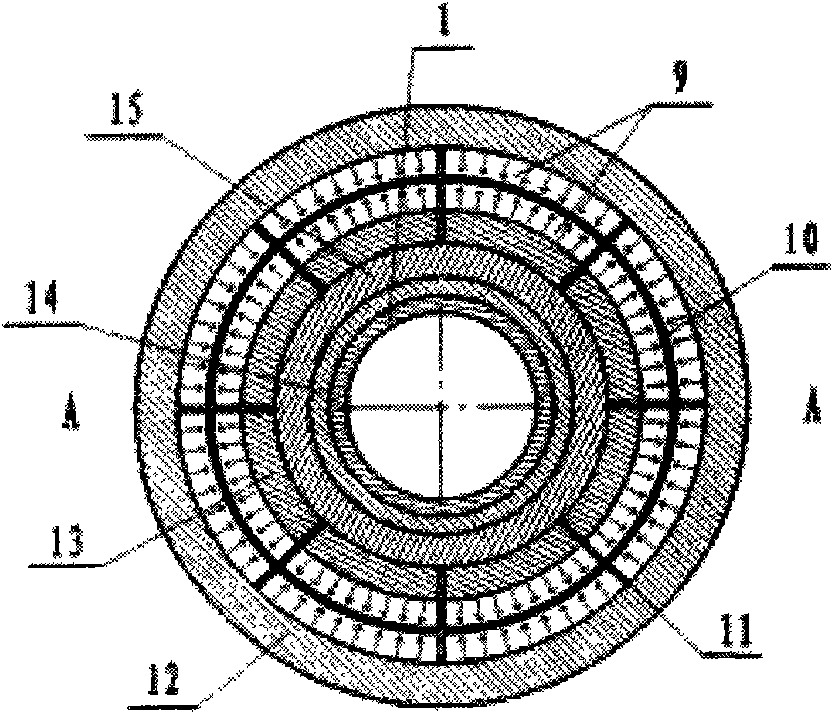

Sandwich type radial direction vibrating piezoelectric ceramic ultrasonic transducer

InactiveCN101111098AOptimization parametersRaise the resonant frequencyPiezoelectric/electrostrictive transducersElectromechanical coupling coefficientOmni directional

The present invention relates to a radial vibration sandwich piezoelectric ceramic ultrasonic transducer. A piezoelectric ceramic ring is arranged between a metal inner ring and a metal outer ring, the upper end surfaces of the metal inner ring, the metal outer ring and the piezoelectric ceramic ring are in the same plane, and lower end surfaces are also in the same plane. The metal inner ring and the metal outer ring can adopt steel rings, aluminum rings, brass or purple copper rings, titanium rings, aluminum nickel copper alloy rings and titanium alloy rings. The present invention realizes the high efficiency work of a radial composite transducer through a radial prestress impressed by the inner and outer metal rings, and realizes the parameter optimization of the transducer through reasonably designing the geometry size of the inner and outer metal rings simultaneously, such as resonance frequency, frequency bandwidth as well as electromechanical coupling coefficient. The present invention can be used for the high efficiency omni-directional acoustic source underwater and all kinds of supersonic processing high efficiency supersonic source in liquid.

Owner:SHAANXI NORMAL UNIV

Method of thermal treatment of myolysis and destruction of benign uterine tumors

ActiveUS8790281B2Shorten treatment timeIncrease opportunitiesUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyHysteroscopic surgeryFibers tissue

A high-power ultrasound heating applicator for minimally-invasive thermal treatment of uterine fibroids or myomas. High-intensity interstitial ultrasound, applied with minimally-invasive laparoscopic or hysteroscopic procedures, is used to effectively treat fibroids within the myometrium in lieu of major surgery. The applicators are configured with high-power capabilities and thermal penetration to treat large volumes of fibroid tissue (>70 cm3) in short treatment times (3-20 minutes), while maintaining three-dimensional control of energy delivery to thermally destroy the target volume.

Owner:RGT UNIV OF CALIFORNIA +1

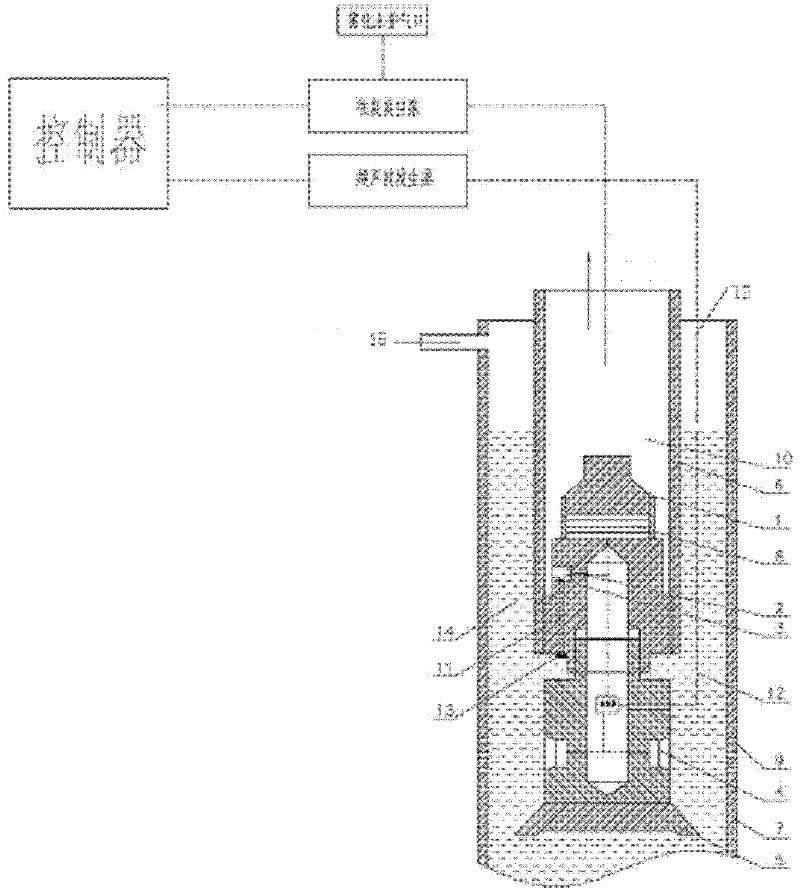

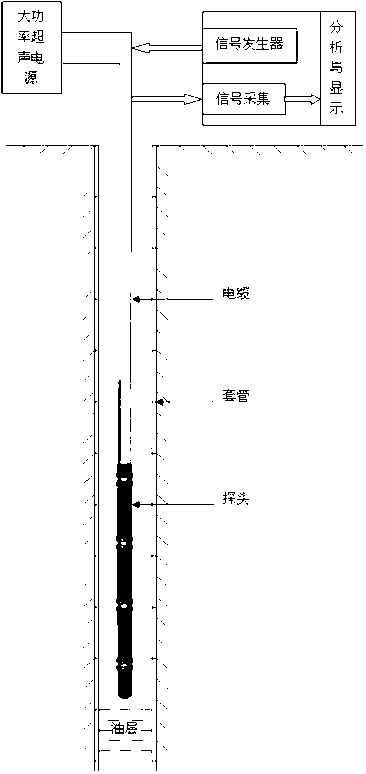

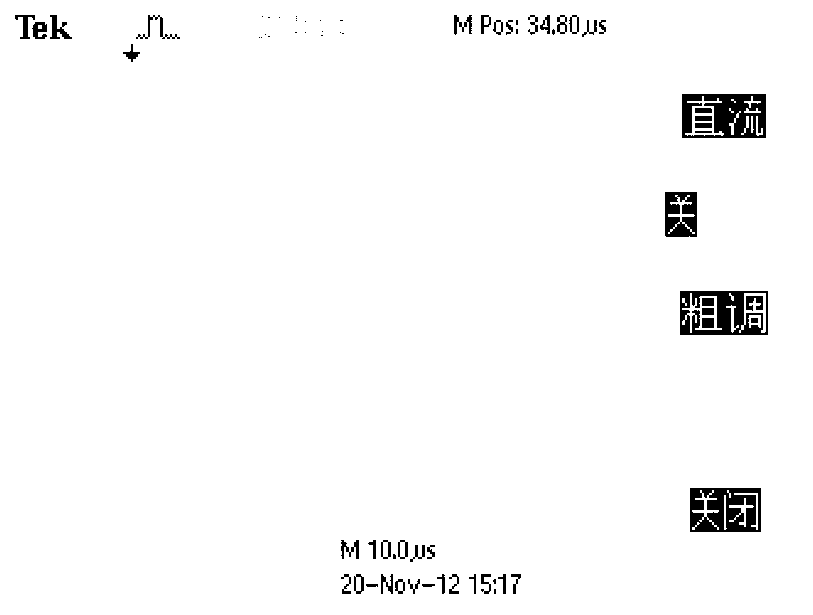

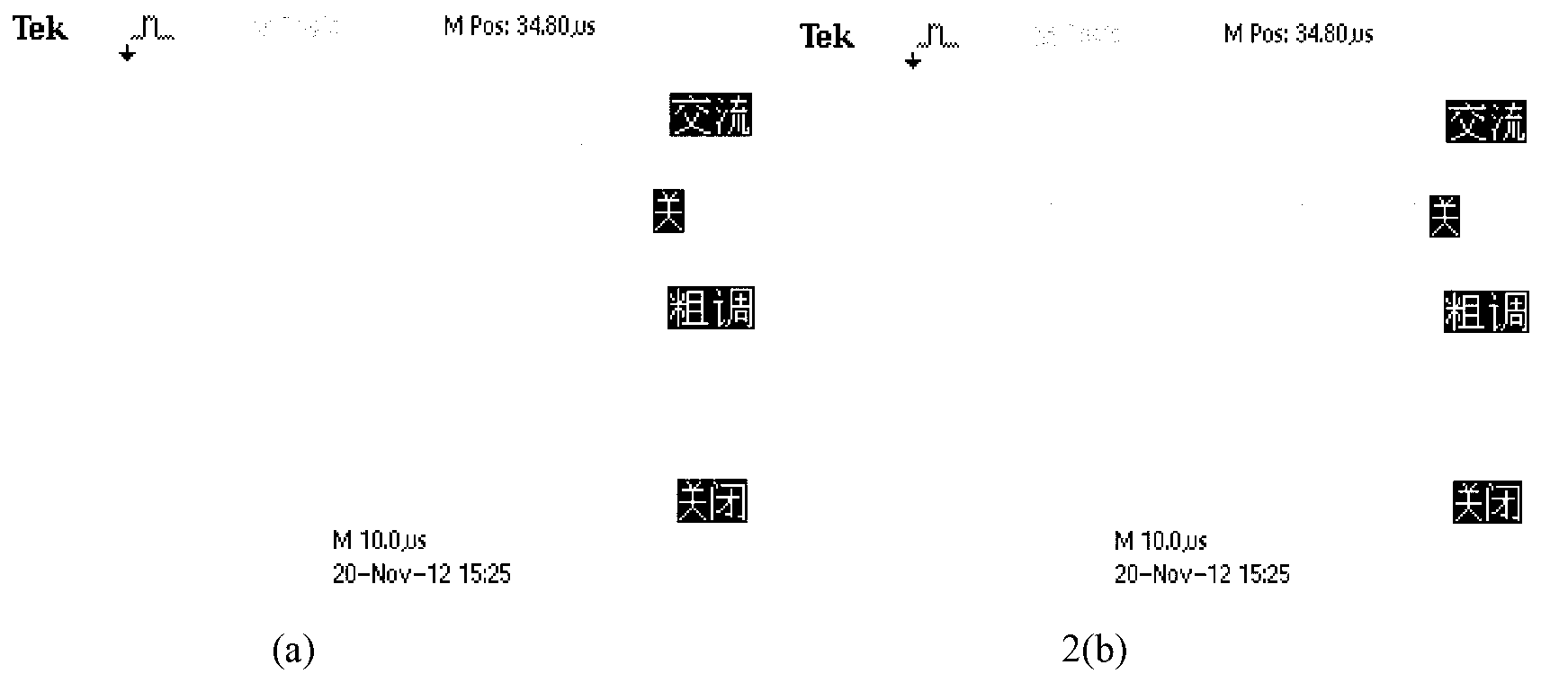

Piezoelectric transducer downhole liquid level measuring instrument

InactiveCN103063274ASimple structureAccurate measurementMachines/enginesLevel indicatorsPower flowSonification

The invention relates to a downhole liquid level measuring device applied to oil exploitation operation process. A simple and easy system which integrates signal generation, acquisition and analysis is provided so as to directly utilize a high-power ultrasonic probe. The technical scheme includes that a piezoelectric transducer downhole liquid level measuring instrument comprises a probe portion, a tunable frequency sinusoidal signal generating portion, a power amplification portion, a peak value detection portion and a phase difference detection portion, a tunable frequency sinusoidal wave generated by the tunable frequency signal generating portion is subjected to amplitude and power amplification, an ultrasonic signal subjected to power amplification is transmitted to a probe through a cable, the impedance of a piezoelectric transducer in the probe is changed, changed peak values of voltage and current signals are obtained through the peak value detection portion, the phase difference between the voltage and current signals is detected through the phase difference detection portion, and cased well liquid level positions are indicated through abrupt change of the phase difference. The piezoelectric transducer downhole liquid level measuring instrument is mainly applied to measurement of downhole liquid levels.

Owner:TIANJIN UNIV

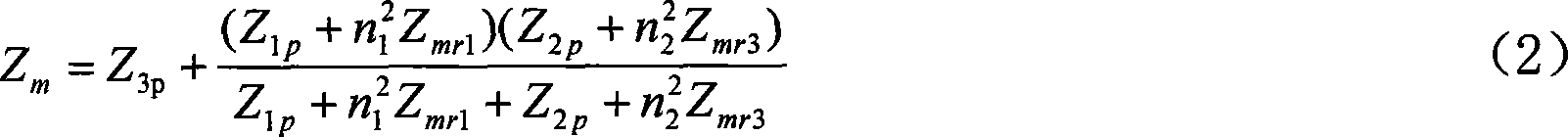

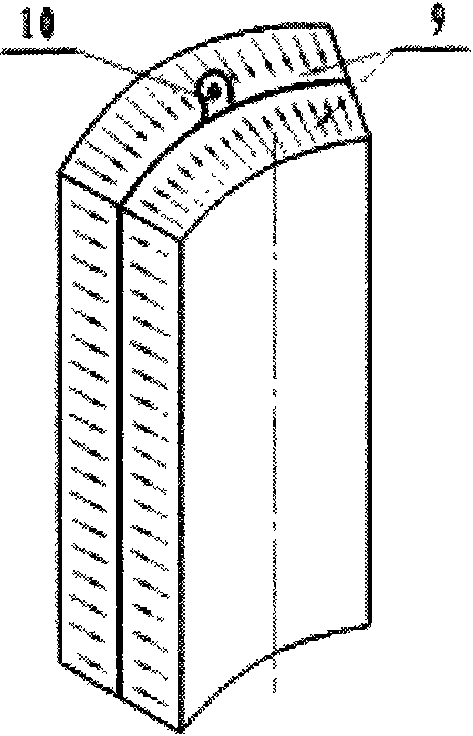

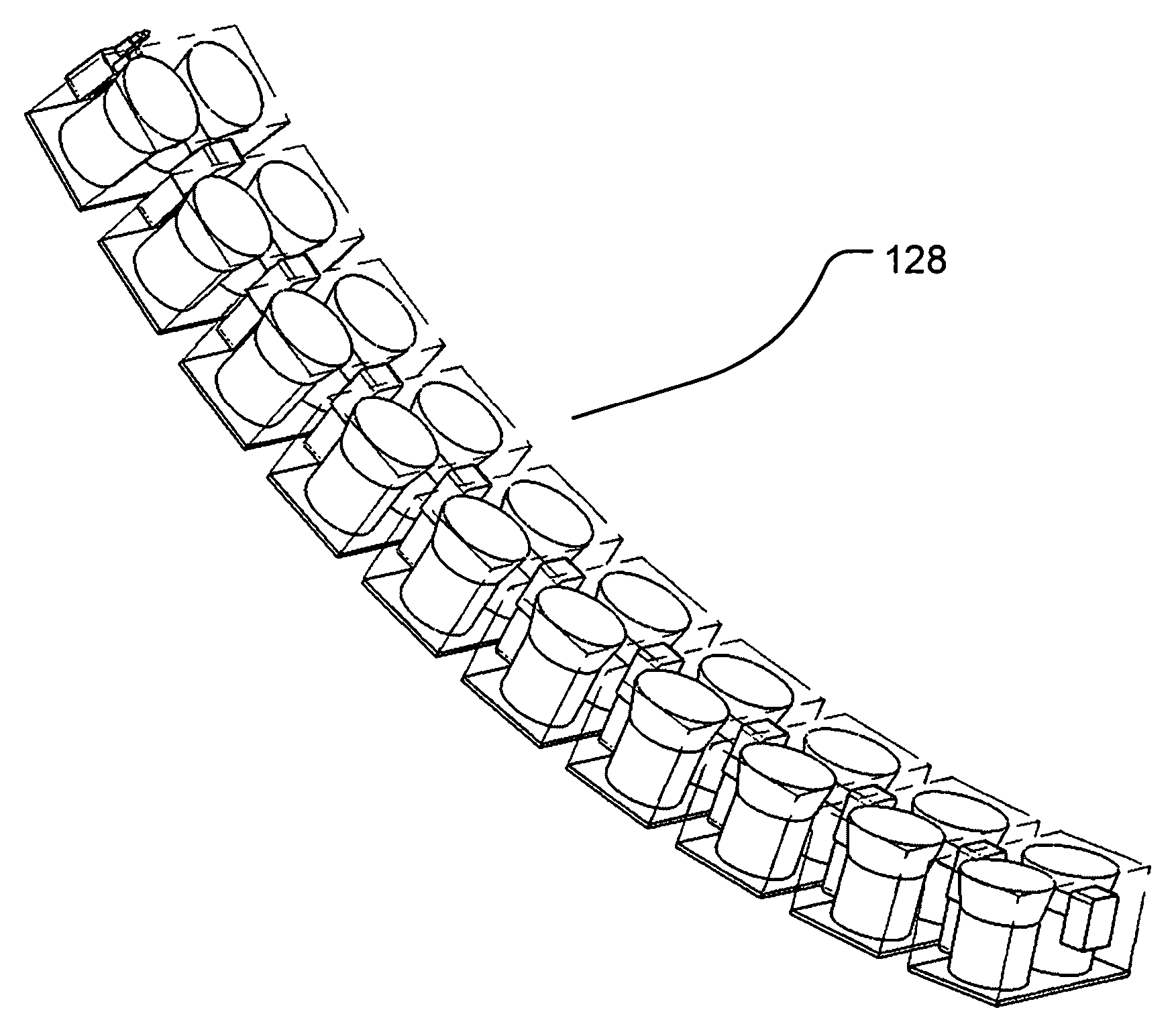

Large power composite ultraphonic pipe

InactiveCN101650937AImprove electromechanical conversion capabilityImprove efficiencySound producing devicesCleaning using liquidsElectricityPre stress

The invention relates to a large power composite ultraphonic pipe. A long composite ultraphonic pipe is formed in such a way that a plurality of short composite pipe piezoelectric transducer units areconnected along the axial direction by hollow thread pipes; both ends of the long composite ultraphonic pipe are provided with covers; each short composite pipe piezoelectric transducer unit comprises at least one cylindrical surface piezoelectric pile ring group; the outer parts of the cylindrical surface piezoelectric pile ring groups are provided with metal prestress shells; the outer walls ofthe cylindrical surface piezoelectric pile ring groups and the inner walls of the metal prestress shells are tightly compounded together; the inner parts of the cylindrical surface piezoelectric pilering groups are provided with expanding type prestress mechanisms; the two adjacent expanding type prestress mechanisms are electrically connected; the metal prestress shells of the two adjacent short composite pipe piezoelectric transducer units are electrically connected; cylindrical surface piezoelectric pile units in each cylindrical surface piezoelectric pile ring group are electrically connected, and the two adjacent cylindrical surface piezoelectric pile ring groups are electrically connected. The large power ultraphonic pipe can generate even cylindrical surface sound radiation in theradial omnidirectional range and is particularly suitable for the ultraphonic processing of liquid.

Owner:ZHEJIANG NORMAL UNIVERSITY

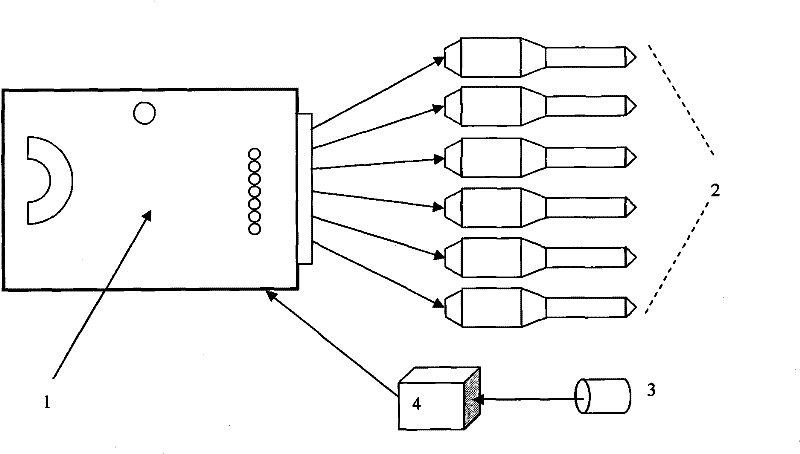

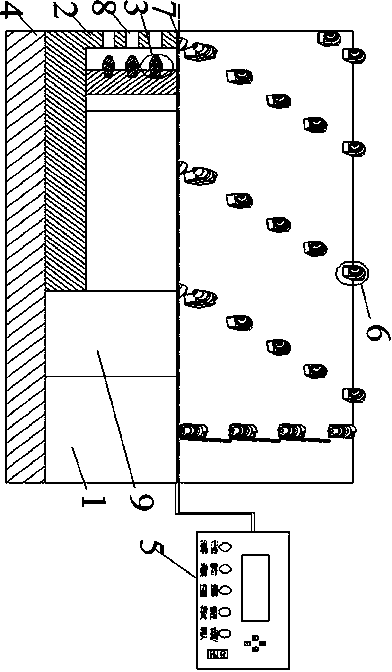

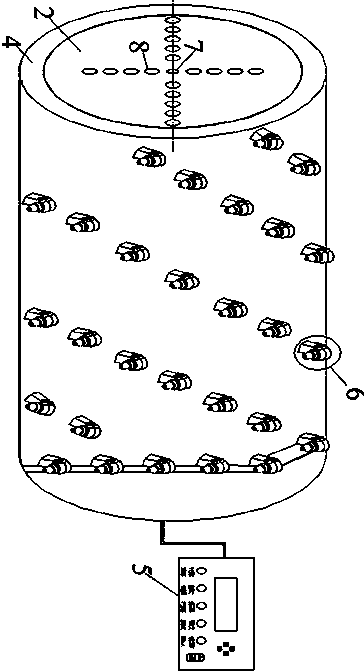

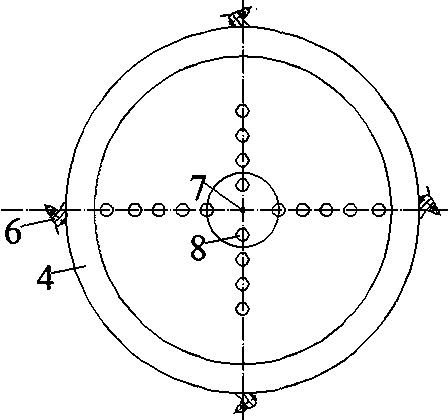

Full-automatic ultrahigh-power ultrasonic anti-scaling and de-scaling device

ActiveCN102225390AReduce energy lossImprove economyCorrosion preventionMechanical vibrations separationSignal processing circuitsEngineering

The invention relates to a full-automatic ultrahigh-power ultrasonic anti-scaling and de-scaling device which comprises a host machine, a plurality of giant magnetostrictive transducers, an external vibration sensor and a sensing signal processing circuit, wherein an ultrasonic signal source oscillator, a power output stage, a machine power circuit, an intelligent control circuit, a direct current excitation circuit and a data receiving circuit are arranged in the host machine; a signal output end of the power output stage is connected with signal input connecting terminals of the giant magnetostrictive transducers through cables and is used for supplying excitation power; an output end of the vibration sensor is connected with an input end of the sensing signal processing circuit; an output end of the sensing signal processing circuit is connected with the intelligent control circuit of the host machine; the ultrasonic signal source oscillator can generate a 11-75kHz ultrasonic signal with adjustable frequency; and the oscillation frequency of an oscillation source can be adjusted by an oscillation circuit and the ultrasonic signal source oscillator. Since the frequency range of ultrasonic wave of the traditional device is only from 15kHz to 25kHz and the discontinuous time of discontinuous pulse cannot be adjusted, the traditional device cannot meet the requirements of preventing and removing different scales for different equipment. These problems cam be solved by the invention of the full-automatic ultrahigh-power ultrasonic anti-scaling and de-scaling device.

Owner:SHANGHAI MACROPROCESS LUSTRATION TECH +1

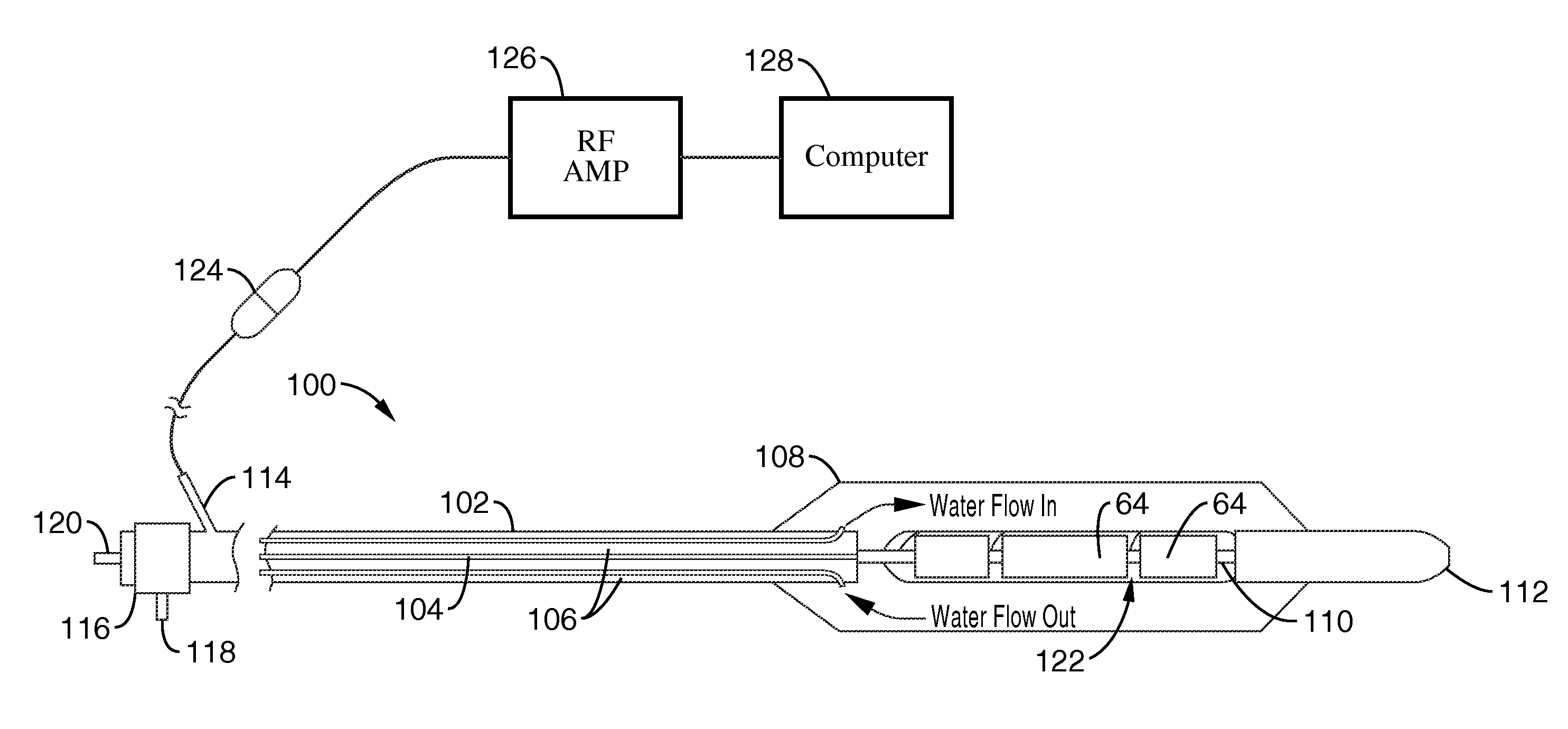

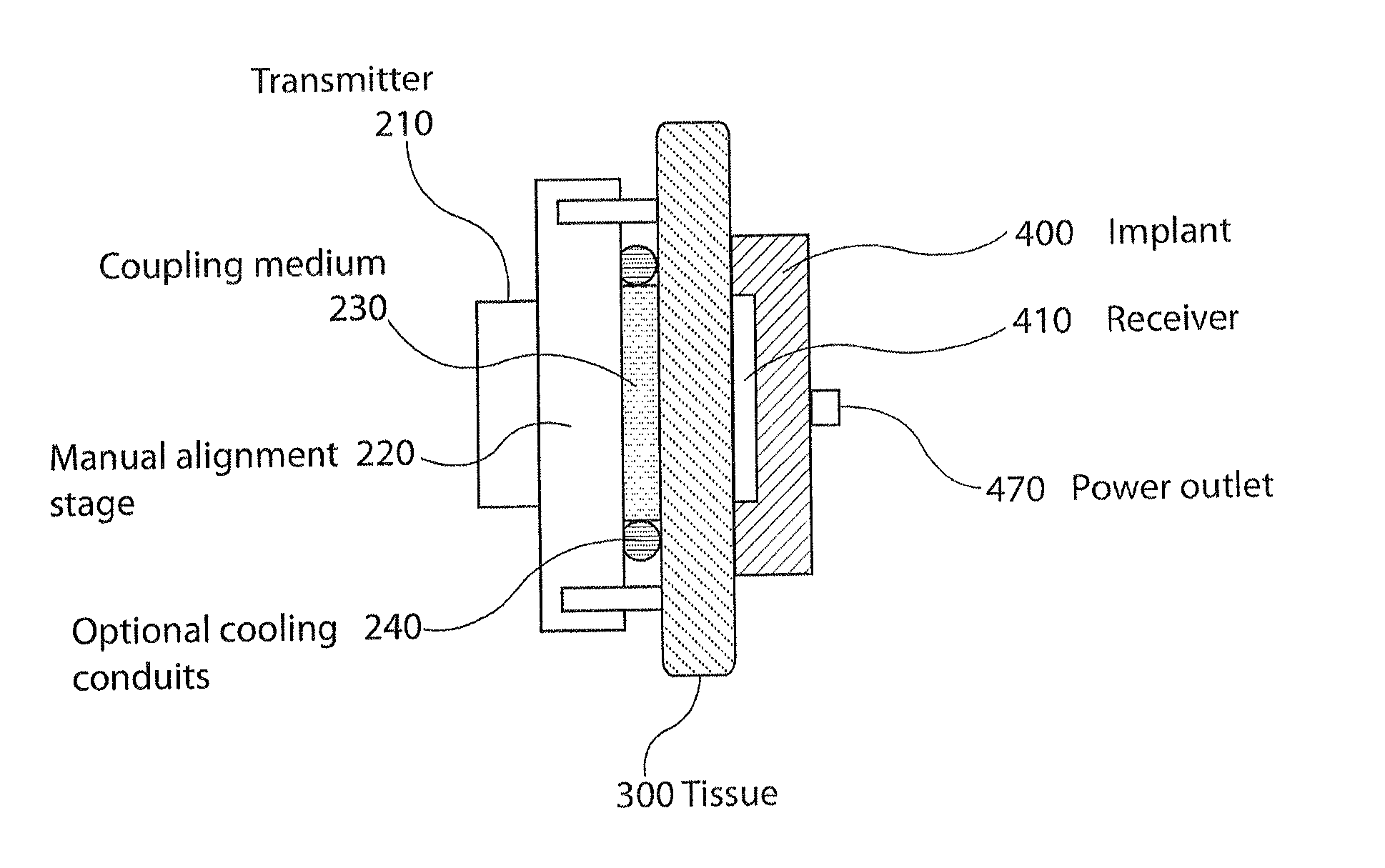

High power ultrasound wireless transcutaneous energy transfer (US-TET) source

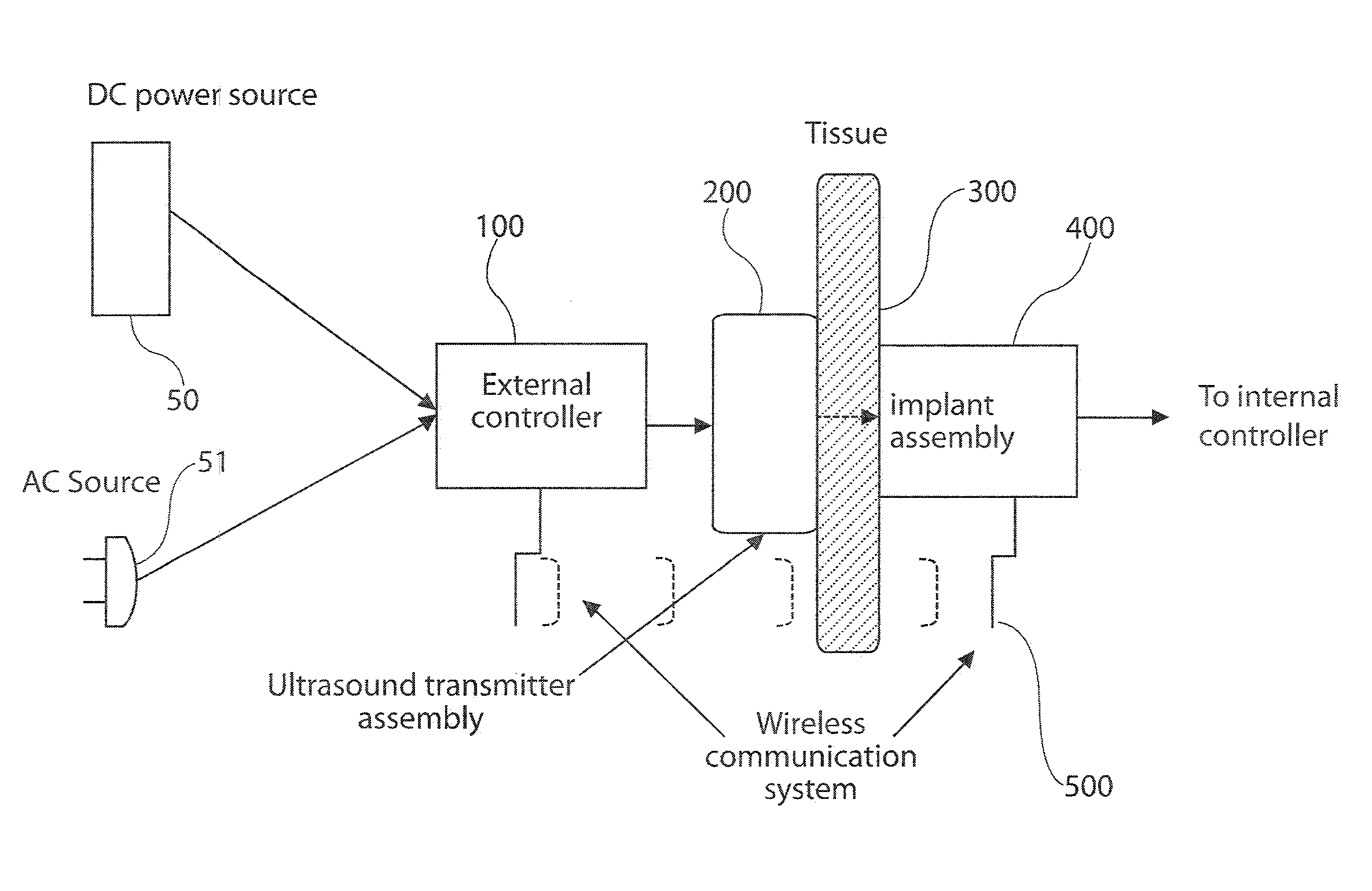

A bio-implantable energy capture and storage assembly is provided. The assembly includes an acoustic energy transmitter and an acoustic energy receiver. The acoustic energy receiver also functions as an energy converter for converting acoustic energy to electrical energy. An electrical energy storage device is connected to the energy converter, and is contained within a bio-compatible implant for implantation into tissue. The acoustic energy transmitter is separate from the implant, and comprises a substantially 2-dimensional array of transmitters. The acoustic energy converter may also provide conditioned power directly to a load, connected to said energy converter.

Owner:PIEZO ENERGY TECH

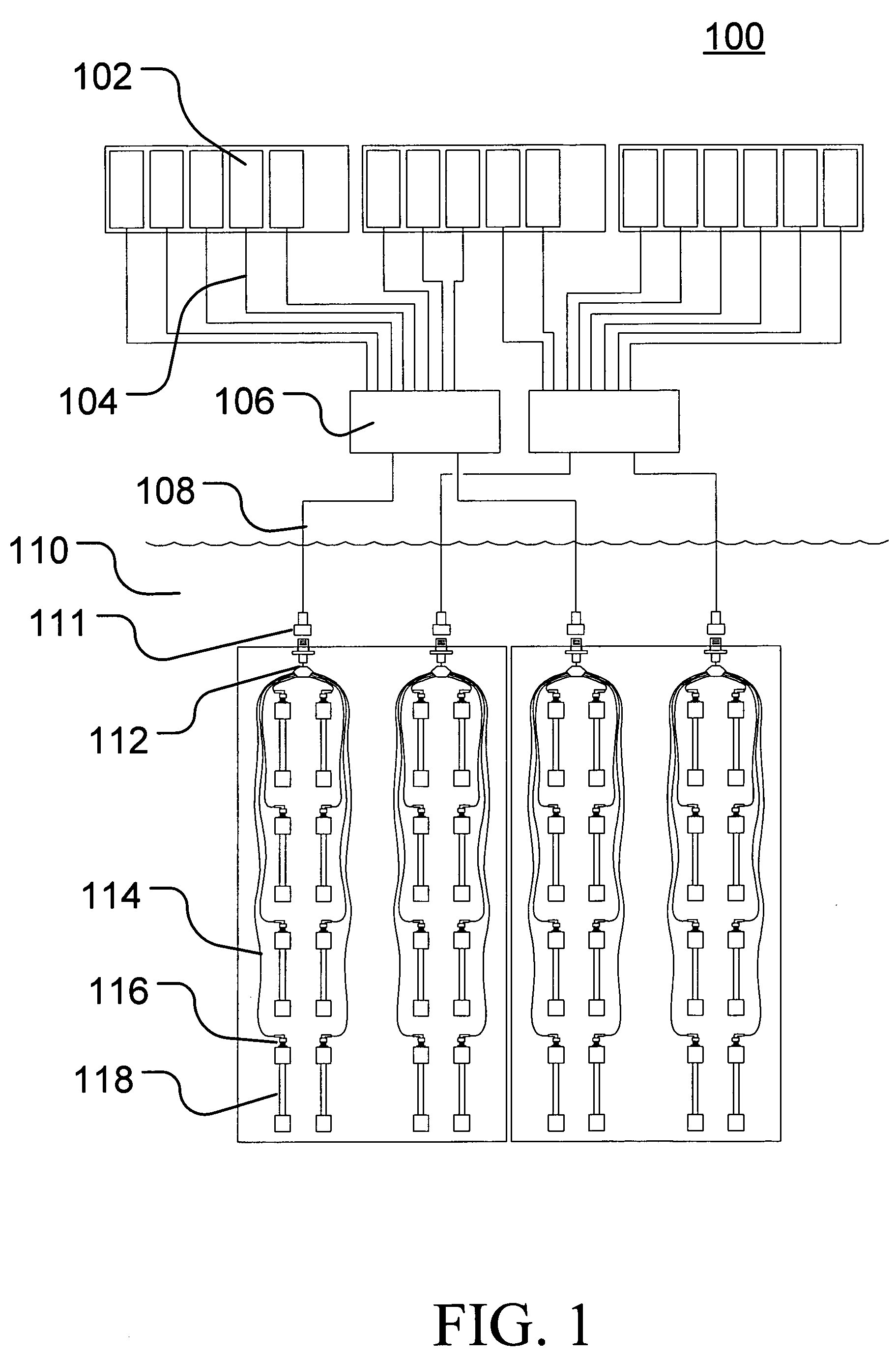

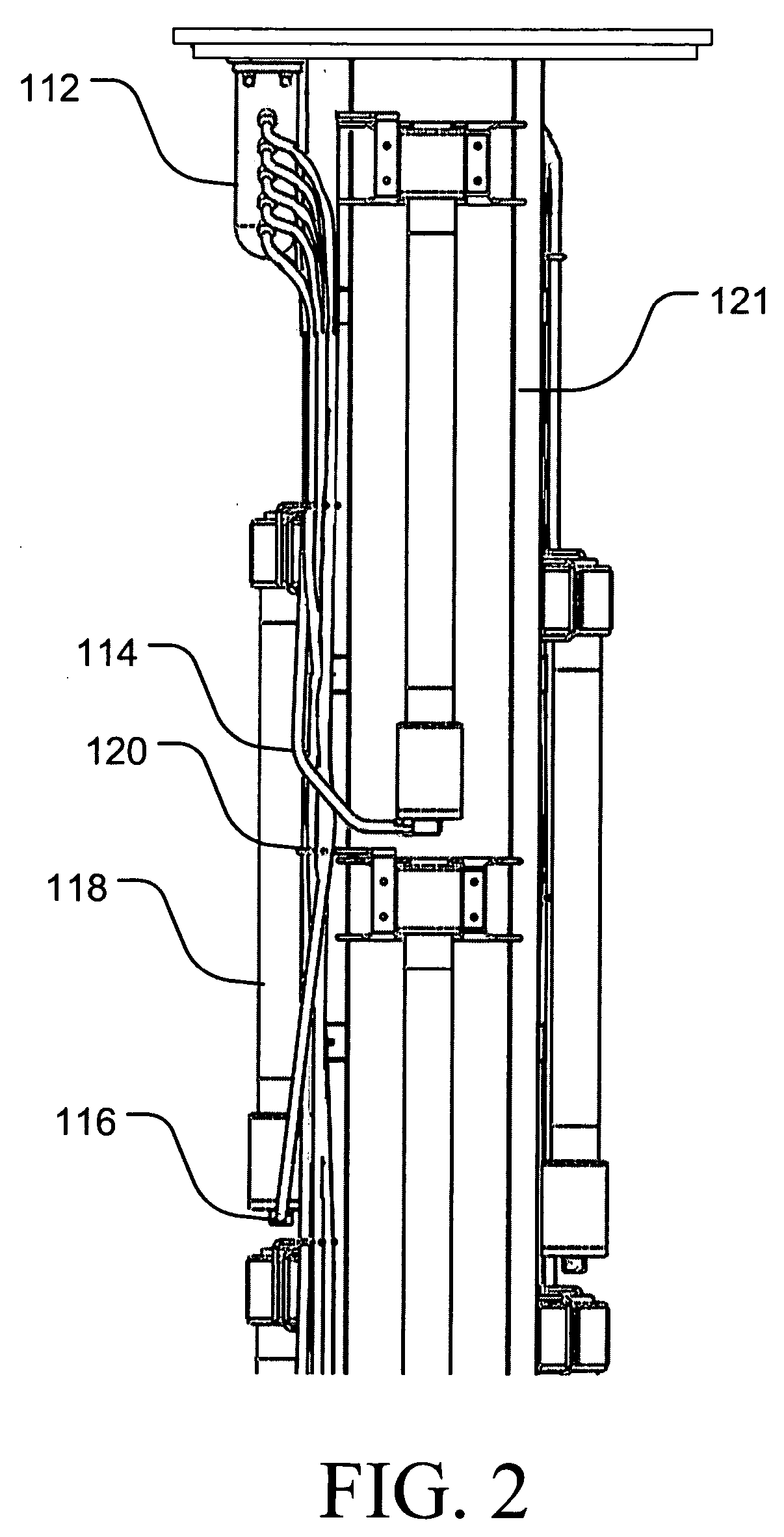

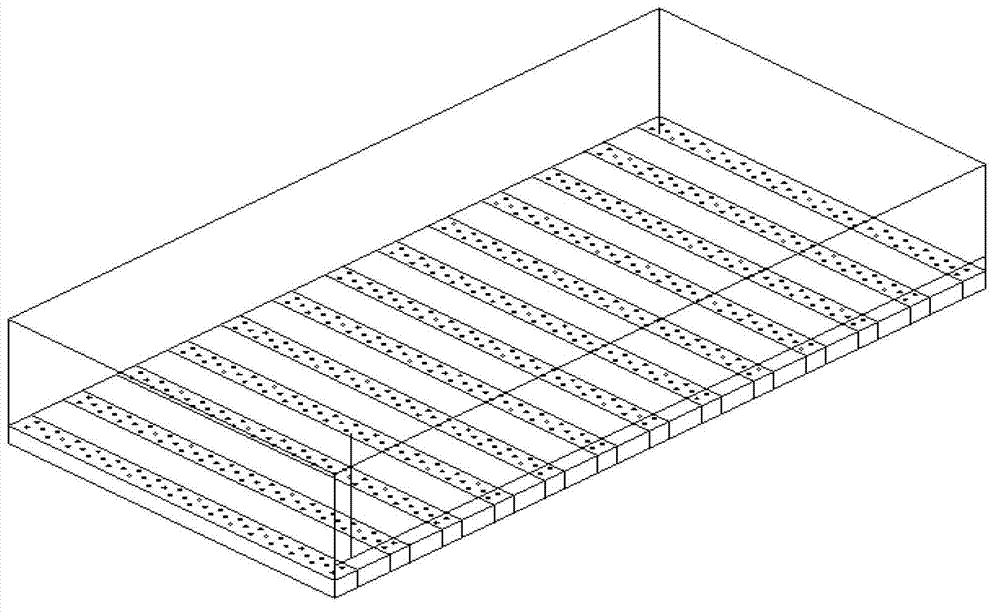

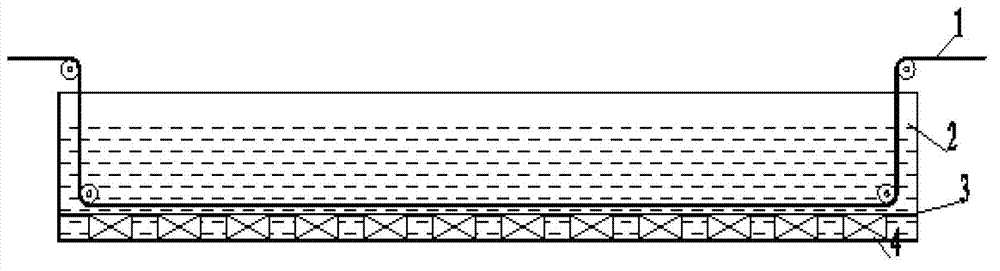

Field transportable high-power ultrasonic transducer assembly

The present invention relates to an improved ultrasonic cleaning system incorporating one or more improvements including, for example, permanently-attached flexible cables, waterproof bulkhead connectors provided on the transducers, submersible breakout assemblies, rigid cable guides and retainers, and at least one electronic switching unit whereby multiple ultrasonic transducers can be selectively driven by a single ultrasonic generator. The improved ultrasonic cleaning system may be configured with various transducer arrangements including, for example, elongated transducers provided on a carrying frame or structure and a more planar array configuration that may be assembled from a plurality of transducer subassemblies.

Owner:ARGUELLES DAVID +2

Large power ultrasonic wave micro-reactor

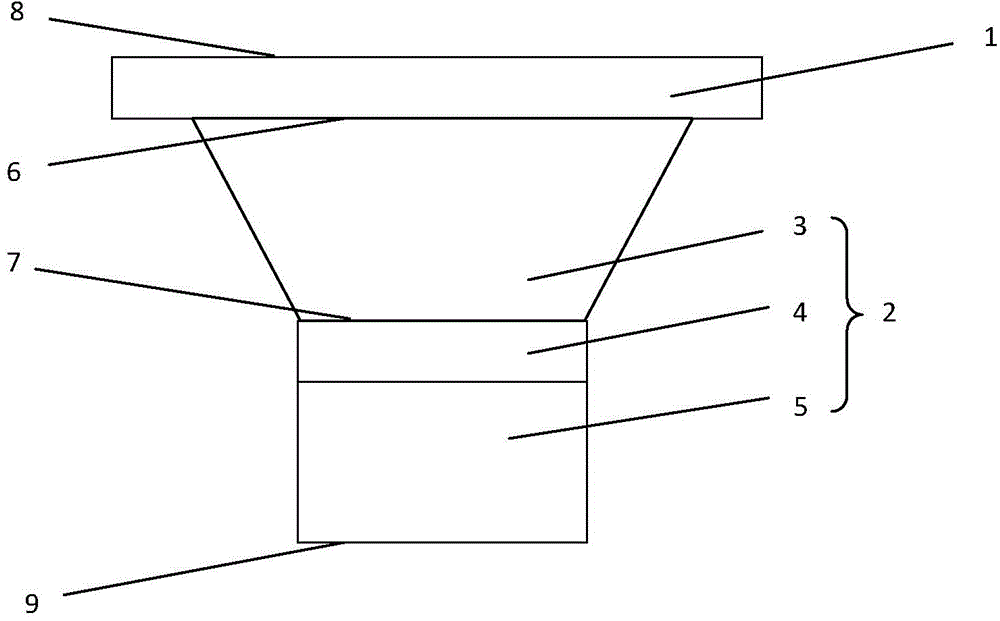

ActiveCN104923468ASolve the blockageEnhanced mixing processMechanical vibrations separationVibration amplitudeWavelength

The invention relates to a large power ultrasonic wave micro-reactor. A horn-shaped sandwich type energy converter with large radiating surface can be directly connected with the micro-reactor in a rigid way, so the energy converter and the micro-reactor can resonate as a whole; the length of the whole ultrasonic micro-reactor in a direction perpendicular to a front radiating surface is a half of the ultrasonic wave length; when the whole ultrasonic micro-reactor works at the resonant frequency, the micro-reactor has the maximum vibration amplitude, so strong ultrasonic energy is achieved in the whole micro-reactor; the ultrasonic wave micro-reactor possesses great power, high ultrasonic energy transmitting efficiency and large ultrasonic reinforced covering area; technology fluid mixture or mass transferring can be intensified for the micro-reactor; and a problem of blocking of the micro-reactor can be solved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

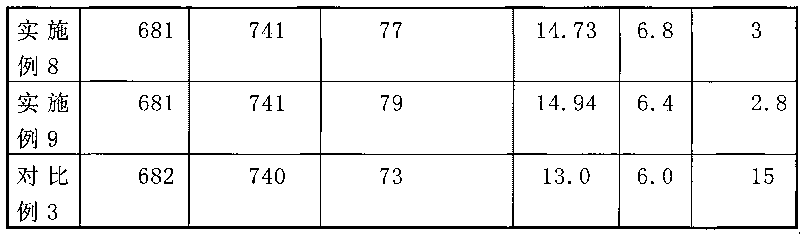

Lead niobium antimonite-containing five-element piezoelectric ceramics material for driver and preparation thereof

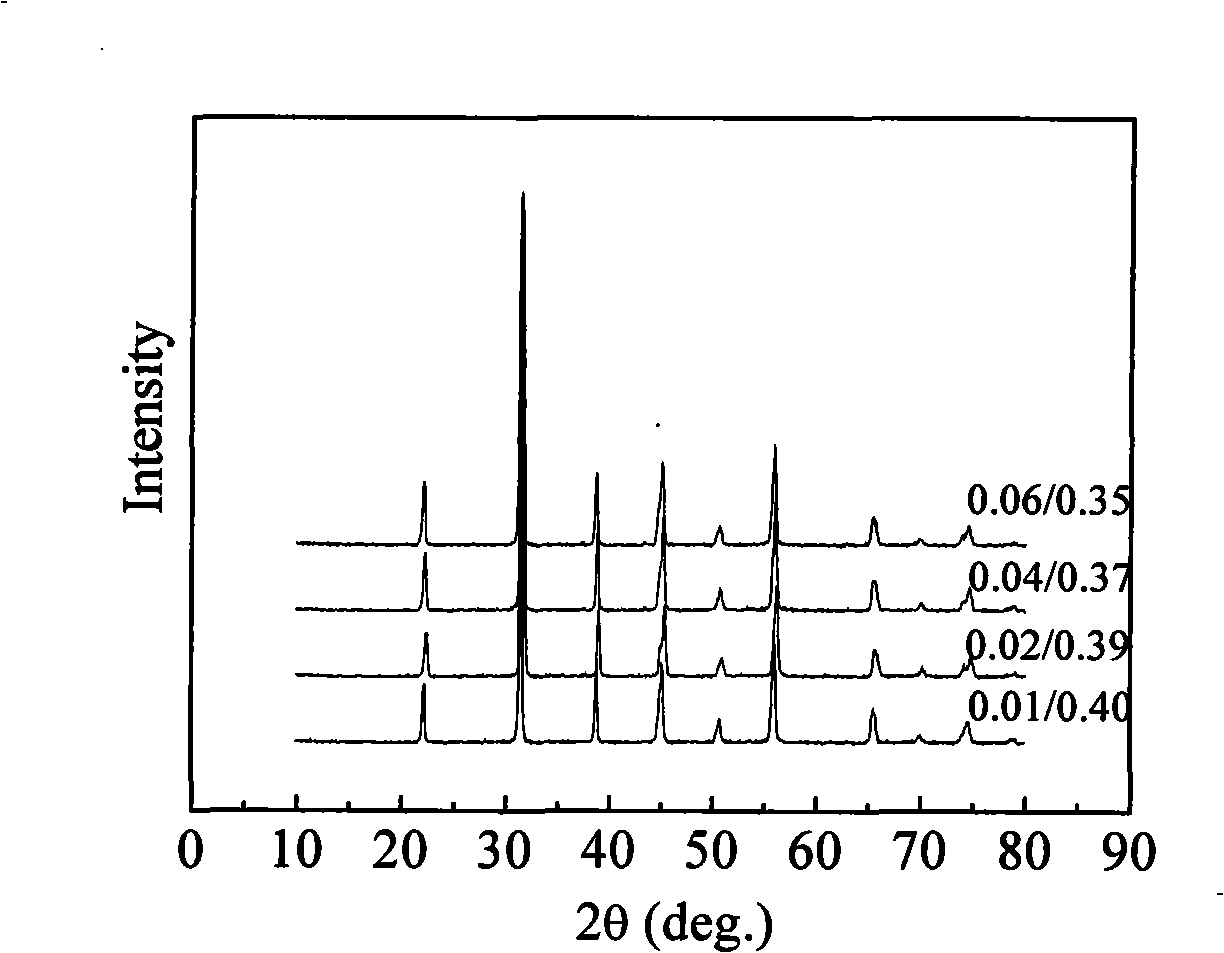

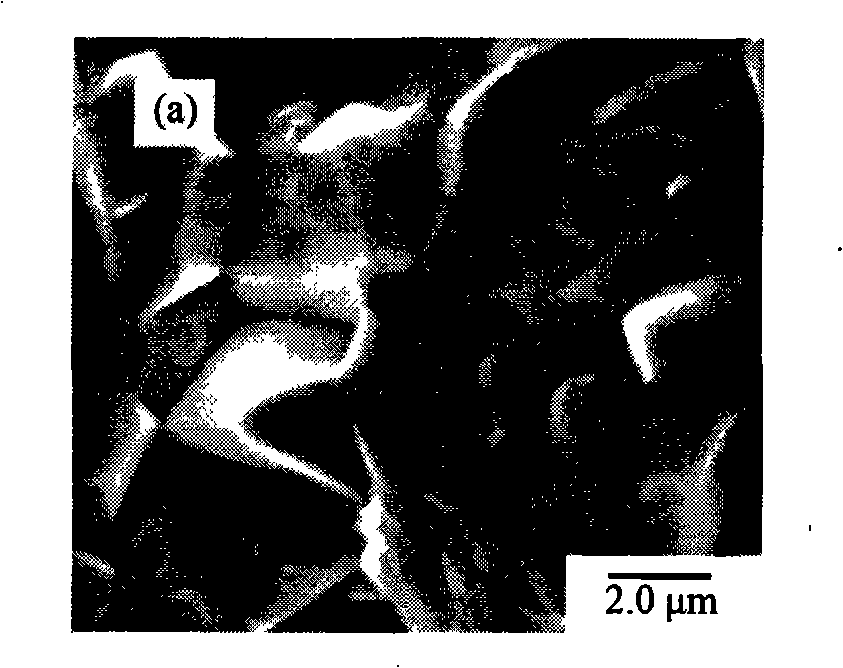

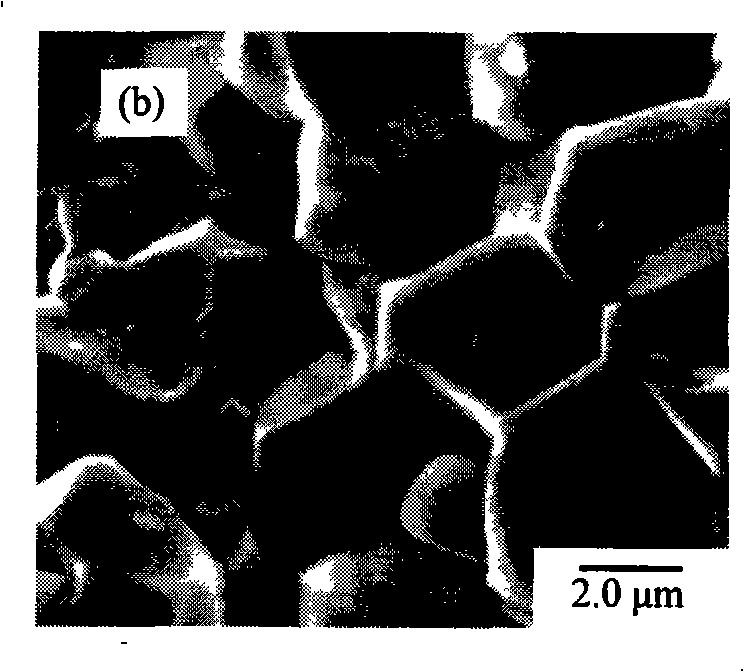

InactiveCN101302105AThe process steps are simpleGood repeatabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive/magnetostrictive devicesElectromechanical coupling coefficientNiobium

The invention discloses a pentabasic piezoelectric ceramic material containing antimonite lead for a drive, consisting of a material expressed by a general formula of xPb ( Mg1 / 2W1 / 2)O3-yPb (Sb1 / 2Nb1 / 2)O3- ( 0.41-x-y)Pb ( Ni1 / 3 Nb2 / 3) O3-Pb0.59 (Zr z Ti 0.59-x )O3, in the formula, the x is more than or equal to 0.05 and less than or equal to 0.07, the y is more than 0 or equal to o and less than or equal to 0.04, and the z is more than or equal to 0.30 and less than or equal to 0.50. A preparing method comprises the processing steps of ingredient synthesis, precalcination, granulation, pressing, evacuation, sintering, silver calcination and polarization, and the processing steps are simple, the repeatability is good and the rate of finished products is high. Piezoelectric ceramic made by the invention passes the test, the tested result shows that the dielectric coefficient is between 600 and 850 pc / N, the electromechanical coupling factor is between 0.55 and 0.75, and the relative dielectric constant in room temperature is between 3500 and 5000. The pentabasic piezoelectric ceramic material can be used for preparing a vibration transducer, a controller shell, a dynamic fuel injected nozzle, a high-power ultrasonic device, a high-temperature and high-frequency vibrometer, a high-temperature flowmeter, a high-temperature resistant swarming buzzer, a high-temperature sensor, a drive and so on arranged in an automobile.

Owner:SHAANXI NORMAL UNIV

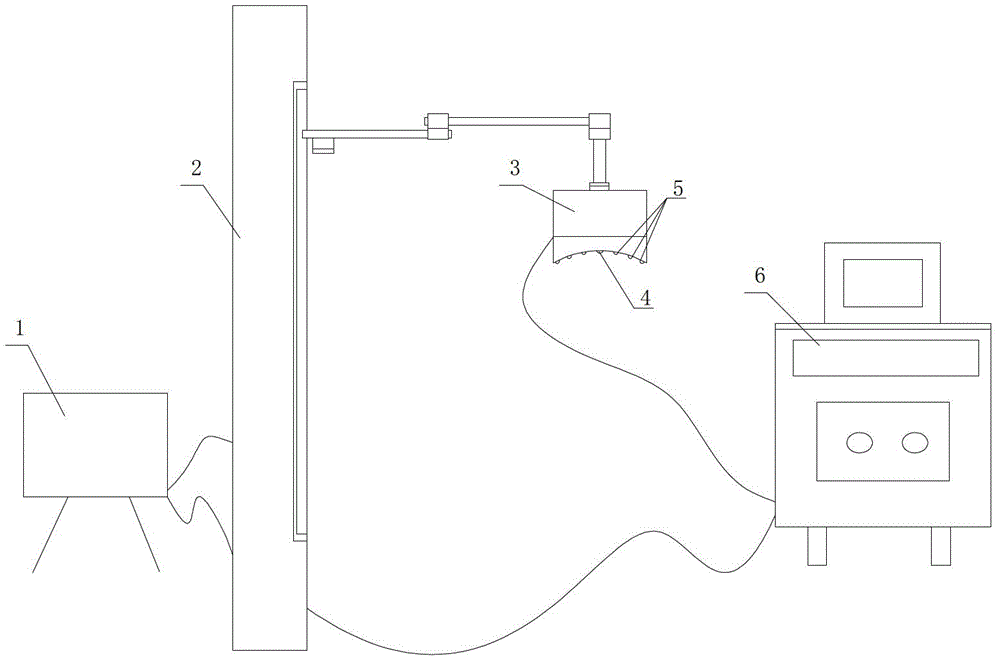

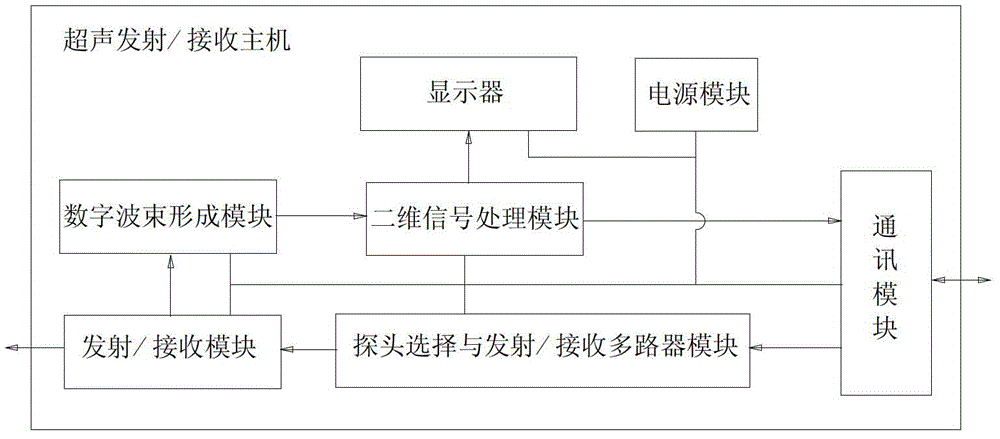

High-strength focusing ultrasonic therapeutic apparatus

The invention discloses a high-strength focusing ultrasonic therapeutic apparatus, which comprises a combined therapeutic head, an ultrasonic transmitting / receiving host machine, a five-DOF (Degree of Freedom) mechanical arm and a work station, wherein the combined therapeutic head comprises a B-ultrasonic probe and a group of therapeutic probes which are relatively accurately fixed in positions; the combined therapeutic head is connected with the five-DOF mechanical arm; and the work station controls the five-DOF mechanical arm and the ultrasonic transmitting / receiving host machine to work respectively. During the therapeutic process, phase image scanning and adjustment of phase therapeutic position are carried out in an electronic manner, so that two-dimensional B-ultrasonic image cross section is effectively overlapped with high-power ultrasonic beam therapeutic cross section, the accuracy and reliability of therapy and real-time observation are ensured, and the five-DOF mechanical arm is accurate to position and flexible to control; the scan image is more intuitive and clear through three-dimensional reconstruction so as to facilitate subsequent observation and diagnosis; and the therapeutic apparatus is particularly suitable for carrying out noninvasive high-strength focusing ultrasonic therapy on pathological tissues of organs such as glandula mammaria, liver, kidney, uterus, anteprostate and the like.

Owner:广州多浦乐电子科技股份有限公司

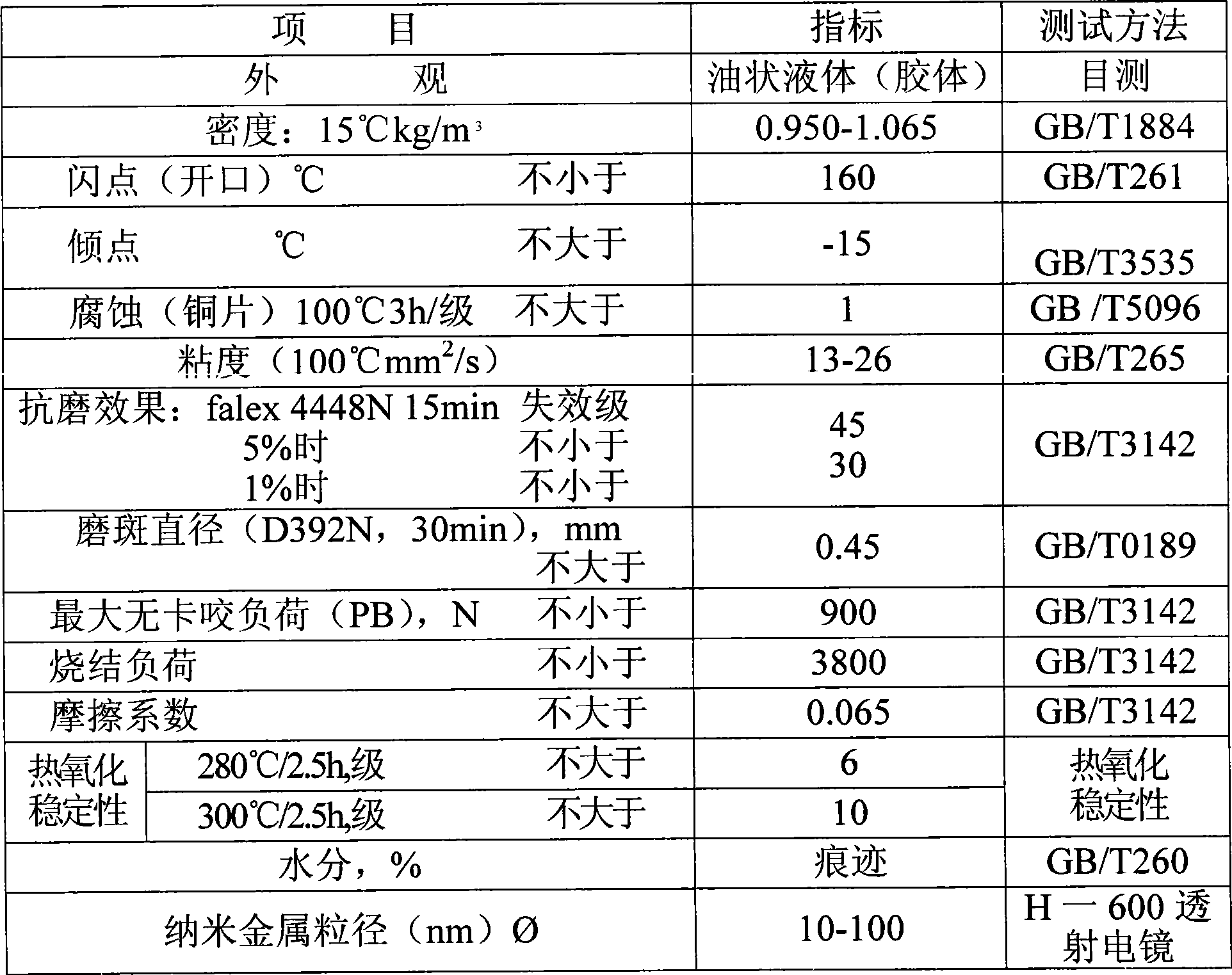

High-efficiency energy-saving nano antiwear agent and preparation method and application thereof

The invention discloses a high-efficiency energy-saving nano anti-wear agent, a preparation method and application thereof. The nano anti-wear agent is made by the following raw materials in weight proportion: 1 to 500 portions of nano metal particles, 100 to 10,000 portions of detergent dispersant, 100 to 10,000 portions of antioxidant, 100 to 5,000 portions of organic high polymer, and 80,000 to 500,000 portions of diluting agent, wherein the nano metal particles are mixture of two or more than two of metal particle molybdenum, boron, chromium, vanadium, titanium, aluminum and cerium. The compositions are mixed according to the proportion, are stirred to react at a specified temperature, are circularly sprayed and dispersed for a plurality of hours through a high-pressure plunger pump, and then form a steady nano-metal eutectic ion organic compound colloid by the dispersion of a high-power ultrasonic device. The nano anti-wear agent has the advantages of good service performance, simple preparation method, and broad application, and can form novel lubricating oil series products with lubricating oil.

Owner:石家庄劲力宝石油化工有限公司

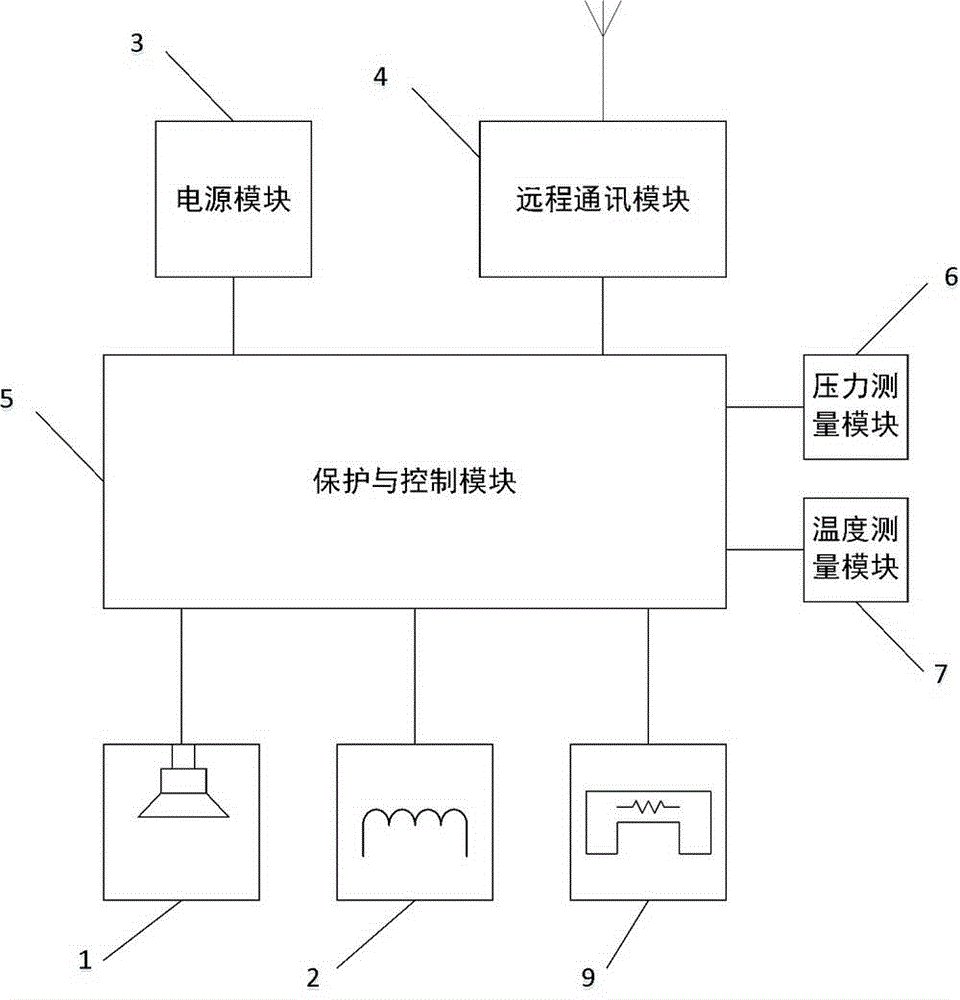

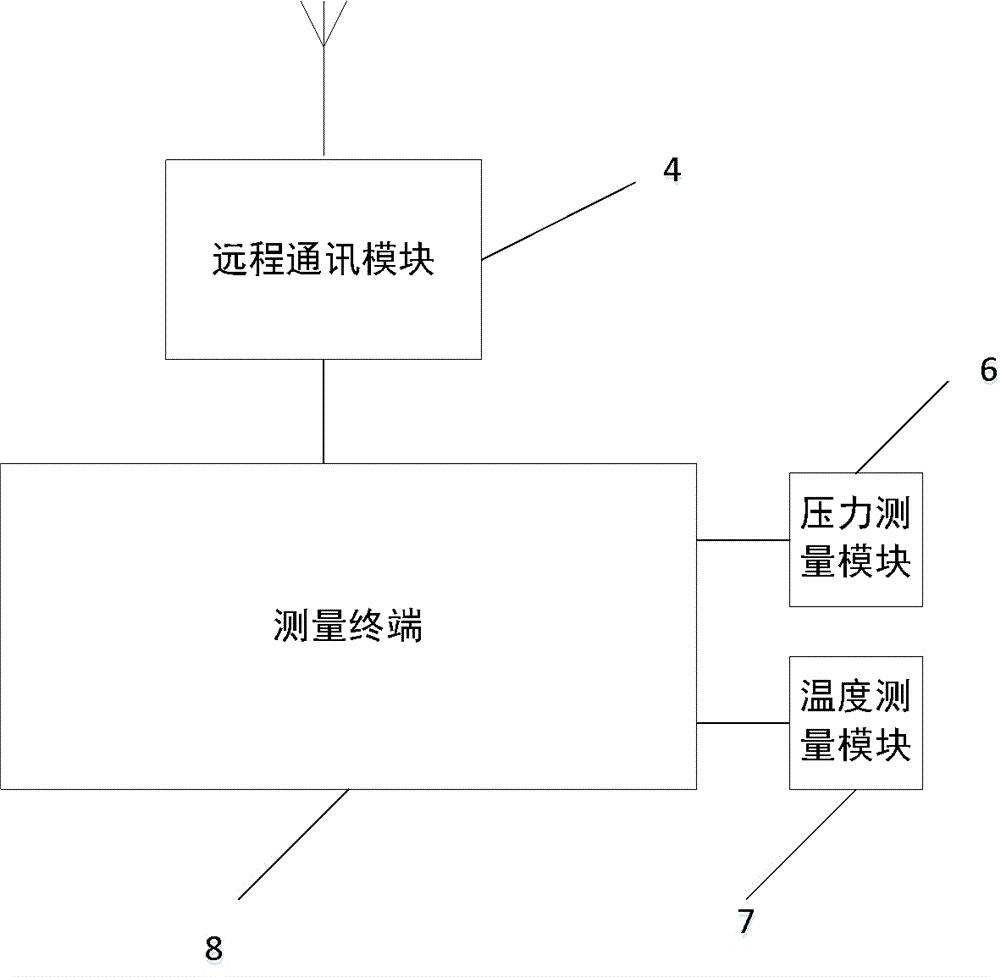

Acoustic-magnetic-thermal combined paraffin-control and plug-removal method and device for oil pipeline

InactiveCN104132215AWill not affect normal productionPower frequency adjustablePipe heating/coolingPipe elementsEngineeringElectromagnetic induction

The invention discloses an acoustic-magnetic-thermal combined paraffin-control and plug-removal method and device for an oil pipeline. According to the method and device, the ultrasonic technology, the electromagnetic induction heating technology and the electromagnetic paraffin-control technology are combined and reinforce one another, and a paraffin-control and plug-removal effect superior to simple superposition can be obtained. The device is composed of an ultrasonic generating module, an electromagnetic induction heating module, a power source module, a remote communication module, a protection and control module, a pressure measuring module, a temperature measuring module, a measuring terminal and an electromagnetic paraffin-control module. By the adoption of the device, precipitation of paraffin is prevented so that scale formation can be avoided and generated paraffin can be removed by means of the high-power ultrasonic cavatition effect and the good paraffin control effect of the alternating magnetic field; the temperature of the oil pipeline is increased by means of the electromagnetic induction heating technology, the temperature of crude oil is kept higher than paraffin precipitation point temperature, and the paraffin precipitation is restrained; meanwhile, the blocking degree of the pipeline can be automatically judged by means of sensors at the head end and tail end of the pipeline, and then corresponding working modes are started. The device is high in universality and operates online completely.

Owner:HARBIN UNIV OF SCI & TECH +1

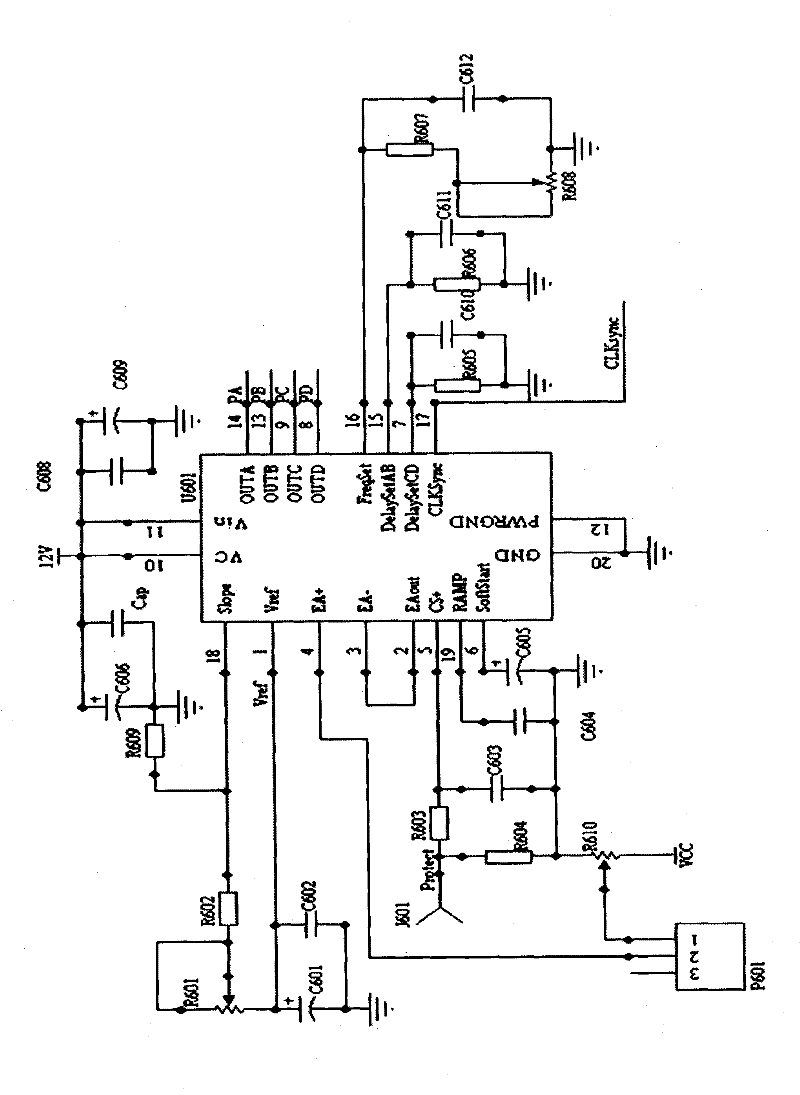

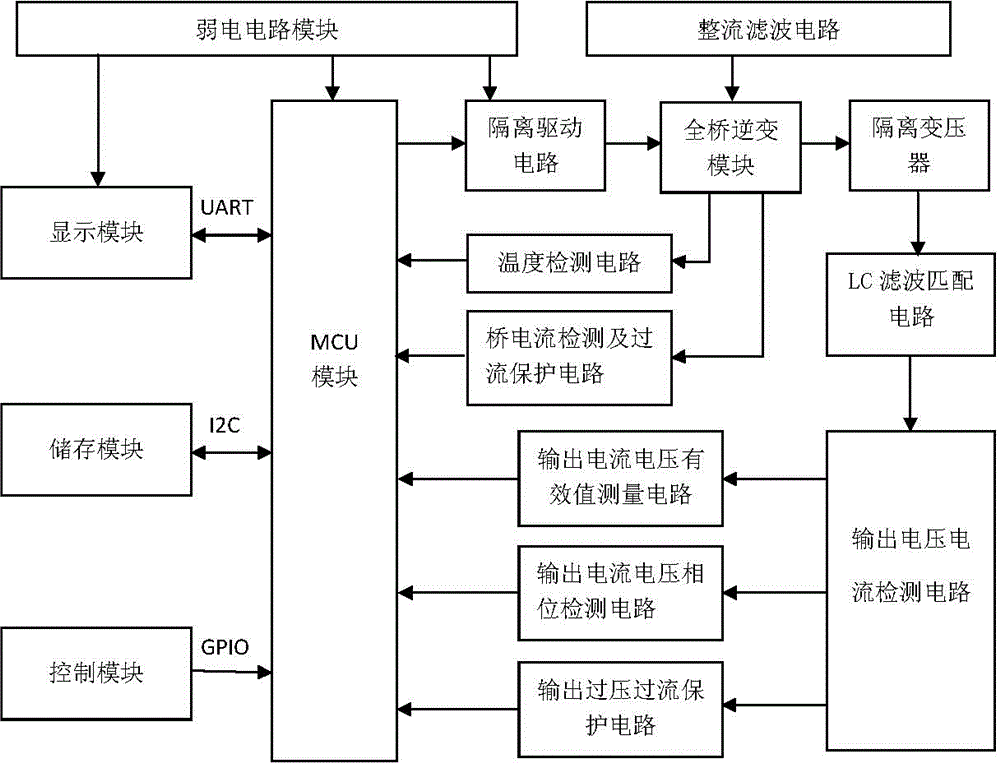

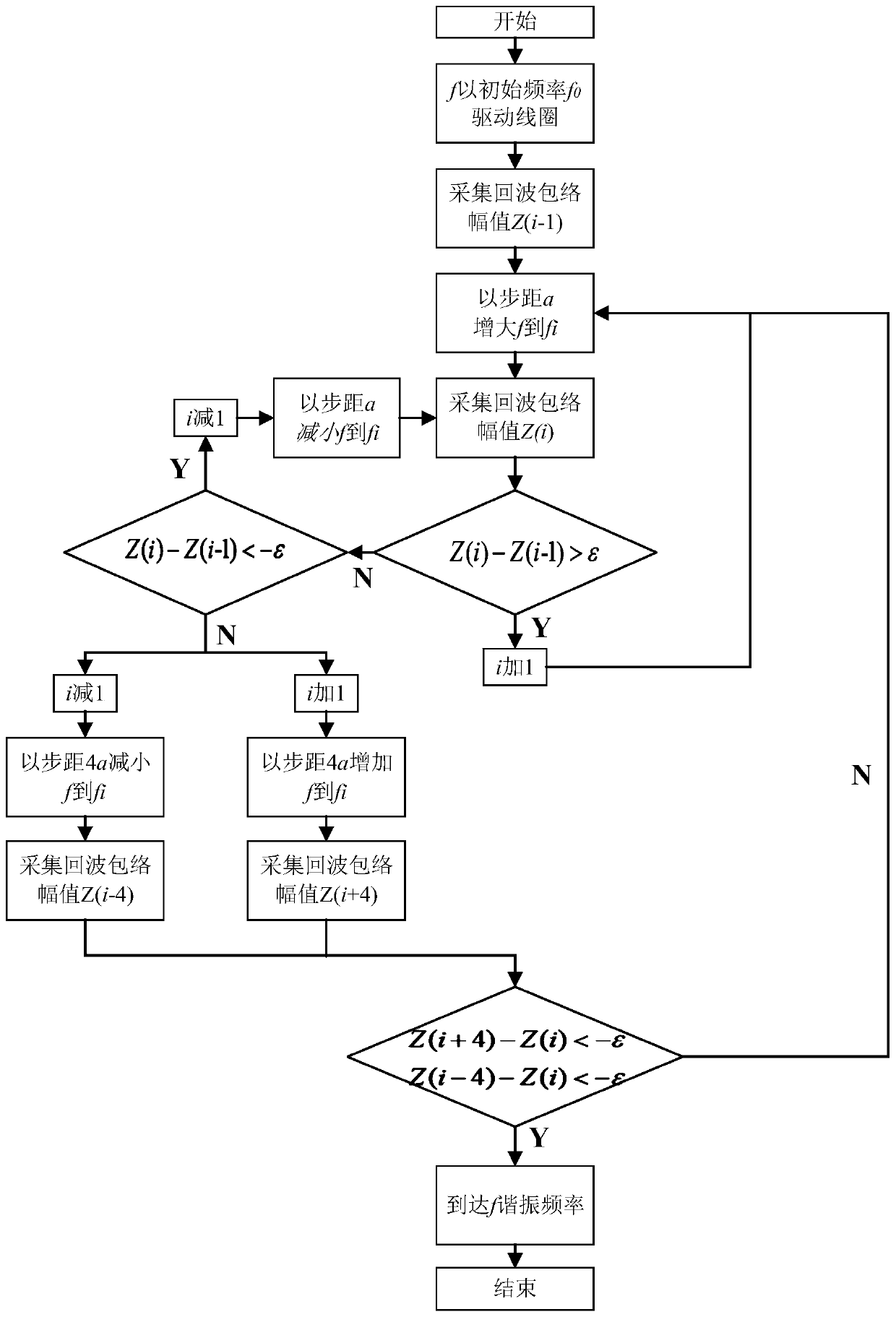

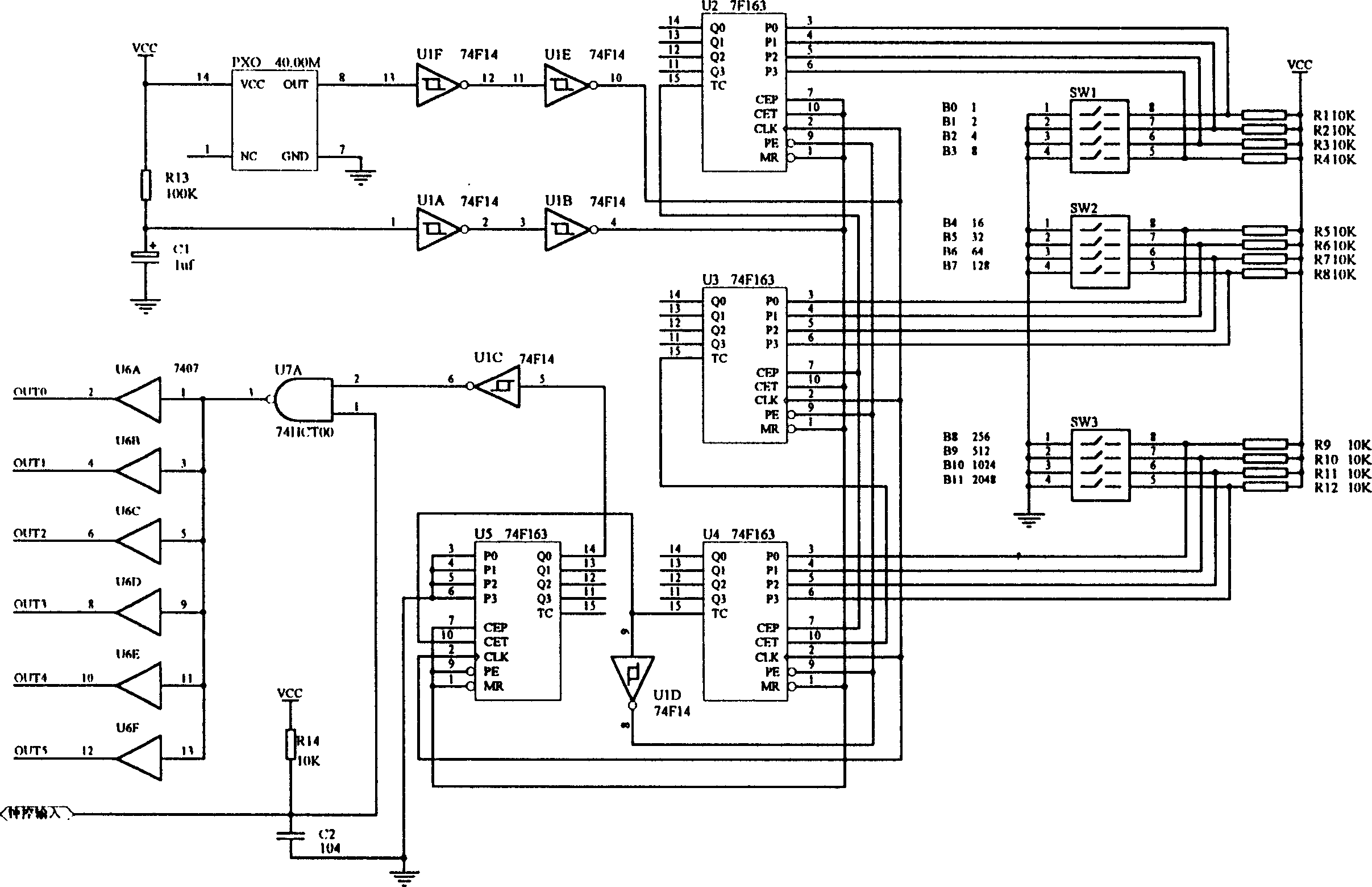

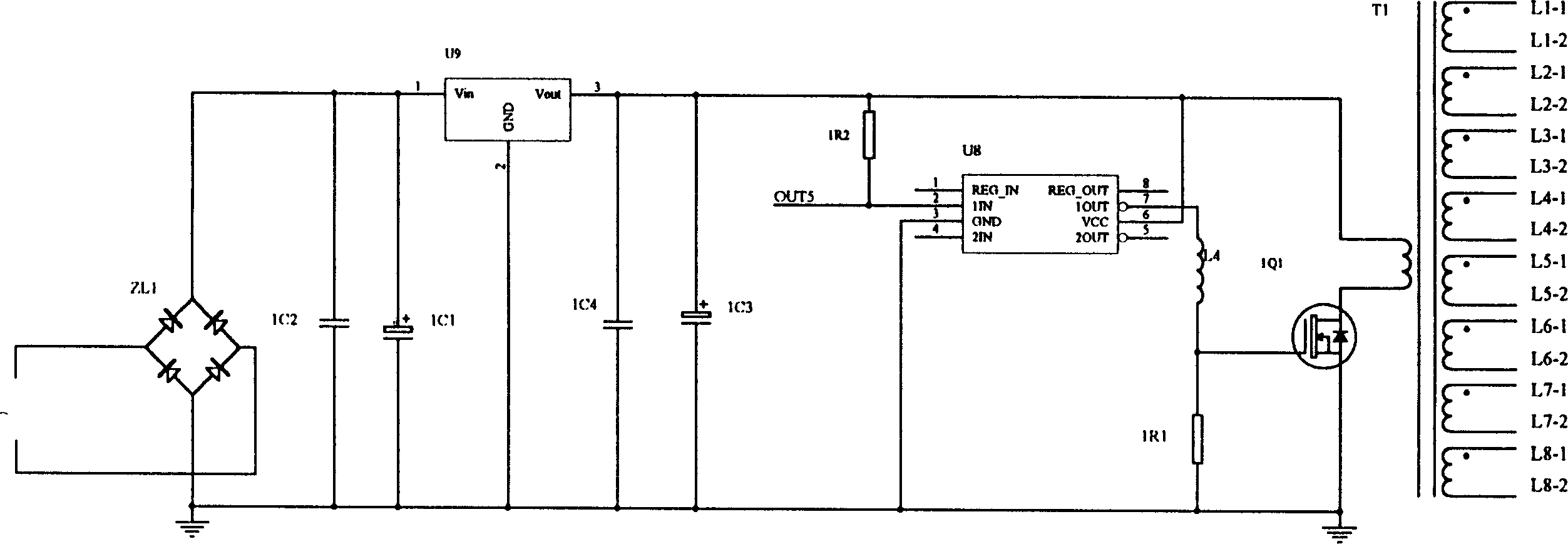

Full-bridge high-power ultrasonic generator based on phase shift

ActiveCN104549979AFinding the Resonant Frequency AccuratelyExactly find the functionMechanical vibrations separationCapacitanceOvervoltage

The invention discloses a full-bridge high-power ultrasonic generator based on phase shift. The full-bridge high-power ultrasonic generator comprises a weak electricity circuit module, an MCU (microprogrammable control unit) module, an isolation driving circuit, a rectifying and filtering circuit, a full-bridge inverter module, an isolation transformer, an LC (inductance and capacitance) filtering matching circuit, an output voltage and current detection circuit, a temperature detection circuit, a bridge current detection and overcurrent protection circuit, an output current and voltage effective value measuring circuit, an output current and voltage phase detection circuit, an output overvoltage and overcurrent protection circuit, a display module, a storage module and a control module. The full-bridge high-power ultrasonic generator has the advantages that the design is skillful and reasonable, the size is small, the radiation is small, the performance is stable, the protection function is complete, the sweep frequency range and sweep frequency voltage self-setting function is realized, the resonance frequency of a transducer can be accurately found, the frequency tracking function is stable, and the output voltage, current, load and impedance information and the like can be monitored in real time during processing; the operation is convenient and simple, the power is high, and the full-bridge high-power ultrasonic generator is suitable for being widely popularized and applied.

Owner:深圳迈菲精密有限公司

High power ultrasound wireless transcutaneous energy transfer (us-tet) source

A bio-implantable energy capture and storage assembly is provided. The assembly includes an acoustic energy transmitter and an acoustic energy receiver. The acoustic energy receiver also functions as an energy converter for converting acoustic energy to electrical energy. An electrical energy storage device is connected to the energy converter, and is contained within a bio-compatible implant for implantation into tissue. The acoustic energy transmitter is separate from the implant, and comprises a substantially 2-dimensional array of transmitters. The acoustic energy converter may also provide conditioned power directly to a load, connected to said energy converter.

Owner:PIEZO ENERGY TECH

Ultrasonically-treated nutritional products having extended shelf life

InactiveUS20140220198A1Extended shelf lifeIncrease powerMilk preservationDough treatmentEngineeringNutritional products

Disclosed are nutritional products and nutritional bars having increased shelf life. The nutritional product or nutritional bar is manufactured utilizing high power ultrasound in combination with an extrusion process or slabbing process. It has been found that by utilizing high power ultrasound during the manufacturing process of nutritional products and nutritional bars, that the resulting product has increased shelf life and improved texture. In some embodiments, the nutritional bars include a solid crisp matrix.

Owner:ABBOTT LAB INC

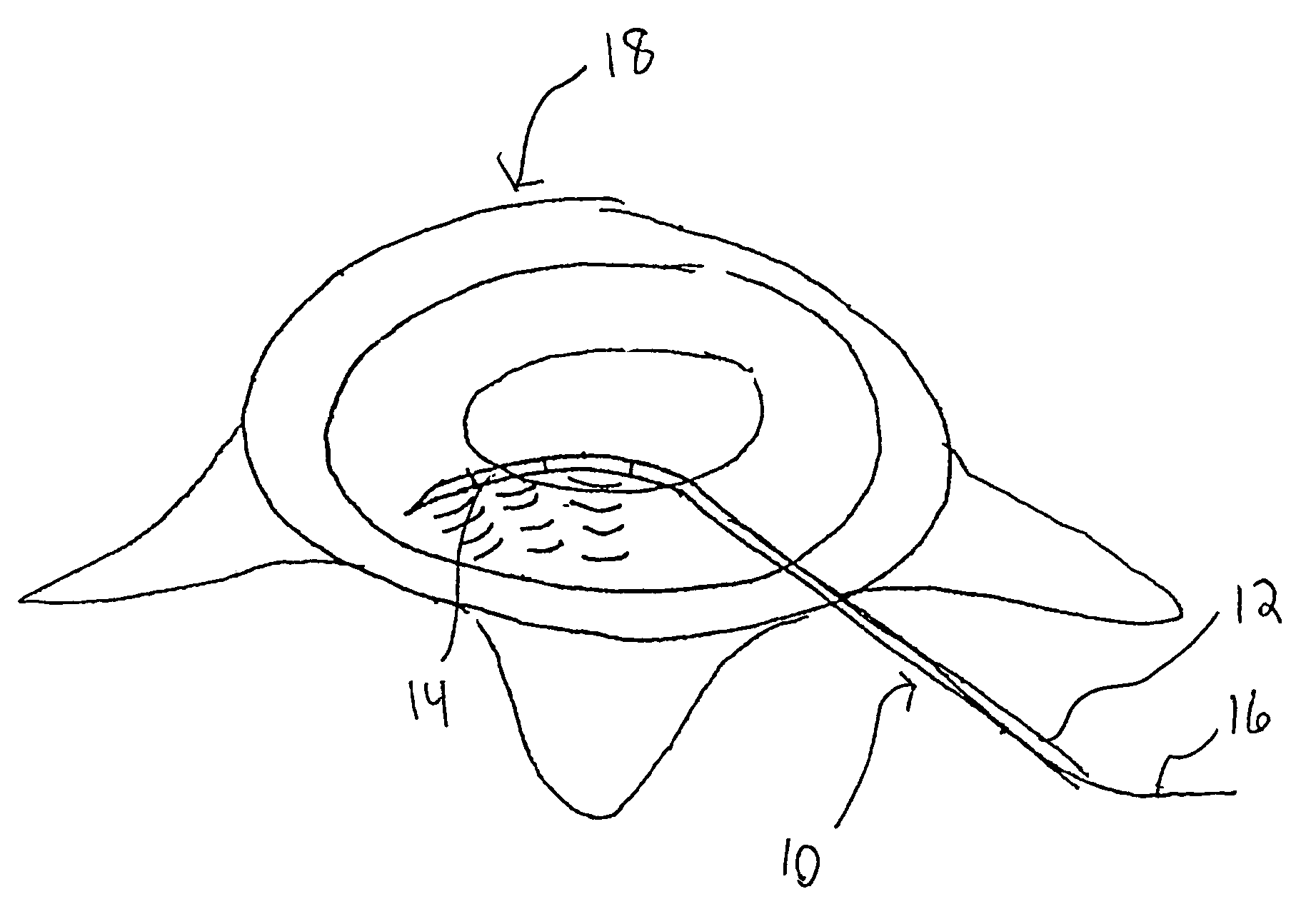

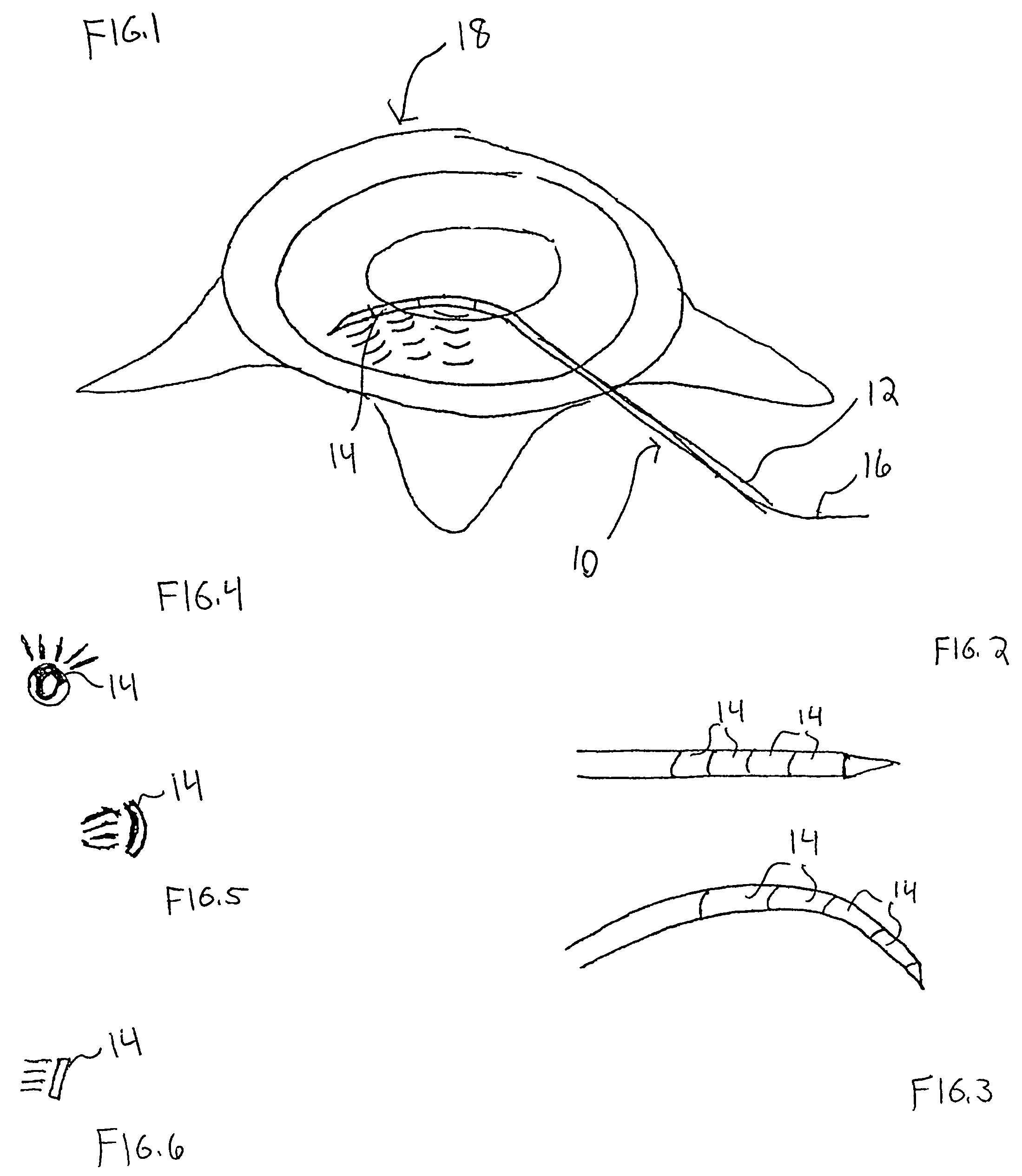

Ultrasound device for treatment of intervertebral disc

InactiveUS8292815B2Improve rendering capabilitiesGood effectUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyFiberSpinal nerve

An ultrasound device and method for the treatment of intervertebral disc tissue for remediation of back pain. An applicator comprises a catheter and / or needle with a distal tip including one or more ultrasound transducer crystals. The crystals produce high-powered ultrasound energy that is transmitted and absorbed in the disc tissue. The resulting temperature elevation of the disc tissue shrinks the collagen fibers in the surrounding tissue, and / or destroying small nerves that may have invaded and innervated the surrounding degenerated tissue, and can provide increased structural integrity and disc support for the fragmented nucleus pulposus to relieve pressure on the spinal nerves.

Owner:ACOUSTIC MEDSYST

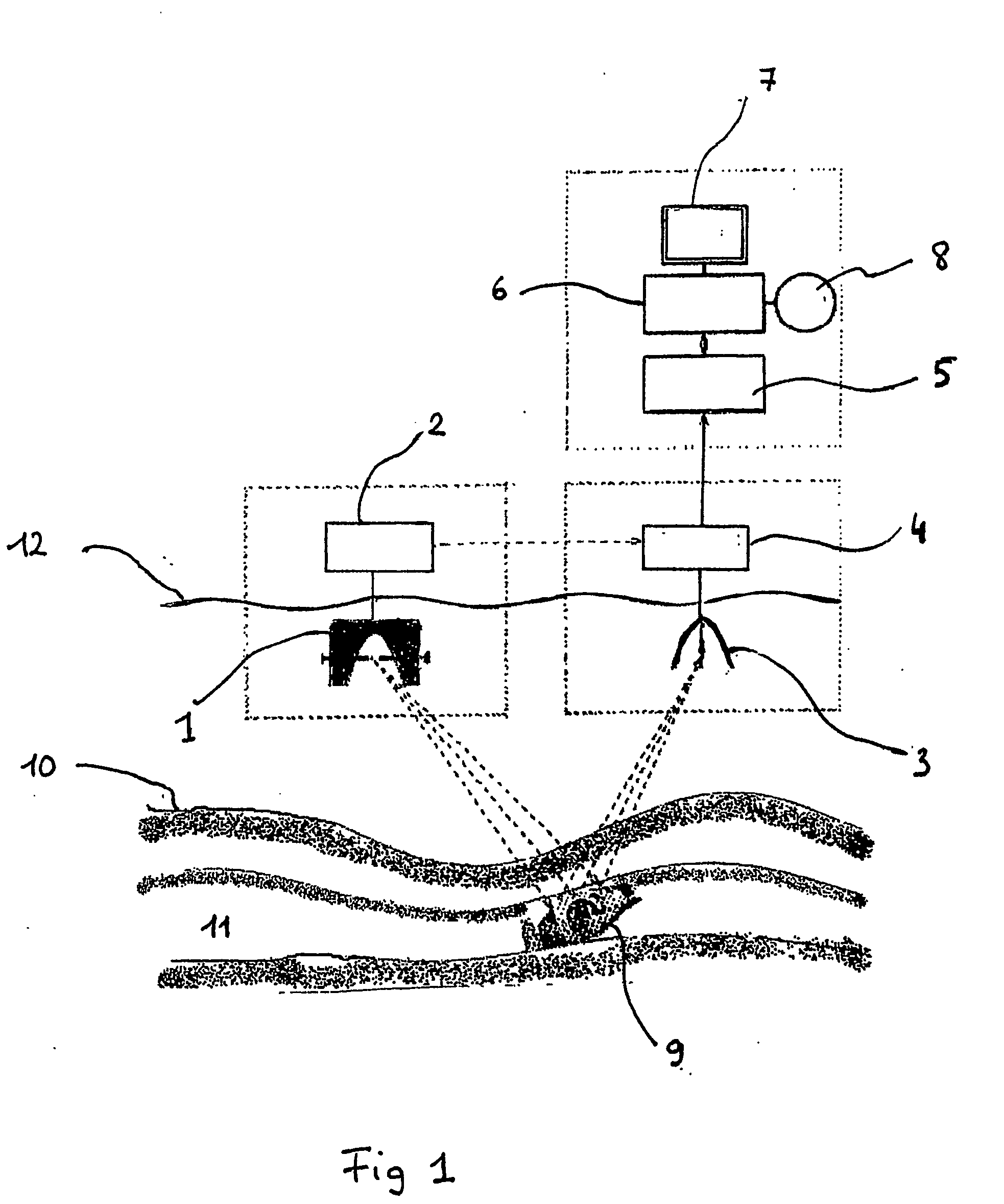

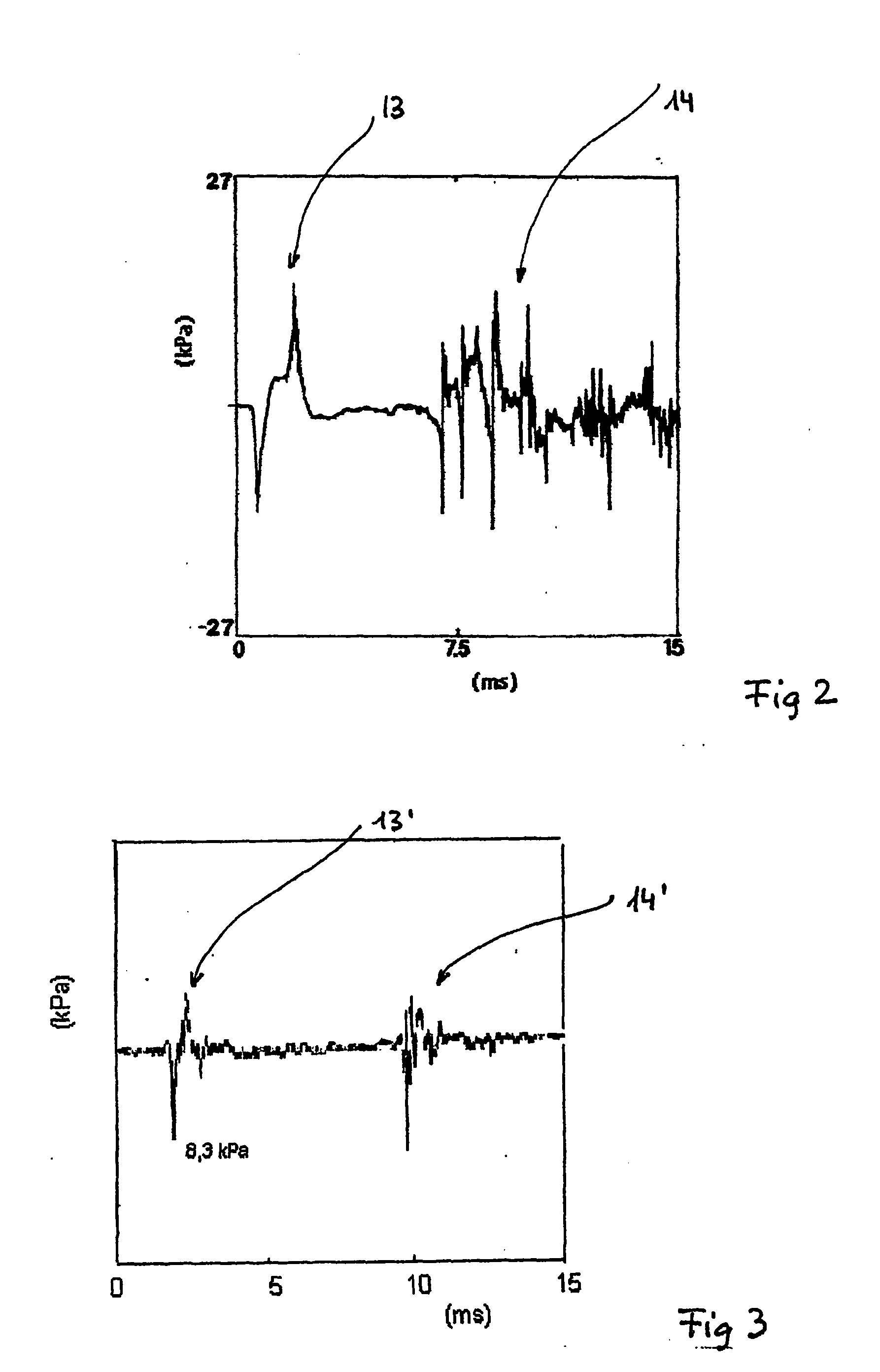

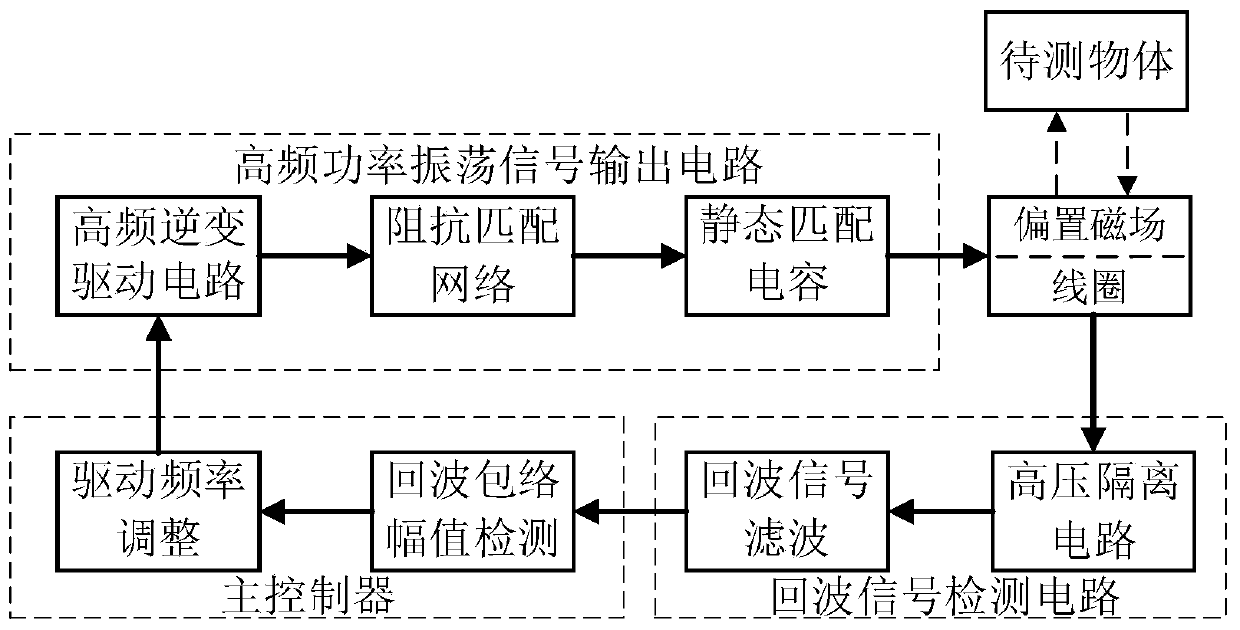

High-resolution and high-power ultrasound method and device, for submarine exploration

A method for underwater exploration which makes use of a parabolic transmitter (1) and a parabolic receiver (3), the transmitter (1) and the receiver (3) being both open at their lower side and immersed below the seawater surface. The electric breakdown discharge occurring between both electrodes (15) of the transmitter (1) generates a primary signal and a pulse which is called “cavitation bubble pulse.” The method consists in enhancing the signal (23) produced by the implosion of the cavitation bubble, to the detriment of the primary signal (13″), by appropriately adjusting the value of the “spark gap” (distance d between the electrodes) so as to optimize the delay time (t) and consequently the acoustic efficiency of the transmitter, by transferring the electrostatic energy to the bubble implosion signal.

Owner:CONSIGLIO NAT DELLE RICERCHE

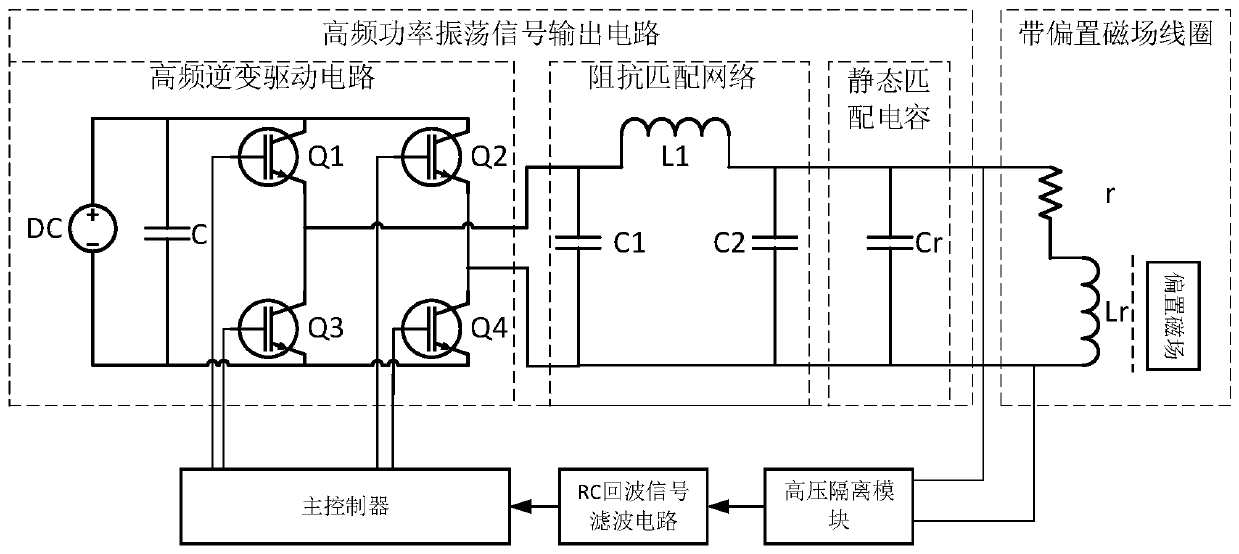

Electromagnetic ultrasonic transducer with improved resonance control and control method thereof

InactiveCN109856251AImprove detection accuracyReduce harmonic contentUltrasonic/sonic/infrasonic wave generationCapacitanceHigh frequency power

The invention discloses an electromagnetic ultrasonic transducer with improved resonance control and a control method thereof. The electromagnetic ultrasonic transducer comprises a high-frequency power oscillation signal output circuit, a coil with a bias magnetic field, an echo signal detection circuit and a main controller. The high-frequency power oscillation signal output circuit is composed of a high-frequency inverter drive circuit, an impedance matching network, and a static matching capacitor. The echo signal detection circuit includes a high-voltage isolation circuit and an echo signal filter circuit. The main controller is used for collecting a filtered ultrasound echo signal and adjusting a high frequency inverter driving frequency based on envelope amplitude feedback of the ultrasonic echo signal. Besides, according to the control method of the electromagnetic ultrasonic transducer with improved resonance control, the power pulse voltage required by the electromagnetic ultrasonic transducer can be provided and the static matching capacitor and the coil work in a quasi-resonant state, so that a maximum power ultrasonic signal can be excited in the to-be-measured object and the harmonic content is small; and thus the detection precision of the electromagnetic resonance transducer with the improved resonance control is high.

Owner:CHONGQING UNIV +1

Heading machine cutting head based on ultrasonic resonance

ActiveCN107780946AFast cutting speedImprove efficiencyTunnelsCutting machinesResonanceUltimate tensile strength

The invention discloses a heading machine cutting head based on ultrasonic resonance. The cutting head consists of an ultrasonic transducer, an ultrasonic vibrator, telescopic cutting teeth, a roller,an ultrasonic generator, fixed cutting teeth and a frequency scanning core, wherein the ultrasonic transducer is a high-power ultrasonic transducer; the ultrasonic vibrator excites rock to vibrate and reduces the rock strength; the telescopic cutting teeth extend out by the aid of hydraulic thrust, cut into rock to cut the rock and can rotate with the ultrasonic vibrator synchronously; the fixedcutting teeth are mounted on the roller and cut the rock through rotation; the frequency scanning core scans the rock frequency in real time and feeds back the rock frequency to an operation system, and the operation system adjusts the ultrasonic frequency emitted by the ultrasonic generator in real time according to the feedback result. The cutting head has good adaptability to geological conditions, performs synchronous vibration and cutting, has controllable vibration range, high broken rock heading speed, high efficiency and long cutting tooth service life and can be applied to roadway heading in high-hardness rock strata to realize efficient breaking of hard rock.

Owner:CHINA UNIV OF MINING & TECH

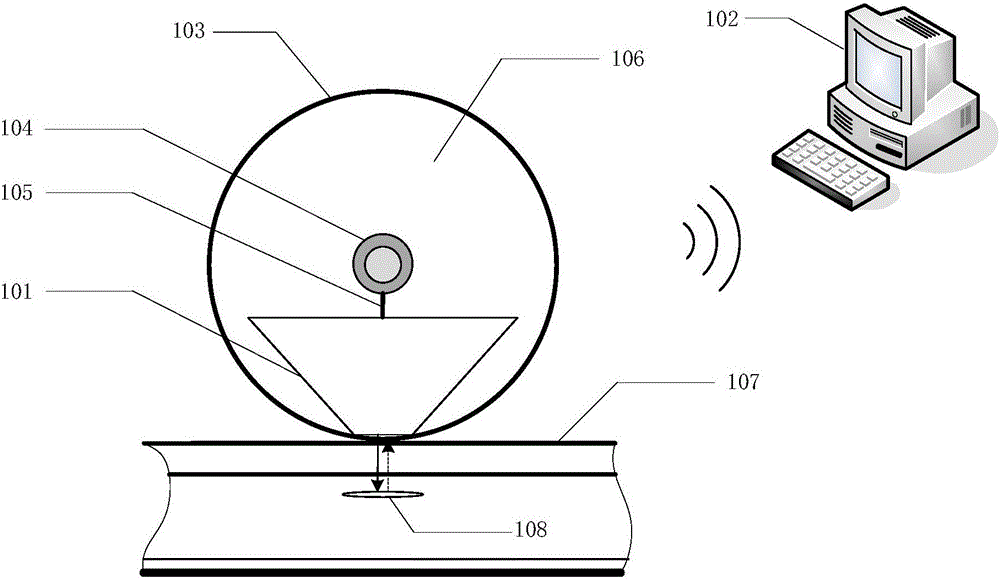

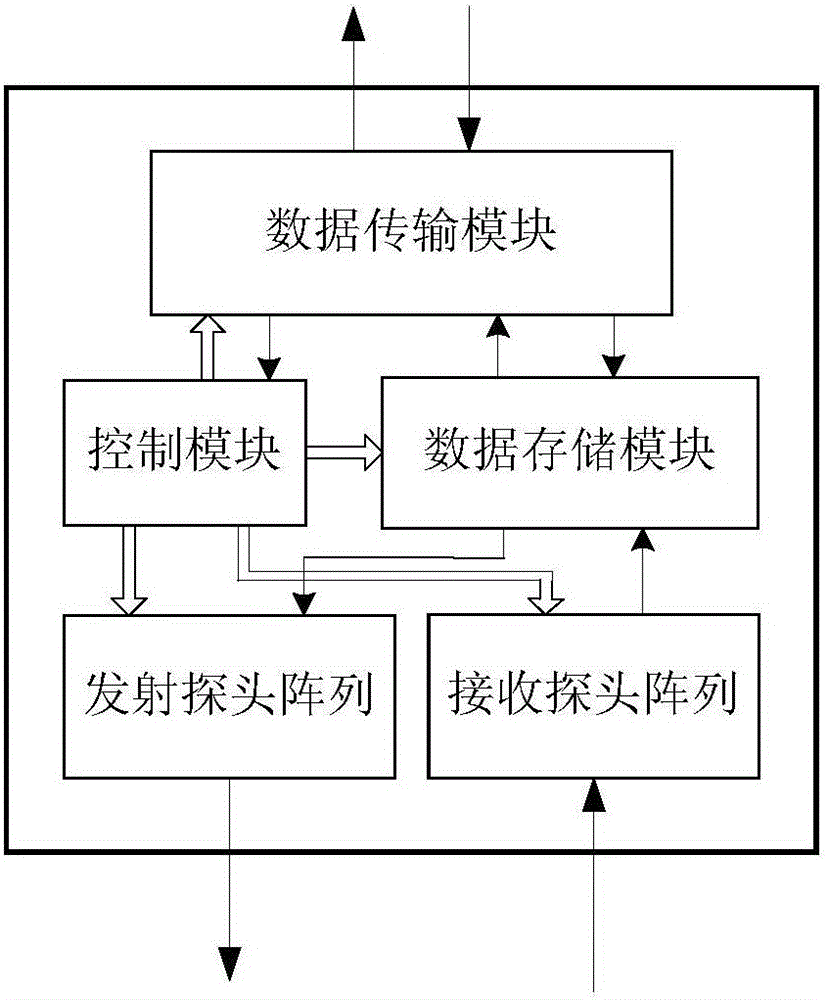

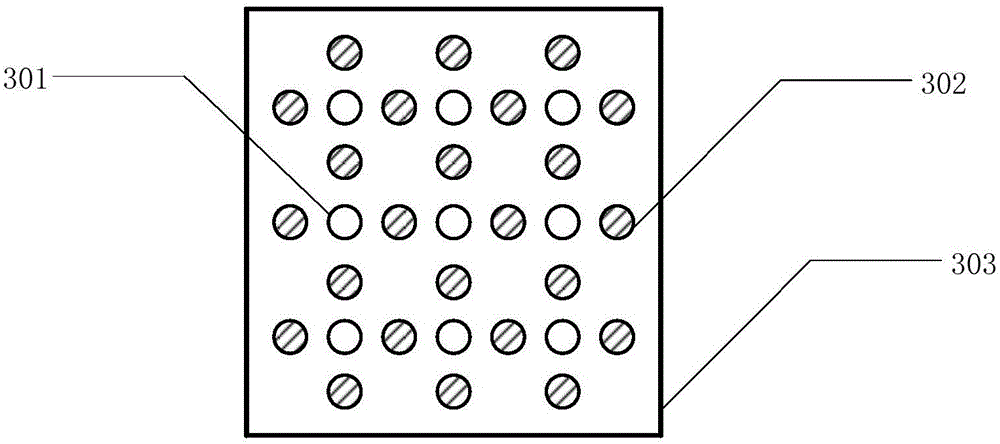

Space-time four-dimensional wideband array-based high speed steel rail ultrasonic detection imaging method and apparatus thereof

InactiveCN105136905ASolve transmit powerResolve conflicts between probe calibersAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerMultiple frequency

The invention discloses a space-time four-dimensional wideband array-based high speed steel rail ultrasonic detection imaging apparatus. The apparatus comprises a detection front end and a background processor, and the detection front end and the background processor are wirelessly connected. An emission probe array in the detection front end expands to a three dimensional array from a traditional two dimensional probe array, and the emission probe is formed by laminating a wideband large-power ultrasonic energy transducer and a three dimensional funnel-shaped power focusing device, and realizes large power and small-caliber emission, so the contradiction between the emission power and the emission caliber is solved. The ultrasonic energy transducer is made through splicing multiple-frequency range strip-shaped ultrasonic energy transducers, and can flexibly generate a required wideband emission signal. The height and the inclination degree of the power focusing device are adjusted as needed to make a limited space accommodate many probes for forming a probe array in order to improve the detection precision. The apparatus and the method can improve the detection precision in many respects, and meets high speed steel rail detection demands.

Owner:GUANGZHOU FENGPU INFORMATION TECH CO LTD

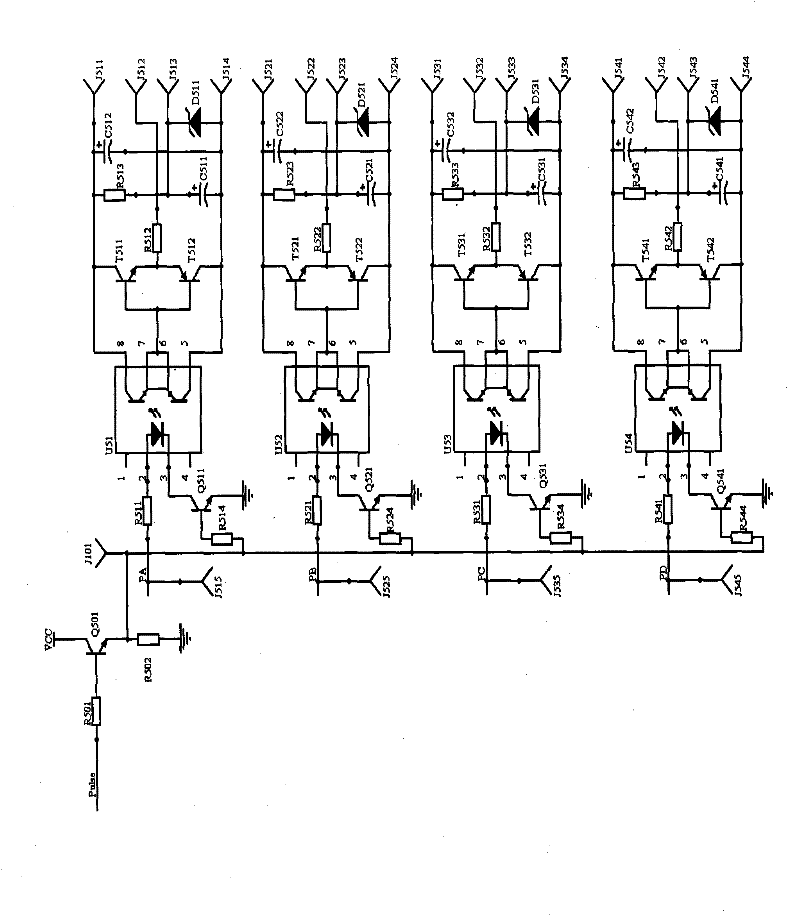

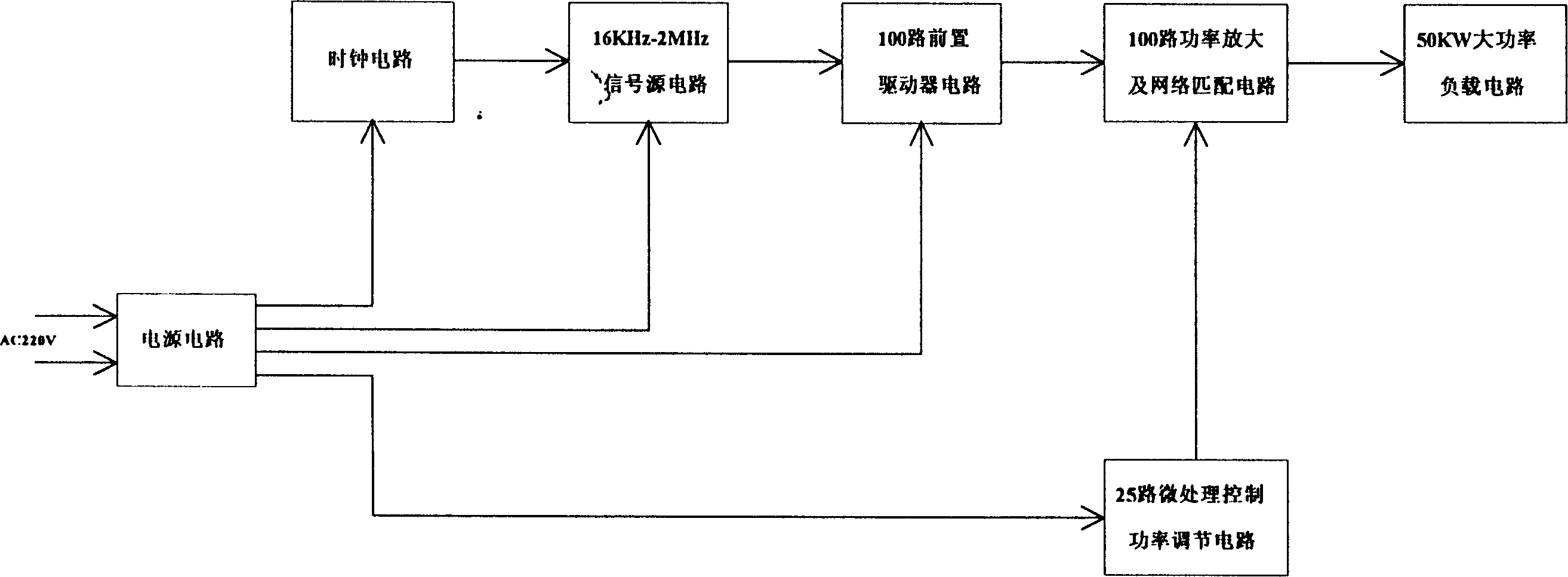

Ultra-high power supersonic generator sharing a oscillation source

InactiveCN1634669ASolving Balanced MatchesConsistent powerMechanical vibrations separationLoad circuitSonification

This invention relates to a super large power ultrasonic generator with one common oscillation source, which comprises the following: power circuit, time circuit, signal generator circuit, front drive circuit, microprocessor power adjusting circuit, power amplifying and matching circuit and load circuit. The signal generator makes fractional frequency division of the time signals and generates control signals with frequency range of 16KHz-2MHz according to frequency points selected. The front drive circuit converts the control signals into drive signals with one to one hundred paths. The front drive signals are amplified with power and gets output pushing signals through matching circuit to fulfill the output power adjusting and controlling.

Owner:杜鹏 +1

Ultrasonic wool-washing device and application thereof

InactiveCN102896109AImprove cleanlinessImprove equipment utilizationCleaning using liquidsSocial benefitsEconomic benefits

The invention relates to a device and a method for cleaning wool by an ultrasonic technique. The device is mainly applied to a wool washing industry of raw wool of wool. The device mainly comprises a wool guide device 1, a washing groove 2, a net plate 3, and a multi-frequency ultrasonic vibrating box 4. The raw wool is added to the washing groove 2 by the wool guide device 1; and the multi-frequency ultrasonic vibrating box 4 is opened to clean the impurity on the wool, and sinks into the bottom of the groove through the net plate 3. A high-power ultrasonic vibrating box emits a strong ultrasonic wave to a wool fiber in the water, so that the efficiency of removing impurities such as the raw wool and wool fat is improved; energy consumption and water are greatly saved, and the ultrasonic wool-washing device has good social benefit and economic benefit.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com