Full-automatic ultrahigh-power ultrasonic anti-scaling and de-scaling device

An ultra-high-power, ultrasonic technology, which is applied in the direction of cleaning heat transfer devices, damage protection, vibration cleaning, etc., can solve the problems of not being able to adapt to different equipment, intermittent pulse intermittent time can not be adjusted, etc., to improve economy and safety, reduce funds and environmental pollution, reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

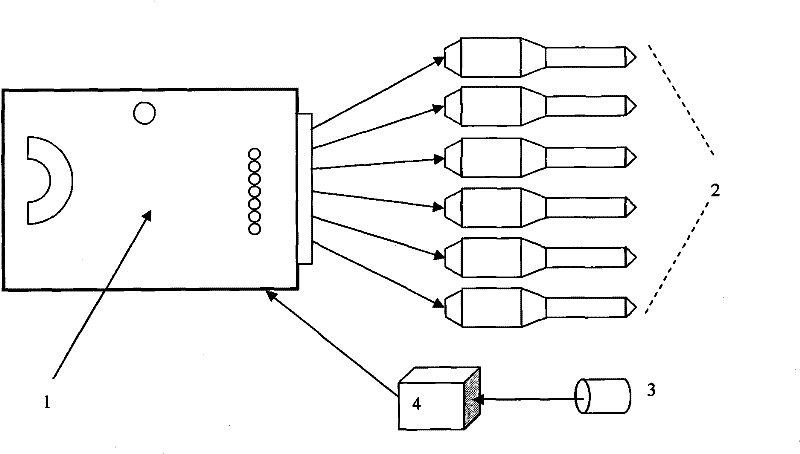

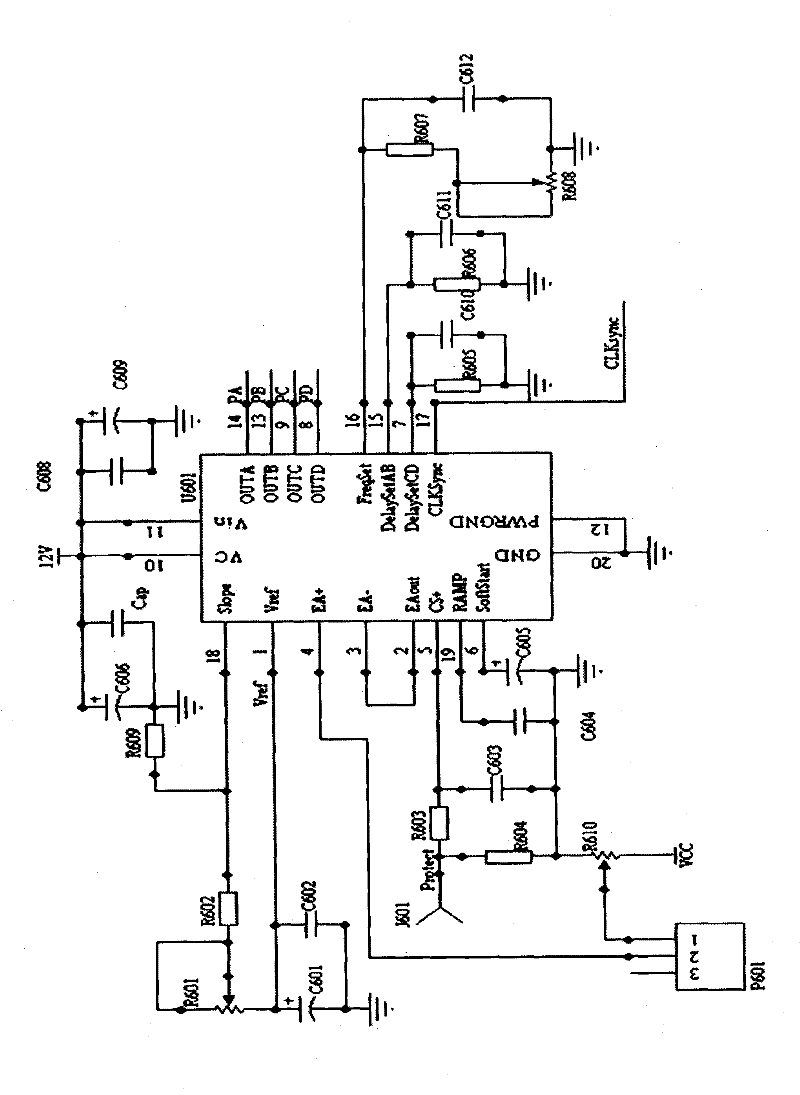

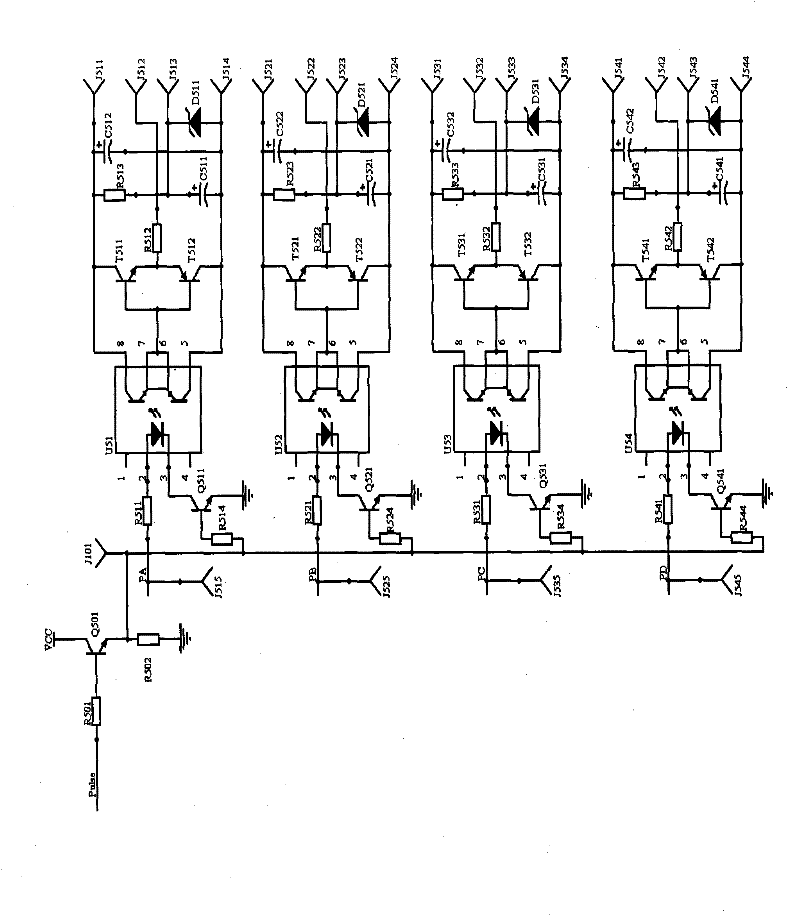

[0022] The invention discloses a full-automatic ultra-high-power ultrasonic anti-scaling and descaling device. Such as figure 1 Shown; The device includes a host 1, a plurality of giant magnetostrictive transducers 2, an external shock sensor 3 and a sensing signal processing circuit 4. The host is equipped with an ultrasonic signal source oscillator, a power output stage, a power supply circuit for the whole machine, an intelligent control circuit, a DC excitation circuit, and a data receiving circuit. The signal output end of the power output stage is connected to the signal input terminal of the giant magnetostrictive transducer 2 through a cable, and an excitation power supply is provided at the same time; the output end of the shock sensor 3 is connected to the input end of the sensing signal processing circuit 4; the sensing signal processing The output end of the circuit 4 is connected with the intelligent control circuit of the host 1 to realize a closed-loop automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com