Ultra-high power supersonic generator sharing a oscillation source

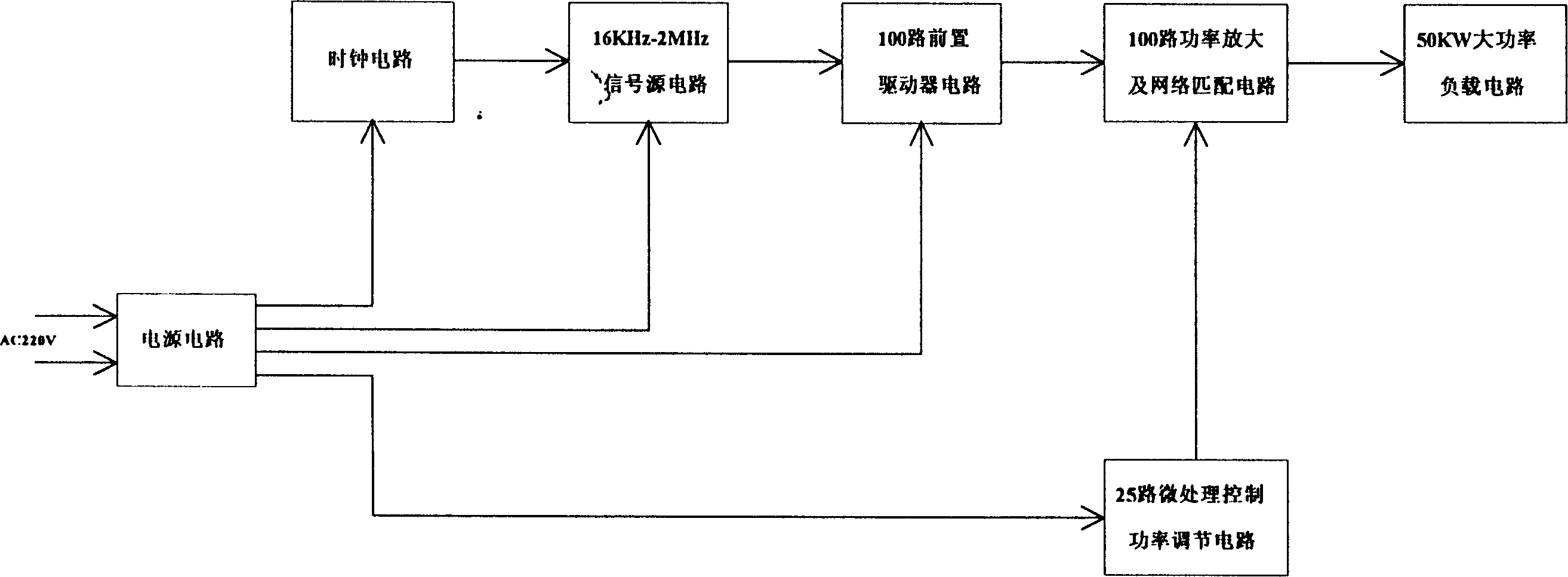

A super-power, generator technology, applied in the direction of the fluid using vibration, can solve the problems of inconvenient operation, the ultrasonic generator cannot reach the best working state, the transformer is bulky, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

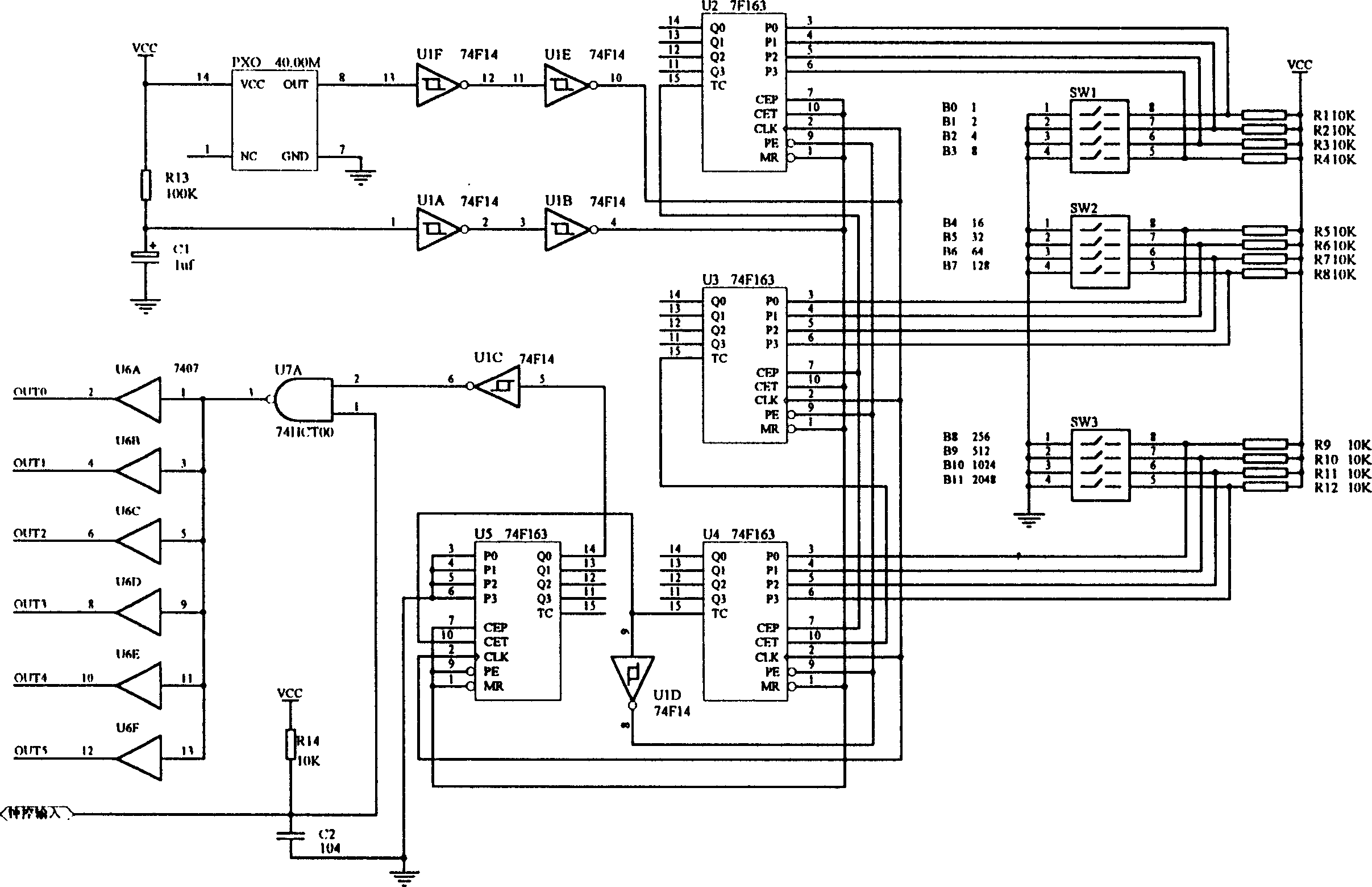

[0021] Selected ultrasonic frequency: 28KHz

[0022] Ultrasonic power: 1.2KW

[0023] The model structure is a split structure of the metal melting tank. Among them, the main device parameters in each circuit diagram are selected as follows:

[0024] 74F14—Six reverse Schmitt triggers

[0025] 74FCT00—Quad 2-Input NAND Gate

[0026] 7407—hex buffer / driver

[0027] 74F163—4-bit binary counter

[0028] CPS2811—Two-input and two-output driver

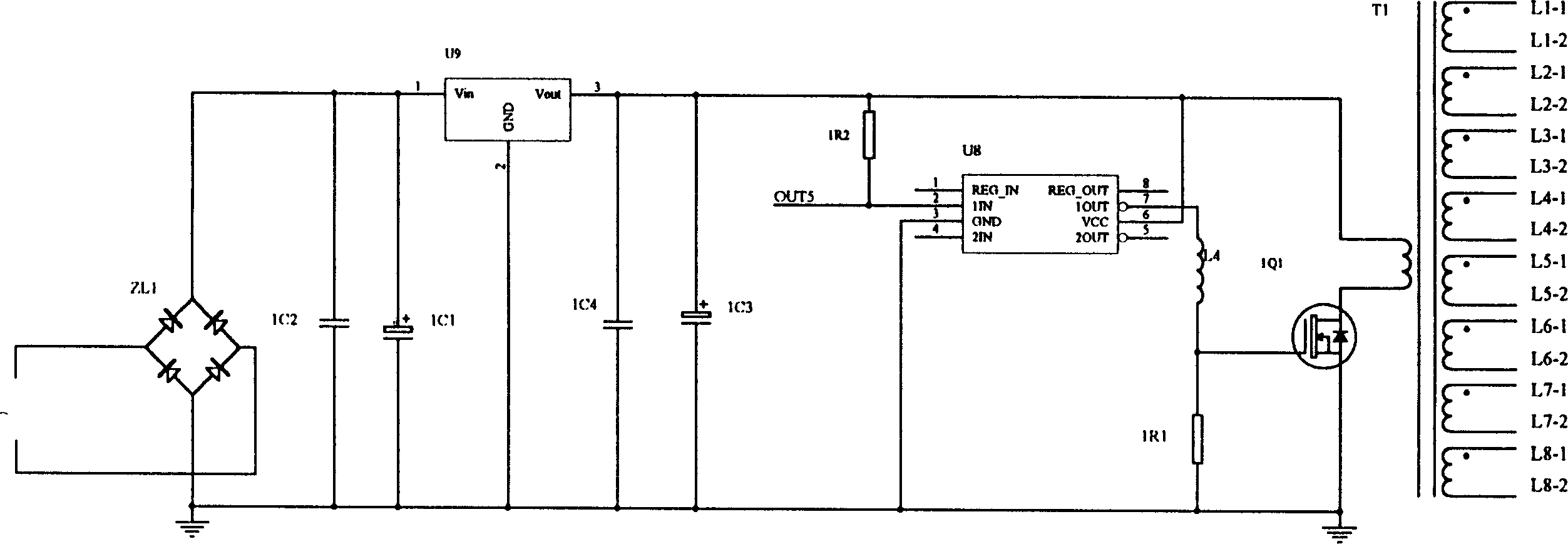

[0029] FR107—fast recovery diode produced by Fairchild, USA

[0030] SSH7N90A—Field effect tube produced by Fairchild, USA

[0031] The quartz crystal oscillator is 40MHz

[0032] KBPC2506 silicon rectifier bridge stack

[0033] 25A600V made in Taiwan

[0034] In the 15KHz-2MHz wide-range frequency source, the method of selecting any frequency point is to short-circuit the zero point with a short-circuit ring, and 1 is an open circuit. For example: 20.346KHz frequency point, select 110000101001. For other frequency selections, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com