High-chroma glass-based pearlescent pigment as well as preparation method and application thereof

A pearlescent pigment, glass-based technology, applied in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc., can solve the problems of low activity, unsolved glass substrates, and difficulty in controlling the degree of ammonium fluoride etching glass , to achieve the effect of reducing metal oxide particles, solving balance matching, and improving coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

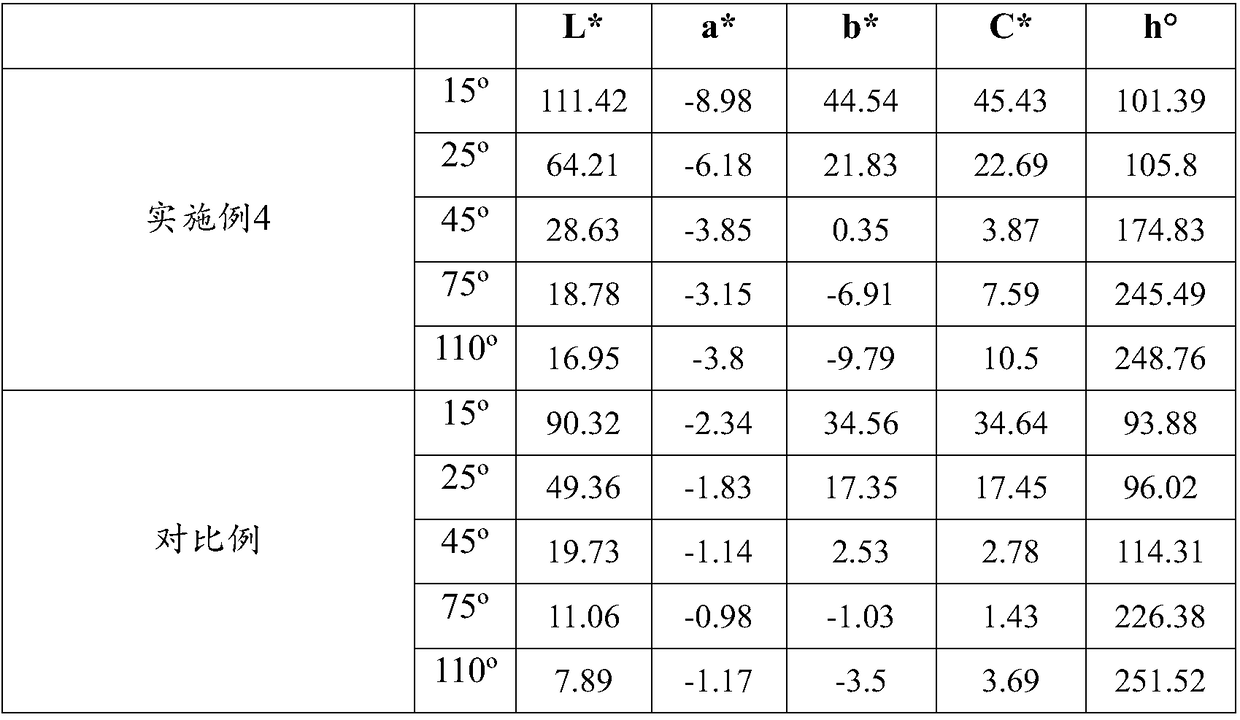

Examples

preparation example Construction

[0033] A preparation method of high chroma glass-based pearlescent pigment, comprising the following steps:

[0034] (1), adding water to the glass substrate for stirring and beating, adjusting the temperature and pH, then adding an inorganic salt treatment agent, then adding an organosilane coupling agent, filtering and washing after the reaction, and then adding water again for beating;

[0035] Preferably, the inorganic salt treatment agent is stannous chloride;

[0036] Preferably, in the step of adding water to the glass substrate for stirring and beating, the quality of the water is 10-50 times the mass of the glass substrate, more preferably 15-25 times, more preferably 18- 22 times;

[0037] (2), adjust the temperature and pH value after beating, add metal salts corresponding to metal oxides to coat the glass substrate, and finally wash, dry, and calcinate to obtain the high-chroma glass-based pearlescent pigment;

[0038] Preferably, the temperature is 75-85°C;

[...

Embodiment 1

[0055] Weigh 100g of glass flakes with a particle size of 10-60μm, put them in a 5L beaker, add 2000mL of deionized water, put them in a water bath, stir at 200-300rps, heat up to 60-70°C, and adjust the solution When the pH value is between 1.2-1.8, add 0.5% stannous chloride, and after stirring for half an hour, continue to add 2.5% N-2-aminoethyl-3-aminopropyltrimethoxysilane, and finish adding in 1 hour After filtering and washing, add deionized water again and stir evenly, raise the temperature to 75-85°C, adjust the pH value of the solution between 2.0-2.5, and add 2mol / L titanium tetrachloride solution dropwise at a rate of 1mL / min , and keep the pH value of the solution constant with NaOH solution, after reacting for 2-3 hours, filter, put the filter cake into a muffle furnace after drying, raise the temperature to 600°C at a heating rate of 10°C / min, and keep it warm for 1 hour, Take it out and cool it down to room temperature to get silver white glass-based pearlesce...

Embodiment 2

[0057] Weigh 100g of glass flakes with a particle size of 10-60μm, put them in a 2L beaker, add 1500mL of deionized water, put them in a water bath, stir at 200-300rps, heat up to 60-70°C, and adjust the solution When the pH value is between 1.2-1.8, add 0.5% stannous chloride, and after stirring for half an hour, continue to add 2.5% N-2-aminoethyl-3-aminopropyltrimethoxysilane, and finish adding in 1 hour After filtering and washing, add deionized water again and stir evenly, heat up to 75-85°C, adjust the pH value of the solution between 3-4, add dropwise 10% ferric chloride solution at a rate of 2mL / min, and Use 30% NaOH solution to maintain the pH value of the solution. After reacting for 3-4 hours, filter, dry the filter cake and put it in a muffle furnace. Raise the temperature to 600°C at a heating rate of 10°C / min and keep it warm for 1 hour. , taken out, and cooled to room temperature to obtain red mica iron pearlescent pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com