Ultrasonic wool-washing device and application thereof

An ultrasonic wave and wool washing technology, which is applied in the field of wool washing treatment devices with ultrasonic technology, can solve the problems of unclean fiber washing, uneven ultrasonic field, weak cleaning effect, etc., so as to reduce energy consumption, improve the cleaning degree of raw wool and Equipment utilization and the effect of reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

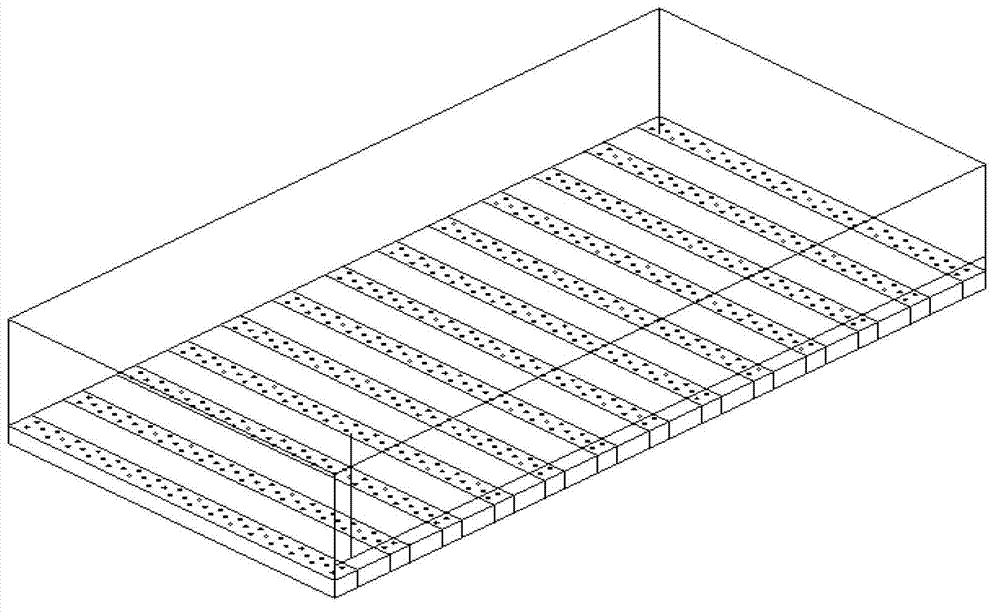

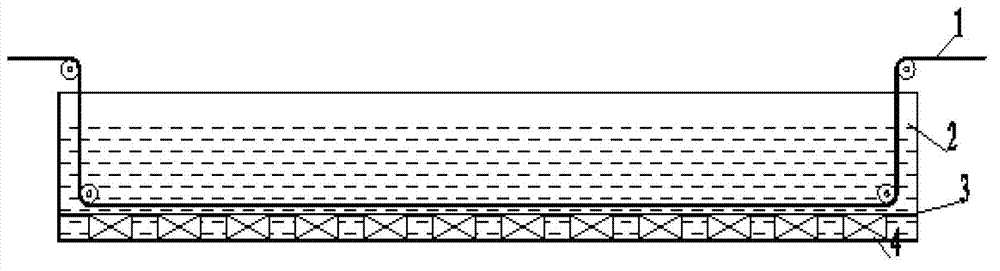

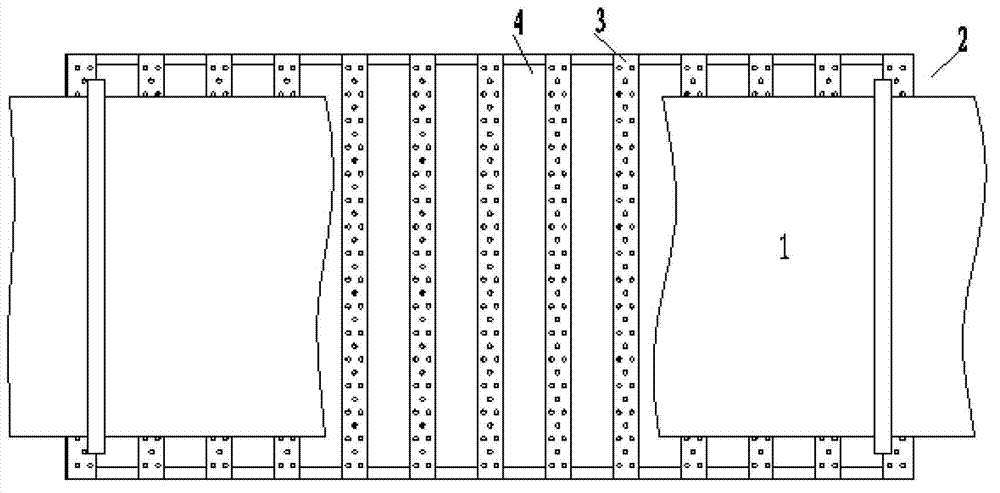

[0019] Embodiment 1 Ultrasonic wool washing device

[0020] figure 2 Shown is a schematic diagram of an ultrasonic hair washing device in a typical embodiment. Including multi-frequency ultrasonic vibrating box 4, mesh plate 3, washing tank 2 and a wool guide device in the water tank, multi-frequency ultrasonic vibrating boxes are installed evenly at intervals of 20cm on the mesh plate of the water tank, and multi-frequency ultrasonic vibrating box 4 is pressed They are fixed in the lower part of the water tank in a certain order and at a certain distance, and the upper surface of the vibrating box is flush with the sand leakage screen 3 . The radiating surface of the ultrasonic box is facing the raw wool in the washing tank, and the ultrasonic box radiates a certain power of ultrasonic waves in the water tank, so that an ultrasonic wave with uniform intensity is formed in the water tank. The ultrasonic wave acts on the raw wool, so that the mechanical effect of the ultraso...

Embodiment 2

[0021] Embodiment 2 Ultrasonic wool washing method

[0022] Add 0.5-0.8g / L detergent 105 and 0.2-0.3g / L additive NaCO to the washing tank in advance 3 , the bath ratio is 1:100~1:120, the wool raw wool is transported to the washing tank 2 through the wool guide device 1, and at 25~35°C, turn on the power supply of the ultrasonic vibration box, ultrasonic frequency: 20~30KHz, ultrasonic power: 500~800W, wash for 3~6min. The washed raw wool is guided into the next washing tank by the wool guide device. During the washing process, the ultrasonic vibrating box emits powerful multi-frequency ultrasonic waves to the wool fiber, so that the impurities on the wool are detached from the fiber surface and sink to the bottom of the tank through the mesh plate to complete the cleaning process. The wool scouring device and method can greatly save energy consumption and water consumption.

[0023] Liquor ratio: The ratio of the mass of raw wool to washing liquid.

Embodiment 3

[0024] Embodiment 3 Ultrasonic velvet washing method

[0025] Add 0.4-0.7g / L detergent 105 and 0.1-0.3g / L additive NaCO to the washing tank in advance 3 , the bath ratio is 1:70~1:100, the wool raw wool is transported to the washing tank 2 through the wool guide device 1, and at 45~60°C, turn on the power supply of the ultrasonic vibrating box, the ultrasonic frequency: 20~30KHz, the ultrasonic power: 500~800W, wash for 3~5min. The washed raw wool is guided into the next washing tank by the wool guide device. During the washing process, the ultrasonic vibrating box emits powerful multi-frequency ultrasonic waves to the wool fiber, so that the impurities on the wool are detached from the fiber surface and sink to the bottom of the tank through the mesh plate to complete the cleaning process. The ultrasonic wool scouring device and method can greatly save energy consumption and water volume, and have good economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com