Full-bridge high-power ultrasonic generator based on phase shift

A phase-shifting full-bridge, high-power technology, applied in the field of high-power ultrasonic generators based on phase-shifting full-bridge, can solve the problems of limited output power and inability to automatically track frequencies, and achieve complete protection functions, ingenious structural design, and high performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

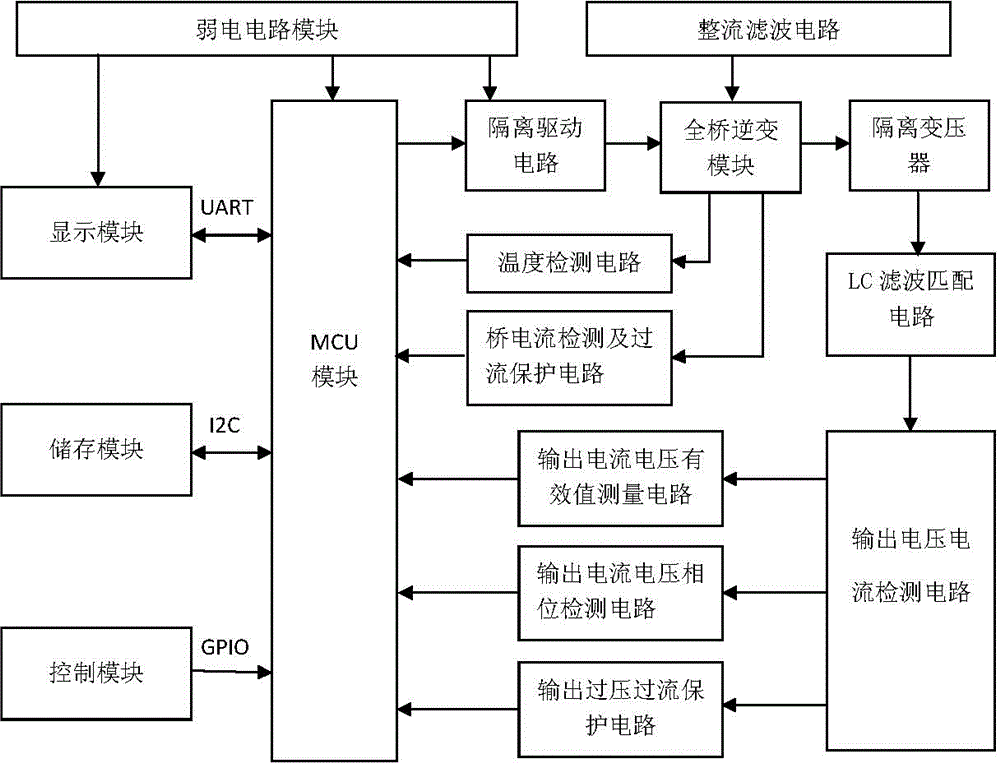

[0014] Example: see figure 1 , this embodiment provides a high-power ultrasonic generator based on a phase-shifted full-bridge, which includes a weak current circuit module, an MCU module, an isolated drive circuit, a rectifier filter circuit, a full-bridge inverter module, an isolation transformer, an LC filter matching circuit, Output voltage and current detection circuit, temperature detection circuit, bridge current detection and overcurrent protection circuit, output current and voltage RMS measurement circuit, output current and voltage phase detection circuit, output overvoltage and overcurrent protection circuit, display module, storage module and control module . Specifically, the MCU module is respectively connected with the weak current circuit module, display module, storage module, control module, isolation drive circuit, temperature detection circuit, bridge current detection and overcurrent protection circuit, output voltage and current detection circuit, output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com