Sandwich type radial direction vibrating piezoelectric ceramic ultrasonic transducer

An ultrasonic transducer, radial vibration technology, applied in the generation or transmission of acoustic or ultrasonic mechanical vibration, sub-acoustic frequency field, can solve the problem that piezoelectric ceramic transducers are difficult to achieve radiation power and radiation intensity, limited tensile strength , difficult to meet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

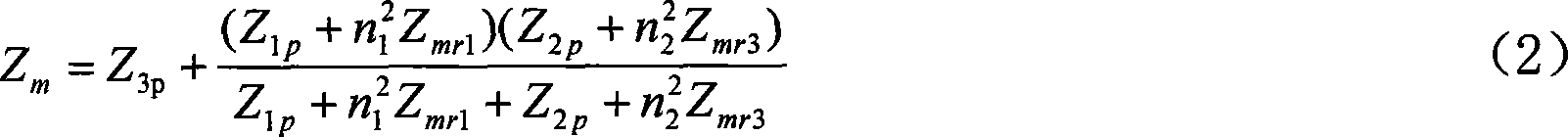

[0038] Taking the resonant frequency of the prepared transducer as 65171Hz as an example, the geometric shape and connection relationship of each component are as follows:

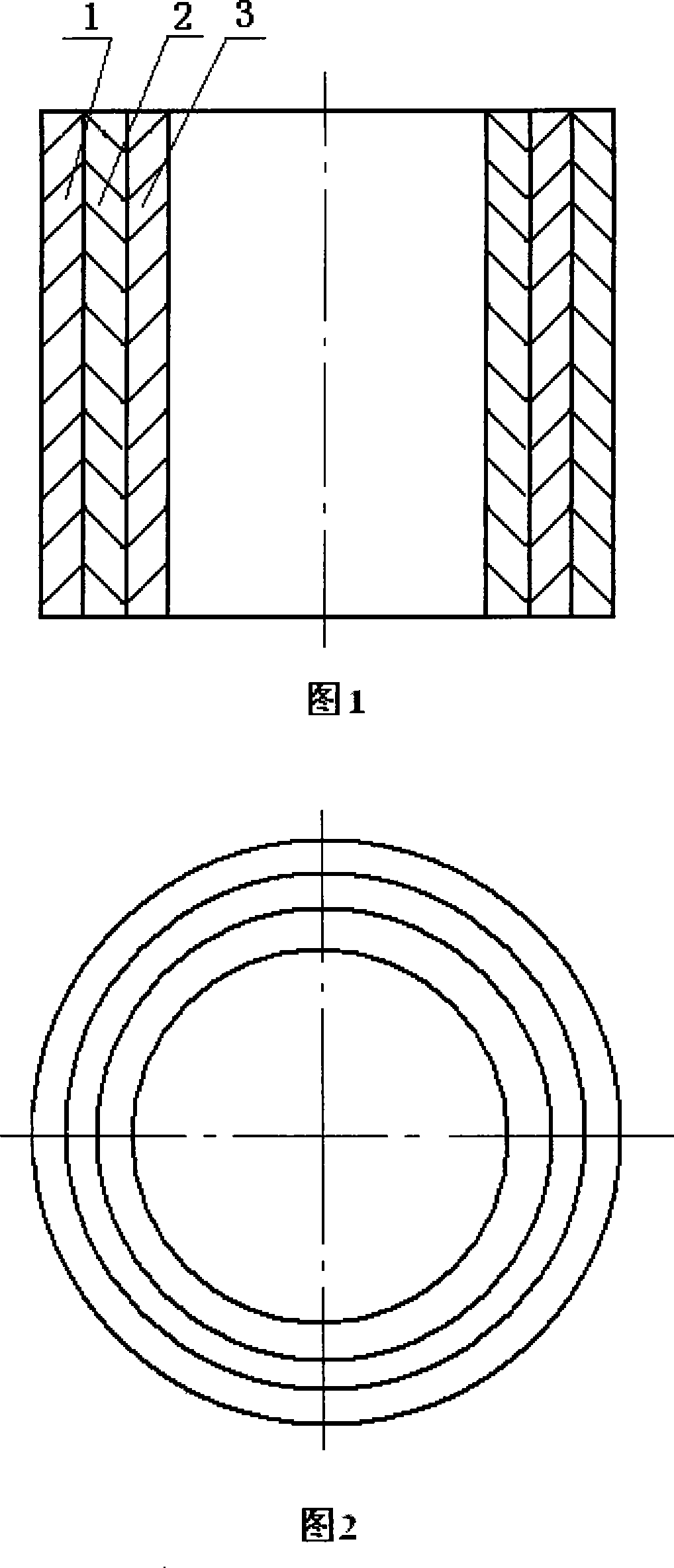

[0039] In FIGS. 1 and 2 , the sandwich type radial vibration piezoelectric ceramic ultrasonic transducer of this embodiment is composed of a metal outer ring 1 , a piezoelectric ceramic ring 2 and a metal inner ring 3 .

[0040] The outer surface of the metal inner ring 3 is bonded to the piezoelectric ceramic ring 2 with a high-temperature resistant epoxy resin adhesive, and the outer surface of the piezoelectric ceramic ring 2 is bonded to the inner surface of the metal outer ring 1 with a high-temperature resistant epoxy resin adhesive. bonding. The high temperature-resistant epoxy resin adhesive of this embodiment adopts Shenliling super glue, and can also use Swiss Araldite universal super glue or Dutch "bison" epoxy resin metal super glue or universal super glue, piezoelectric Ceramic ring 2, metal ...

Embodiment 2

[0045] Taking the resonant frequency of the prepared transducer as 55625Hz as an example, the geometric shape and connection relationship of each component are as follows:

[0046] In this example, the inner radius R1 of the metal inner ring 3 is 5mm, the outer radius R2 is 10mm, the inner radius R3 of the metal outer ring 1 is 15mm, the outer radius R4 is 25mm, and the height H is 5mm, and the inner radius R2 of the piezoelectric ceramic ring 2 is 10mm, and the outer radius R3 is 15mm.

[0047] The metal inner ring 3 and the metal outer ring 1 are steel rings in the shape of circular rings, and the piezoelectric ceramic ring 2 is made of lead zirconate titanate, and its material parameters are the same as those in Example 1.

[0048] According to formulas (1)-(10), the resonance frequency of this embodiment is calculated to be 55625 Hz. The coupling relationship of the parts is the same as that of Embodiment 1.

Embodiment 3

[0050] Taking the resonant frequency of the prepared transducer as 48603Hz as an example, the geometric shape and connection relationship of each component are as follows:

[0051] In this example, the inner radius R1 of the metal inner ring 3 is 5mm, the outer radius R2 is 10mm, the inner radius R3 of the metal outer ring 1 is 15mm, the outer radius R4 is 30mm, and the height H is 5mm, and the inner radius R2 of the piezoelectric ceramic ring 2 is 10mm, and the outer radius R3 is 15mm.

[0052] The metal inner ring 3 and the metal outer ring 1 are steel rings in the shape of circular rings, and the piezoelectric ceramic ring 2 is made of lead zirconate titanate, and its material parameters are the same as those in Example 1.

[0053] According to formulas (1)-(10), the resonant frequency of this embodiment is calculated as 48603 Hz. The coupling relationship of the parts is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com