Lead niobium antimonite-containing five-element piezoelectric ceramics material for driver and preparation thereof

A technology of piezoelectric ceramics and lead niobium antimonate, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., and can solve the problems of rare systems problems, to achieve the effect of high yield, good repeatability and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

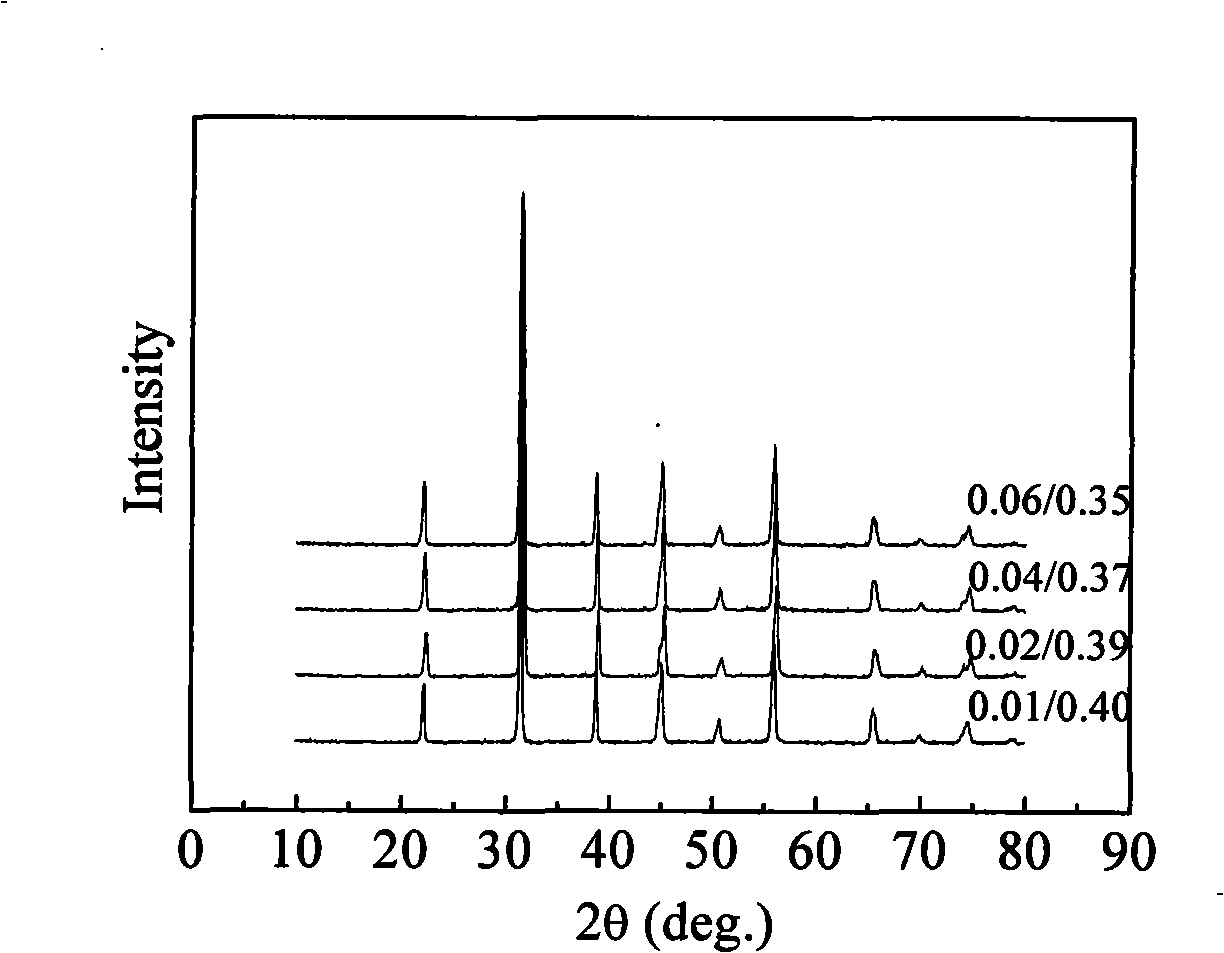

[0043] Take the used raw material 100g of producing product of the present invention as example, when x is 0.02, y is 0.01, z is 0.38, use general formula 0.02Pb(Mg 1 / 2 W 1 / 2 )O 3 -0.01Pb(Sb 1 / 2 Nb 1 / 2 )O 3 -0.38Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -Pb 0.59 (Zr 0.38 Ti 0.21 )O 3 The expressed raw materials and their weight proportions are:

[0044] Pb 3 o 4 67.22g

[0045] ZrO 2 13.77g

[0046] TiO 2 4.93g

[0047] Mg(OH) 2 · MgCO 3 ·6H 2 O 0.3g

[0048] WO 3 0.68g

[0049] Sb 2 o 5 0.22g

[0050] Nb 2 o 5 10.10g

[0051] NiO 2.78g

[0052] Its preparation method is as follows:

[0053] 1. Ingredients synthesis

[0054] Pb stoichiometrically according to the general formula above 3 o 4 , ZrO 2 、TiO 2 , Mg(OH) 2 · MgCO 3 ·6H 2 O. WO 3 , Sb 2 o 5 , Nb 2 o 5 , NiO mixed, put into a nylon tank, add 50g of absolute ethanol as a dispersant and ...

Embodiment 2

[0072] Take the used raw material 100g of producing product of the present invention as example, when x is 0.005, y is 0, z is 0.30, use general formula 0.005Pb (Mg 1 / 2 W 1 / 2 )O 3 -0.405Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -Pb 0.59 (Zr 0.30 Ti 0·29 )O 3 The expressed raw materials and their weight proportions are:

[0073] Pb 3 o 4 64.66g

[0074] ZrO 2 10.46g

[0075] TiO 2 6.56g

[0076] Mg(OH) 2 · MgCO 3 ·6H 2 O 0.07g

[0077] WO 3 0.16g

[0078] Sb 2 o 50g

[0079] Nb 2 o 5 15.23g

[0080] NiO 2.86g

[0081] Its preparation method is as follows:

[0082] The raw materials were put into a nylon tank, 50 g of absolute ethanol was added as a dispersant, and zirconia balls were used as a ball milling medium. The other steps of this process step were the same as in Example 1. In step 2 of the pre-firing process, the ground material is placed ...

Embodiment 3

[0084] Take the used raw material 100g of producing product of the present invention as example, when x is 0.07, y is 0.04, z is 0.50, use general formula 0.07Pb(Mg 1 / 2 W 1 / 2 )O 3 -0.04Pb(Sb 1 / 2 Nb 1 / 2 )]O 3 -0.30Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -Pb 0.59 (Zr 0.50 Ti 0·09 )O 3 The expressed raw materials and their weight proportions are:

[0085] Pb 3 o 4 68.16g

[0086] ZrO 2 18.37g

[0087] TiO 2 2.14g

[0088] Mg(OH) 2 · MgCO 3 ·6H 2 O 1.05g

[0089] WO 3 2.42g

[0090] Sb 2 o 5 0.87g

[0091] Nb 2 o 5 4.76g

[0092] NiO 2.23g

[0093] Its preparation method is as follows:

[0094] The raw materials are packed into a nylon tank, and 50 g of absolute ethanol is added as a dispersant, which is a ball milling medium. The other steps of this process step are the same as in Example 1. In step 2 of the pre-fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com