Boned neodymium iron boron permanent magnet and manufacturing method thereof

A permanent magnet, NdFeB technology, applied in the field of rare earth permanent magnets and their manufacturing, can solve problems such as poor dynamic balance performance of bonded NdFeB magnets, and achieve improved unbalanced performance, high stability, and improved density uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

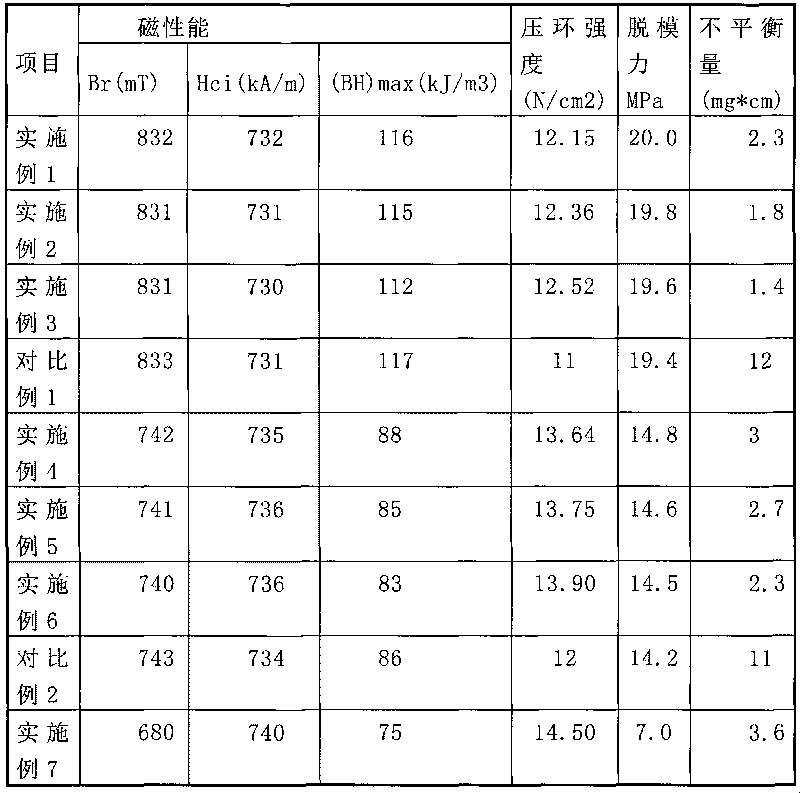

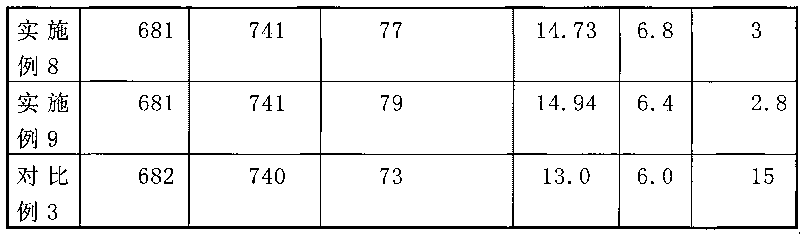

Embodiment 1

[0037]100 mesh MQP-B magnetic powder 10kg, D.E.R.663U epoxy resin 100g, HT2844 dicyandiamide curing agent 3.5g, zinc stearate 3g, nano alumina 5g, KH-550 coupling agent 0.15g. Mix the thermosetting resin, curing agent, and acetone whose weight is 1 to 4 times the weight of the resin; then add the nano-alumina powder treated with the silane coupling agent KH-550 into the mixed suspension of epoxy resin-curing agent-acetone In the turbid liquid; use a high-power ultrasonic generator to disperse the nano-alumina powder, and then dry it; use a large mixer to mix the dried resin and magnetic powder mixed with the nano-alumina powder; finally add a lubricant and mix well , to obtain the magnetic powder mixture of the present invention. Use a briquette forming machine to make a cylindrical briquette with a diameter of 10 units and a height of 8 units (φ10*8), and measure the magnetic properties of the briquette with an HT610 magnetic measuring instrument; use a S-20A 20T press at 13t...

Embodiment 2

[0039] 100-mesh MQP-B magnetic powder 10kg, D.E.R.663U epoxy resin 100g, HT2844 dicyandiamide curing agent 3.5g, zinc stearate 3g, nano-alumina 20g, KH-550 coupling agent 0.6g. The preparation method and various performance test methods of the bonded NdFeB permanent magnet are the same as in Example 1.

Embodiment 3

[0041] 100 mesh MQP-B magnetic powder 10kg, D.E.R.663U epoxy resin 100g, HT2844 dicyandiamide curing agent 3.5g, zinc stearate 3g, nano alumina 30g, KH-550 coupling agent 0.9g. The preparation method and various performance test methods of the bonded NdFeB permanent magnet are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com