High-efficiency energy-saving nano antiwear agent and preparation method and application thereof

A nano-anti-wear, high-efficiency and energy-saving technology, used in additives, base materials, petroleum industry, etc., can solve the problems of nano metal particle additives difficult to maintain chemical and physical stability for a long time, lubricating oil difficult to maintain dispersion stability for a long time, application restrictions and other problems , to achieve the effect of good cold start function, good dispersibility and not easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

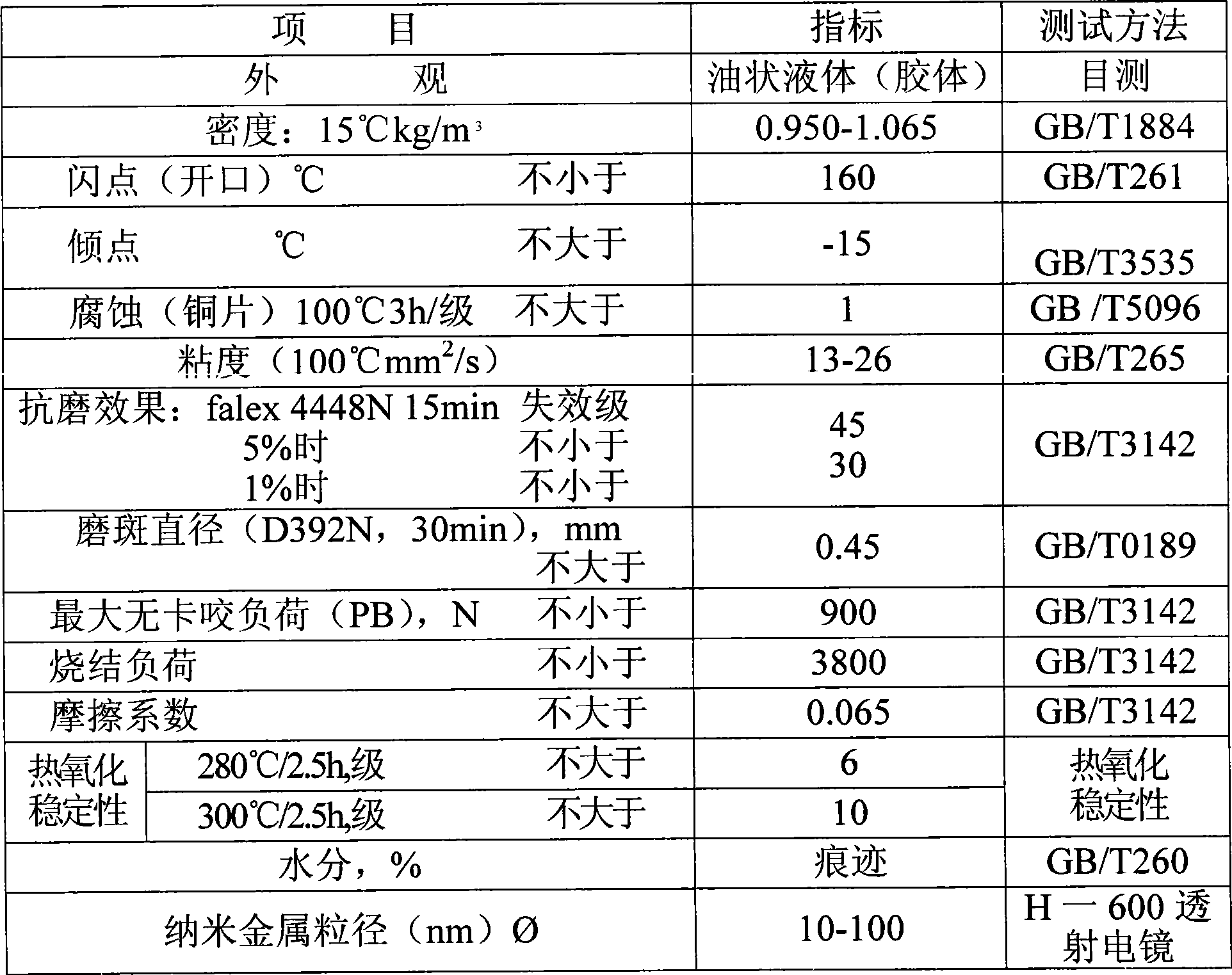

Image

Examples

Embodiment 1

[0027]Embodiment 1: the nanometer antiwear agent of the present invention is to be made by the raw material of following weight ratio: 250 grams of nanometer metal microparticles, 5000 grams of cleaning and dispersing agents, 5000 grams of antioxidants, 3000 grams of organic high polymers, diluted Dosage 200,000 grams. Wherein, the above-mentioned nano-metal particles are metal particles molybdenum, boron, chromium, vanadium, titanium, aluminum, cerium, a mixture of two or more (that is, a combination of two or more), the particle size of the nano-metal particles 1 to 100nm. For example, the nano metal particles can be a combination of metal particles chromium and vanadium, or a combination of metal particles titanium, aluminum and cerium. The particle size of the nano metal particles may be 40-60 nm. Detergent and dispersant are calcium petroleum sulfonate with medium alkali value, barium polyisobutylene sulfur phosphate, calcium sulfide alkyl phenate, monosuccinimide ashle...

Embodiment 2

[0029] Embodiment 2: the nanometer antiwear agent of the present invention is to be made by the raw material of following weight ratio: 50 grams of nanometer metal microparticles, 100 grams of cleaning and dispersing agents, 100 grams of antioxidants, 300 grams of organic polymers, diluted Dosage 90000 grams. Wherein, the above-mentioned nano-metal particles are metal particles molybdenum, boron, chromium, vanadium, titanium, aluminum, cerium, a mixture of two or more (that is, a combination of two or more), the particle size of the nano-metal particles 1 to 100nm. For example, the nano-metal particles can be a combination of metal particles molybdenum and boron, or a combination of metal particles boron, chromium, vanadium, titanium, and aluminum. The particle size of the nano metal particles may be 70-80 nm, or may be 10-30 nm. Detergent and dispersant are calcium petroleum sulfonate with medium alkali value, barium polyisobutylene sulfur phosphate, calcium sulfide alkyl p...

Embodiment 3

[0030] Embodiment 3: the nanometer antiwear agent of the present invention is to be made by the raw material of following weight proportion: 500 grams of nanometer metal microparticles, 10000 grams of cleaning and dispersing agents, 9000 grams of antioxidants, 3500 grams of organic high polymers, diluted Dose 400,000 grams. Its preparation method is with embodiment 1 (or with embodiment 2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com