Method for preparing waterproof polyvinyl alcohol trademark adhesive

A technology of polyvinyl alcohol and polyvinyl alcohol solution, which is applied in the field of preparation of polyvinyl alcohol trademark glue, can solve the problems of easy gelation, label peeling off, poor water resistance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

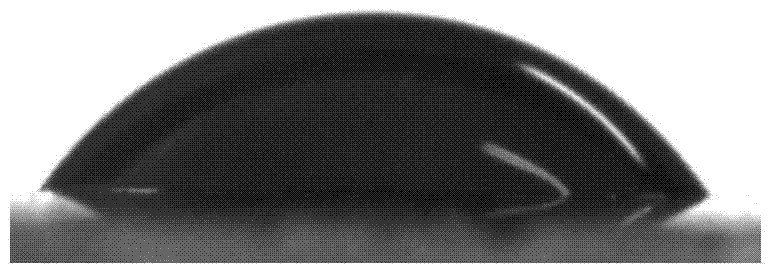

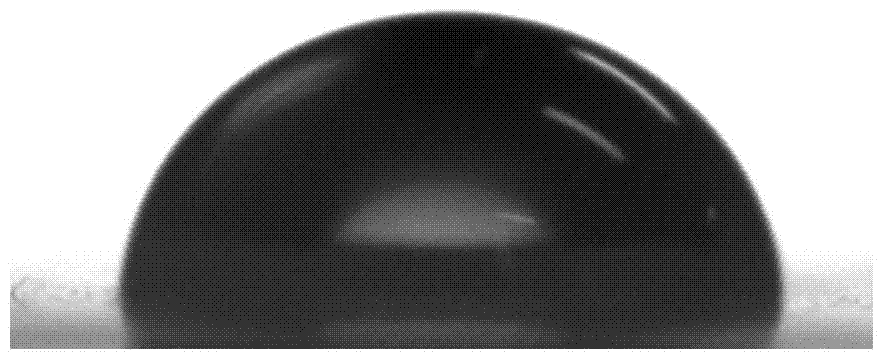

Image

Examples

Embodiment 1

[0017] Weigh a certain amount of polyvinyl alcohol, and dissolve the weighed polyvinyl alcohol in water, heat it in a water bath to 70°C, stir and swell to obtain a polyvinyl alcohol solution with a mass concentration of 8%, cool it down to 55°C, Add aluminum sulfate and stir at constant temperature for 30 minutes to obtain water-resistant polyvinyl alcohol trademark glue, wherein the mass of aluminum sulfate is 12% of the mass of polyvinyl alcohol.

Embodiment 2

[0019] Weigh a certain amount of polyvinyl alcohol, and dissolve the weighed polyvinyl alcohol in water, heat it in a water bath to 80°C, stir and swell to obtain a polyvinyl alcohol solution with a mass concentration of 20%, and cool it down to 60°C, Add aluminum sulfate and stir at constant temperature for 20 minutes to obtain water-resistant polyvinyl alcohol trademark glue, wherein the mass of aluminum sulfate is 20% of the mass of polyvinyl alcohol.

Embodiment 3

[0021] Weigh a certain amount of polyvinyl alcohol, and dissolve the weighed polyvinyl alcohol in water, heat it in a water bath to 85°C, stir and swell to obtain a polyvinyl alcohol solution with a mass concentration of 10%, and cool it down to 65°C, Add aluminum sulfate and stir at constant temperature for 20 minutes to obtain water-resistant polyvinyl alcohol trademark glue, wherein the mass of aluminum sulfate is 15% of the mass of polyvinyl alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com