Patents

Literature

32results about How to "Good high temperature resistance and flame retardant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrile resin monomer, nitrile resin polymer and preparation method of nitrile resin monomer and nitrile resin polymer

InactiveCN102976972ALow viscosityReduce liquidityCarboxylic acid nitrile preparationOrganic compound preparationPolymer scienceResin matrix

The invention discloses a nitrile resin monomer, a nitrile resin polymer and a preparation method of the nitrile resin monomer and the nitrile resin polymer, belonging to the technical field of organic polymer materials. The nitrile resin monomer is a tetraphthalonitrile resin monomer containing benzoxazine cycle, and the nitrile resin polymer is a product obtained by heating polymerization of the nitrile resin monomer. The nitrile resin monomer has a low viscosity, a good mobility and the processing performances of low-temperature curing and the like at a low temperature. The nitrile resin polymer has the good curing performances of self-flame resistance, adhesion, heat stability and the like. The resin monomer has the good processing performances of benzoxazine resins, and the resin polymer has the high-temperature resistance of nitrile resins, thus reducing the curing processing temperature and being capable of being used in a high-temperature temperature, namely, having the advantages of low temperature processing, medium temperature formation and high temperature use; and the resin monomer and the resin polymer can be used in the fields of coatings, adhesives, electronic packaging materials, aeronautics, astronautics, ships, resin matrix composites and the like. The preparation method is simple and easy to control, low in reaction temperature, energy-saving, and suitable for industrialized production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

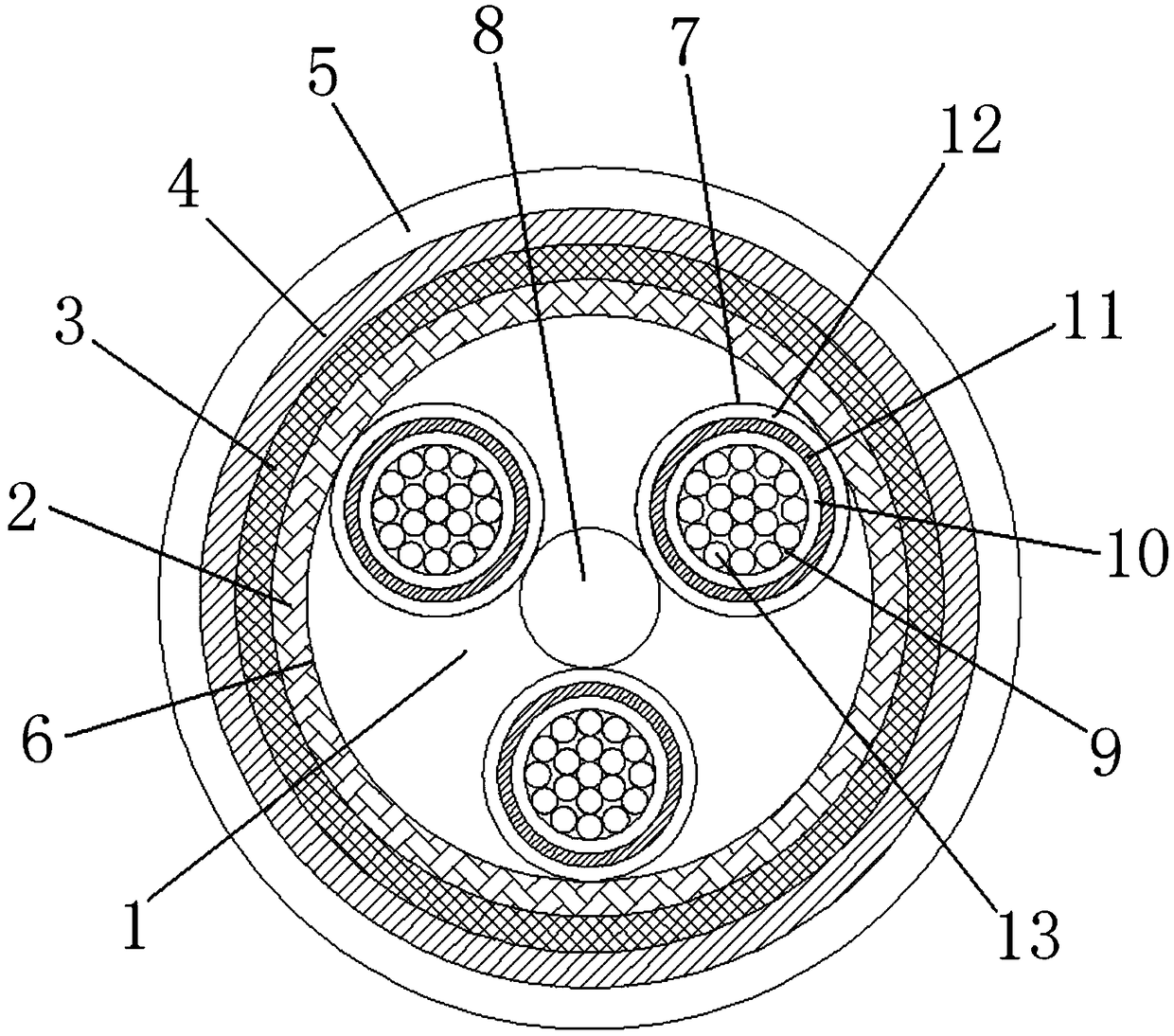

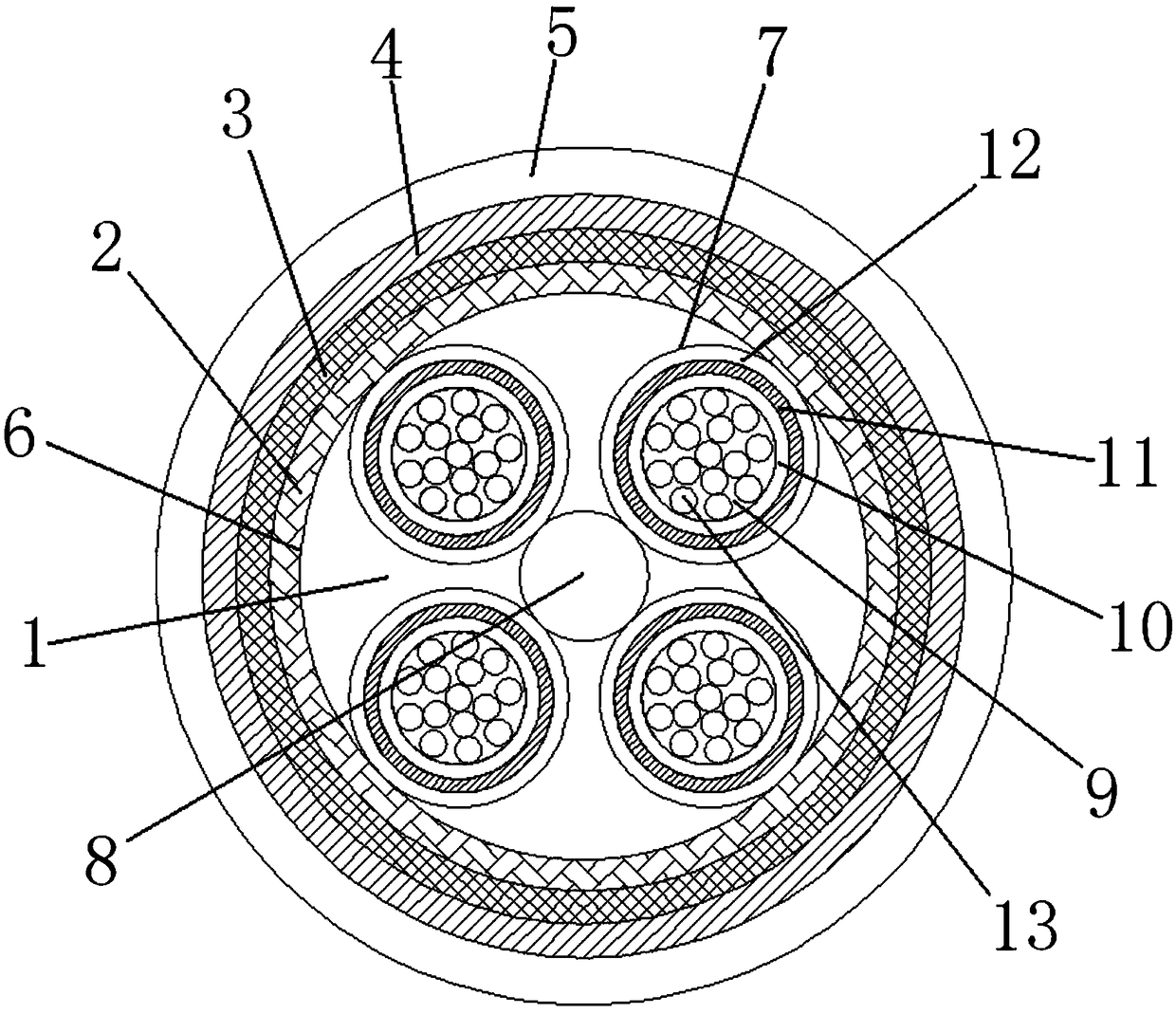

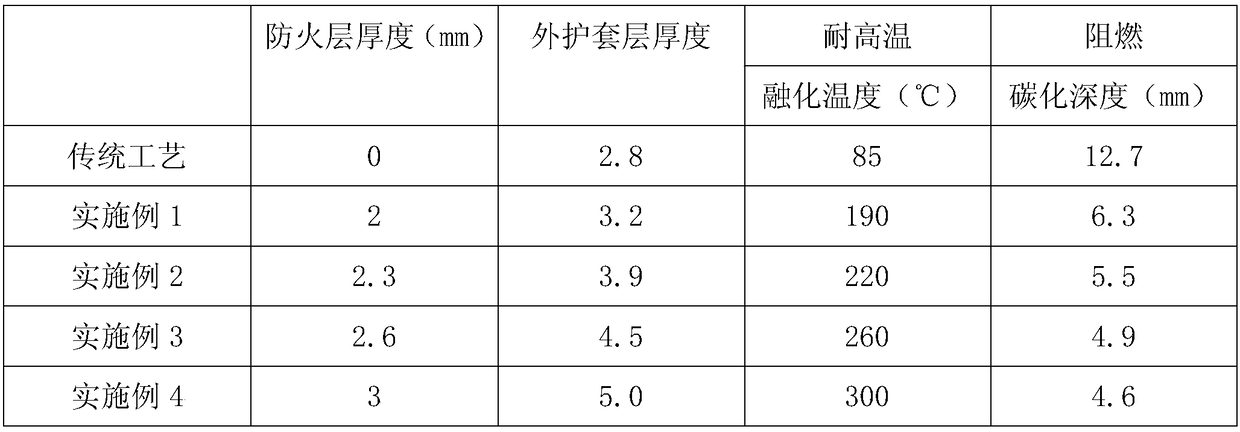

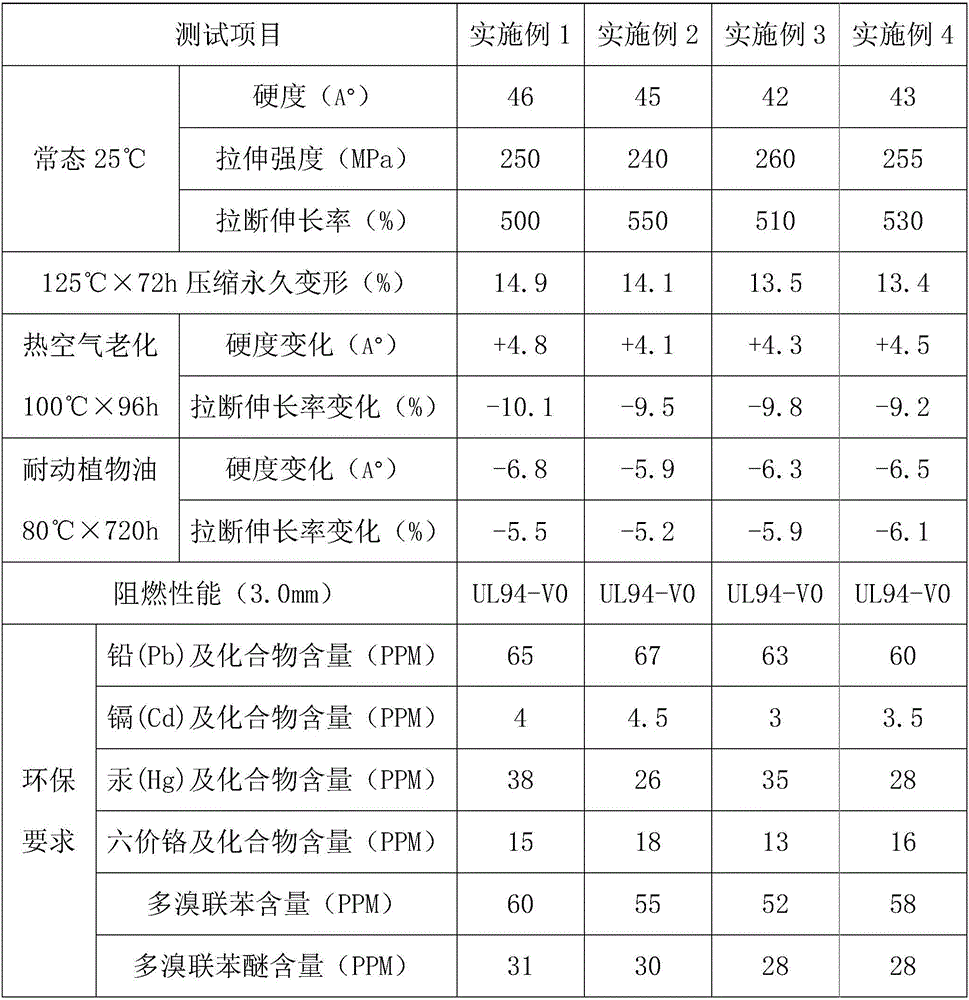

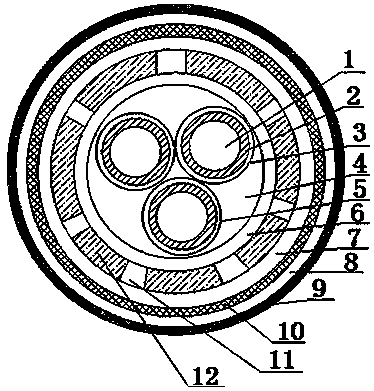

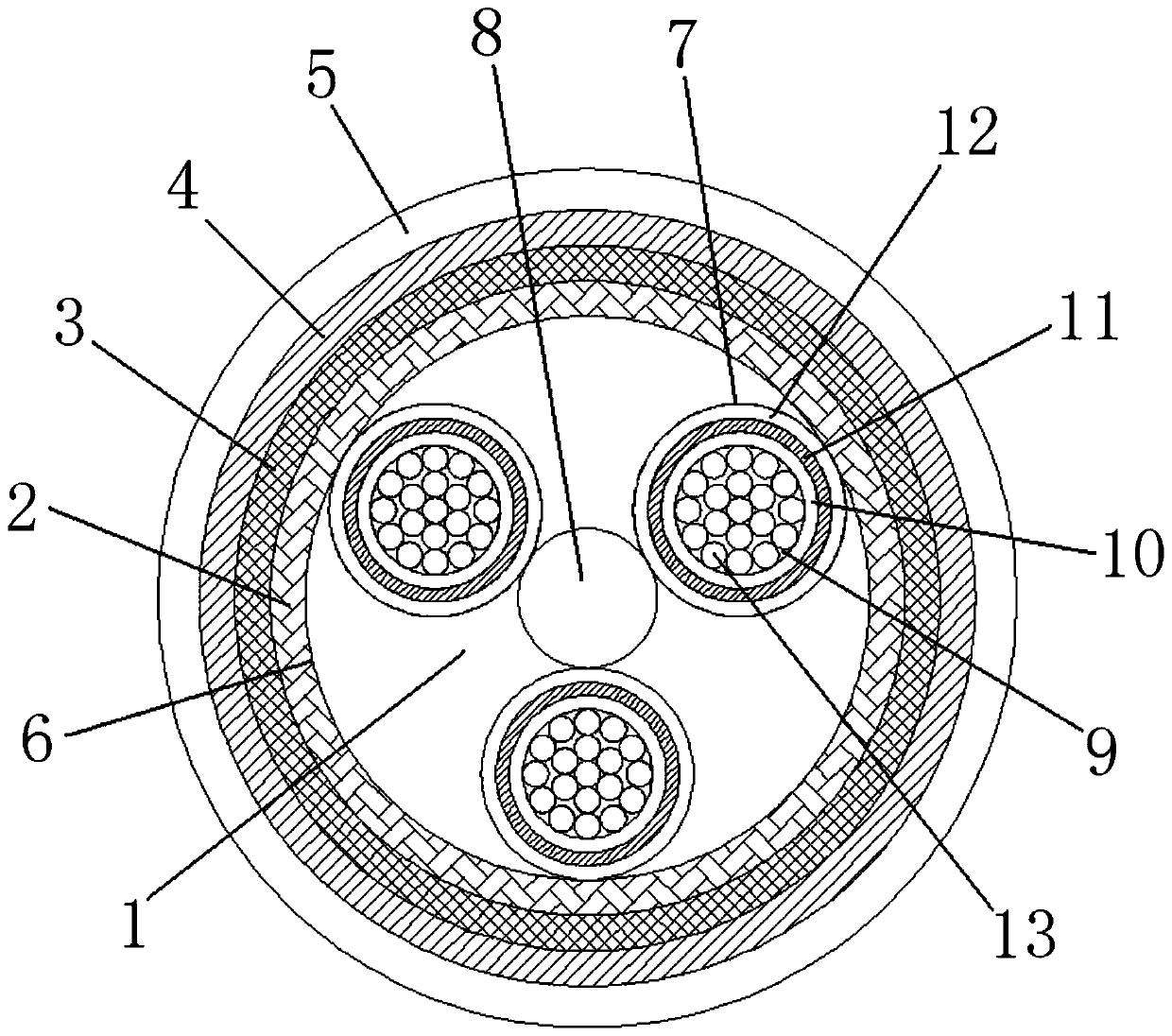

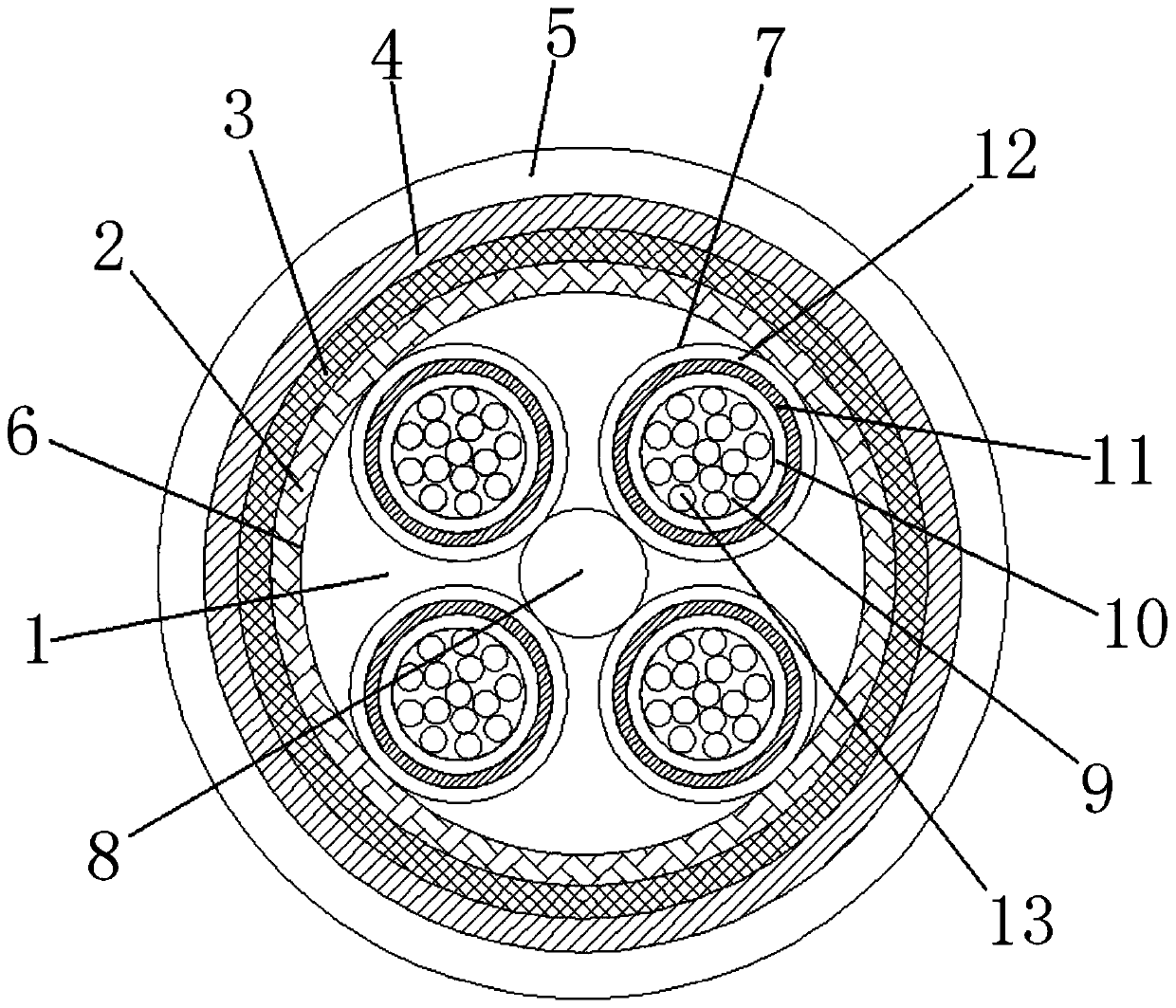

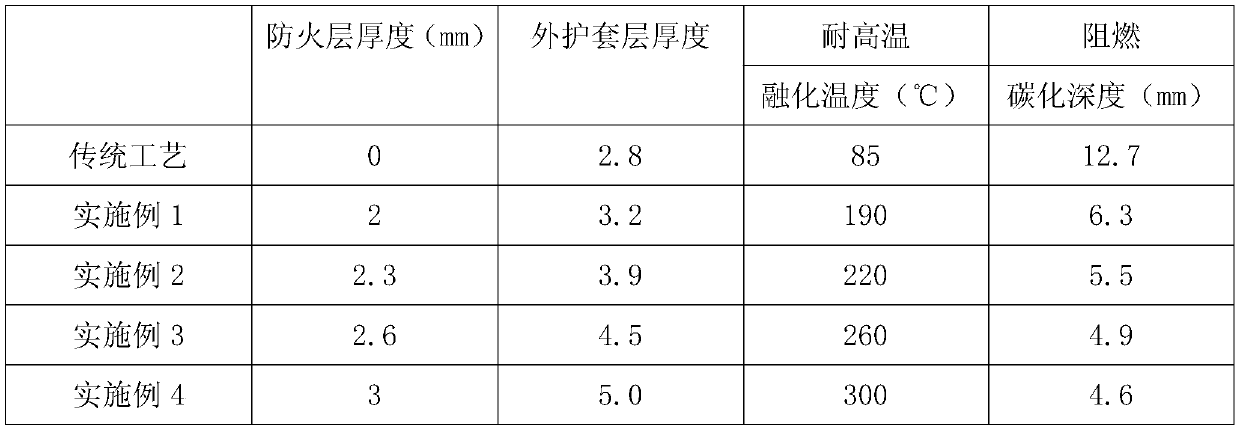

High temperature resistant and flame retardant computer cable and preparation method thereof

ActiveCN109285628AHigh elongationAvoid breakingInsulated cablesInsulated conductorsElectrical conductorEngineering

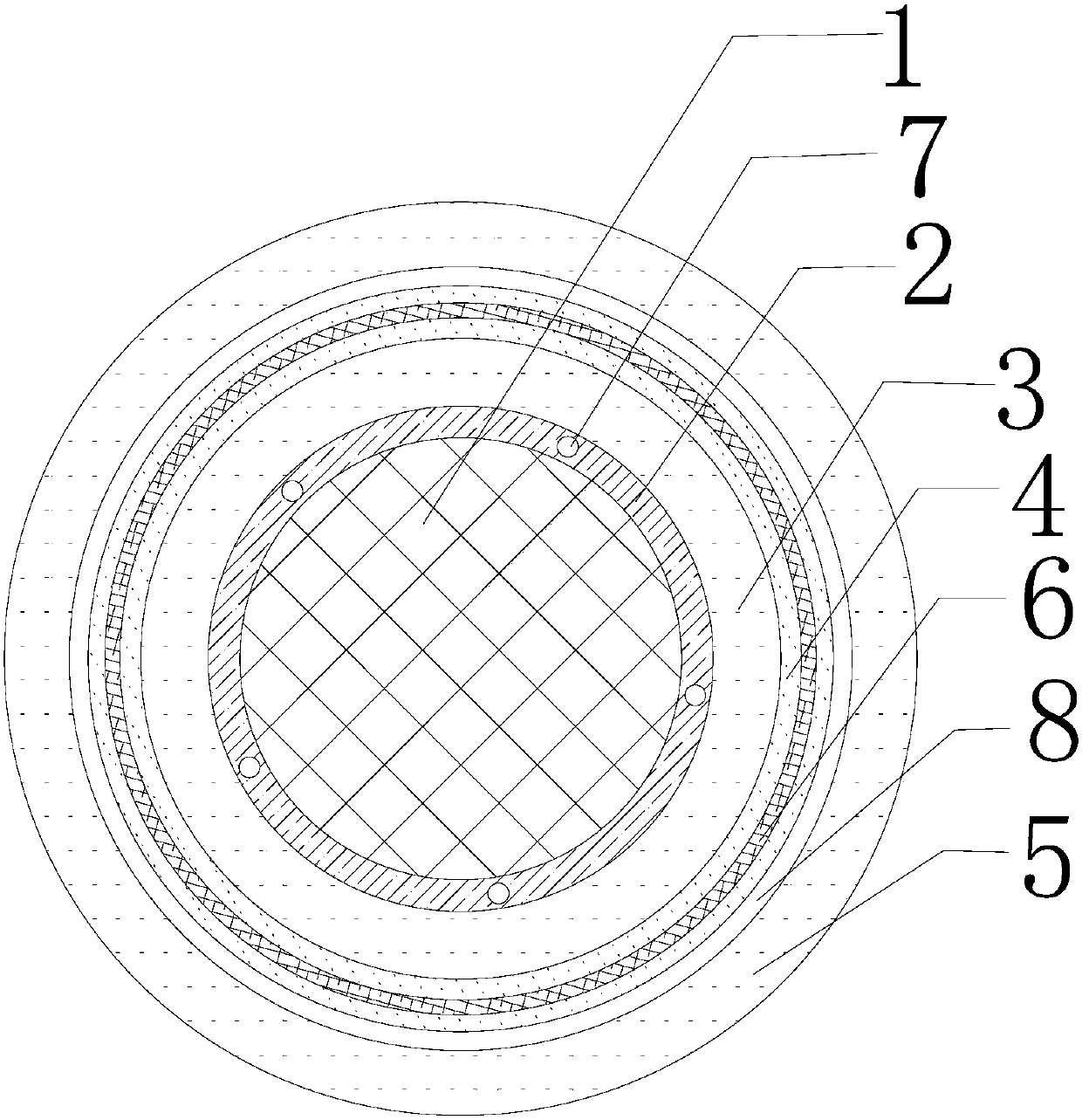

The invention discloses a high temperature resistant and flame retardant computer cable and a preparation method thereof. The preparation method comprises the preparation steps of a, carrying out drawing and annealing to obtain conductors; b, mutually twisting the conductors to obtain conductor cores; c, extruding an insulating layer outside each conductor core by adopting an extruding machine, then wrapping a shielding layer outside the insulating layer, and finally wrapping a fire resistant layer outside the shielding layer to obtain a wire core; d, mutually twisting the wire cores around the outer surface of a reinforcement core to obtain a cable core; e, wrapping a filling layer; f, wrapping an inner wrapping belt layer; g, extruding a fireproof layer; h, wrapping an outer wrapping belt layer; and i, extruding an outer sheath layer. The preparation method carries out improvement in allusion to the existing computer cable preparation method so as to improve the problems such as poorhigh temperature resistance, poor flame retardance, low structural strength and short service life of the existing computer cable. The computer cable prepared according to the invention is high in structural strength and long in service life and has excellent high temperature resistance and flame retardance.

Owner:安徽华电线缆股份有限公司

Flame-retardant sealing ring for motors of range hoods

The invention discloses a flame-retardant sealing ring for motors of range hoods. The flame-retardant sealing ring is made from raw materials including nitrile rubber, zinc oxide, stearic acid, carbon black, white carbon black, sulphur powder, an accelerant CZ, an accelerant M, an accelerant TMTD, ETU-80, light magnesium oxide, pottery clay, chloroprene rubber adhesive, aluminum hydroxide, a silane coupling agent, zinc borate, antimonous oxide, modified flame retardant, dioctyl phthalate, carnauba wax, antiager 2246, antiager BZ and a processing agent WB-16. The flame-retardant sealing ring is good in high-temperature resistance and flame retardant performance, and meanwhile has the advantages of oil resistance, no halogen, low toxicity and environment friendliness.

Owner:NINGGUO ZOYE PLASTIC & RUBBER CO LTD

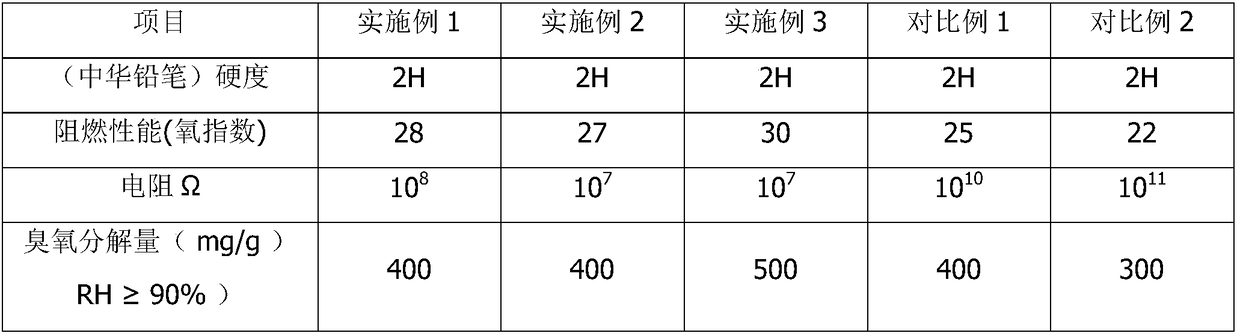

Flameproof antistatic water-based coating and preparation method thereof

PendingCN109370340AImprove antistatic performanceFast dryingFireproof paintsElectrically-conductive paintsIonEmulsion

The invention relates to the technical field of coating, and particularly discloses flameproof antistatic water-based coating and a preparation method thereof. The coating is prepared from the following components in parts by mass: 10-30 parts of acrylic emulsion, 5-20 parts of amino resin, 0.5-2 parts of diatomite, 0.1-1 part of silicone powder, 2-4 parts of aluminum hydroxide, 3-5 parts of silica sol, 3-8 parts of flame retardant, 0.5-2 parts of an antistatic agent, 0.1-0.5 part of ozonolysis catalyst, 0.1-0.2 part of pH regulator, 2-5 parts of a coalescing agent, 0.3-0.5 part of dispersant,0.3-0.5 part of a base material wetting agent, 0.5-1.0 part of a thickening agent and 5-10 parts of deionized water. According to the fireproof antistatic water-based coating, the flame retardant andantistatic performance of a film can be improved, the film has excellent flame retardance and antistatic effect, has the characteristic of decomposing ozone generated by static electricity and is favorable to body health of printer operators.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Low-smoke halogen-free polyolefin insulated and shielded cable and preparation method thereof

ActiveCN105679426AGood flexibilityImprove transmission qualityFlexible cablesFlexible conductorsShielded cableLow smoke zero halogen

The invention discloses a low-smoke halogen-free polyolefin insulated and shielded cable, which comprises a conductive core, an isolating guide layer, an insulating sheath layer, a shielding sheath layer and an outer protecting sleeve layer. A preparation method of the low-smoke halogen-free polyolefin insulated and shielded cable comprises a wire drawing procedure, a wire bundling procedure, a compound stranding procedure, an isolating guide layer process, an insulating sheath layer process, a shielding sheath layer process and an outer protecting sleeve layer process. By the low-smoke halogen-free polyolefin insulated and shielded cable and the preparation method thereof, the cable can have good anti-stretching and anti-bending properties, high temperature resistant and flame retardant properties and good insulating and shielding properties, can effectively shield the interference of external electromagnetism and the like, improves the transmission quality of the cable and is long in service lifetime and beneficial to popularization and application.

Owner:JIANGSU TAIXIANG WIRE CABLE CO LTD

Flame-retardant resin

The invention relates to a flame-retardant resin which comprises the following components in parts by mass: 10-20 parts of chlorinated styrene, 10-15 parts of maleic anhydride, 20-30 parts of tetrachloro phthalic anhydride, 40-55 parts of neopentyl glycol, 2-7 parts of methyl methacrylate, 8-15 parts of fiber, 6-10 parts of copper naphthenate, 1-3 parts of cobalt isooctoate, 20-30 parts of calcium carbonate and 8-12 parts of silicon dioxide. The tetrachloro phthalic anhydride used as the raw material can enhance the flame retardancy of the resin, and the chlorinated styrene used as the curing agent further enhances the flame retardancy of the resin. The flame-retardant resin has the characteristics of high temperature resistance, corrosion resistance, high strength, long service life of the prepared part, simple processing technique, no toxicity after curing, high bonding strength, simple and controllable technical process, short production cycle and the like, and can be cured at normal temperature. In the resin synthesis process, the heat generated by chemical reaction is fully utilized, thereby saving the energy and avoiding generating three wastes.

Owner:WUXI NANLIGONG TECH DEV

High temperature resistant conductive rubber material

InactiveCN105367857AChanging the situation where only a single acetylene black is usedImprove conductivityRubber materialSilicone rubber

The invention discloses a high temperature resistant conductive rubber material and relates to the field of rubber. The high temperature resistant conductive rubber material comprises, by weight, 40-120 parts of chloroprene rubber, 50-150 parts of fluorinated silicone rubber, 30-50 parts of polyacrylate rubber, 1-4 parts of conductive particles, 10-30 parts of carbon black N300, 3-7 parts of conductive graphite, 4-20 parts of a reinforcing agent, 2-10 parts of calcium carbonate, 1-5 parts of an anti-aging agent, 3-5 parts of dibutyl phthalate, 1-4 parts of zinc diethyl dithiocarbamaate, 1-4 parts of 2-mercaptoimidazoline, 5-18 parts of a flame retardant, and 3-5 parts of a vulcanizing agent. According to the invention, a rubber material with good conductivity, high tensile strength, high temperature resistance and flame resistance can be produced.

Owner:季桂金

Fireproof coal ash heat insulation material and preparation method thereof

The invention discloses a fireproof coal ash heat insulation material which comprises, by weight, 15-25 parts of compressed coal ash, 20-40 parts of acidified coal ash, 10-14 parts of water glass, 12-18 parts of adsorption filling soil, 5-7 parts of coupling agents, 15-25 parts of adhesives, 9-13 parts of glass beads, 8-16 parts of reinforced fibers and 7-11 parts of flame-retardant additives. The coal ash is comprehensively recycled, resources are saved, environments are protected, waste is sufficiently used, the prepared heat insulation material is low in specific gravity, high in strength, good in heat insulation performance, excellent in high-temperature resistance and flame resistance and good in stability. Besides, the preparation method is low in material cost and simple and clear in process and has a high practical value and a good application prospect, and raw materials are easily obtained.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

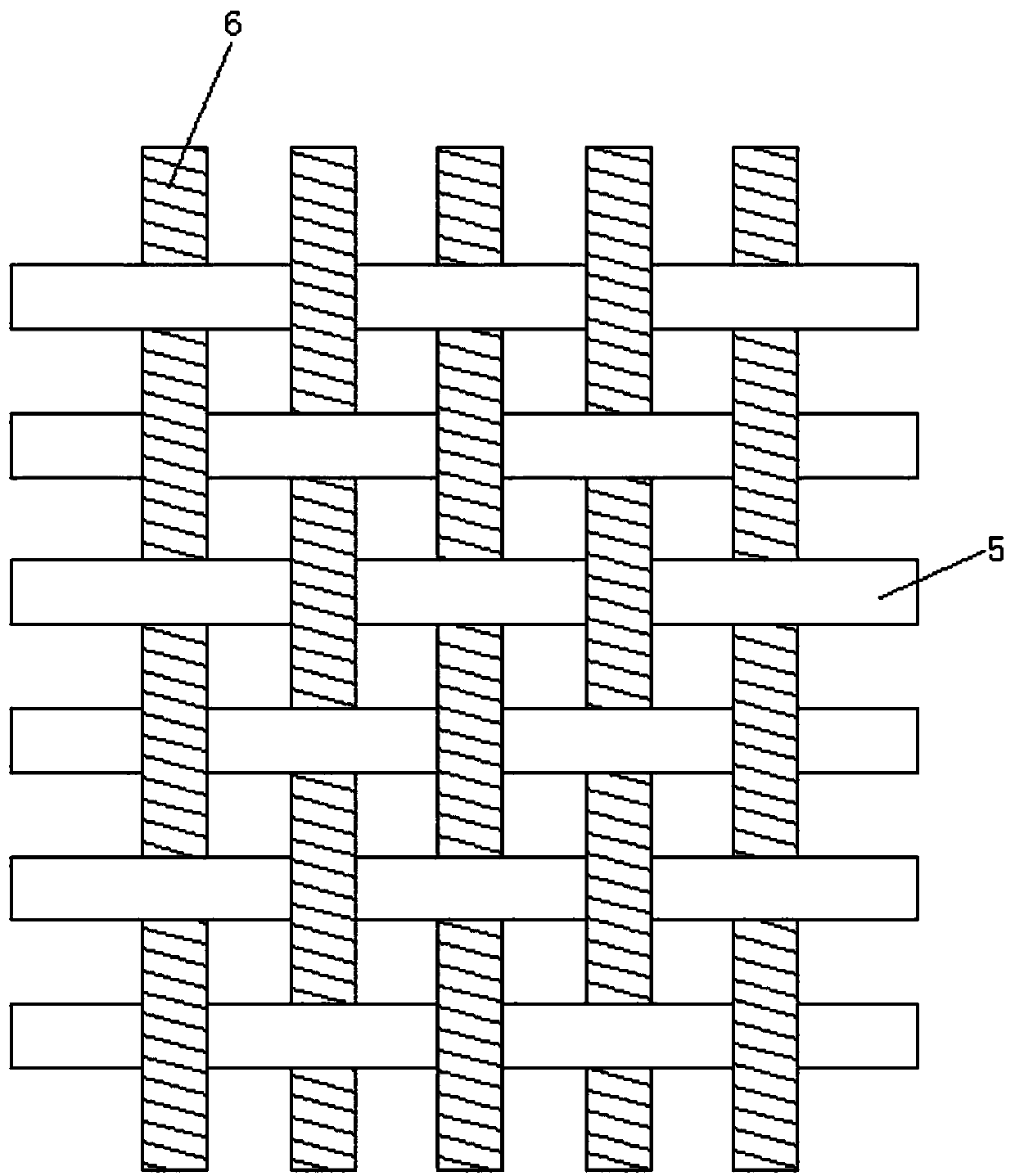

Flame-retardant fabric

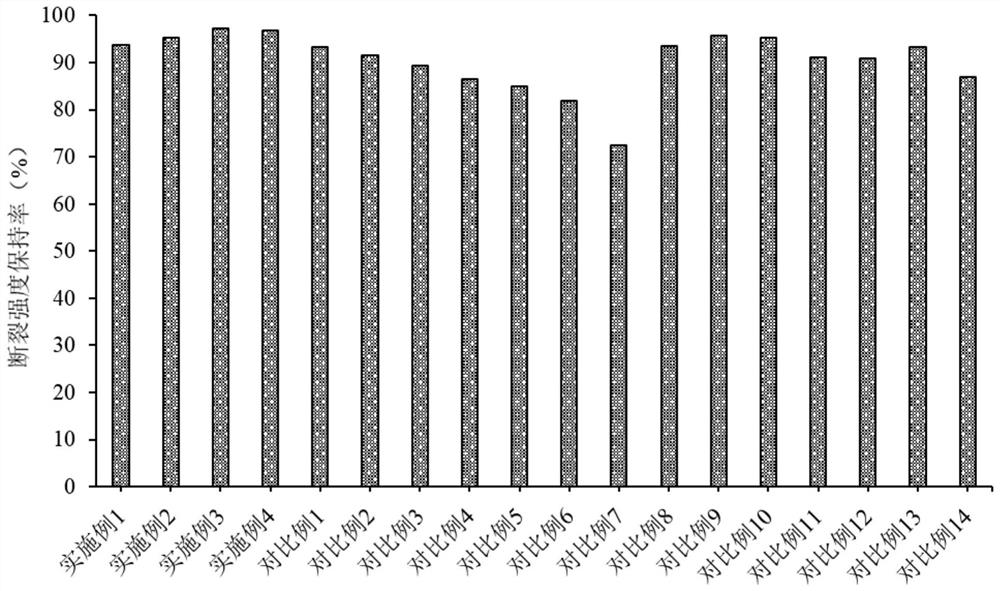

InactiveCN109652896AGood high temperature resistance and flame retardant effectLayered productsWoven fabricsYarnEngineering

The invention discloses a flame-retardant fabric which comprises an inner layer, a flame-retardant layer and a glass fiber layer which are sequentially distributed from inside to outside. The inner layer and the flame-retardant layer are in stitching joint through flame-retardant terylene, weft yarns and warp yarns adopting polyphenylene sulfide fibers are woven to form the inner layer, the weft yarns comprise terylene and flame retardant layers coating the periphery of the terylene, and aramid fibers are woven to form the flame-retardant layer. The flame-retardant fabric is high in structuralstrength and good in flame-retardant effect.

Owner:绍兴柯桥名瑶纺织品有限公司

Polysulfonamide permanent flame-retardant heat-insulation warm-keeping fabric sheet and preparation method thereof

ActiveCN104562434AGood high temperature resistance and flame retardant effectImprove wash resistanceNon-woven fabricsFiberPolymer science

The invention discloses a polysulfonamide permanent flame-retardant heat-insulation warm-keeping fabric sheet which is prepared from the following raw material components in parts by weight: 90-100 parts of PSA fibers and 0-10 parts of low-melting-point fibers. After being prepared into a fiber net, the raw materials are treated by a flame-retardant adhesive solution to obtain the polysulfonamide permanent flame-retardant heat-insulation warm-keeping fabric sheet. The polysulfonamide permanent flame-retardant heat-insulation warm-keeping fabric sheet has a permanent flame-retardant heat-insulation warm-keeping function, also can be used for guaranteeing the fabric sheet to have a good high-temperature-resistant and flame-retardant effect and a washing-resistant effect, guaranteeing the elasticity and fluffy restoration after washing of the fabric sheet.

Owner:中芳新材料有限公司 +1

Anti-microbial high temperature-resistant water-resistant fuel filter paper and preparation method thereof

InactiveCN103993512AImprove the adsorption and filtration effectHas antibacterial propertiesFiltration separationInorganic compound additionAdhesiveSilanes

The invention discloses an anti-microbial high temperature-resistant water-resistant fuel filter paper. The fuel filter paper is characterized by being prepared from the following raw materials by weight: 53 to 56 parts of mulberry bark pulp, 47 to 51 parts of waste cotton pulp, 2 to 3 parts of butyl acrylate, 0.4 to 0.6 part of sodium polyacrylate, 2 to 4 parts of propylene glycol, 3 to 4 parts of quartz sand, 2 to 3 parts of activated clay, 8 to 10 parts of polyvinyl acetate emulsion adhesive, 0.5 to 0.6 part of silver chloride, 0.4 to 0.7 part of benzotriazol, 1 to 2 parts of pomegranate seed, 0.5 to 0.8 part of a silane coupling agent kh792, 0.7 to 0.9 part of alum, 2 to 3 parts of fine soybean powder, 1 to 2 parts of an auxiliary agent and a proper amount of water. The filter paper provided by the invention is strong and durable and has high temperature resistance, flame retardation performance and good adsorption and filtering effects; due to addition of quartz sand, the filter paper has good high temperature resistance and flame retardation performance; benzotriazol and silver chloride are added, so the filter paper has a certain anti-microbial effect; the auxiliary agent is added, which is safe and environment-friendly, small pores are formed in the surface of the filter paper, so adsorptivity is improved and the filter paper has water resistance.

Owner:BENGBU PIONEER FILTER

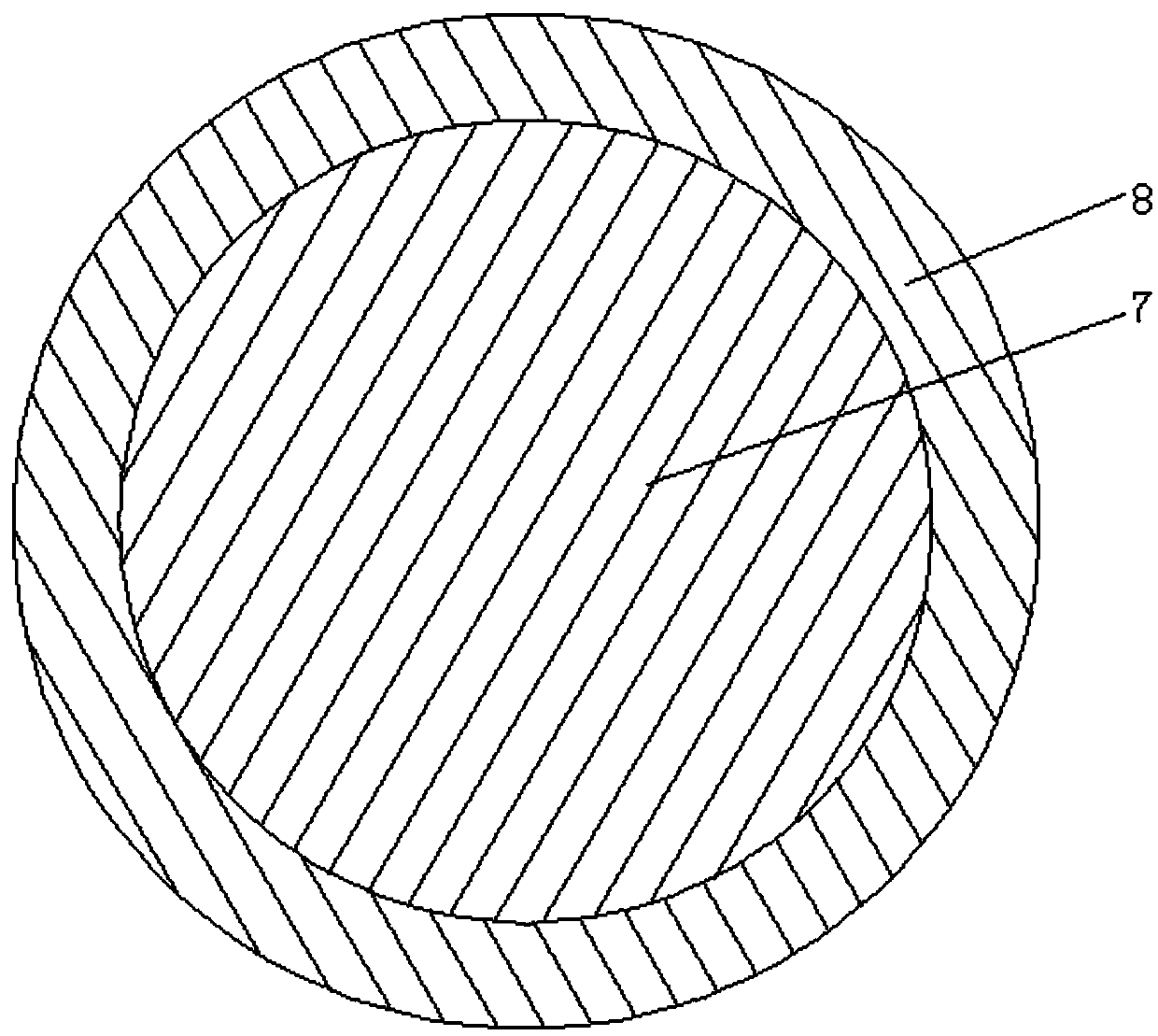

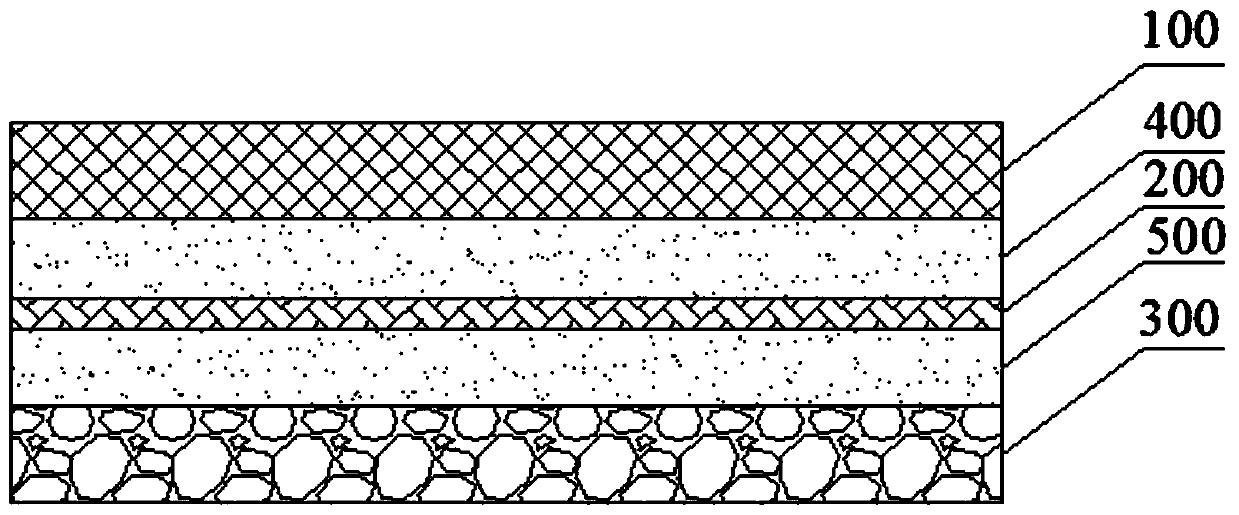

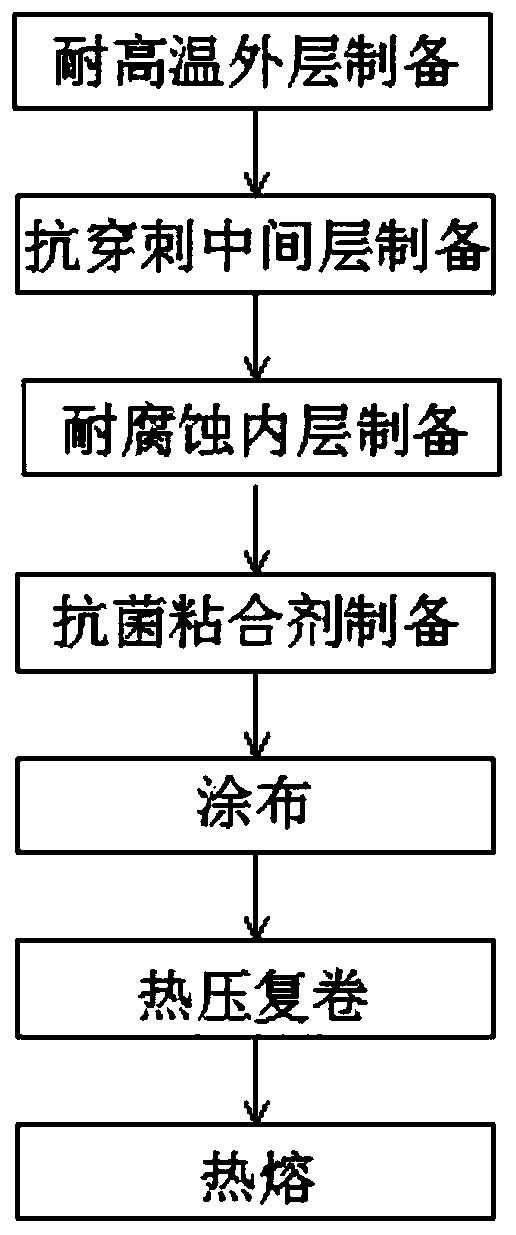

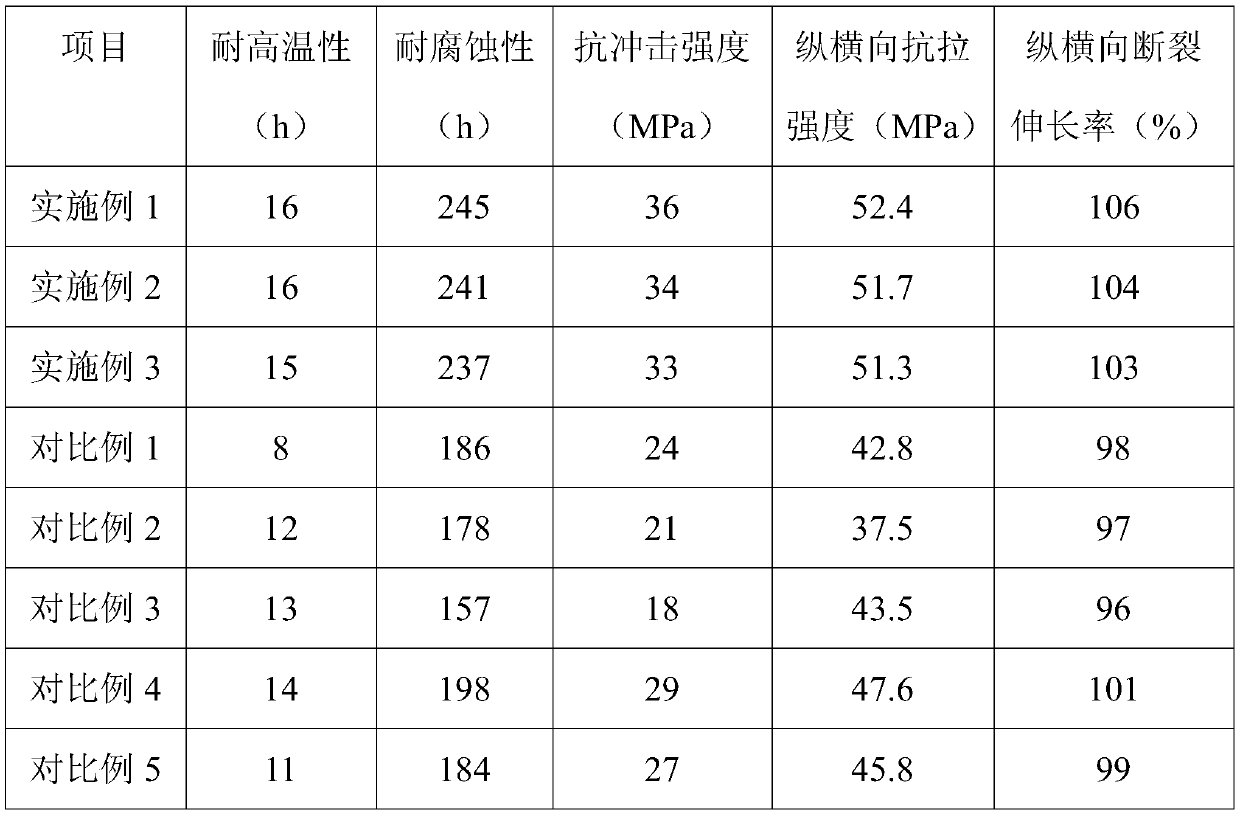

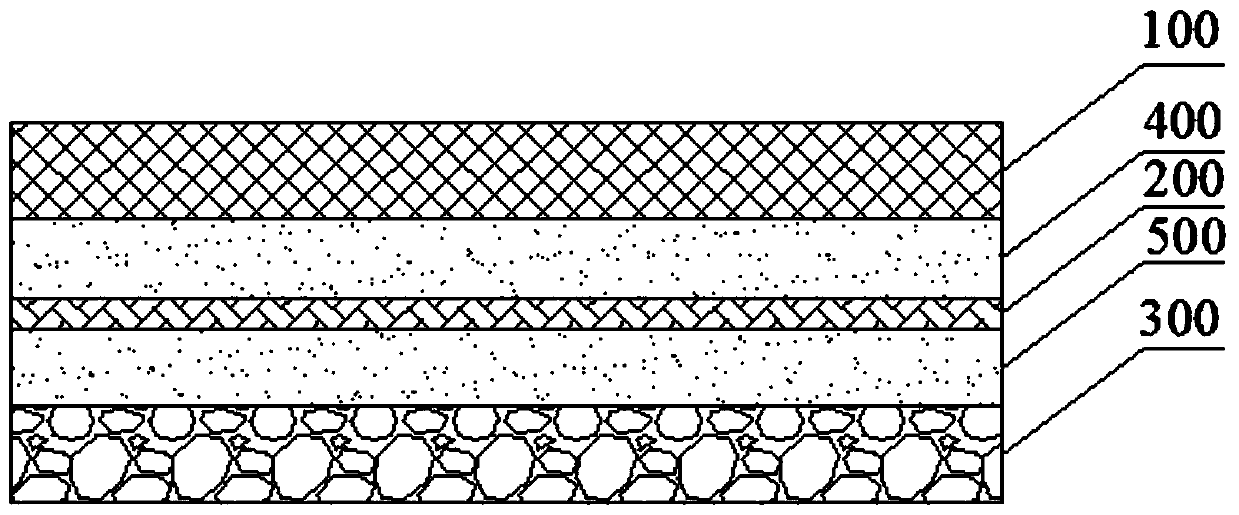

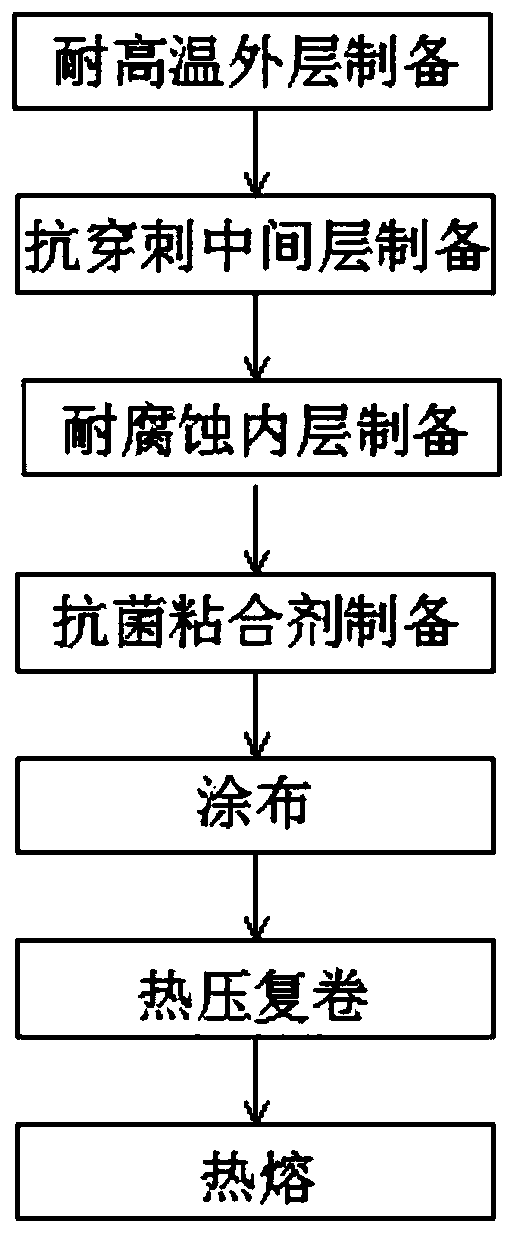

Vacuum compression bag with antibacterial function and production process thereof

ActiveCN110254933APromote absorptionImprove barrier propertiesNon-macromolecular adhesive additivesBio-packagingEscherichia coliStaphylococcus aureus

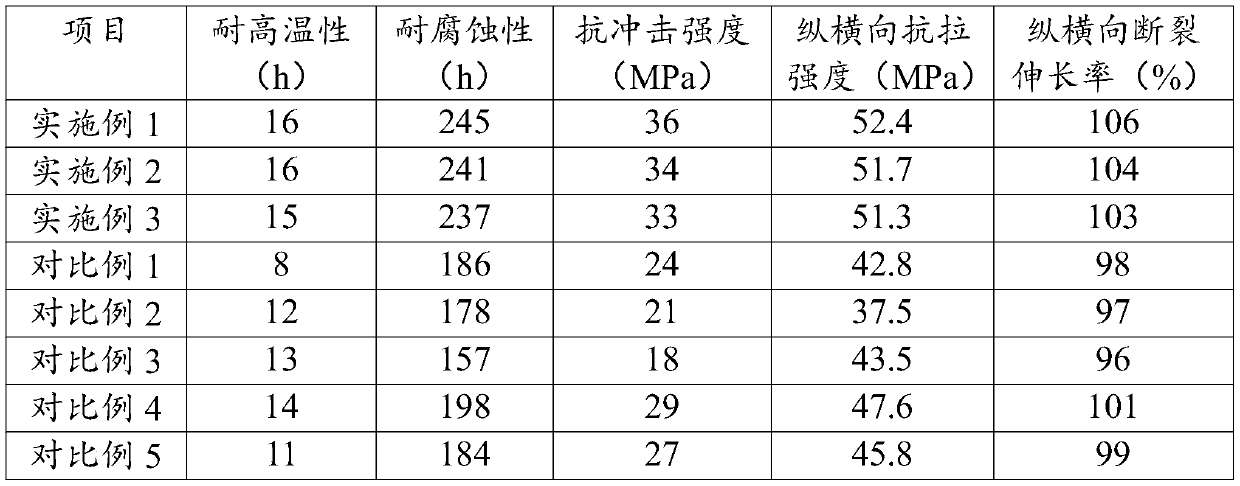

The invention discloses a vacuum compression bag with an antibacterial function and a production process thereof, and relates to the field of packaging materials. The vacuum compression bag is formed by a high-temperature-resistant outer layer, a first antibacterial adhesive layer, an impact-resistant intermediate layer, a second antibacterial adhesive layer and a corrosion-resistant inner layer from outside to inside through hot pressing. The production process comprises the seven procedures of preparation of the high-temperature-resistant outer layer, preparation of the impact-resistant intermediate layer, preparation of the corrosion-resistant inner layer, preparation of an antibacterial adhesive, coating, hot-pressing and rewinding and hot melting. Compared with the prior art, the vacuum compression bag has excellent antibacterial property, corrosion resistance, impact resistance, breakdown resistance and high temperature resistance, and is suitable for vacuum storage of materials in a high-temperature corrosion environment, the impact strength reaches 36 MPa, the tensile strength reaches 52.4 MPa, the elongation at break reaches 106%, and the antibacterial rate to escherichia coli, staphylococcus aureus and candida albicans reaches 99.7%, 98.3% and 95.7% correspondingly.

Owner:YUYAO HUAYIN PACKING MATERIAL CO LTD

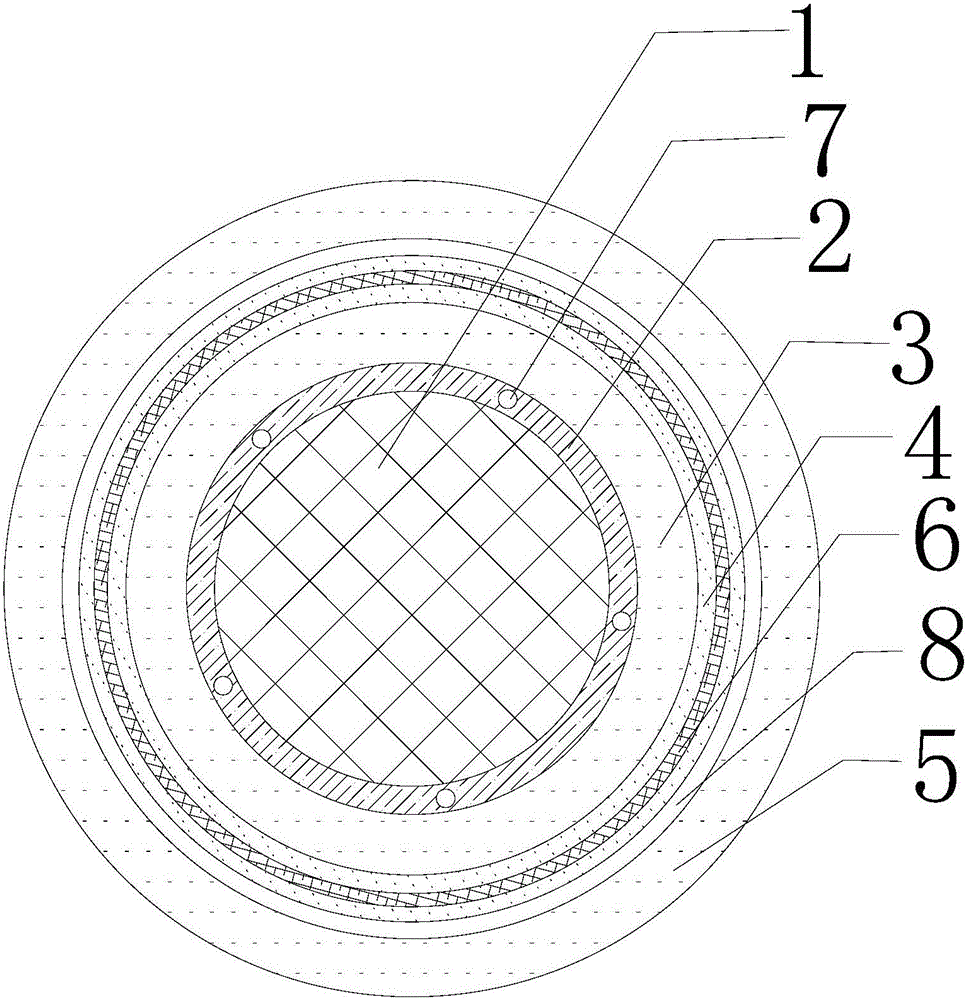

High-temperature-resistant flame-retardant cable

InactiveCN109326376ANon-flammableGood high temperature resistance and flame retardant effectPower cables with screens/conductive layersInsulated cablesEngineeringTemperature resistance

The invention discloses a high-temperature-resistant flame-retardant cable, which comprises a plurality of cable cores. Each cable core is externally wrapped by a PLA layer and a first shielding layerin sequence. The first shielding layers are externally provided with waterproof sheathings in vertically corresponding arrangement, and the waterproof sheathings in vertically corresponding arrangement are internally provided with a storage groove in which the cable cores are positioned. The waterproof sheathings are externally wrapped by a second shielding layer which is externally wrapped by ahalogen-free flame-retardant TPU layer, and a double-layer insulating sleeve outside the halogen-free flame-retardant TPU layer is externally provided with a flame retardant coating. The high-temperature-resistant flame-retardant cable has advantages of high temperature resistance and flame retardation, great structural airtightness, environmental friendliness, high safety factor, low production cost and the like.

Owner:惠州市太金电线电缆有限公司

High-strength heat-resistant lead-acid battery plastic shell and preparation method thereof

The invention relates to the field of lead-acid battery manufacturing, in particular to a high-strength heat-resistant lead-acid battery plastic shell and a preparation method thereof. The problems that a lead-acid storage battery shell in the prior art is low in strength, cannot cope with large impact force, cannot resist to a high temperature, and is easily softened and deformed at a high temperature are solved. The battery plastic shell provided by the invention comprises the following components in parts by weight: 100 parts of acrylonitrile butadiene styrene (ABS) resin, 10-25 parts of glass fiber subjected to surface treatment, 18-30 parts of organic silicon modified sepiolite, 10-20 parts of dimethyl silicone oil, 1-5 parts of zinc stearate and 0.5-3 parts of an antioxidant. The battery plastic shell has the following advantages: (1) the mechanical property is good and the strength of the plastic shell is high; (2) the plastic shell provided by the invention has good high-temperature resistance and flame retardancy; and (3) the preparation process is simple and the cost is low.

Owner:ZHEJIANG CHANGTONG SCI & TECH

High-temperature-resistant flame-retardant conveying rail and preparation method thereof

InactiveCN106752602AGood dispersionStable and stableFireproof paintsEpoxy resin coatingsCarbon monofluorideEpoxy

The invention discloses a high-temperature-resistant flame-retardant conveying rail which comprises a conveying rail body, wherein the outer surface of the conveying rail body is coated by a layer of high-temperature-resistant flame-retardant layer. The high-temperature-resistant flame-retardant layer is prepared from a first component and a second component which are mixed according to a mass ratio of the first component to the second component being 7 to 2. The first component is prepared from the following ingredients in parts by mass: 33 to 37 parts of ATO powder, 12 to 16 parts of E-20 epoxy resin, 24 to 26 parts of alcohol-soluble acrylate resin, 8 to 13 parts of benzyl alcohol, 17 to 22 parts of carbon monofluoride, 9 to 12 parts of alcohol, 13 to 16 parts of flame retardant, 5 to 7 parts of thickening agent and 11 to 13 parts of coalescing agent. The second component is prepared from the following ingredients in mass fraction: 9 to 11 parts of ultraviolet light absorber, 5 to 9 parts of dispersing agent, 8 to 12 parts of thickening agent, 15 to 18 parts of coalescing agent, 2 to 5 parts of sodium tetraborate, 3 to 7 parts of mixed phosphate, 1 to 3 parts of potassium biphthalate, 4 to 6 parts of allyl alcohol, 13 to 15 parts of auxiliary materials and 20 to 35 parts of solvent. The high-temperature-resistant flame-retardant conveying rail disclosed by the invention not only improves work efficiency, but also reduces environmental pollution; in addition, practicability of the conveying rail is enhanced.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

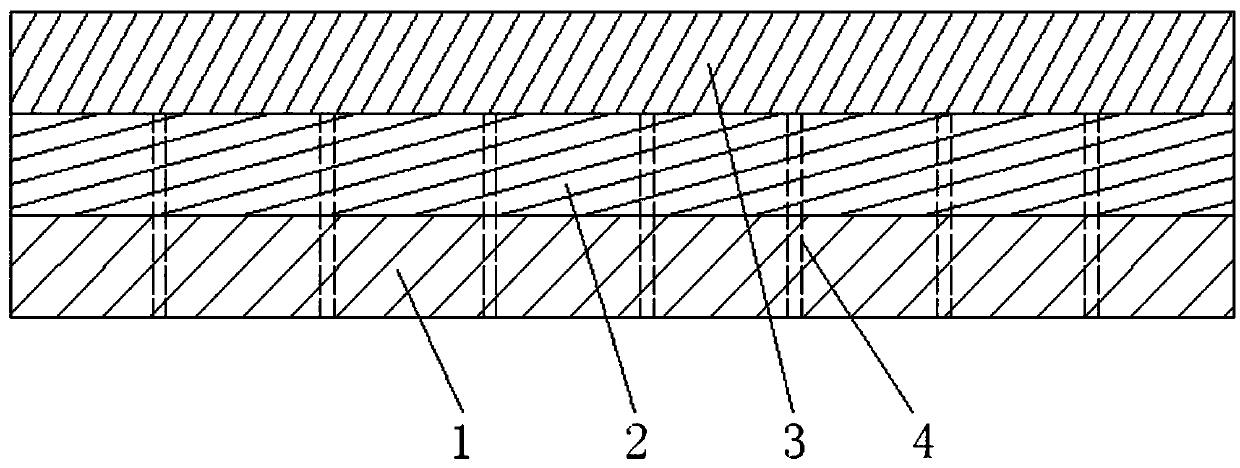

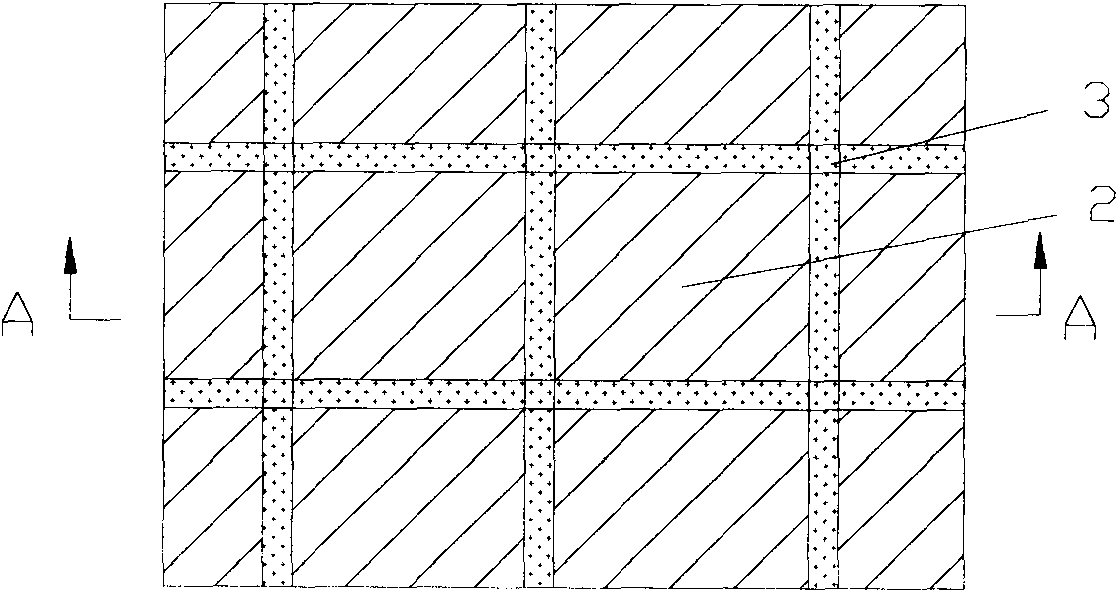

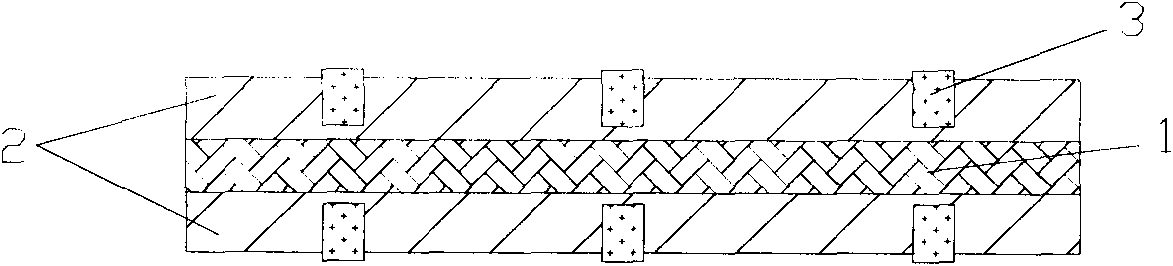

Gold-thread wool circle composite cloth resistant to high temperature

InactiveCN102888695AHighlight the sense of hierarchyGood high temperature resistance and flame retardant effectTextile decorationWoven fabricsWoolTextile

The invention relates to a piece of gold-thread wool circle composite cloth resistant to high temperature, which is widely applied to preparing high-grade clothes and belongs to the field of textile fabrics. The composite cloth comprises a cloth body (1) which is formed by weaving composite flame-retardant fibers; the composite flame-retardant fibers are formed by blending aramid fibers and flame-retardant viscose fibers; both the upper surface and the lower surface of the cloth body (1) are provided with a wool circle layer (2) and a plurality of gold threads (3); the gold threads (3) are filament tows consisting of a plurality of single gold filaments; the gold threads (3) are arranged outside the wool circle layer (2) and are distributed longitudinally and horizontally to form large lattices; and the wool circle layer (2) and the gold threads (3) are fixed on the cloth body (1) by threads. The wool circle layer and the gold threads of the double-side gold-thread wool circle composite cloth are embraced with one another to highlight the hierarchy sensation and satisfy the requirement on fashion fabrics.

Owner:黄文平

High-strength colored organic flame-retardant regenerated cellulose fiber and preparation method thereof

ActiveCN105297164AHigh color fastnessAvoid pollutionArtificial filament washing/dryingMonocomponent cellulose artificial filamentPolymer scienceSpinning

The invention relates to the technical field of regenerated cellulose fibers, in particular to a preparation method of a high-strength colored organic flame-retardant regenerated cellulose fiber. The preparation steps include the procedure of preparing a spinning solution, the procedure of preparing flame-retardant spinning adhesives, the procedure of spinning, and the procedure of post-processing. In the procedure of preparing the flame-retardant spinning adhesives, flame retardants, denaturants and color paste need to be added after the procedure of preparing the spinning solution, organic pyrophosphate flame retardants are adopted as the flame retardants, polyoxyethylene fatty amine is adopted as the denaturants, and the particle size of the color paste is required to be smaller than or equal to 0.5 micron. The limit oxygen index of the flame-retardant fiber prepared through the method is larger than or equal to 28.0%, the cotton staining grade and the original sample color changing grade of the fiber are both higher than the fourth grade, and the color fastness is good. Environmental protection pressure caused by subsequent dyeing of downstream customers is greatly reduced, and the flame-retardant performance attenuation problem caused by high temperature dyeing is solved. The mode that drying is performed before cutting is adopted for the post-processing procedure, the mixing problem of fibers in different colors is avoided, and production cost is greatly reduced.

Owner:潍坊欣龙生物材料有限公司

Wear-resistant and high-temperature-resistant vehicle wire material and preparation method thereof

PendingCN114213785AReduce hydrophilic groupsGood high temperature resistance and flame retardant effectPolyvinyl chlorideCalcium alginate

The invention discloses a wear-resistant and high-temperature-resistant vehicle wire material and a preparation method thereof, and relates to the technical field of wire materials. When the material for the wear-resistant and high-temperature-resistant vehicle wires is prepared, modified zinc stannate is used as a flame-retardant component and is blended with polyvinyl chloride; the modified zinc stannate is prepared by grafting oxidized sodium alginate and hyperbranched polyurethane with an epoxy group on zinc hydroxystannate, crosslinking the oxidized sodium alginate into calcium alginate, and finally preparing into aerogel; when the hyperbranched polyurethane is prepared, glycidol is introduced, and the hyperbranched polyurethane with an epoxy group is prepared. The wear-resistant and high-temperature-resistant vehicle wire material prepared by the invention not only has flame-retardant and wear-resistant effects, but also is more flexible.

Owner:邵桐

High-temperature-resistant flame-retardant rubber new material and production process thereof

InactiveCN110746669AReasonable designGood high temperature resistance and flame retardant effectActive agentSodium phosphates

The invention provides a high-temperature-resistant flame-retardant rubber new material and a production process thereof. The rubber new material comprises, by weight, 40-60 parts of chloroprene rubber, 20-30 parts of silicone rubber, 15-25 parts of styrene butadiene rubber, 10-15 parts of aluminum hydroxide, 5-10 parts of stearic acid, 5-10 parts of antimonous oxide, 5-10 parts of sodium hexametaphosphate, 1-5 parts of carbon black, 1-5 parts of an active agent, 1-5 parts of a flame retardant, 1-5 parts of an anti-aging agent, 1-5 parts of a scorch retarder and 1-5 parts of an accelerant. According to the rubber new material, composition design and matching are reasonable, and rubber produced from the new material has good high-temperature-resistant and flame-retardant effects and is lowin production cost and good in economic benefit.

Owner:SUZHOU HAOLI CULTURE MEDIA TECH CO LTD

Preparation method of flame-retardant resin

The invention relates to a preparation method a flame-retardant resin. The preparation method adopts crosslinking chemical reaction, and comprises the following steps: (1) at normal temperature, weighing all the raw materials according to parts by weight for later use; (2) at normal temperature, dissolving maleic anhydride, tetrachloro phthalic anhydride, neopentyl glycol, a curing agent chlorinated styrene and methyl methacrylate, and uniformly mixing by sufficient stirring; (3) curing: curing the uniformly mixed solution obtained in the step (2) to obtain an unsaturated polyester resin, wherein the initial curing temperature is 20-30 DEG C, the initial curing time is 10-30 hours, the postcuring temperature is 25-35 DEG C, and the postcuring time is 4-6 hours; and (4) at normal temperature, mixing and dissolving fibers, copper naphthenate, cobalt isooctoate, calcium carbonate and silicon dioxide in the unsaturated polyester resin prepared in the step (3), uniformly mixing by sufficient stirring, and aging at 25 DEG C for at least 36 hours to obtain the flame-retardant resin.

Owner:WUXI NANLIGONG TECH DEV

Reinforced carbon fiber and ultra-high molecular weight polyethylene fiber composite fiber material and preparation method thereof

ActiveCN112778605AIn line with the concept of green environmental protectionImprove performanceEpoxyFiber

The invention discloses an enhanced carbon fiber and ultra-high molecular weight polyethylene fiber composite fiber material and a preparation method thereof. The preparation method comprises the steps of weaving carbon fibers and ultra-high molecular weight polyethylene fibers into base cloth by adopting a blending process; stirring and mixing epoxy resin, fluorocarbon resin, silicon-oxygen inorganic resin and a solvent to prepare a chemical solution; adding nanoscale carbon powder, nanoscale titanium dioxide and nanoscale silicon dioxide into the chemical solution, and stirring and mixing; continuously adding a curing agent, a dispersing agent and the base cloth, and stirring and mixing to uniformly attach each material to the base cloth; and taking out the base cloth, and drying to obtain the composite fiber material. The manufacturing process is simple and easy to operate, the prepared enhanced carbon fiber / ultra-high molecular weight polyethylene fiber composite fiber material improves the performance of an original material and can have excellent performance such as impact resistance and high temperature resistance, the service life of the material is prolonged, and the original defects of the material are overcome.

Owner:广东冠豪新材料研发有限公司 +1

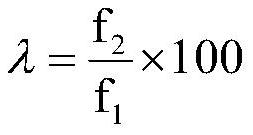

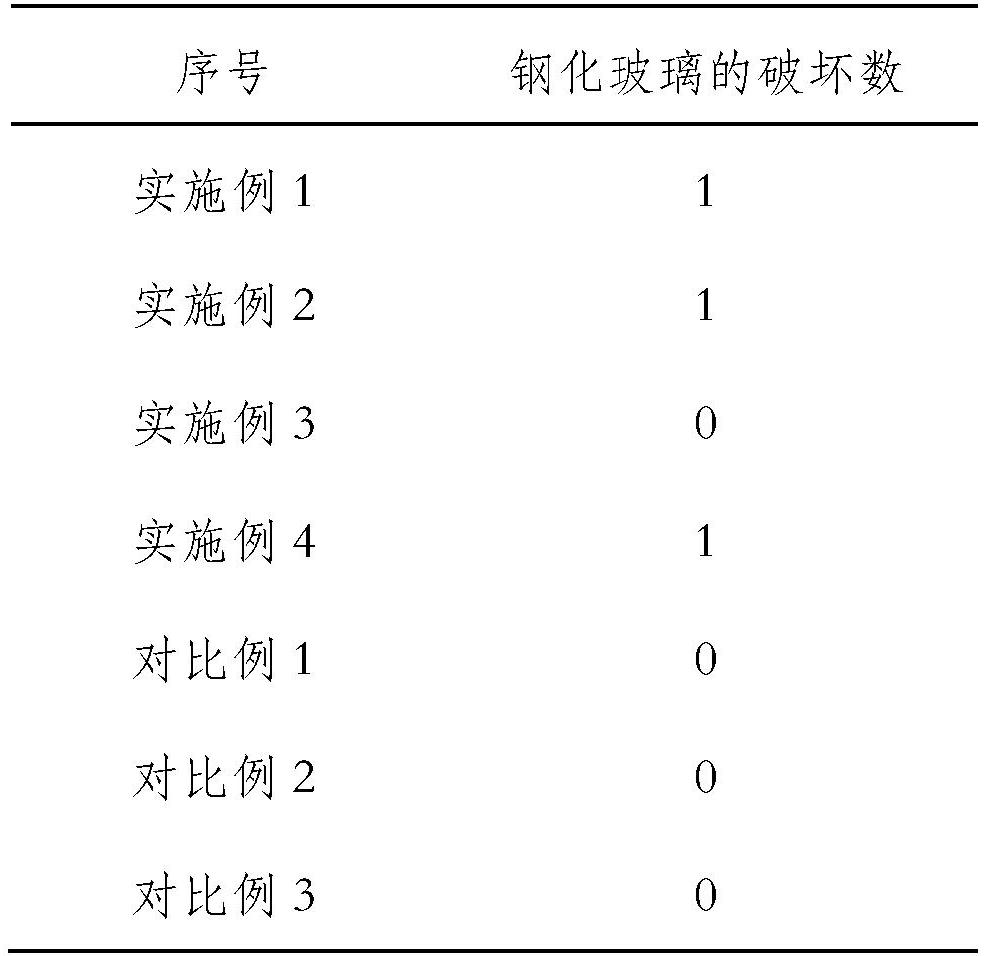

A kind of high-strength flame-retardant PVC car film and preparation method thereof

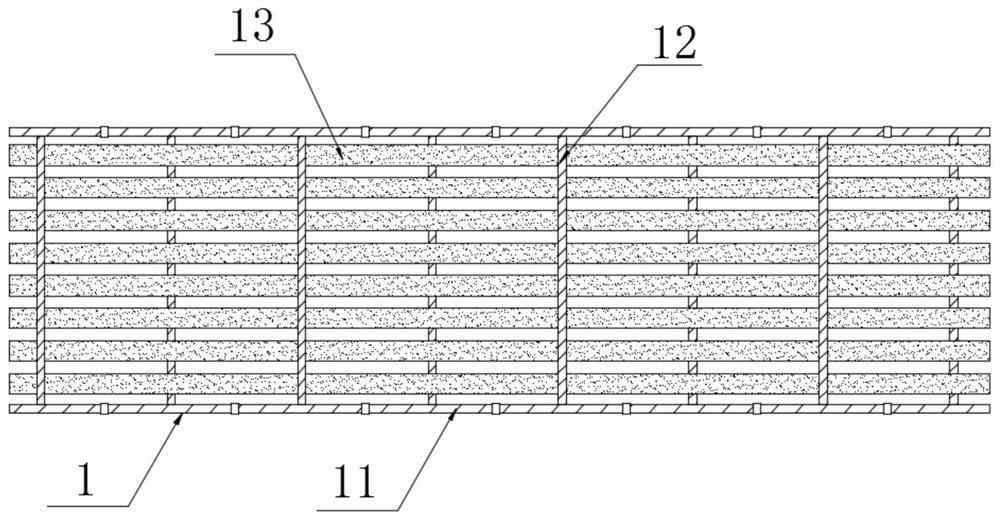

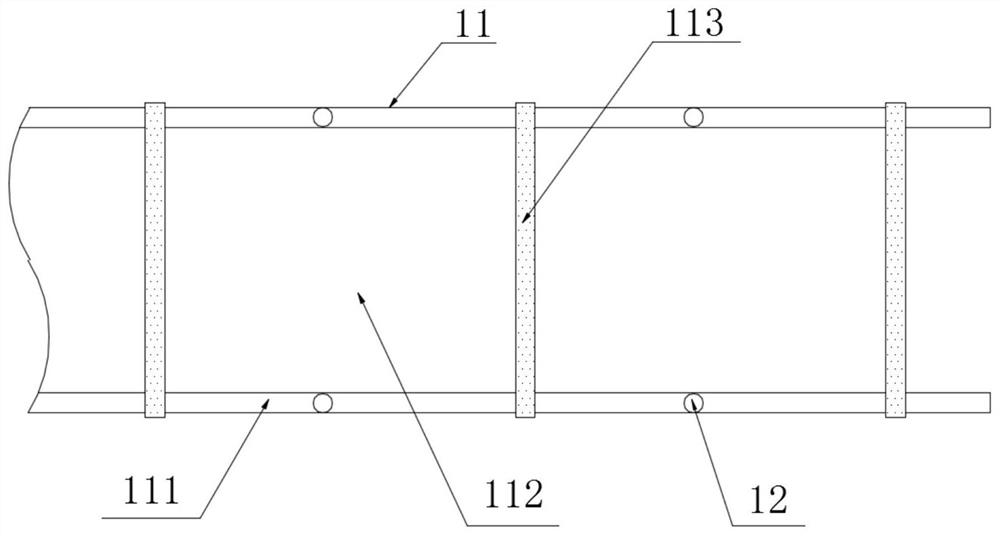

ActiveCN111421919BImprove warp tensile strengthIncrease weft tensile strengthWindowsWindscreensHigh intensityMechanical engineering

The invention discloses a high-strength flame-retardant PVC car film and a preparation method thereof, specifically relates to the field of car film production, including a reinforced base layer, a film layer and a flame-retardant layer, the film layer is provided with two layers, and the two layers of the film Layers are respectively located at the top and bottom of the reinforced base layer, and the flame retardant layer is located at the top of the upper film layer of the reinforced base layer; the reinforced base layer includes a forming frame, a No. 2 fixing line and a fixing film, and two groups of , the No. 2 fixed line is fixedly arranged between two sets of forming frames, and the fixed film is movably arranged between the two sets of forming frames. The forming frame includes No. 1 fixed line, cavity and connecting strip. The vertical direction of No. 1 fixed line corresponds to two groups, and the cavity is located between the two groups of No. 1 fixed line. The invention can improve the overall strength, and the forming frame formed as the central support layer has better tensile strength in the warp direction and weft direction, and can effectively prevent the film layer from leaving creases when it is bent.

Owner:佛山堃林装饰材料有限公司

A vacuum compression bag with antibacterial function and its production process

ActiveCN110254933BImprove antibacterial propertiesImprove corrosion resistanceNon-macromolecular adhesive additivesBio-packagingEscherichia coliAdhesive

The invention discloses a vacuum compression bag with an antibacterial function and a production process thereof, and relates to the field of packaging materials. The vacuum compression bag is formed by a high-temperature-resistant outer layer, a first antibacterial adhesive layer, an impact-resistant intermediate layer, a second antibacterial adhesive layer and a corrosion-resistant inner layer from outside to inside through hot pressing. The production process comprises the seven procedures of preparation of the high-temperature-resistant outer layer, preparation of the impact-resistant intermediate layer, preparation of the corrosion-resistant inner layer, preparation of an antibacterial adhesive, coating, hot-pressing and rewinding and hot melting. Compared with the prior art, the vacuum compression bag has excellent antibacterial property, corrosion resistance, impact resistance, breakdown resistance and high temperature resistance, and is suitable for vacuum storage of materials in a high-temperature corrosion environment, the impact strength reaches 36 MPa, the tensile strength reaches 52.4 MPa, the elongation at break reaches 106%, and the antibacterial rate to escherichia coli, staphylococcus aureus and candida albicans reaches 99.7%, 98.3% and 95.7% correspondingly.

Owner:YUYAO HUAYIN PACKING MATERIAL CO LTD

Fluorocarbon coating material special for aluminum profile and preparation method of fluorocarbon coating material

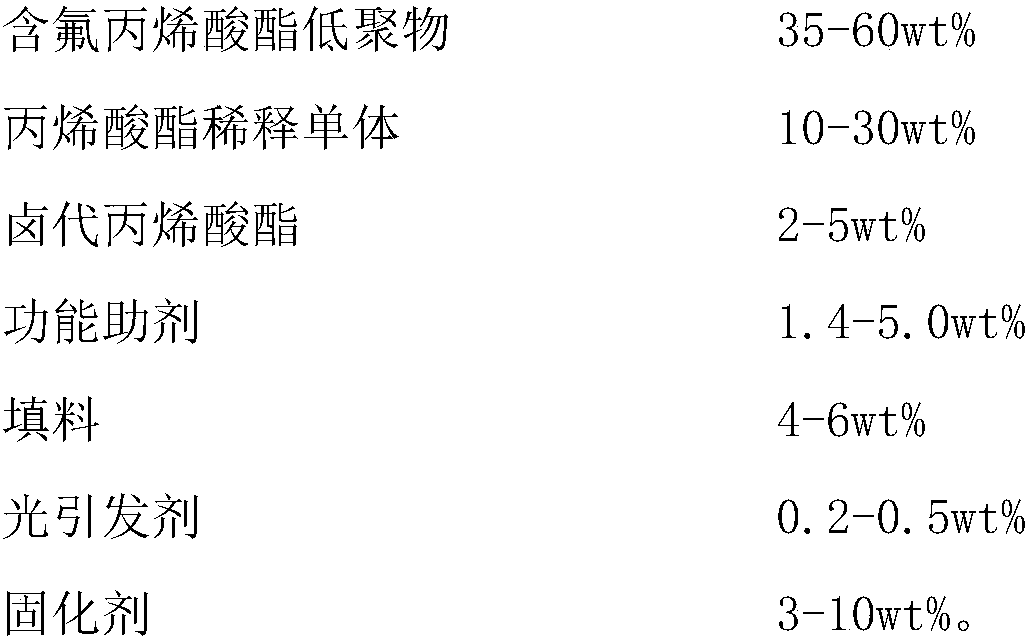

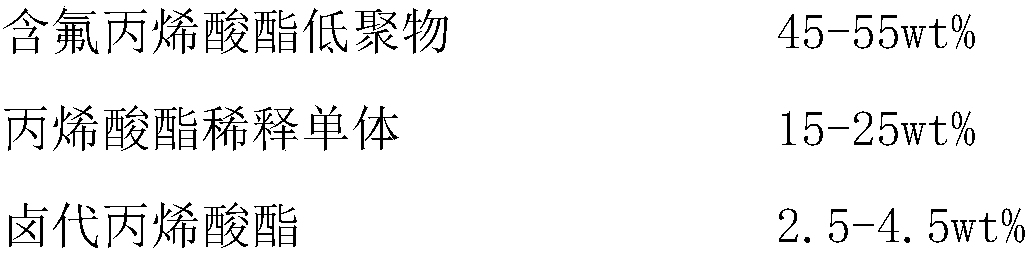

InactiveCN108359299AGuaranteed corrosion protectionGuaranteed scratch resistanceFireproof paintsAnti-corrosive paintsOligomerMetallurgy

The invention discloses a fluorocarbon coating material special for an aluminum profile and a preparation method of the fluorocarbon coating material. The fluorocarbon coating material is prepared from the following raw materials in percentage by weight: 35 to 60 weight percent of a fluorine-containing acrylate oligomer, 10 to 30 weight percent of acrylate diluted monomer, 2 to 5 weight percent ofhalogenated acrylate, 1.4 to 5.0 weight percent of functional additive, 4 to 6 weight percent of filler, 0.2 to 0.5 weight percent of photoinitiator and 3 to 10 weight percent of curing agent. The fluorocarbon coating material disclosed by the invention has very strong adhesion on the aluminum profile and has good weather fastness and good durability.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

A preparation method of low-smoke halogen-free polyolefin insulated and shielded cable

ActiveCN105679426BGood flexibilityImprove transmission qualityFlexible cablesFlexible conductorsShielded cablePolyolefin

Owner:JIANGSU TAIXIANG WIRE CABLE CO LTD

Halogen-free flame retardant polystyrene foam

InactiveCN109135087AGood high temperature resistance and flame retardant effectGood mechanical propertiesPolystyreneTemperature resistance

The invention relates to the field of foamed plastics, in particular to halogen-free flame retardant polystyrene foam, and solves the problem that the flame retardant function cannot be realized better due to poor high-low-temperature resistance of a foam material in the prior art. The halogen-free flame retardant polystyrene foam comprises components in parts by weight as follows: 100 parts of polystyrene masterbatch, 10-20 parts of organosilicone grafted polystyrene, 3-10 parts of silicone rubber micropowder, 20-30 parts of inorganic filler, 2-10 parts of n-pentane, 4-10 parts of halogen-free flame retardant, 0.15-1 part of a catalyst and 0.1-0.3 parts of dimethyl silicone oil. The halogen-free flame retardant polystyrene foam can be prepared in a conventional foaming mode. The halogen-free flame retardant polystyrene foam has the following advantages: (1), high-temperature resistance and flame-retardant performance are excellent; (2), the polystyrene foam is halogen-free and flame-retardant and cannot produce greasy dirt, harmful substances or substances polluting the environment in a burning process; (3), the mechanical property is excellent, and the impact resistance is strong.

Owner:德清舒华泡沫座椅有限公司

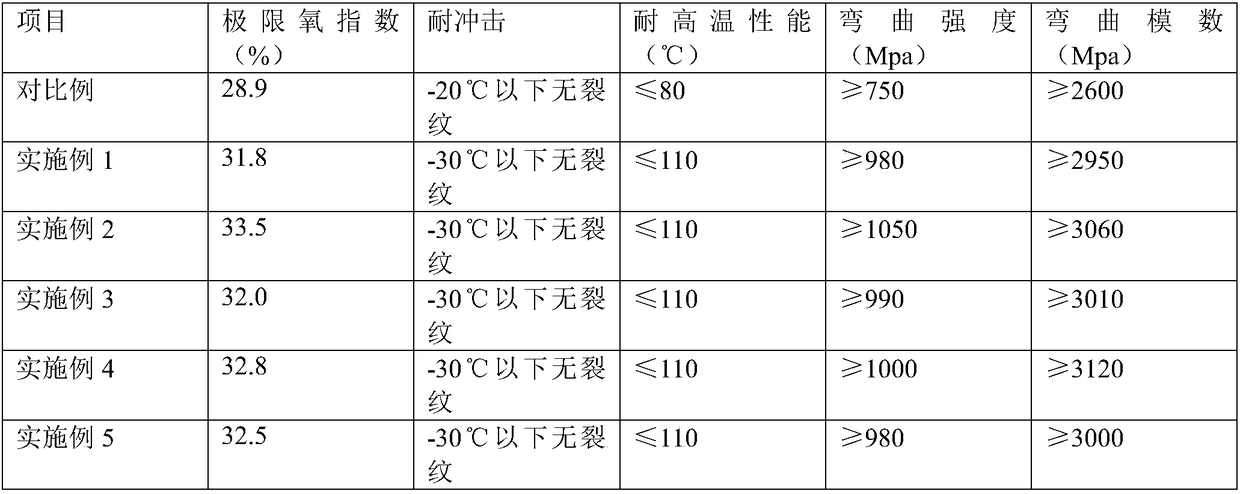

Bisphenol A SMC mold pressing resin composition and preparation method thereof

PendingCN112724608AReduced activityGood high temperature resistance and flame retardant effectFiberPolymer science

The invention belongs to the technical field of SMC mold pressing, and particularly relates to a bisphenol A type SMC mold pressing resin composition. The composition comprises a bisphenol A type polyester resin, a low-shrinkage additive, a curing agent, a demolding agent, a filler, fibers and a stripping agent, wherein the bisphenol A polyester resin is 18 to 23 parts by weight, the low-shrinkage additive comprises 5-8 parts of a low-shrinkage resin, the curing agent comprises 0.2 to 0.5 part of tert-butyl peroxybenzoate, the demolding agent is prepared from 0.5 to 1.5 parts of zinc stearate and 0.005 to 0.035 part of grease, the filler is 20-40 parts, the fibers are 25-55 parts, and the stripping agent comprises 0.1-0.3 part of magnesium oxide. According to the invention, the novel resin composition is formed by taking common hand lay-up bisphenol A resin as a matrix and adding other components, during SMC mould pressing, the novel resin composition is uniform in curing, smooth in demolding and regular in forming, and the product of the novel resin composition has the characteristics of strong acid and alkali corrosion resistance, high mechanical strength, high temperature resistance and flame retardance.

Owner:河北铭特环保设备科技有限公司

Preparation method of halogen-free flame-retarding polystyrene foam

InactiveCN109265851AGood high temperature resistance and flame retardant effectImprove mechanical propertiesPolystyreneMechanical property

The invention relates to the field of foam plastic and in particular relates to a preparation method of halogen-free flame-retarding polystyrene foam. The preparation method comprises the following steps: (1) preparing organic silicon grafted polystyrene: (1.1) preparing an organic silicon grafted polystyrene component A; (1.2) preparing an organic silicon grafted polystyrene component B; (1.3) compounding; (2) mixing materials; (3) pre-foaming; (4) curing to obtain the halogen-free flame-retarding polystyrene foam. By adopting the preparation method, the problems in the prior art that the high and low temperature resisting performance of a foam material is relatively low and a flame-retarding function cannot be released better are solved; the prepared halogen-free flame-retarding polystyrene foam has the following beneficial effects that (1) the high-temperature-resisting and flame-retarding performance is excellent; (2) a halogen-free flame-retarding function is realized, and oil stain harmful substances and environment pollution substances are not generated in a combustion process; (3) the mechanical properties are excellent and the anti-impact capability is strong.

Owner:德清舒华泡沫座椅有限公司

Mining full-length bolting-grouting agent and preparation method thereof

PendingCN114262205AReduce the impactImprove permeabilityAnchoring boltsPolymer adhesivePtru catalyst

The invention discloses a mining full-length bolting-grouting agent and a preparation method thereof. A group of materials comprise, by mass, 40-50 parts of polyisocyanate, 10-20 parts of a reactive diluent, 1-3 parts of a surfactant, 10-20 parts of anhydrous calcium chloride, 20-30 parts of aggregate and 5 parts of a suspending agent; the material group B comprises the following components in parts by mass: 40-50 parts of an inorganic silicate solution, 12-22 parts of small molecular alcohol, 0.1-0.5 part of polymer rubber powder, 0.1 part of a catalyst, 2 parts of a suspending agent and 30-40 parts of aggregate; the volume ratio of the component A material to the component B material is 1: (0.5-1). The problems that an existing anchoring agent is inconvenient to use for full-length anchoring of an anchor rod or an anchor cable, the anchoring force is reduced when the anchoring agent encounters water, and diffusivity is poor are solved.

Owner:于守东

A kind of high temperature resistant flame retardant computer cable and its preparation method

ActiveCN109285628BGood high temperature resistance and flame retardant effectImprove high temperature resistanceInsulated cablesInsulated conductorsElectrical conductorEngineering

Owner:安徽华电线缆股份有限公司

Popular searches

Improve liquidity Excellent low temperature curing Improve thermal stability Improve flame retardant performance Easy to process Low softening point Improve moisture resistance The preparation method is simple and controllable The control method is simple and convenient Suitable for industrial production

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com