Flameproof antistatic water-based coating and preparation method thereof

A water-based coating and antistatic technology, applied in fireproof coatings, conductive coatings, coatings, etc., can solve problems that affect human health, printers are prone to heat, and potential safety hazards, and achieve good antistatic effects, fast drying speed, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

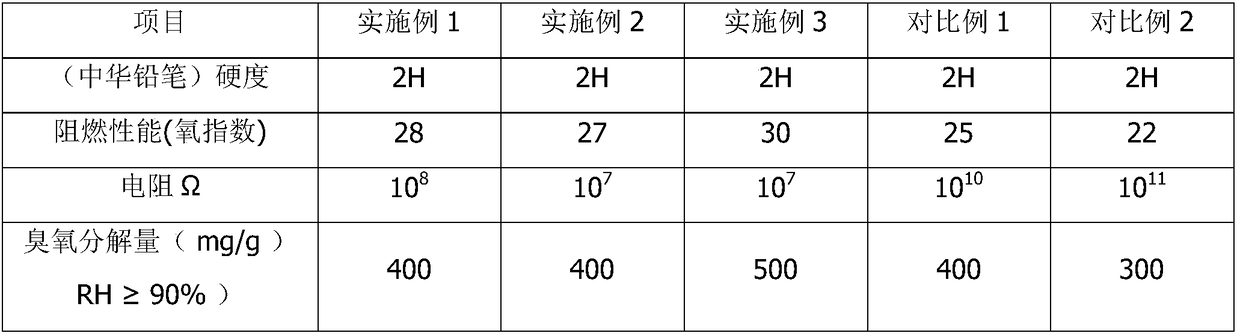

Examples

Embodiment 1

[0032] A fire-resistant and antistatic water-based paint, comprising the following components in parts by mass:

[0033] 10 parts of water-based hydroxyl acrylic emulsion F-862B;

[0034] 6 parts of Cymel325 amino resin;

[0035] 0.5 parts of diatomaceous earth;

[0036] 0.1 parts of silicone powder;

[0037] 2 parts aluminum hydroxide;

[0038] 3 parts of silica sol;

[0039] 3 parts of TM-960 flame retardant;

[0040] 0.5 parts of JL-WT antistatic agent;

[0041] 0.1 part of DOZ-710 ozone decomposition catalyst;

[0042] 0.1 part of dimethylethanolamine;

[0043] 12 parts of alcohol ester;

[0044] 0.3 parts of BYK190 dispersant;

[0045] 0.3 parts of Tego-4100 substrate wetting agent;

[0046] 0.5 parts of 0620 thickener;

[0047] 5 parts of deionized water,

[0048] Wherein, the particle size of aluminum hydroxide is 100 nm.

[0049] The preparation method of described refractory antistatic water-based paint, comprises the steps:

[0050] (1) take each compon...

Embodiment 2

[0055] A fire-resistant and antistatic water-based paint, comprising the following components in parts by mass:

[0056] 30 parts of water-based hydroxyl acrylic emulsion F-862B;

[0057] 20 parts of Cymel325 amino resin;

[0058] 2 parts diatomaceous earth;

[0059] 1 part silicone powder;

[0060] 4 parts of aluminum hydroxide;

[0061]5 parts of silica sol;

[0062] 8 parts of TM-960 flame retardant;

[0063] JL-WT antistatic agent 2 parts;

[0064] 0.5 parts of DOZ-710 ozone decomposition catalyst;

[0065] 0.2 parts of dimethylethanolamine;

[0066] Alcohol ester twelve 5 parts;

[0067] 0.5 parts of BYK190 dispersant;

[0068] 0.5 parts of Tego-4100 substrate wetting agent;

[0069] 0620 thickener 1.0 parts;

[0070] 10 parts of deionized water.

[0071] The preparation method of described refractory antistatic water-based paint, comprises the steps:

[0072] (1) take each component according to the described raw material ratio;

[0073] (2) 40% of the deio...

Embodiment 3

[0077] A fire-resistant and antistatic water-based paint, comprising the following components in parts by mass:

[0078] 20 parts of water-based hydroxyl acrylic emulsion F-862B;

[0079] 10 parts of Cymel325 amino resin;

[0080] 1 part diatomaceous earth;

[0081] 0.7 parts of silicone powder;

[0082] 3 parts of aluminum hydroxide;

[0083] 4 parts of silica sol;

[0084] 5 parts of TM-960 flame retardant;

[0085] 1.5 parts of JL-WT antistatic agent;

[0086] 0.3 parts of DOZ-710 ozone decomposition catalyst;

[0087] 0.15 parts of dimethylethanolamine;

[0088] Alcohol ester twelve 3 parts;

[0089] 0.4 parts of BYK190 dispersant;

[0090] 0.4 parts of Tego-4100 substrate wetting agent;

[0091] 0.8 parts of 0620 thickener;

[0092] 8 parts of deionized water.

[0093] The preparation method of described refractory antistatic water-based paint, comprises the steps:

[0094] (1) take each component according to the described raw material ratio;

[0095] (2) 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com