A vacuum compression bag with antibacterial function and its production process

A vacuum compression bag and function technology, which is applied in the directions of bags, laminations, sacks, etc., can solve the problems of reduced impact resistance of the middle structure, reduced protection of the items in the bag, and difficulty in ensuring antibacterial and antifungal effects. The effect of uniform thickness and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

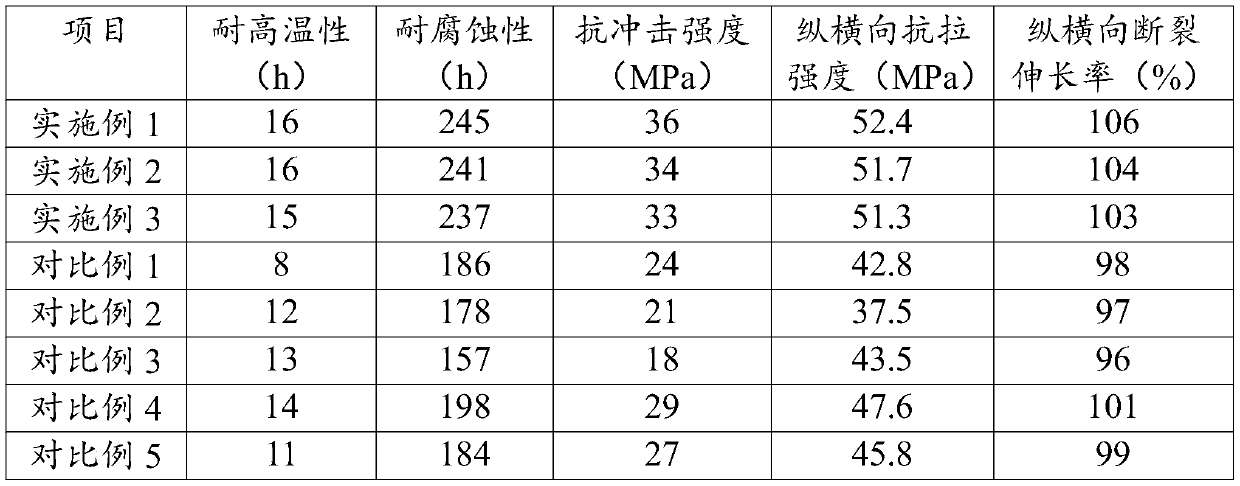

Embodiment 1

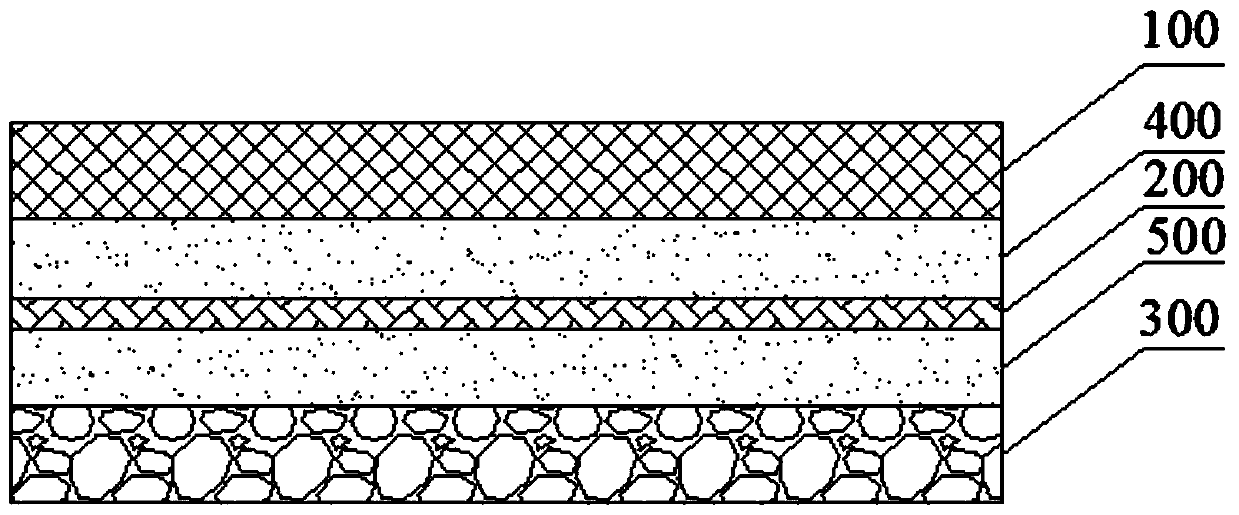

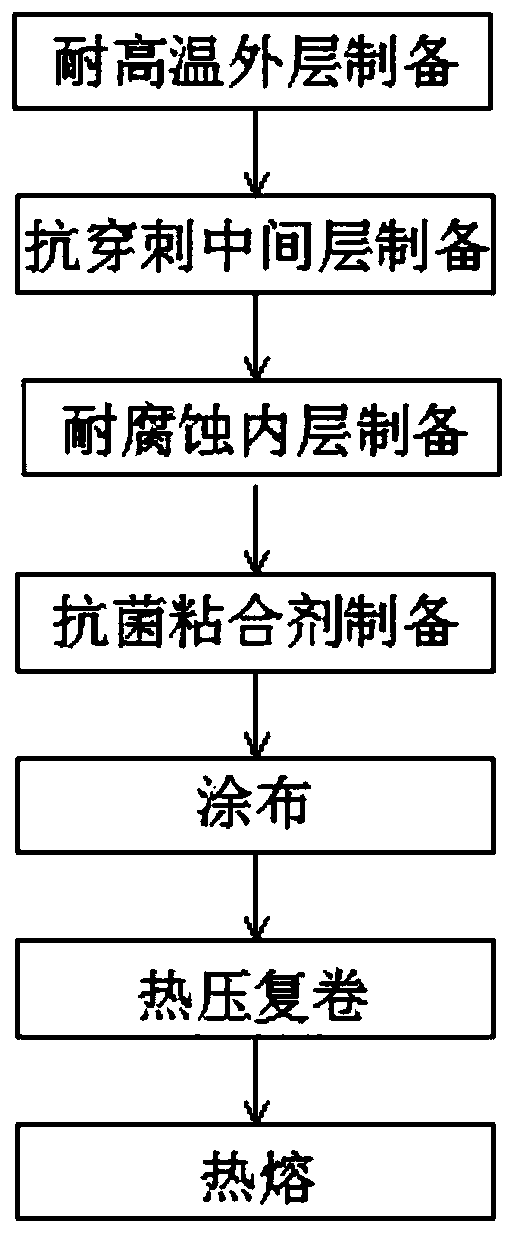

[0043] refer to Figure 1-2 As shown, the present embodiment provides a vacuum compression bag with antibacterial function, including a heat-resistant outer layer 100 formed by hot pressing, an impact-resistant middle layer 200, a corrosion-resistant inner layer 300, a high-temperature resistant outer layer 100 and an impact-resistant middle layer. A first antibacterial adhesive layer 400 is provided between the layers 200 , and a second antibacterial adhesive layer 500 is provided between the corrosion-resistant inner layer 300 and the impact-resistant middle layer 200 .

[0044] Among them, the high-temperature-resistant outer layer is prepared from the following components by weight: 110 parts of epoxy resin, 13 parts of hexamethylenetetramine, 8 parts of 3-(2,3-glycidoxy)propyltrimethoxysilane 2.8 parts, 2.8 parts of polycrystalline mullite fiber, and 1.2 parts of nano-titanium dioxide; the polycrystalline mullite fiber contains 30-40wt% of aluminum oxide and 60-70wt% of s...

Embodiment 2

[0059] refer to Figure 1-2 As shown, the present embodiment provides a vacuum compression bag with antibacterial function, including a heat-resistant outer layer 100 formed by hot pressing, an impact-resistant middle layer 200, a corrosion-resistant inner layer 300, a high-temperature resistant outer layer 100 and an impact-resistant middle layer. A first antibacterial adhesive layer 400 is provided between the layers 200 , and a second antibacterial adhesive layer 500 is provided between the corrosion-resistant inner layer 300 and the impact-resistant middle layer 200 .

[0060] Among them, the high-temperature-resistant outer layer is prepared from the following components by weight: 110 parts of epoxy resin, 12 parts of hexamethylenetetramine, 9 parts of 3-(2,3-glycidoxy)propyltrimethoxysilane 2.9 parts, 2.9 parts of polycrystalline mullite fiber, and 1.5 parts of nano-titanium dioxide; the polycrystalline mullite fiber contains 30-40wt% of aluminum oxide and 60-70wt% of s...

Embodiment 3

[0075] refer to Figure 1-2 As shown, the present embodiment provides a vacuum compression bag with antibacterial function, including a heat-resistant outer layer 100 formed by hot pressing, an impact-resistant middle layer 200, a corrosion-resistant inner layer 300, a high-temperature resistant outer layer 100 and an impact-resistant middle layer. A first antibacterial adhesive layer 400 is provided between the layers 200 , and a second antibacterial adhesive layer 500 is provided between the corrosion-resistant inner layer 300 and the impact-resistant middle layer 200 .

[0076] Among them, the high-temperature-resistant outer layer is prepared from the following components by weight: 108 parts of epoxy resin, 15 parts of hexamethylenetetramine, 10 parts of 3-(2,3-glycidoxy)propyltrimethoxysilane 3.3 parts, 3.3 parts of polycrystalline mullite fiber, 1.7 parts of nano titanium dioxide; the polycrystalline mullite fiber contains 30-40wt% aluminum oxide and 60-70wt% silicon di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com