High-strength heat-resistant lead-acid battery plastic shell and preparation method thereof

A lead-acid battery, high-strength technology, applied in the field of high-strength heat-resistant lead-acid battery plastic case and its preparation, can solve the problems of low strength of the lead-acid battery case, unable to cope with impact force, unable to withstand high temperature, etc., to achieve good durability High-temperature flame-retardant performance, enhanced reinforcement ability, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

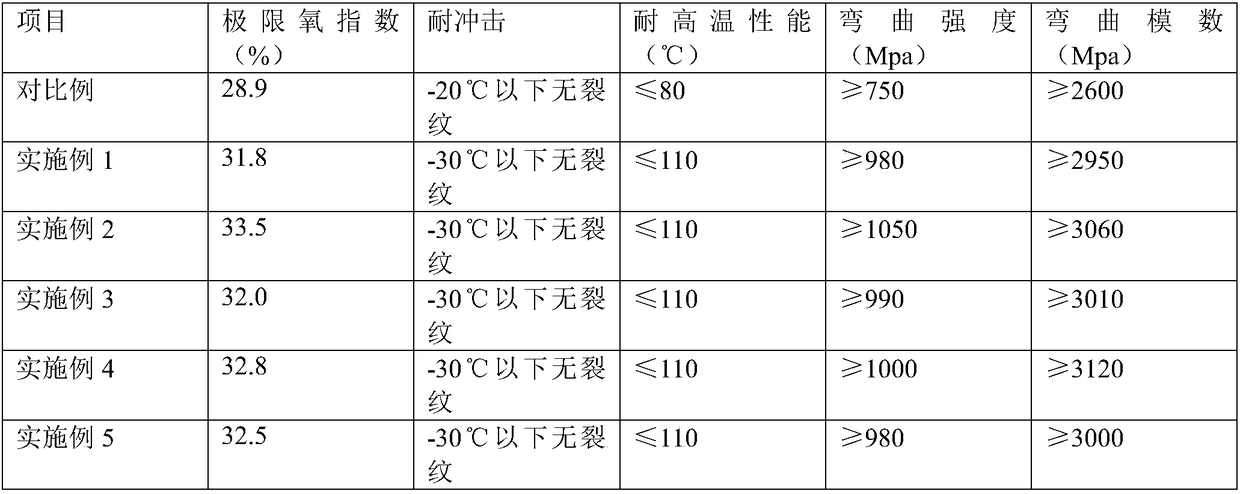

Examples

Embodiment 1

[0034] A high-strength heat-resistant lead-acid battery plastic case, the battery plastic case includes the following components in parts by weight: 100 parts of ABS resin, 10 parts of surface-treated glass fiber, 18 parts of organosilicon modified sepiolite 1 part, 10 parts of simethicone oil, 1 part of zinc stearate and 0.5 part of antioxidant BHT.

[0035] The glass fibers are surface-treated, and the treatment steps are as follows: place the glass fibers in a glass corrosion solution, corrode them at 30°C for 30 seconds, and then wash them with clean water to obtain surface-corroded glass fibers, wherein the glass fibers The formula of the corrosion solution is as follows: 1000 parts of distilled water, 0.5 parts of boric acid, 3 parts of humic acid, 0.25 parts of sodium fluoride and 2 parts of polyvinyl alcohol; the mass ratio of KH-550 and ethanol after surface corrosion is mixed at 1:20 The solution is 10-30 minutes, and then taken out and solidified at 60° C. for 2 hou...

Embodiment 2

[0046] A high-strength heat-resistant lead-acid battery plastic case, the battery plastic case includes the following components in parts by weight: 100 parts of ABS resin, 25 parts of surface-treated glass fiber, 30 parts of organosilicon modified sepiolite parts, 20 parts of simethicone oil, 5 parts of zinc stearate and 3 parts of antioxidant 1010.

[0047] The glass fibers are surface-treated, and the treatment steps are as follows: put the glass fibers in a glass corrosion solution, corrode them at 45°C for 120 seconds, and then wash them with water to obtain surface-corroded glass fibers, wherein the glass fibers The formula of the corrosion solution is as follows: 1000 parts of distilled water, 5 parts of boric acid, 10 parts of humic acid, 1.5 parts of sodium fluoride, and 6 parts of polyvinyl alcohol; the mass ratio of KH560 and ethanol after surface corrosion is impregnated with a mixed solution of 1:20 for 30 minutes, and then taken out and cured at 80° C. for 4 hour...

Embodiment 3

[0058] A high-strength heat-resistant lead-acid battery plastic case, said battery plastic case includes the following components in parts by weight: 100 parts of ABS resin, 15 parts of surface-treated glass fiber, 18 parts of organosilicon modified sepiolite part, 10 parts of simethicone oil, 1 part of zinc stearate and 0.5 part of antioxidant 168.

[0059] The glass fibers are surface-treated, and the treatment steps are as follows: put the glass fibers in a glass corrosion solution, corrode them at 45°C for 60 seconds, and wash them with clean water to obtain surface-corroded glass fibers, wherein the glass fibers The formula of the corrosion solution is as follows: 1000 parts of distilled water, 2 parts of boric acid, 5 parts of humic acid, 1 part of sodium fluoride and 5 parts of polyvinyl alcohol; the mass ratio of KH-570 and ethanol after surface corrosion is 1:20. The solution was taken out for 15 minutes, and then taken out and solidified at 75° C. for 3 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com