Low-smoke halogen-free polyolefin insulated and shielded cable and preparation method thereof

A technology of insulation shielding and polyolefin, applied in the field of low-smoke halogen-free polyolefin insulation shielding cable and its preparation, can solve the problems of high temperature resistance, large cable consumption, toxic substances, etc., and achieve good tensile bending resistance, insulation Good shielding performance, the effect of shielding electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

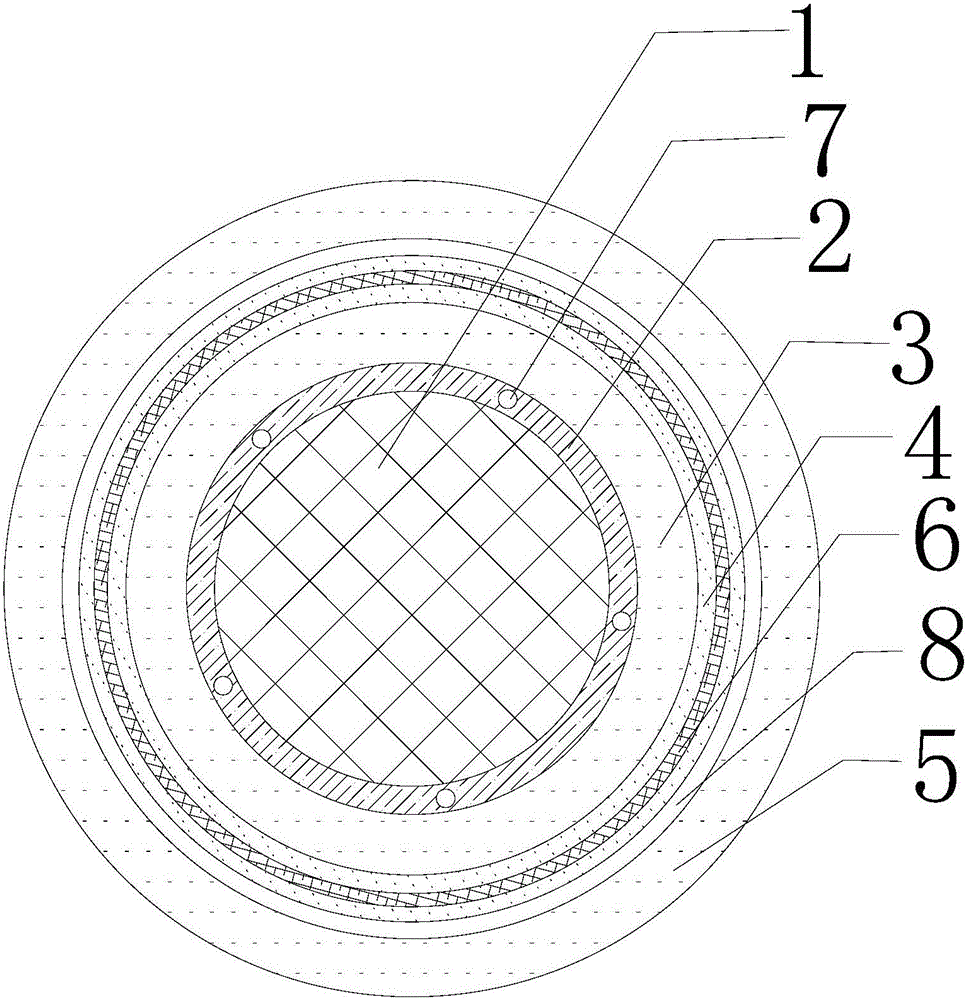

[0019] refer to figure 1 , a low-smoke halogen-free polyolefin insulated and shielded cable of the present invention, comprising a conductive core 1, an isolation guide layer 2, an insulating sheath layer 3, a shielding sheath layer 4, and an outer protective sheath layer 5. The low-smoke The preparation method of the halogen-free polyolefin insulated and shielded cable comprises the following steps:

[0020] Step 1: Wire drawing process, using multiple copper wires with a diameter of 1.0mm to draw a 0.3mm single copper wire;

[0021] Step 2: Beaming process, use DCSS-550 beaming machine to cut 20mm 2 The stranded structure is 624 0.3mm copper wire monofilaments stranded, the stranded pitch is controlled at about 30mm, the stranded direction is leftward, the stranded wire diameter is controlled to 2.15±0.05mm, and 6 strands are stranded to make a conductive wire share;

[0022] Step 3: re-twisting process, using JB-500 / 6 tubular stranding machine to twist six conductive wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com