Halogen-free flame retardant polystyrene foam

A polystyrene foam, polystyrene technology, applied in the field of foam plastics, can solve the problems of poor high and low temperature resistance, inability to have good flame retardant function, etc., and achieve excellent high temperature resistance and flame retardant performance, strong impact resistance, mechanical Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

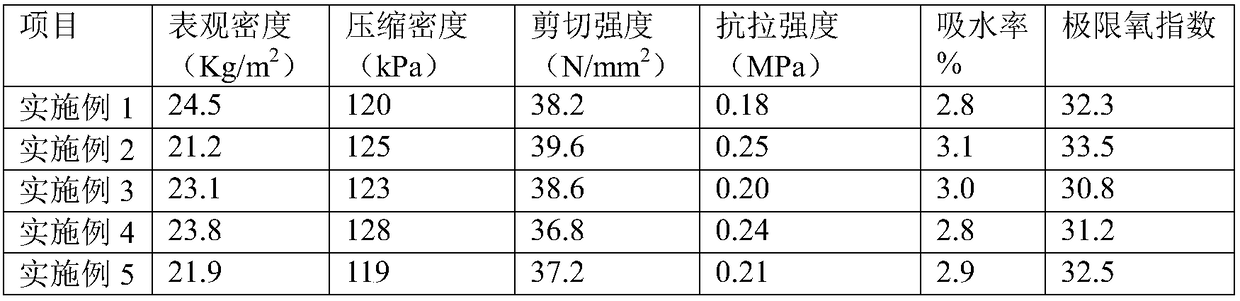

Examples

Embodiment 1

[0028] A halogen-free flame-retardant polystyrene foam, said halogen-free flame-retardant polystyrene foam comprises the following components in parts by weight: 100 parts of polystyrene masterbatch, 10 parts of silicone grafted polystyrene, 3 parts of methylphenyl silicone rubber micropowder with a phenyl content of 10%, 20 parts of fumed silica, 2 parts of n-pentane, 4 parts of aluminum hydroxide, 0.15 parts of zinc octoate and 0.1 part of simethicone.

[0029] The organosilicon-grafted polystyrene is prepared by mixing the A component containing organosilicon and the B component containing an organotin catalyst, wherein the mass ratio between the A component and the B component is 1: 1.

[0030] The preparation method of the A component is as follows: take 100 parts of polystyrene masterbatch in parts by weight and place it in an open mill, add 0.5 parts of vinyl-containing alkoxysilane and 0.02 parts of peroxide Diisopropylbenzene, after blending uniformly at 125°C, extru...

Embodiment 2

[0033] A halogen-free flame-retardant polystyrene foam, said halogen-free flame-retardant polystyrene foam comprises the following components in parts by weight: 100 parts of polystyrene masterbatch, 20 parts of silicone grafted polystyrene, 3-10 parts of methylphenyl silicone rubber micropowder with a phenyl content of 25%, 30 parts of nano calcium carbonate, 10 parts of n-pentane, 10 parts of magnesium hydroxide, 1 part of magnesium octanoate and 0.3 parts of dimethyl silicone oil.

[0034] The organosilicon-grafted polystyrene is prepared by mixing the A component containing organosilicon and the B component containing an organotin catalyst, wherein the mass ratio between the A component and the B component is 1: 3.

[0035] The preparation method of the A component is as follows: take 100 parts of polystyrene masterbatch in parts by weight and place it in an open mill, add 3 parts of vinyl-containing alkoxysilane and 0.25 parts of peroxide Diisopropylbenzene, after blendi...

Embodiment 3

[0038]A halogen-free flame-retardant polystyrene foam, said halogen-free flame-retardant polystyrene foam comprises the following components in parts by weight: 100 parts of polystyrene masterbatch, 15 parts of silicone grafted polystyrene, 5 parts of methylphenyl silicone rubber micropowder with a phenyl content of 20%, 25 parts of a mixture of nano-calcium carbonate and diatomaceous earth with a mass ratio of 1:1, 3-8 parts of n-pentane, magnesium hydroxide and triethyl phosphate 5 parts of a mixture with a mass ratio of 3:5, 0.15 parts of calcium naphthenate and 0.1 part of simethicone.

[0039] The organosilicon-grafted polystyrene is prepared by mixing the A component containing organosilicon and the B component containing an organotin catalyst, wherein the mass ratio between the A component and the B component is 1: 2.

[0040] The preparation method of the A component is as follows: take 100 parts of polystyrene masterbatch in parts by weight and place it in an open mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com