Preparation method of halogen-free flame-retarding polystyrene foam

A polystyrene foam, polystyrene technology, applied in the field of foam plastics, can solve the problems of inability to have good flame retardant function, poor high and low temperature resistance, etc., and achieve excellent high temperature resistance and flame retardant performance, strong impact resistance, mechanical Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

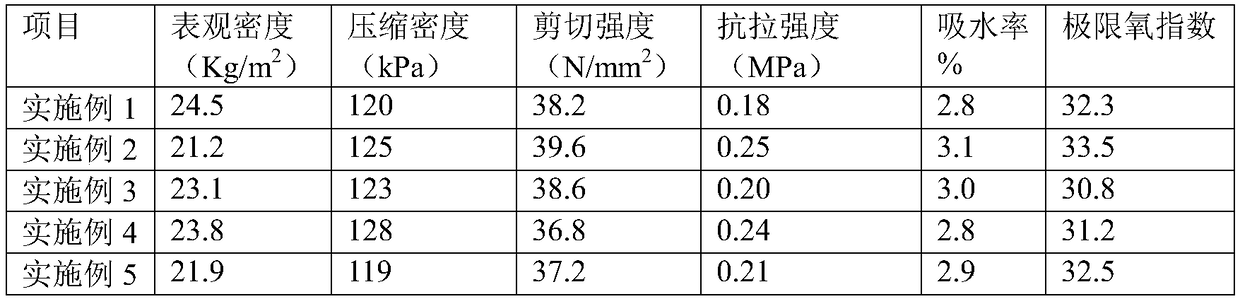

Examples

Embodiment 1

[0034] A kind of preparation method of halogen-free flame-retardant polystyrene foam, described preparation method comprises the following steps:

[0035] (1) Preparation of silicone grafted polystyrene:

[0036] (1.1) Preparation of silicone-grafted polystyrene A component: take 100 parts of polystyrene masterbatch in parts by weight and place it in an open mixer, add 0.5 parts of vinyl-containing alkoxysilane and 0.02 parts of dicumyl peroxide, blended uniformly at 125°C, extruded and granulated at 140°C to obtain component A containing silicone, the vinyl-containing alkoxysilane is methyl Vinyldimethoxysilane;

[0037] (1.2) Preparation of silicone-grafted polystyrene B component: take 100 parts of polystyrene masterbatch according to parts by weight and place it in an open mixer, add 1 part of dibutyltin dilaurate and 0.5 part of Chromium acetylacetonate, after uniform blending at 125°C, extruded and granulated at 140°C to obtain component B containing organotin catalyst...

Embodiment 2

[0043] A kind of preparation method of halogen-free flame-retardant polystyrene foam, described preparation method comprises the following steps:

[0044](1) Preparation of silicone grafted polystyrene:

[0045] (1.1) Preparation of silicone-grafted polystyrene A component: take 100 parts of polystyrene masterbatch in parts by weight and place it in an open mill, add 3 parts of vinyl-containing alkoxysilane and 0.25 parts of dicumyl peroxide, blended uniformly at 140°C, extruded and granulated at 160°C to obtain component A containing silicone, the vinyl-containing alkoxysilane is ethylene Trimethoxysilane;

[0046] (1.2) Preparation of silicone-grafted polystyrene component B: take 100 parts of polystyrene masterbatch in parts by weight and place it in an open mixer, add 3 parts of dibutyltin dilaurate and 1.5 parts of Chromium acetylacetonate, after uniform blending at 140°C, extruded and granulated at 160°C to obtain component B containing organotin catalyst;

[0047] (1...

Embodiment 3

[0052] A kind of preparation method of halogen-free flame-retardant polystyrene foam, described preparation method comprises the following steps:

[0053] (1) Preparation of silicone grafted polystyrene:

[0054] (1.1) Preparation of silicone-grafted polystyrene component A: take 100 parts of polystyrene masterbatch in parts by weight and place it in an open mixer, add 1 part of vinyl-containing alkoxysilane and 0.15 parts of dicumyl peroxide, blended uniformly at 135°C, extruded and granulated at 145°C to obtain component A containing silicone, the vinyl-containing alkoxysilane is benzene Vinyldimethoxysilane;

[0055] (1.2) Preparation of silicone-grafted polystyrene B component: take 100 parts of polystyrene masterbatch in parts by weight and place it in an open mixer, add 2 parts of dibutyltin dilaurate and 1 part of Chromium acetylacetonate, after uniform blending at 135°C, extruded and granulated at 145°C to obtain component B containing organotin catalyst;

[0056] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com