A kind of high temperature resistant flame retardant computer cable and its preparation method

A technology for computer cables and high temperature resistance, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of low structural strength, poor performance of high temperature resistance and flame retardancy, and short service life, so as to improve structural strength and service life, Increased toughness and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

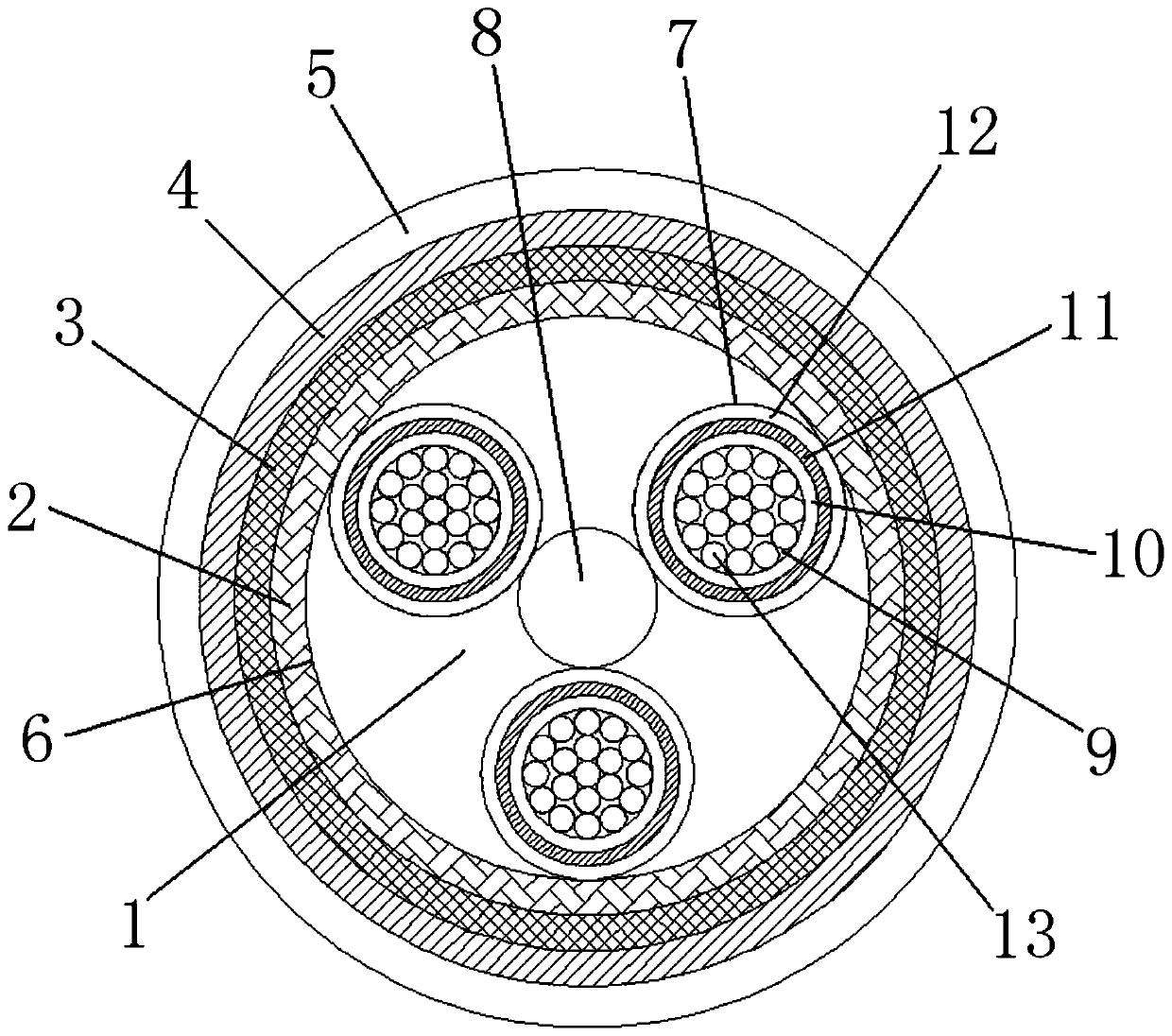

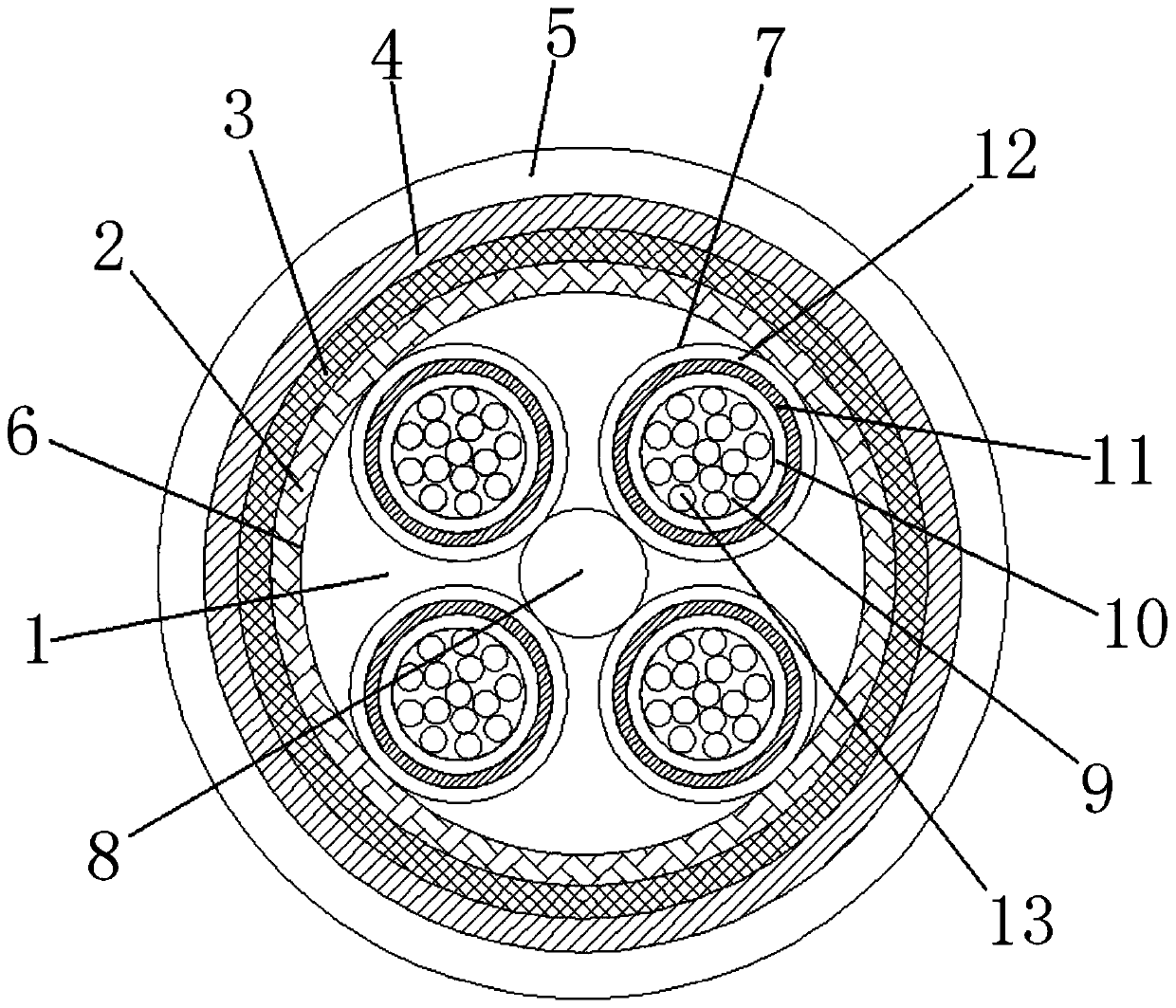

Image

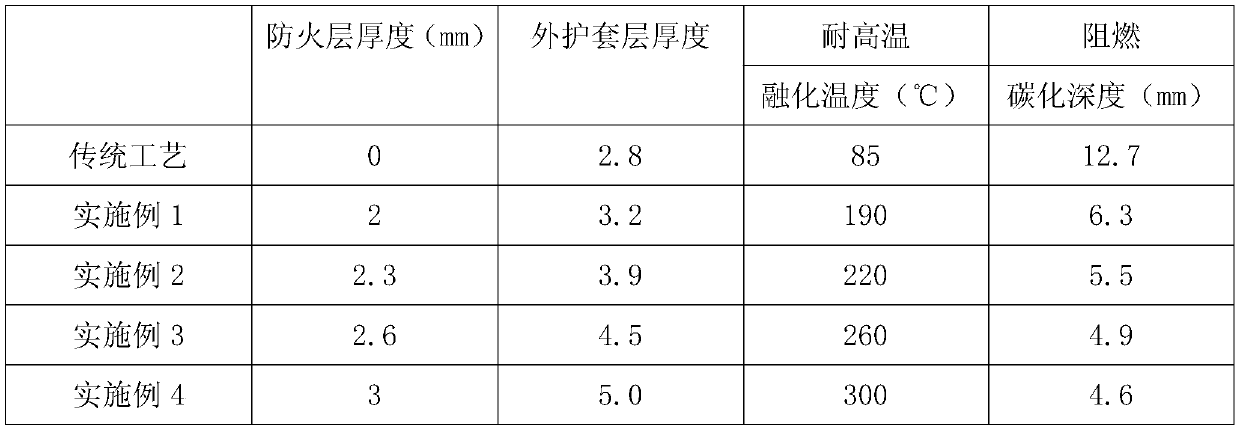

Examples

Embodiment 1

[0049] Embodiment 1 discloses a preparation method of a high temperature resistant flame retardant computer cable, comprising the following preparation steps:

[0050] Step a: use a wire drawing machine to stretch the copper rod to obtain a copper wire, and then anneal the copper wire to obtain a conductor. The steps specifically include:

[0051] First put the copper wire into the heating furnace and heat it to 560-670°C and keep it warm for 2-3 hours;

[0052] Then stop heating the heating furnace, let the copper wire cool down to 300-350°C with the heating furnace;

[0053] Then the copper wire is taken out from the heating furnace, cooled naturally to normal temperature to obtain a conductor;

[0054] Step b: twisting the conductors of 20 to each other to obtain a guide core;

[0055] Step c: Use an extruder to extrude a layer of insulating layer on the outside of the guide core, then wrap a layer of shielding layer on the outside of the insulating layer, and finally wr...

Embodiment 2

[0068] Embodiment 2 discloses a preparation method of a high temperature resistant flame retardant computer cable, comprising the following preparation steps:

[0069] Step a: use a wire drawing machine to stretch the copper rod to obtain a copper wire, and then anneal the copper wire to obtain a conductor. The steps specifically include:

[0070] First put the copper wire into the heating furnace and heat it to 560-670°C and keep it warm for 2-3 hours;

[0071] Then stop heating the heating furnace, let the copper wire cool down to 300-350°C with the heating furnace;

[0072] Then the copper wire is taken out from the heating furnace, cooled naturally to normal temperature to obtain a conductor;

[0073] Step b: Twisting 20 conductors with each other to obtain a guide core;

[0074] Step c: Use an extruder to extrude a layer of insulating layer on the outside of the guide core, then wrap a layer of shielding layer on the outside of the insulating layer, and finally wrap a ...

Embodiment 3

[0087] Embodiment 3 discloses a preparation method of a high temperature resistant flame retardant computer cable, comprising the following preparation steps:

[0088] Step a: use a wire drawing machine to stretch the copper rod to obtain a copper wire, and then anneal the copper wire to obtain a conductor. The steps specifically include:

[0089] First put the copper wire into the heating furnace and heat it to 560-670°C and keep it warm for 2-3 hours;

[0090] Then stop heating the heating furnace, let the copper wire cool down to 300-350°C with the heating furnace;

[0091] Then the copper wire is taken out from the heating furnace, cooled naturally to normal temperature to obtain a conductor;

[0092] Step b: Twisting 30 conductors with each other to obtain a guide core;

[0093] Step c: Use an extruder to extrude a layer of insulating layer on the outside of the guide core, then wrap a layer of shielding layer on the outside of the insulating layer, and finally wrap a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com