Carbon fiber paper with conductive network enhanced by carbon black and preparation method of carbon fiber paper

A carbon fiber paper and conductive network technology, applied in the field of papermaking, can solve the problem that carbon fiber paper cannot meet the heating rate and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of preparation method of the carbon fiber paper of the present invention strengthens conductive network with carbon black, comprises the following steps:

[0036] Step 1, prepare a slurry with uniform fiber dispersion through a standard fiber disintegrator; the slurry with uniform fiber dispersion is obtained as follows;

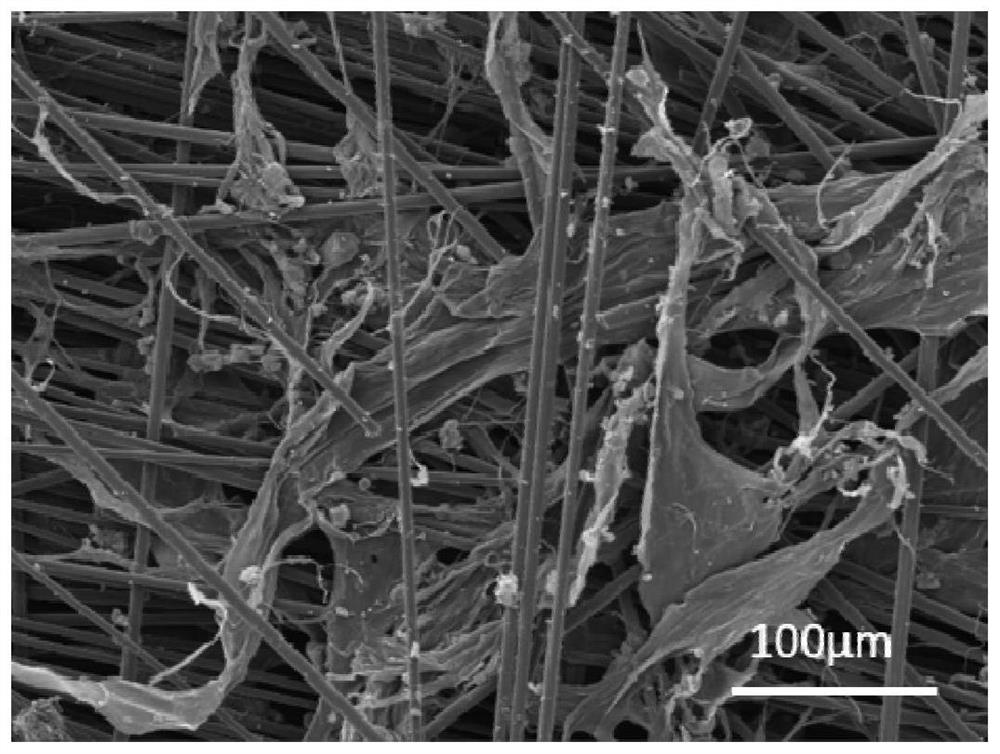

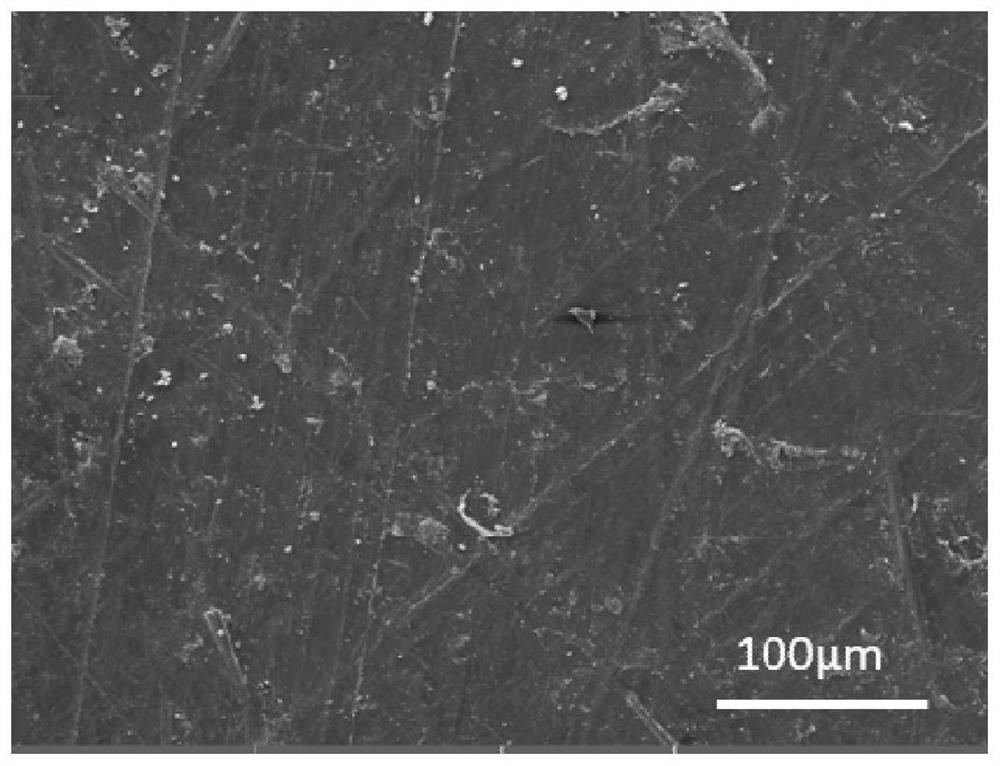

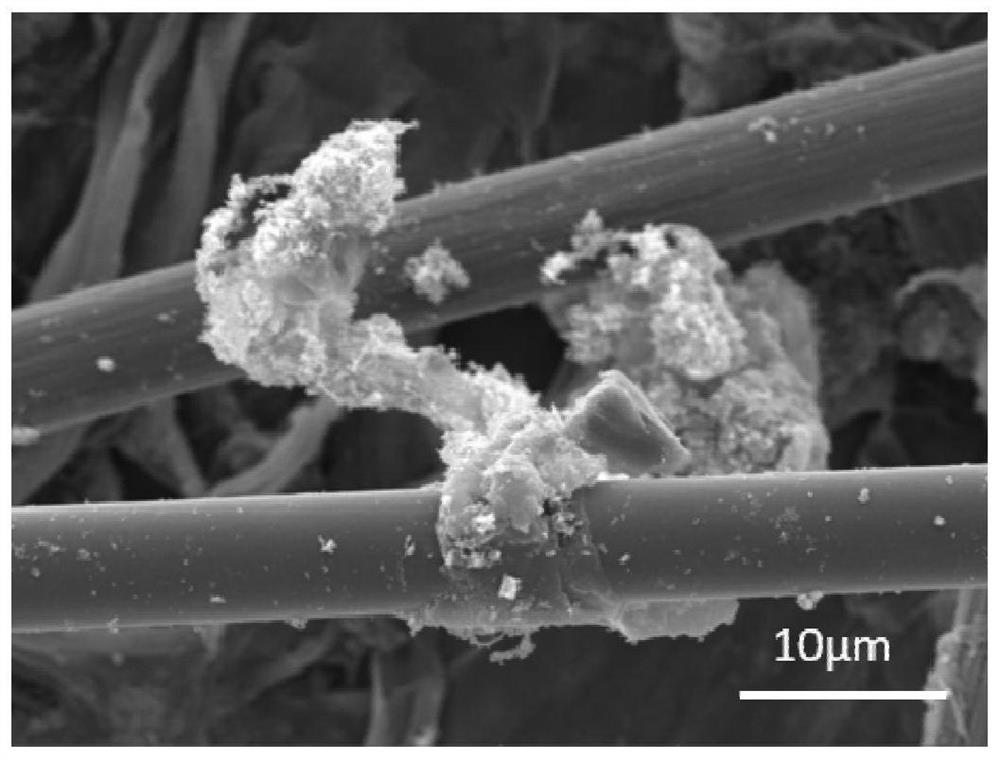

[0037] Step 1a, mix solid A and solvent A according to the ratio of 1.884g: 20ml to obtain solution A, solid A is a mixture of carbon fiber, aramid fibrid, and carbon black, and solvent A is a dispersant polyethylene oxide (PEO) aqueous solution, Made by adding 0.5g of PEO to 100ml of water. The mass fraction of each component of solid A is: carbon fiber: 40%-80%; aramid fibrid: 10%-50%; carbon black: 10%. The length of the carbon fiber is 6mm, and the diameter is 7 μm; the length of the aramid fibrids is 4mm;

[0038] Step 1b, add solution A to deionized water according to the ratio of 20ml:1000ml to obtain mixed system A;

[0039] Step 1c,...

Embodiment 1

[0049] Step 1, prepare a slurry with uniform fiber dispersion through a standard fiber disintegrator; the slurry with uniform fiber dispersion is obtained as follows;

[0050] Step 1a, mix 1.884g of solid A and 20ml of solvent A to obtain solution A, solid A is a mixture of carbon fiber, aramid fibrid, and carbon black, and solvent A is a PEO aqueous solution with a concentration of 0.005g / mL. Wherein the mass fraction of each component of the solid A is: carbon fiber: 80%; aramid fibrid: 10%; carbon black: 10%. The carbon fiber has a length of 6mm and a diameter of 7 μm; the length of the aramid precipitated fiber is 4mm;

[0051] Step 1b, adding solution A to 1000ml deionized water to obtain mixed system A;

[0052] Step 1c, use a standard fiber deflatter to stir the mixed system A, the stirring speed is 300r / min, and the stirring time is 10min.

[0053] Step 2, pouring the slurry with evenly dispersed fibers into a sheet forming machine for sheet forming to obtain a carbo...

Embodiment 2

[0061] Step 1, prepare a slurry with uniform fiber dispersion through a standard fiber disintegrator; the slurry with uniform fiber dispersion is obtained as follows;

[0062] Step 1a, mix solid A and solvent A in a ratio of 1.884g solid A and 20ml to obtain solution A, solid A is a mixture of carbon fiber, aramid fibrid, and carbon black, and solvent A is PEO with a concentration of 0.005g / mL aqueous solution. Wherein the mass fraction of each component of the solid A is: carbon fiber: 60%; aramid fibrid fiber: 30%; carbon black: 10%. The carbon fiber has a length of 6mm and a diameter of 7 μm; the length of the aramid precipitated fiber is 4mm;

[0063] Step 1b, adding solution A to 1000ml deionized water to obtain mixed system A;

[0064] In step 1c, use a standard fiber deflaker to stir the mixed system A, the stirring speed is 300r / min, and the stirring time is 8min.

[0065] Step 2, pouring the slurry with evenly dispersed fibers into a sheet forming machine for sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com