Plant nanocellulose-based flexible electromagnetic shielding film as well as preparation method and application thereof

A technology of nanocellulose and electromagnetic shielding film, which is applied in the field of plant nanocellulose-based flexible electromagnetic shielding film and its preparation, can solve the problems of uneven dispersion of graphene, non-environmental protection of reducing agents, etc., and achieve good conductivity and good antibacterial effect, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

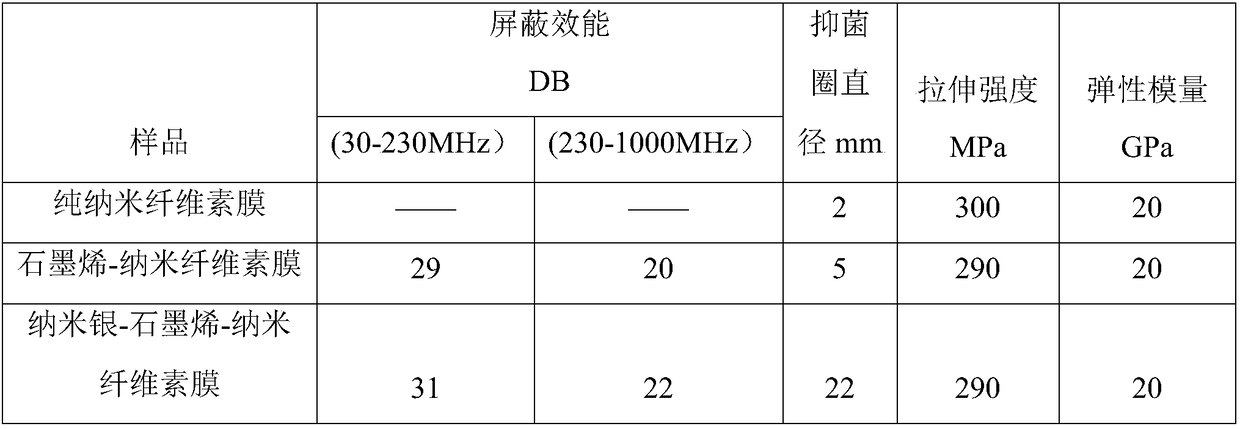

Embodiment 1

[0041] (1) Adopt Hummers method to prepare graphene oxide, after drying, dispersing, be dissolved in deionized water to obtain 400mL of 2.0mg / mL graphene oxide dispersion liquid; Wherein the prepared graphene oxide monolayer rate is 70%~80% , the sheet diameter is 100nm~200nm, and the single layer thickness is 0.8nm~1.0nm;

[0042](2) Add 10mg of nano-silver (the particle size of nano-silver is 25-50nm) into 25mL of the above-mentioned graphene oxide dispersion and stir for 1h (300-350r / min) to obtain a uniformly dispersed nano-silver-graphene oxide dispersion liquid;

[0043] (3) adding all the nanometer silver-graphene oxide dispersion liquid that step (2) obtains to 1000g mass fraction is in the nanocellulose dispersion liquid of 0.1% and stirs 2~3h (300~350r / min), obtains the evenly dispersed Nano silver-graphene oxide-nanocellulose dispersion;

[0044] (4) Vibrate all the dispersion liquid obtained in step (3) for 40min under 400w ultrasonic conditions, and form a film ...

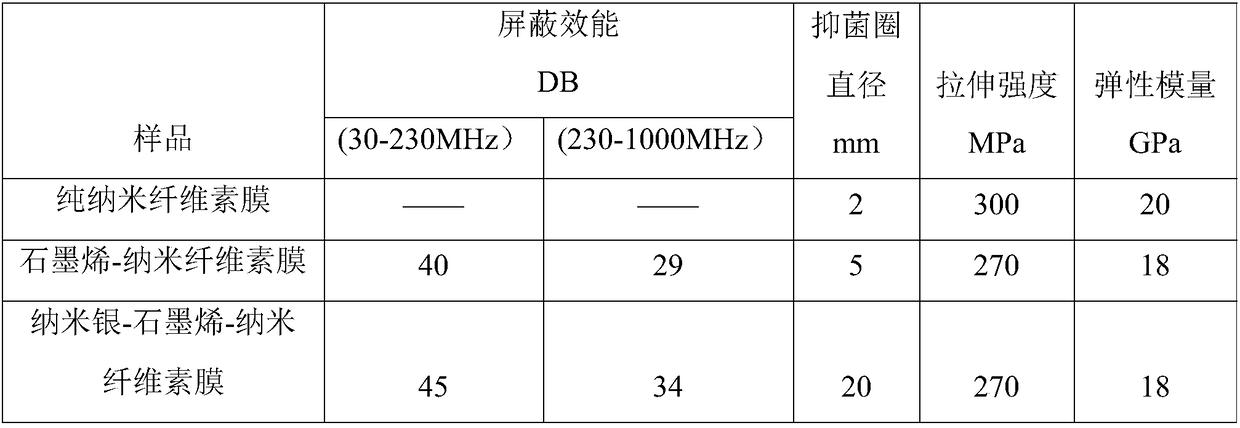

Embodiment 2

[0051] (1) Adopt Hummers method to prepare graphene oxide, after drying, dispersing, be dissolved in deionized water to obtain 400mL of 1.0mg / mL graphene oxide dispersion liquid; Wherein the prepared graphene oxide monolayer rate is 70%~80% , the sheet diameter is 100nm~200nm, and the single layer thickness is 0.8nm~1.0nm;

[0052] (2) Add 1 mg nano silver (the particle size of nano silver is 25-50 nm) to 100 mL of the 1.0 mg / mL graphene oxide dispersion prepared above and stir for 1 h (300-350 r / min) to obtain a uniformly dispersed Nano silver-graphene oxide dispersion;

[0053] (3) Add all the nano-silver-graphene oxide dispersion into 100g mass fraction of 1% nano-cellulose dispersion and stir for 2-3h (300-350r / min) to obtain uniformly dispersed nano-silver-graphene oxide - nanocellulose dispersion;

[0054] (4) Vibrate all the dispersion liquid obtained in step (3) for 60min under 400w ultrasonic conditions, and form a film through vacuum suction filtration, take out th...

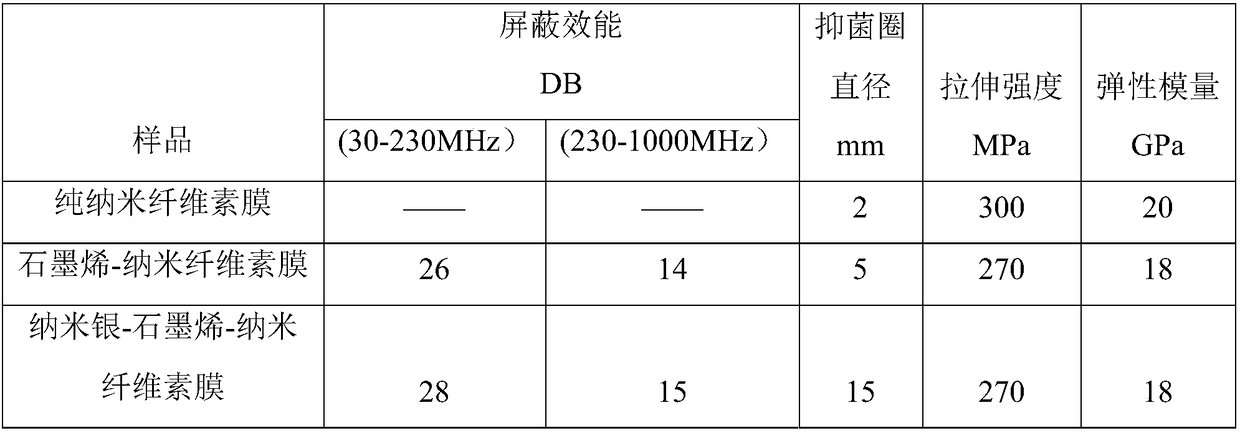

Embodiment 3

[0061] (1) Adopt Hummers method to prepare graphene oxide, after drying, dispersing, be dissolved in deionized water to obtain 400mL of 1.0mg / mL graphene oxide dispersion liquid; Wherein the prepared graphene oxide monolayer rate is 50%~60% , the sheet diameter is 100nm~1μm, and the single layer thickness is 0.8nm~1.2nm;

[0062] (2) Add 1mg of nano-silver (the particle size of nano-silver is 50-100nm) into 100mL of the above graphene oxide dispersion and stir for 1h (300-350r / min) to obtain a uniformly dispersed nano-silver-graphene oxide dispersion liquid;

[0063] (3) Add all nano-silver-graphene oxide dispersion liquid to 100g mass fraction of 1% nano-cellulose dispersion liquid and stir for 2-3h (300-350r / min) to obtain uniformly dispersed nano-silver-graphene oxide ene-nanocellulose dispersion;

[0064] (4) Vibrate all the dispersion liquid obtained in step (3) for 60min under 400w ultrasonic conditions, and form a film through vacuum suction filtration, take out the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com