Inorganic/polymer composite plugging agent for ultrahigh-temperature-resistant oil-based drilling fluid, and preparation method and application thereof

An oil-based drilling fluid and composite material technology, which is applied in the field of polymer composite plugging agents, can solve problems such as poor adaptability, insufficient adsorption performance, and poor temperature resistance, so as to overcome poor temperature resistance, increase deformability, and enhance The effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

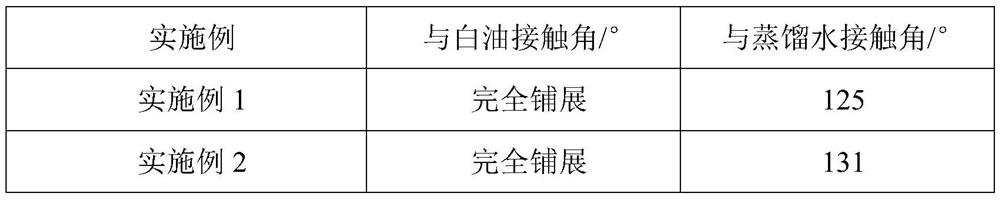

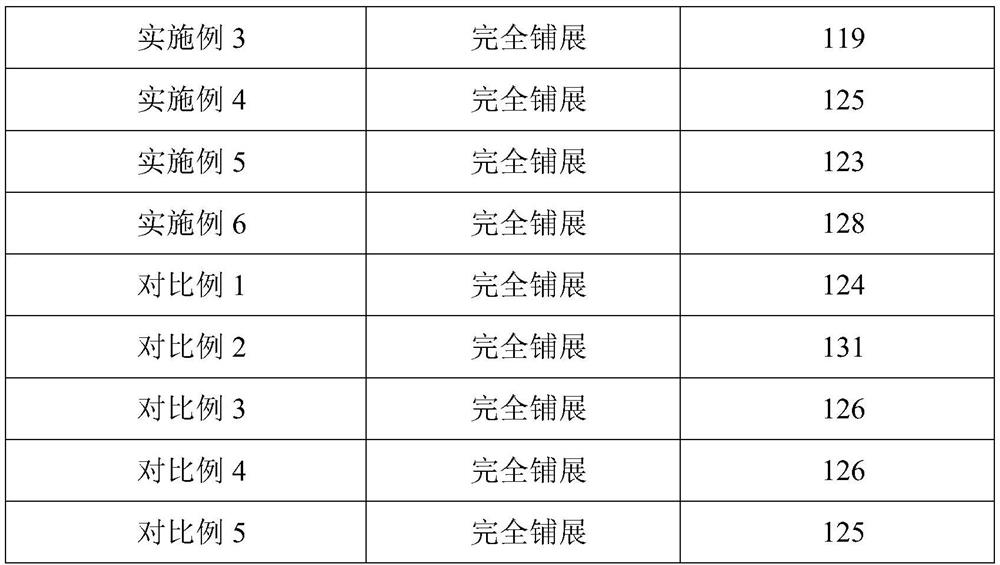

Examples

Embodiment 1

[0043] A method for preparing an inorganic / polymer composite plugging agent for ultra-high temperature oil-based drilling fluid, comprising the following steps:

[0044] (1) Heat 100g of quartz powder to 60°C, add 2g of ammonia water, stir for 30min at a stirring rate of 500r / min, and dry the resulting product at 120°C for 5h to obtain dried quartz powder; Heat the powder to 120°C, then add 0.5g of silane coupling agent KH570, and react for 60min at a stirring rate of 500r / min and a temperature of 120°C to obtain silane coupling agent-modified quartz powder;

[0045] (2) Mix 18g of styrene, 5g of methyl methacrylate, 5g of butyl acrylate, 1g of vinyltrichlorosilane, and 2g of polyetheramine D230 to obtain mixture A;

[0046] (3) Dissolve 2g of emulsifier MS-1 in 70mL of deionized water, stir evenly to obtain an emulsifier solution; then add 7g of silane coupling agent-modified quartz powder prepared in step (1) to the emulsifier solution and step (2) The obtained mixture A wa...

Embodiment 2

[0049] A method for preparing an inorganic / polymer composite plugging agent for ultra-high temperature oil-based drilling fluid, comprising the following steps:

[0050] (1) Heat 100g of dried quartz powder to 60°C, add 2g of ammonia water, stir for 30min at a stirring rate of 500r / min, and dry the resulting product at 120°C for 5h to obtain dried quartz powder; The quartz powder was heated to 120°C, and then 0.5g of silane coupling agent KH560 was added, and the stirring rate was 500r / min, and the temperature was 120°C for 60 minutes to obtain silane coupling agent modified quartz powder;

[0051] (2) Mix 18g of styrene, 5g of methyl methacrylate, 5g of lauryl acrylate, 1g of vinyltrichlorosilane, and 2g of polyetheramine D230 to obtain mixture A;

[0052] (3) Dissolve 2g of emulsifier MS-1 in 70mL of deionized water, stir evenly to obtain an emulsifier solution; then add 7g of silane coupling agent-modified quartz powder prepared in step (1) to the emulsifier solution and st...

Embodiment 3

[0055] A method for preparing an inorganic / polymer composite plugging agent for ultra-high temperature oil-based drilling fluid, comprising the following steps:

[0056] (1) Heat 100g of dried quartz powder to 60°C, add 2g of ammonia water, stir for 30min at a stirring rate of 500r / min, and dry the resulting product at 120°C for 5h to obtain dried quartz powder; The quartz powder was heated to 120°C, and then 0.5g of silane coupling agent KH570 was added, and the stirring rate was 500r / min, and the temperature was 120°C for 60 minutes to obtain silane coupling agent modified quartz powder;

[0057] (2) Mix 20g of styrene, 3g of methyl methacrylate, 5g of butyl acrylate, 1g of vinyltriethoxysilane, and 1g of polyetheramine D230 to obtain mixture A;

[0058] (3) Dissolve 2g of emulsifier MS-1 in 70mL of deionized water, stir evenly to obtain an emulsifier solution; then add 5g of silane coupling agent modified quartz powder prepared in step (1) to the emulsifier solution and ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com