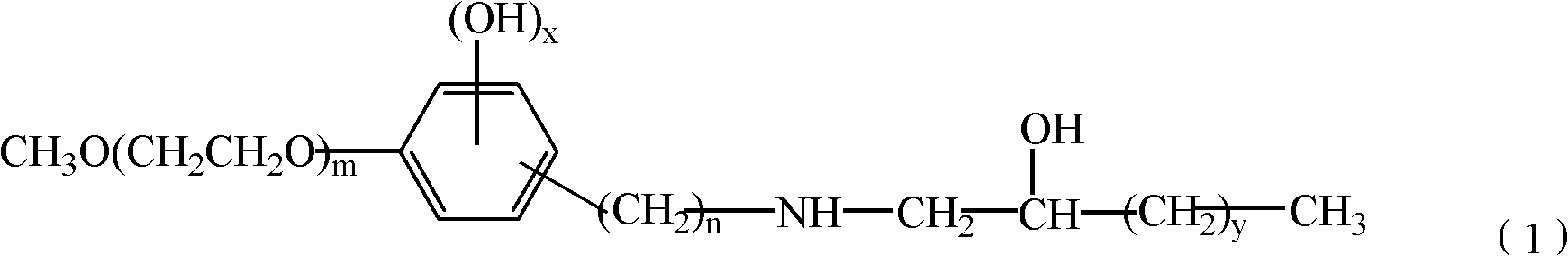

Non-ionic active epoxy emulsifier preparation method and waterborne epoxy resin preparation method

A water-based epoxy resin and epoxy emulsifier technology, applied in the chemical industry, can solve the problems of reducing the water absorption rate of the polymer film, poor hydrolysis resistance, poor water resistance and solvent resistance of the polymer film, etc., to achieve stable structure and performance. Stable, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

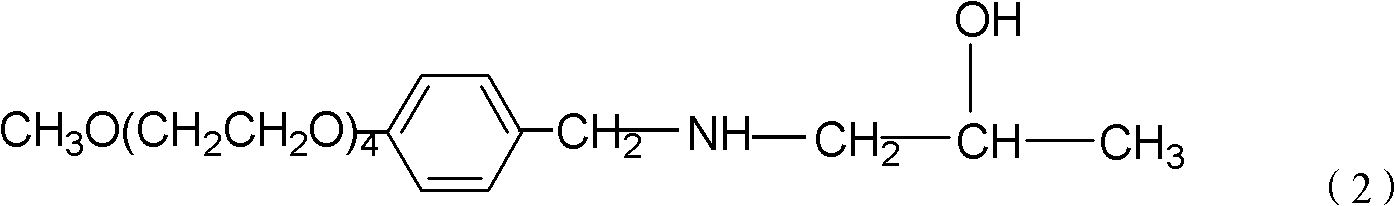

[0022] (1) Add 0.1mol α-methoxy-ω-alkyl polyetheramine (MPE1) and 0.1mol propylene oxide (PO) to the reaction kettle, and stir the reaction for 12 hours at room temperature to obtain propylene oxide-capped α-methoxy-ω-N-isopropanol alkyl polyether (referred to as PO-MPE1). The molecular formula of the adduct is (2):

[0023]

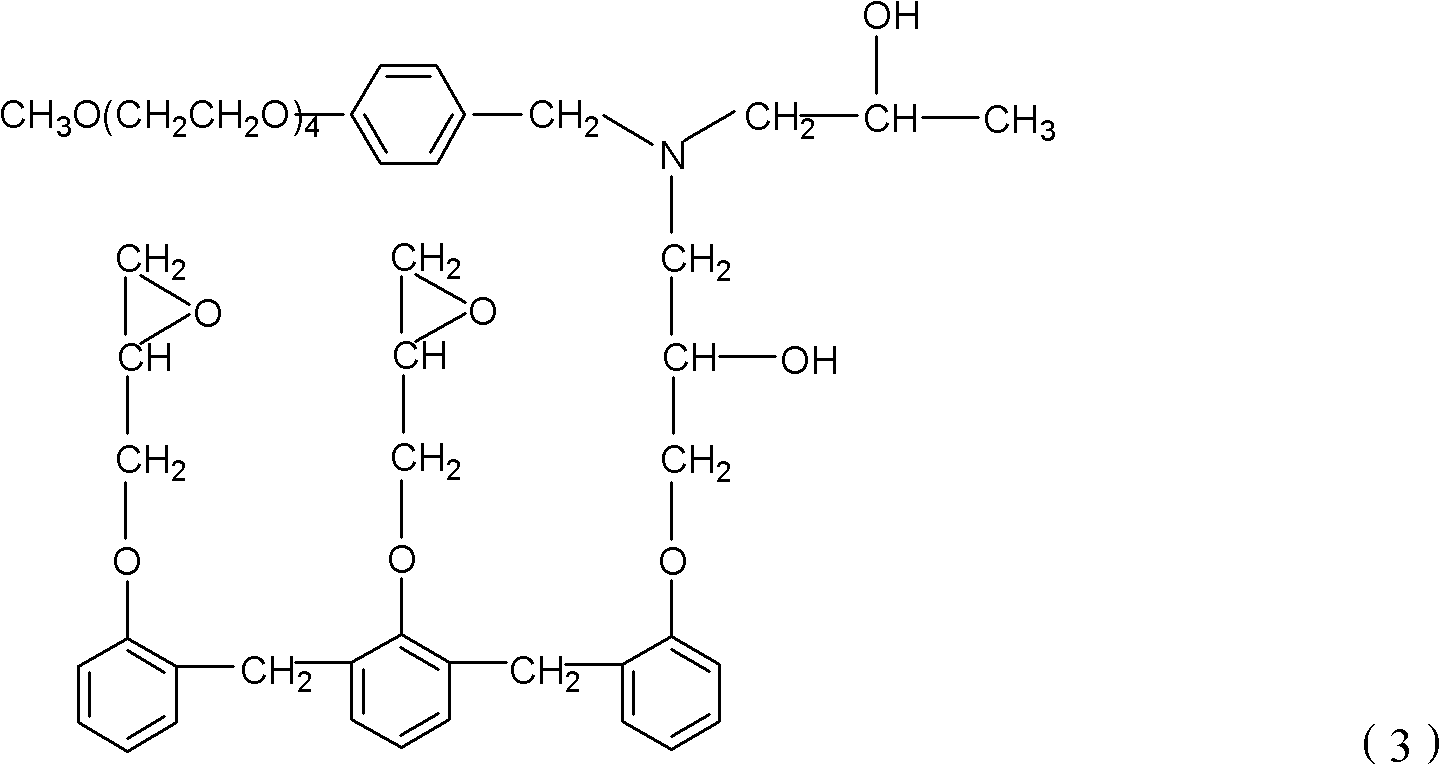

[0024] (2) Then add 0.1mol novolac epoxy resin and appropriate amount of tetrahydrofuran, stir to form a homogeneous solution, and react at 50°C for 6 hours. After the reaction, the solvent is distilled off under reduced pressure to obtain a nonionic active emulsifier, referred to as MPEF1. The molecular formula of the adduct is (3):

[0025]

[0026] (3) The emulsifier can be directly added with deionized water to prepare an epoxy resin aqueous emulsion (abbreviated as MPEF1 aqueous emulsion) with a solid content of 50%.

Embodiment 2

[0028] (1) Add 1mol α-methoxy-ω-alkyl polyetheramine (MPE2) and 1mol propylene oxide (PO) into the reactor, and stir for 18 hours at room temperature to obtain propylene oxide-capped α- Methoxy-ω-N-isopropanol alkyl polyether (referred to as PO-MPE2). The molecular formula of the adduct is (4):

[0029]

[0030] (2) Then add 1mol novolak epoxy resin and appropriate amount of tetrahydrofuran, stir to form a homogeneous solution, and react at 40°C for 16 hours. After the reaction, the solvent is distilled off under reduced pressure to obtain a nonionic active emulsifier, MPEF2 for short. The molecular formula of the adduct is (5):

[0031]

[0032] (3) The emulsifier and epoxy resin E44 are added in a dispersing kettle in a molar ratio of 1: 10 and mixed evenly, and then deionized water is added dropwise to prepare a 60% epoxy resin aqueous emulsion (abbreviated as MPEF2 / E44 water emulsion).

Embodiment 3

[0034] (1) Add 1mol α-methoxy-ω-alkyl polyetheramine (MPE3) and 1mol propylene oxide (PO) into the reaction kettle, and stir the reaction for 24 hours at room temperature to obtain propylene oxide-terminated α- Methoxy-ω-N-isopropanol alkyl polyether (referred to as PO-MPE3). The molecular formula of this adduct is (6):

[0035]

[0036] (2) Then add 1mol novolac epoxy resin and appropriate amount of acetone, stir to form a homogeneous solution, and react at 30°C for 12 hours. After the reaction, the solvent acetone is distilled off under reduced pressure to obtain a nonionic active emulsifier, referred to as MPEF3. The molecular formula of this adduct is (7):

[0037]

[0038] (3) The emulsifier and epoxy resin F44 are added into the dispersion kettle in a molar ratio of 1: 30 and mixed evenly, and then deionized water is added dropwise to prepare a 60% epoxy resin aqueous emulsion (abbreviated as MPEF3 / F44 water emulsion).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com