Inorganic-organic silicon hybridized chain transfer agent as well as preparation method thereof, modified (methyl) acrylate polymerization emulsion and preparation method thereof

A technology of chain transfer agent and acrylate, which is applied in the field of acrylate emulsion preparation, can solve the problems of large specific surface area, high surface energy, and poor compatibility of nano-silica, achieve good high and low temperature resistance, improve dispersibility and Excellent compatibility and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An inorganic-organosilicon hybrid chain transfer agent and its modified (meth)acrylate polymer emulsion and preparation method, comprising the following steps:

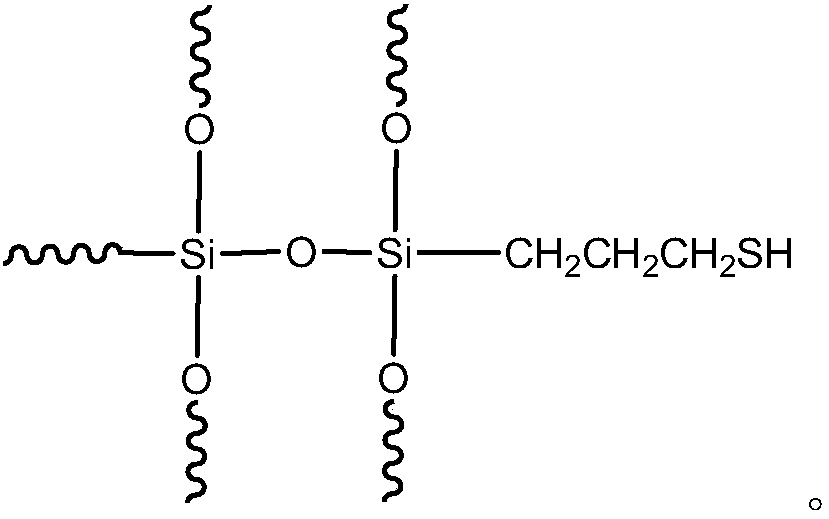

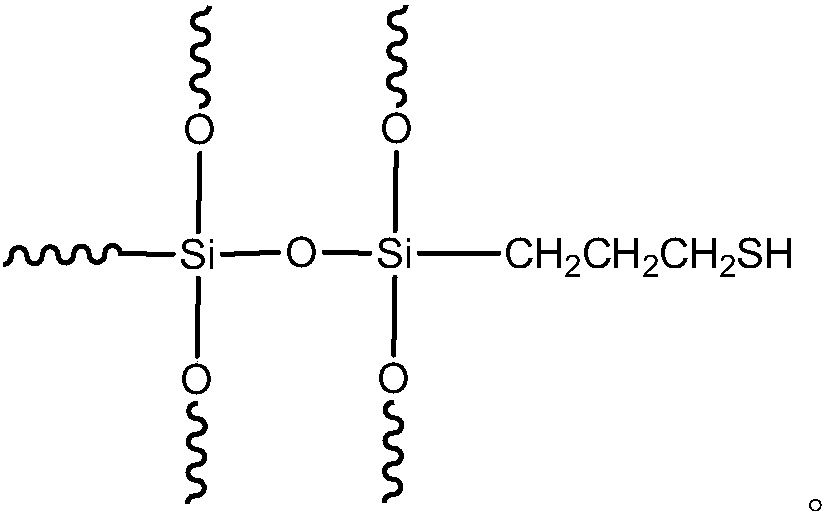

[0032] (1) Preparation of inorganic-organosilicon hybrid chain transfer agent

[0033] Add 10 parts by weight of tetraethyl orthosilicate and 40 parts by weight of absolute ethanol in a reactor equipped with a thermometer, a condenser tube and a stirrer, heat to 30 ° C, and then add 0.2 parts by weight of ammonia water and 2 parts by weight of deionized water. The mixture was reacted at 30° C. for 2 hours, and then 5 parts by weight of methyltrimethoxysilane was continuously added, and reacted at 30° C. for 4 hours to obtain a modified nano-silica sol. Continue to add 2 parts by weight of mercaptopropyltrimethoxysilane and react at 40° C. for 4 hours to obtain an inorganic-organosilicon hybrid chain transfer agent.

[0034] (2) Preparation of (meth)acrylate emulsion modified by inorganic-organic silicon hybrid...

Embodiment 2

[0038] An inorganic-organosilicon hybrid chain transfer agent and its modified (meth)acrylate polymer emulsion and preparation method, comprising the following steps:

[0039] (1) Preparation of inorganic-organosilicon hybrid chain transfer agent

[0040] Add 20 parts by weight of tetraethyl orthosilicate and 40 parts by weight of absolute ethanol in a reactor equipped with a thermometer, a condenser tube and a stirrer, heat to 45 ° C, and then add 0.5 parts by weight of hydrochloric acid and 10 parts by weight of deionized water The mixture was reacted at 45° C. for 12 hours, and then 10 parts by weight of dimethyldimethoxysilane was continuously added, and reacted at 45° C. for 8 hours to obtain a modified nano-silica sol. Continue to add 10 parts by weight of mercaptopropyltrimethoxysilane and react at 50° C. for 12 hours to obtain an inorganic-organosilicon hybrid chain transfer agent.

[0041] (2) Preparation of (meth)acrylate emulsion modified by inorganic-organic silic...

Embodiment 3

[0045] An inorganic-organosilicon hybrid chain transfer agent and its modified (meth)acrylate polymer emulsion and preparation method, comprising the following steps:

[0046] (1) Preparation of inorganic-organosilicon hybrid chain transfer agent

[0047]Add 30 parts by weight of tetraethyl orthosilicate and 60 parts by weight of absolute ethanol into a reactor equipped with a thermometer, condenser and stirrer, heat to 50°C, then add 0.8 parts by weight of sodium hydroxide and 10 parts by weight of deionized Mixture of water, react at 50°C for 16h, then continue to add 5 parts by weight of methyltriethoxysilane and 10 parts by weight of dimethyldimethoxysilane, react at 50°C for 8h, and obtain modified nano-dioxide Silica sol. Further, 10 parts by weight of mercaptopropyltrimethoxysilane was added and reacted at 50° C. for 16 hours to obtain an inorganic-organosilicon hybrid chain transfer agent.

[0048] (2) Preparation of (meth)acrylate emulsion modified by inorganic-orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com