Micron-nano short-fiber rubber composite material for automobile driving belt and method for preparing same

A technology of short fiber rubber and composite materials, applied in the direction of transmission belt, mechanical equipment, belt/chain/gear, etc., can solve the problems of low elongation at break, short absolute length, etc., to improve processing technology, improve oil resistance, improve The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

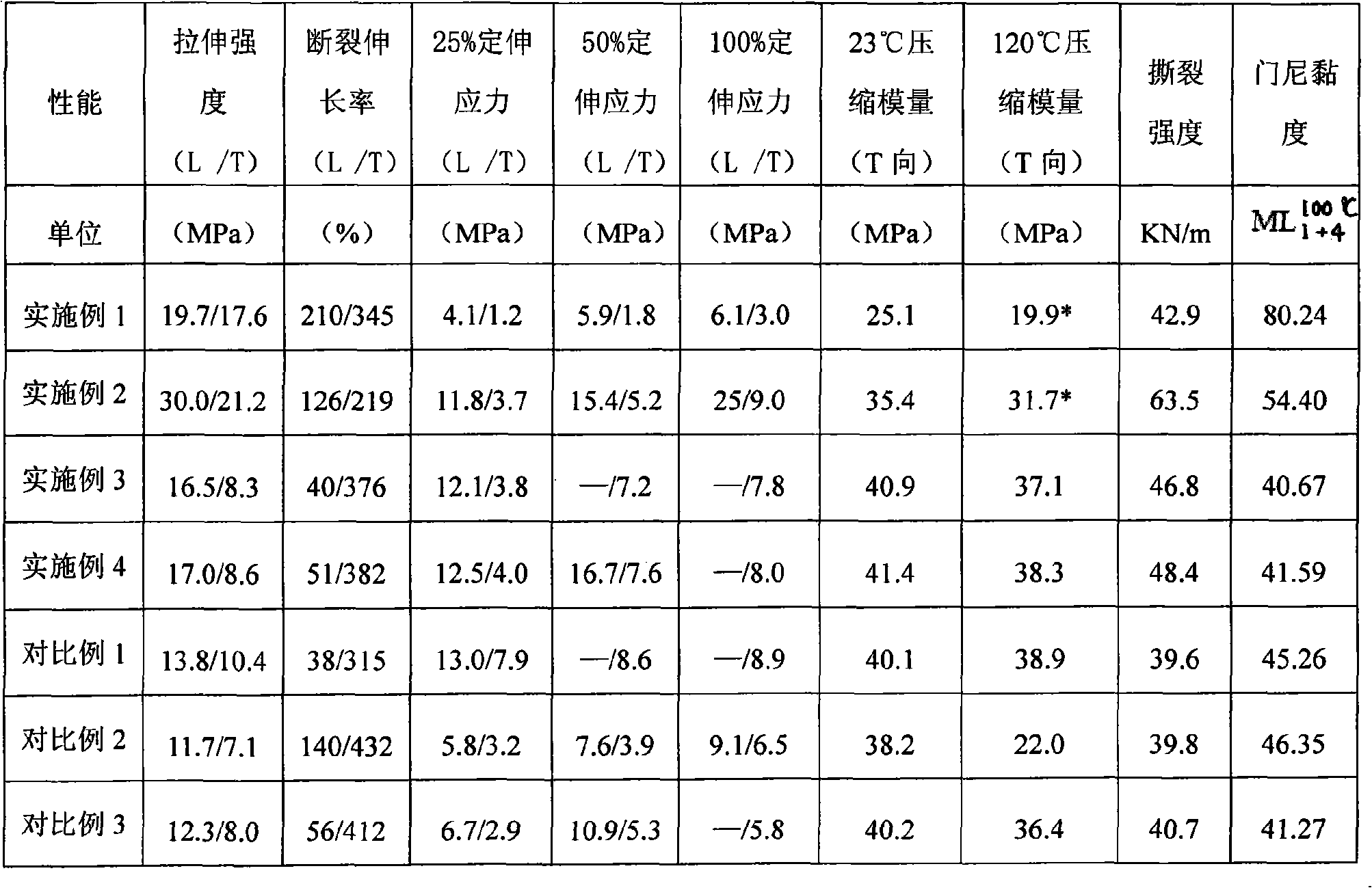

Embodiment 1

[0036] Embodiment 1: micro-nano short-fiber rubber composite material for automobile transmission belt, the mass parts of each component are:

[0037] 100 parts of hydrogenated nitrile rubber matrix;

[0038] 10 parts of 1250 mesh acicular silicate;

[0039] 3 parts of γ-methacryloxypropyltrimethoxysilane;

[0040] 20 parts of micron aramid staple fiber;

[0041] 15 parts of magnesium methacrylate;

[0042] Antiaging agent: 0.5 parts of N-4 (anilinophenyl) maleimide (MC);

[0043] Cross-linking aid: 2 parts of basic zinc carbonate;

[0044] Crosslinking agent: 15 parts of brominated phenolic resin;

[0045] Preparation method: first add 100 parts of hydrogenated nitrile rubber base to masticate on a double-roll mill, then add 10 parts of 1250 mesh acicular silicate and 3 parts of γ-methacryloxypropyl trimethoxysilane At the same time, mechanically mix, under the action of mechanical shear for about 20 minutes until the natural acicular silicate is dissociated into nano-s...

Embodiment 2

[0046] Embodiment 2: micro-nano short-fiber rubber composite material for automobile transmission belt, the mass parts of each component are:

[0047] 100 parts of hydrogenated nitrile rubber matrix;

[0048] 80 parts of 1250 mesh acicular silicate;

[0049] 24 parts of γ-methacryloxypropyltrimethoxysilane;

[0050] 3 parts of micron aramid staple fiber;

[0051] 3 parts of magnesium methacrylate;

[0052] Antiaging agent: 3 parts of N-4 (anilinophenyl) maleimide (MC);

[0053] Cross-linking aid: 4 parts of basic zinc carbonate;

[0054] Crosslinking agent: 20 parts of brominated phenolic resin;

[0055] Preparation method: first add 100 parts of hydrogenated nitrile rubber base to masticate on a double-roll mill, then add 80 parts of 1250 mesh acicular silicate and 24 parts of γ-methacryloxypropyl trimethoxysilane At the same time, mechanically mix, under the action of mechanical shear for about 15 minutes until the natural acicular silicate is dissociated into nano-sho...

Embodiment 3

[0056] Embodiment 3: micro-nano short-fiber rubber composite material for automobile transmission belt, the mass parts of each component are:

[0057] 100 parts of EPDM matrix;

[0058] 32 parts of 1000 mesh acicular silicate;

[0059] 10 parts of vinyltrimethoxysilane;

[0060] Micron nylon-66 staple fiber 11.4 parts;

[0061] 6 parts of zinc methacrylate;

[0062] Antiaging agent: 3 parts of N-4 (anilinophenyl) methacrylamide;

[0063] Cross-linking aid: 1 part of triallyl isocyanurate (TAIC);

[0064] Crosslinking agent: 3 parts of dicumyl peroxide (DCP);

[0065] Preparation method: first add 100 parts of EPDM rubber matrix on a double-roller mill for mastication, then add 30 parts of 1000-mesh acicular silicate and 10 parts of vinyl trimethoxysilane and mix mechanically at the same time. Under the action for about 20 minutes until the natural acicular silicate is dissociated into nano-short fibers, then add 11.4 parts of micron nylon-66 short fibers and mix (the vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com