Rare earth oxide modified Si-Mo-O gradient anti-oxidation coating layer and production method thereof

A technology of rare earth oxides and anti-oxidation coatings, which is applied in the field of high-temperature anti-oxidation, can solve the problems of inter-diffusion of components between coatings, lack of composition gradients in coatings, and easy cracking of coatings, etc., and achieve excellent high-temperature oxidation resistance. Significant economic and social benefits, the effect of low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

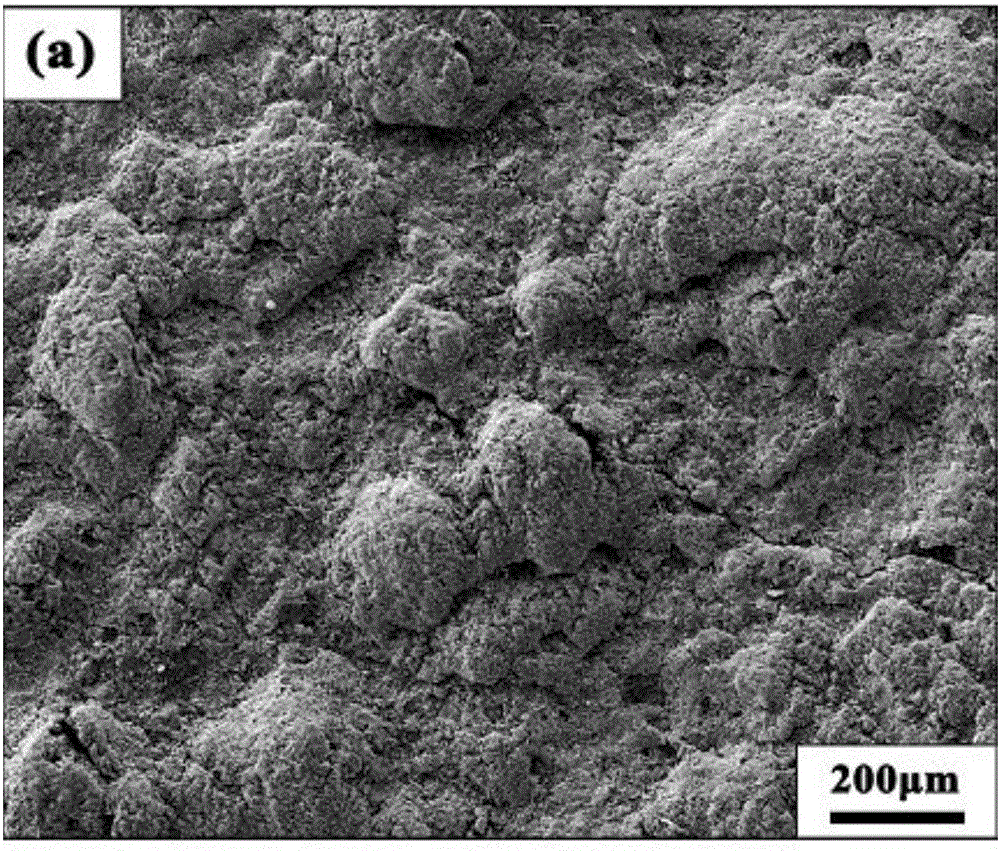

[0025] 1) C / C composite material (density 1.65-1.75g / cm 3 ) Grind the chamfer with sandpaper and ultrasonically clean with alcohol for 10-20min, and dry the cleaned sample in an oven at 60-90℃ for 4-10h for later use.

[0026] To prepare a gradient coating on the surface of the C / C composite material, first embed the SiC inner coating to relieve the thermal stress caused by the difference in thermal expansion coefficient between the substrate and the coating, and then prepare SiC-MoSi 2 The intermediate transition layer solves the problem of thermal adaptation between the inner and outer coatings, and then sprays the rare earth oxide modified Si-Mo-O outer coating, and finally soaks it in a silica sol solution and heats it, seals the holes, and improves the density of the coating surface .

[0027] 2) Preparation method of inner coating: weigh 75% Si powder, 20% C powder, 5% Al 2 o 3 powder, put the mixed powder into a ball mill to mix evenly, and dry it, then put the powde...

Embodiment approach 2

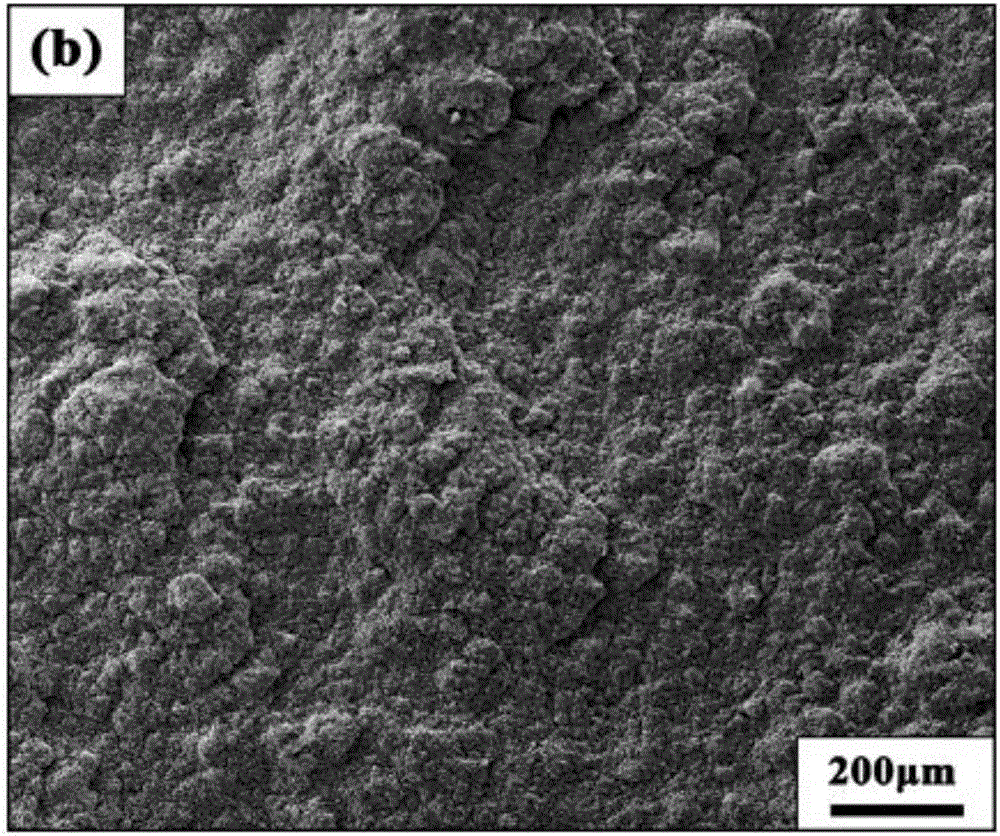

[0032] 1) C / C composite material (density 1.65-1.75g / cm 3 ) Grind the chamfer with sandpaper and ultrasonically clean with alcohol for 10-20min, and dry the cleaned sample in an oven at 60-90℃ for 4-10h for later use.

[0033] To prepare gradient coatings on the surface of C / C composite materials, first prepare SiC inner coatings to relieve the thermal stress caused by the mismatch of thermal expansion coefficients between the substrate and coatings, and then prepare SiC-MoSi 2 The intermediate transition layer solves the problem of thermal adaptation between the inner and outer coatings, and then sprays the rare earth oxide modified Si-Mo-O outer coating, and finally soaks it in a silica sol solution and heats it, seals the holes, and improves the density of the coating surface .

[0034] 2) Preparation method of inner coating: weigh 75% Si powder, 20% C powder, 5% Al 2 o 3 Put the mixed powder into a ball mill and mix it evenly, then dry it, then put the powder into a sma...

Embodiment approach 3

[0039] 1) C / C composite material (density 1.65-1.75g / cm 3 ) Grind the chamfer with sandpaper and ultrasonically clean with alcohol for 10-20min, and dry the cleaned sample in an oven at 60-90℃ for 4-10h for later use.

[0040] To prepare a gradient coating on the surface of the C / C composite material, first embed the SiC inner coating to relieve the thermal stress caused by the mismatch between the thermal expansion coefficient between the substrate and the coating, and then prepare SiC-MoSi 2 The intermediate transition layer solves the problem of thermal adaptation between the inner and outer coatings, and then sprays the rare earth oxide modified Si-Mo-O coating, and finally soaks it in a silica sol solution and heats it to seal the pores to increase the density of the coating surface.

[0041] 2) Preparation method of inner coating: weigh 75% Si powder, 20% C powder, 5% Al 2 o 3 Put the mixed powder into a ball mill and mix it evenly, then dry it, then put the powder int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com