Test blanket module for international thermonuclear experimental reactor with low toroidal field waviness

An experimental cladding module and thermonuclear fusion technology, applied in the field of experimental cladding modules of the International Thermonuclear Experimental Reactor, can solve problems such as the difficulty of connecting different materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

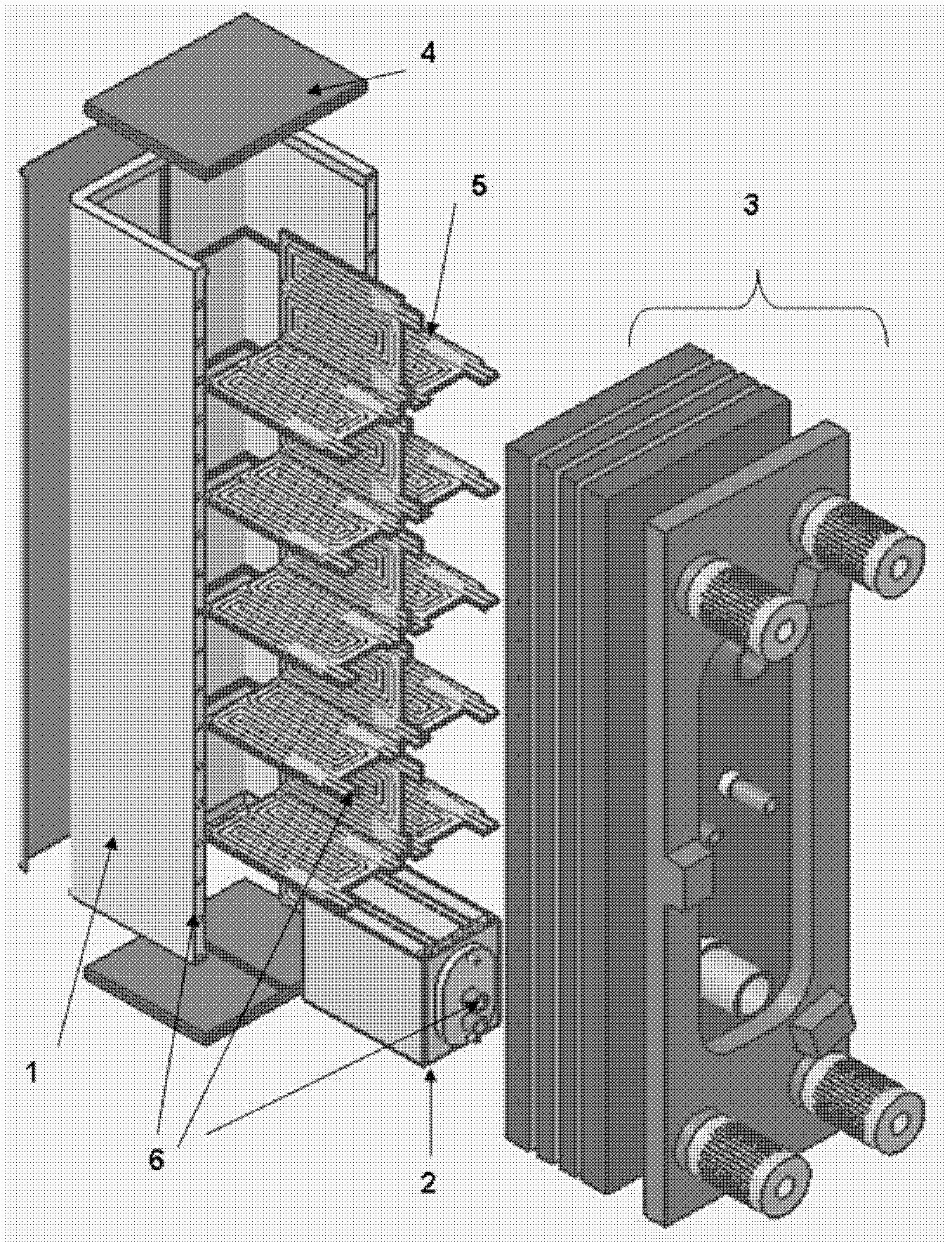

[0026] The present invention is a method for reducing the content of ferromagnetic structural material CLF-1 in CN HCCB TBM, the purpose of which is to reduce the ferromagnetism of CN HCCB TBM on the basis of meeting the functional requirements of CN HCCB TBM and without greatly changing the overall design of existing CN HCCB TBM The use of substances, thereby reducing the toroidal magnetic field ripple of the ITER magnetic confinement device caused by the CNHCCB TBM.

[0027] Specific technical solutions include:

[0028] 1. The rear plate of CN HCCB TBM adopts non-ferromagnetic material SS 316LN-IG instead of CLF-1 as the structural material;

[0029] 2. The first wall 1 of CN HCCB TBM, the tritium breeding area 2, the upper and lower cover plates 4, and the shelf 5 still use CLF-1 as the structural material;

[0030] 3. Introduce an intermediate transition layer structure at the pipeline interface 6 between the first wall 1 of the CN HCCB TBM, the tritium breeding area 2, ...

Embodiment 2

[0034] A method of reducing the content of ferromagnetic structure material CLF-1 in CN HCCB TBM of the present invention aims at reducing the ferromagnetism of CN HCCB TBM on the basis of meeting the functional requirements of CN HCCB TBM and without substantially changing the overall design of existing CN HCCB TBM The use of materials, thereby reducing the tokamak device ring magnetic field ripple caused by the CNHCCB TBM.

[0035] Specific measures include:

[0036] 1. Prepare Inconel718 and SS 316LN-IG uniformly mixed composite material with a molar ratio of 1:1 by powder metallurgy method, and roll it into a 1-3mm plate;

[0037] 2. Using the vacuum thermal diffusion process to roll a multi-layer composite board consisting of four layers of CLF-1 layer, Inconel718 layer, Inconel718 and SS 316LN-IG composite layer, and SS 316LN-IG layer; the CLF-1 layer is 1mm thick, Inconel718 layer 2mm thick, Inconel718 and SS 316LN-IG composite layer 2mm thick, SS 316LN-IG layer 1mm th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com