Anti-sticking coating used for motor and electric appliance connection wire and its coating process

A technology of anti-adhesive coating and lead wire, applied in the direction of circuits, coatings, electrical components, etc., can solve the problems of environment, human harm, toxicity, etc., achieve good uniformity, prevent mutual bonding and hardening, and prevent contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

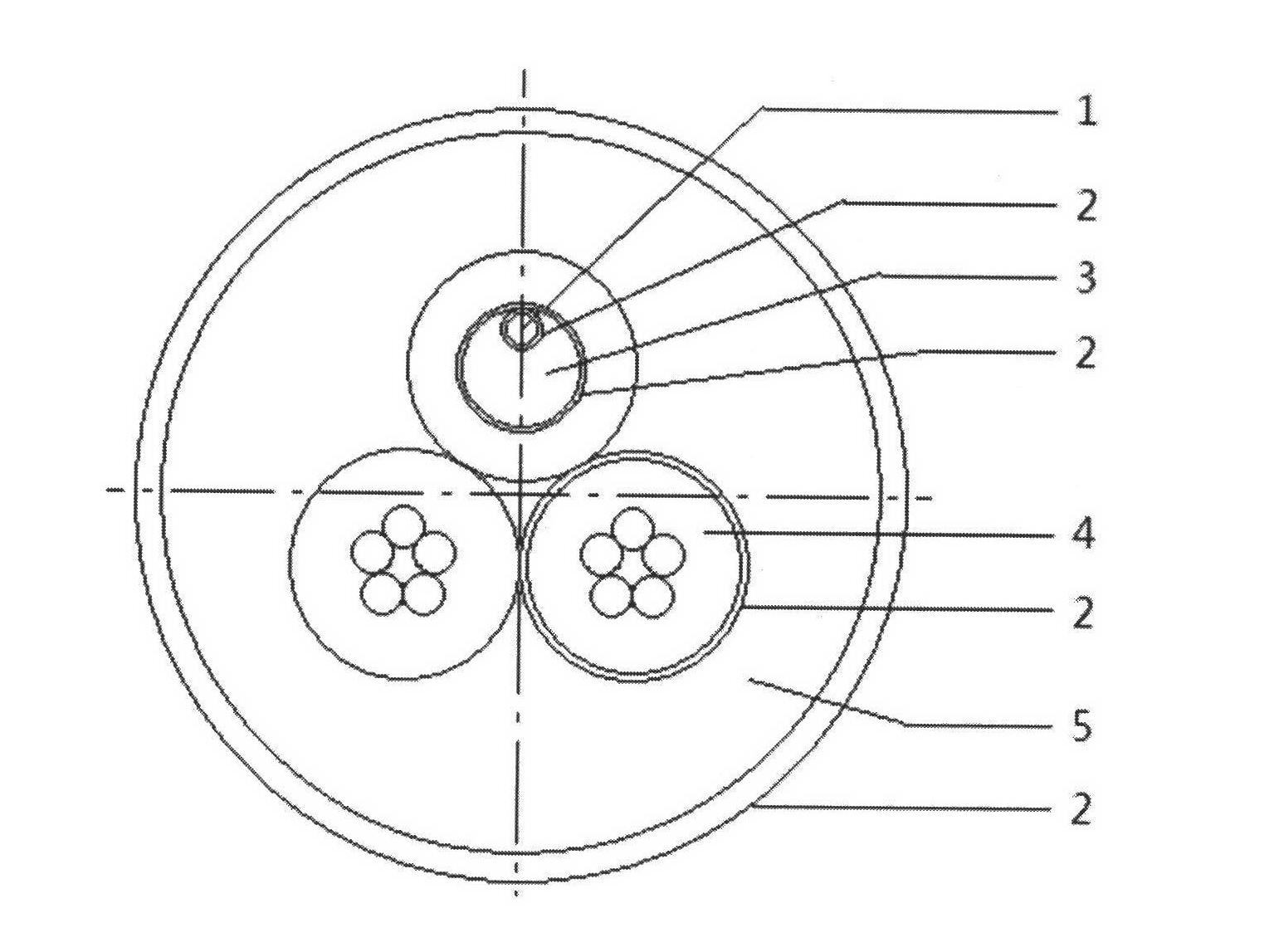

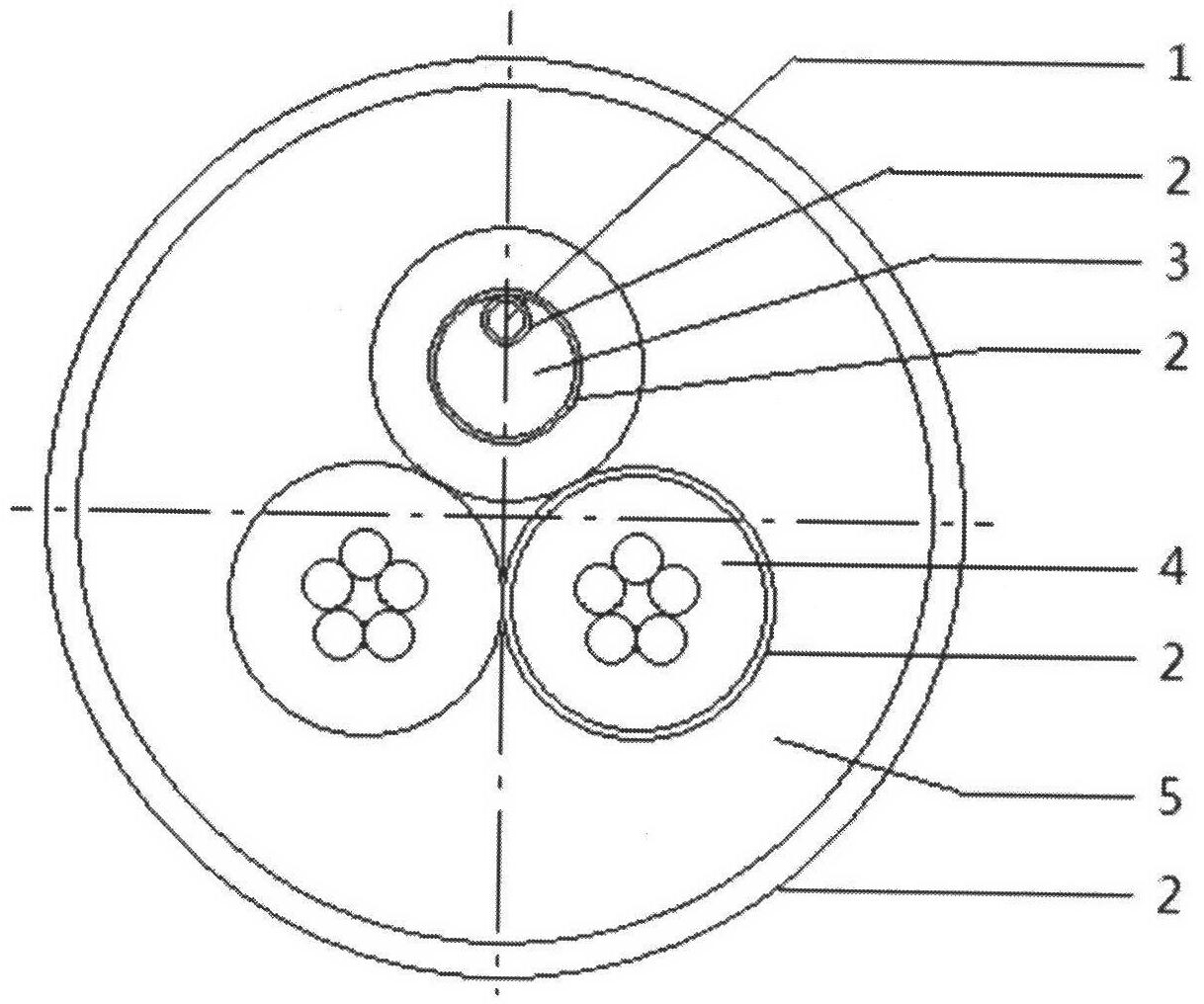

Image

Examples

Embodiment

[0033] The anti-sticking material is 239 silicone grease, and its diluent is 120# industrial gasoline.

[0034] First, at room temperature, slowly pour 120# industrial gasoline into a container containing anti-sticking materials, and stir while pouring until it is evenly diluted and completely diluted.

[0035] An anti-adhesive paint coating process for electrical lead wires, the process steps are as follows:

[0036] A. Anti-adhesive treatment of metal filaments

[0037] The weight ratio of anti-sticking material to industrial gasoline is 1:6.

[0038] During the unwinding process before the metal filament bundle, the metal filament 1 is continuously passed through the container filled with the anti-stick coating prepared above, so that the anti-stick coating is evenly coated on the outer layer of each metal filament, and then the It passes through a hot air device continuously, and the temperature of the hot air is controlled at 180-200°C. The anti-adhesive material coated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com