Method for packaging SMT crystal resonator/oscillator by epoxy resin mold

A technology of crystal resonator and epoxy resin, applied in the direction of electrical components, impedance network, etc., can solve the problem of low yield, achieve the effect of improving yield and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] see Figure 6 , Figure 7 , the present invention comprises the following steps:

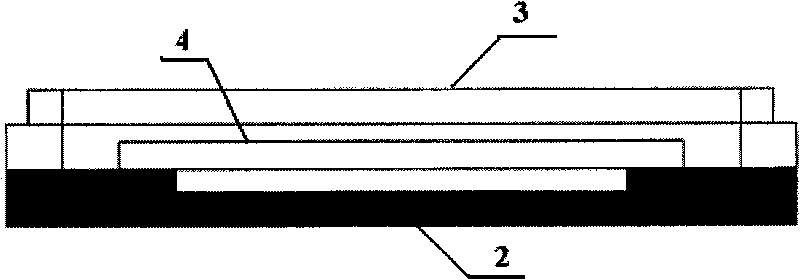

[0021] A10, the welding spot on the crystal resonator or the oscillator base 2 is integrated with the substrate 7 through solder 8, and the thickness of the solder 8 is less than 40 microns;

[0022] A20. Place the crystal resonator or oscillator with the substrate welded between the upper mold 10 and the lower mold 11, pressurize and pour 160°C to 180°C thermosolid epoxy resin into the mold cavity 9 through the sprue port 12, The perfusion pressure is 2MPa-4Mpa, and the epoxy resin is mixed with spherical silicon particles with a diameter of 13-75 microns;

[0023] A30. After 90 seconds of curing time, demould to obtain an SMT crystal resonator or oscillator, Figure 7 Among them, 4 is the quartz plate inside the crystal resonator or the oscillator, 6 is the metal shell of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com