Heat-storage maintaining furnace

A heat preservation furnace and heat storage technology, applied in the field of aluminum casting furnaces, can solve problems such as furnace cavity cracking, and achieve the effect of preventing furnace cracking, uniform stress, and uniform thermal deformation without cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

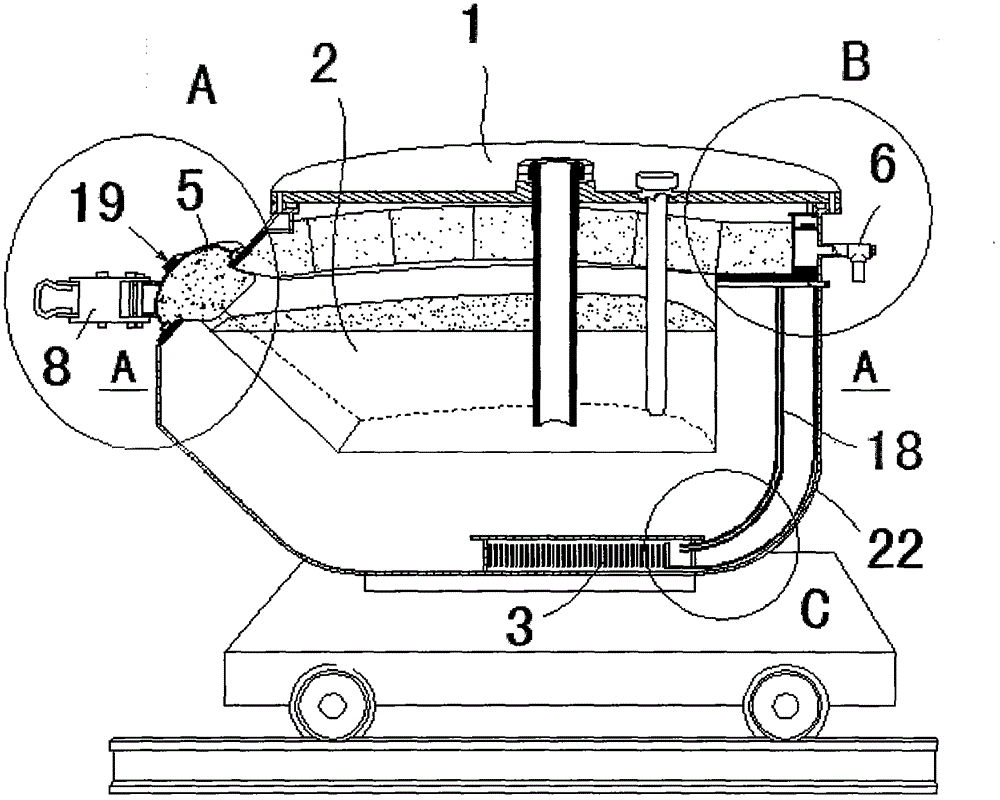

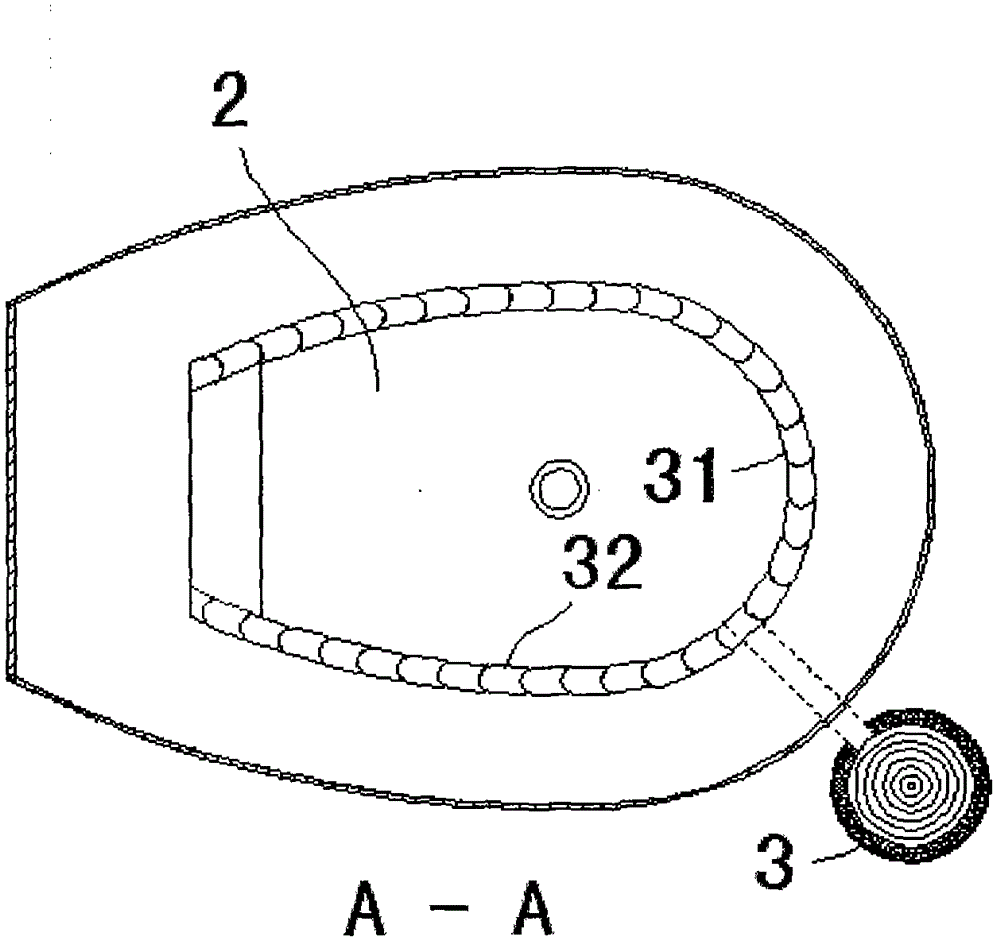

[0033] attached Figure 1-2 Shown is the general structure of the present invention.

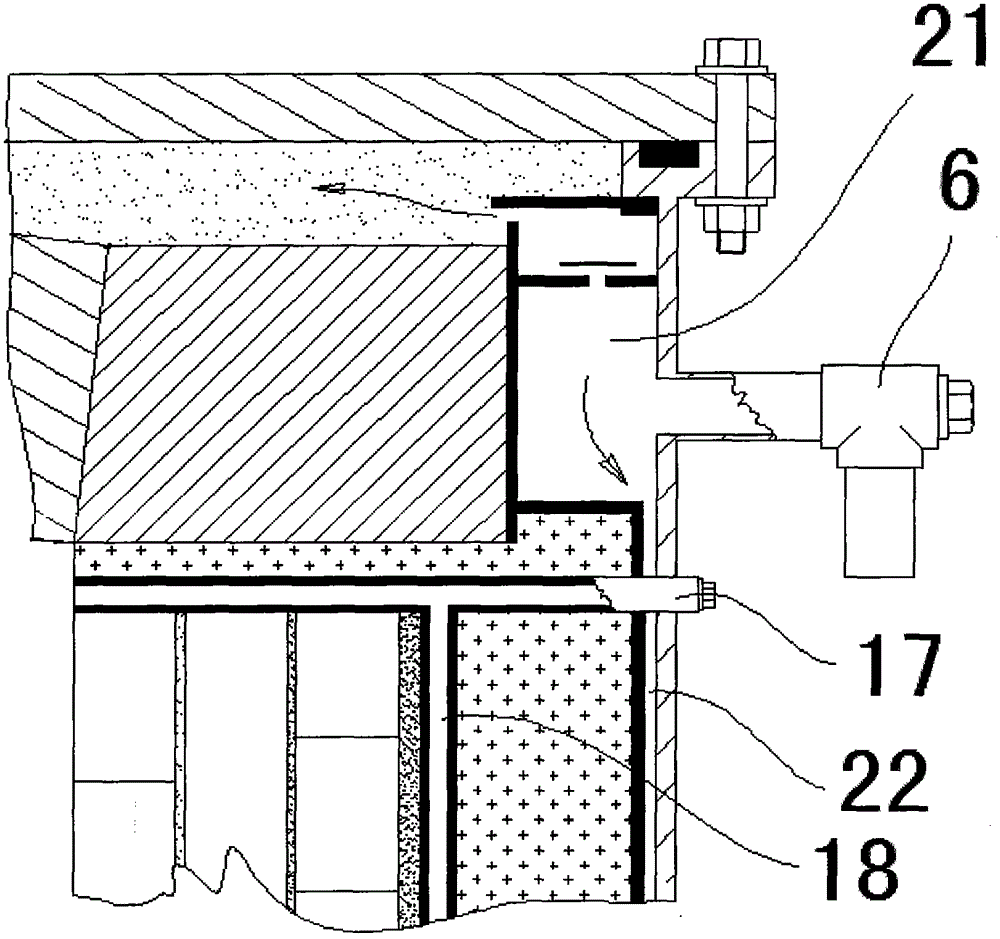

[0034] attached Figure 3-5 Shown is the furnace cavity masonry and furnace heat storage structure.

[0035] In the furnace 1, the cavity 3 is in the shape of an arc of water droplets, two symmetrical large arcs 32 vertical walls of the cavity 3 and small arcs 31 vertical walls are cut and formed, and the vertical walls and the bottom of the cavity 3 are formed by more than three layers Masonry masonry, the inner lining layer is ceramic masonry layer, the other is thermal insulation masonry layer, the surface of thermal insulation masonry is attached with aluminum foil, 5 layers of powder are formed between the masonry layer and 5 layers of powder Filling fine powder 5, fine powder 5 ≤ 320 mesh mineral composition, specific gravity ≥ 2.7g / cm, ≤ 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com