A porous ultrafiltration ceramic material, products containing the material and its preparation

A technology of ceramic materials and raw materials, applied in the field of porous ultrafiltration ceramic materials, can solve the problems of secondary blockage, clogging and short service life of filter holes, and achieve the effects of avoiding secondary blockage, wide application environment and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A second aspect of the present invention provides a method for preparing a porous ultrafiltration ceramic material, which comprises the following steps: ball-milling, filtering, and removing impurities from the preparation raw material of the porous ultrafiltration ceramic material, and then pressing it into a mud block; The green body is obtained by inner rolling forming and demoulding; the green body is fired in a high-temperature kiln, and after cooling, the porous ultrafiltration ceramic material is obtained.

[0045] In one embodiment, the preparation method of the porous ultrafiltration ceramic material includes: ball-milling, filtering, and removing impurities from the preparation raw material of the porous ultrafiltration ceramic material, and then pressing it into a mud block; Roll forming and demoulding to obtain green body; the green body is baked in a high temperature kiln to 1000-1200 ℃, cooled and removed from the kiln, and the surface is polished with 600-...

Embodiment 1

[0056] Embodiment 1 of the present invention provides a porous ultrafiltration ceramic material, which contains lithium element, and the porous ultrafiltration ceramic material is crushed without grinding. The T21650.2-2008 test shows that the average pore size of the porous ultrafiltration ceramic material is 8nm; the thickness is 4mm; when the surface area of the porous ceramic material is 315cm 2 , when the water pressure is 0.2MPa, the initial flow rate reaches 1.4L / min.

[0057] In parts by weight, the preparation raw materials of the porous ultrafiltration ceramic material are 21 parts of water, 44 parts of lithium ore, 34 parts of clay, and 1 part of plasticizer.

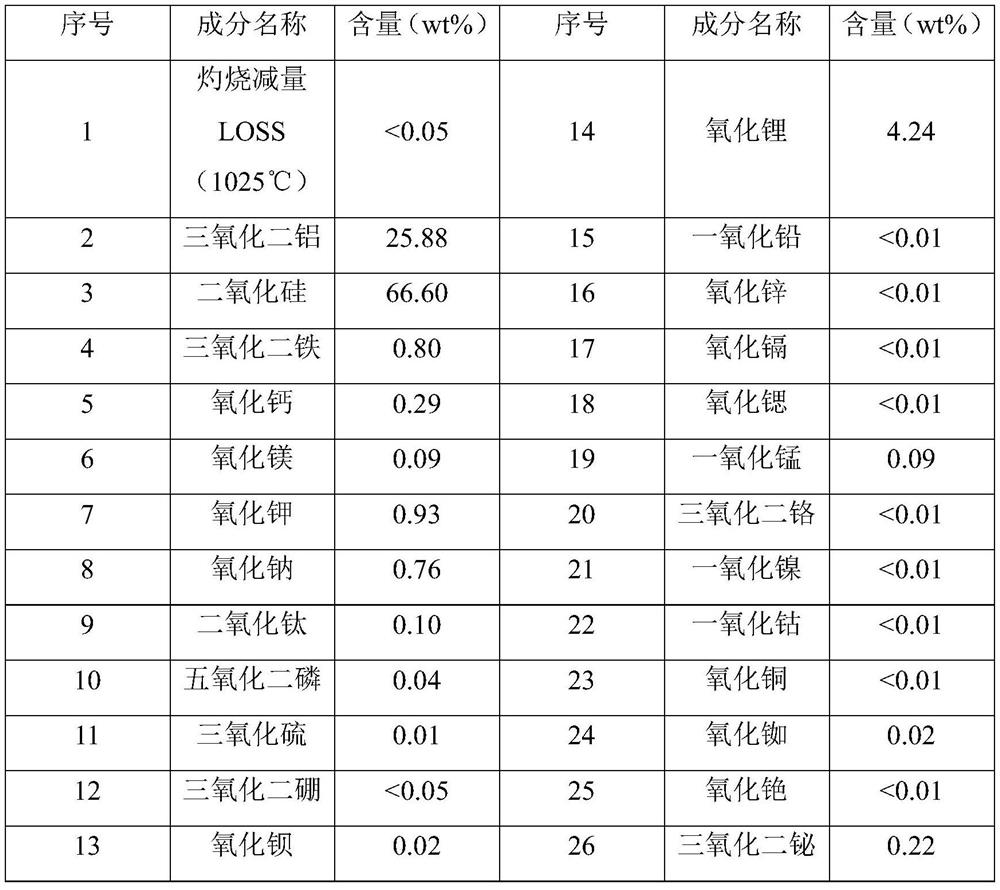

[0058] The lithium ore is monoclinic spodumene, with a particle size of 120 mesh, purchased from Tianqi Lithium Industry Co., Ltd., and the lithium content is 7.2wt%; the clay was purchased from Shijiazhuang Dakun Mineral Products Co., Ltd.; The plasticizer was purchased from Guangzhou Yifeng Chemical Tech...

Embodiment 2

[0061] Embodiment 2 of the present invention provides a porous ultrafiltration ceramic material, which contains lithium element, and the porous ultrafiltration ceramic material is crushed without grinding. According to T21650.2-2008 test, the average pore size of the porous ultrafiltration ceramic material is 9nm; the thickness is 6mm; when the surface area of the porous ceramic material is 315cm 2 , when the water pressure is 0.2MPa, the initial flow rate reaches 1.8L / min.

[0062] In parts by weight, the preparation raw materials of the porous ultrafiltration ceramic material are 22 parts of water, 52 parts of lithium ore, 25 parts of clay, and 1 part of plasticizer.

[0063] The lithium ore is monoclinic spodumene, with a particle size of 120 mesh, purchased from Tianqi Lithium Industry Co., Ltd., and the lithium content is 7.2wt%; the clay was purchased from Shijiazhuang Dakun Mineral Products Co., Ltd.; The plasticizer was purchased from Guangzhou Yifeng Chemical Techn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com