Antibacterial powder coating

An antibacterial powder and coating technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of poor durability, easy dissolution, slow antibacterial effect, etc., achieve long-lasting antibacterial effect, reduce dissolution speed, and accelerate The effect of release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

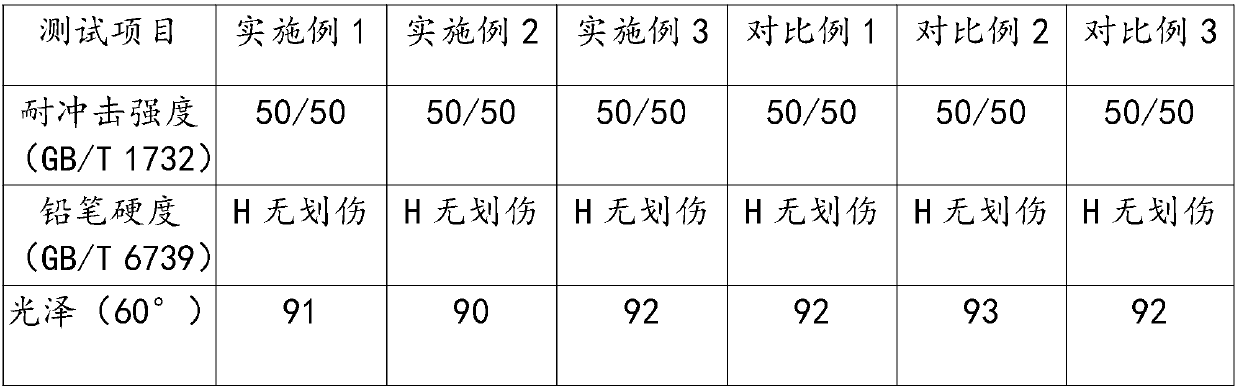

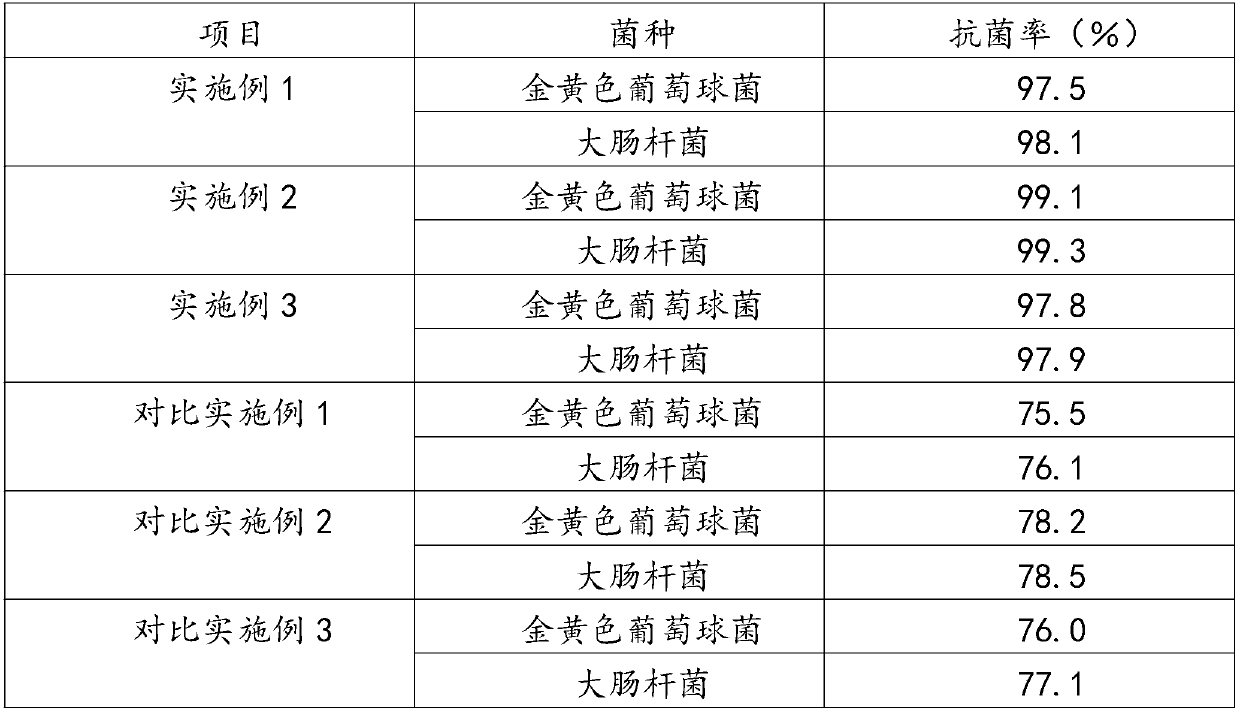

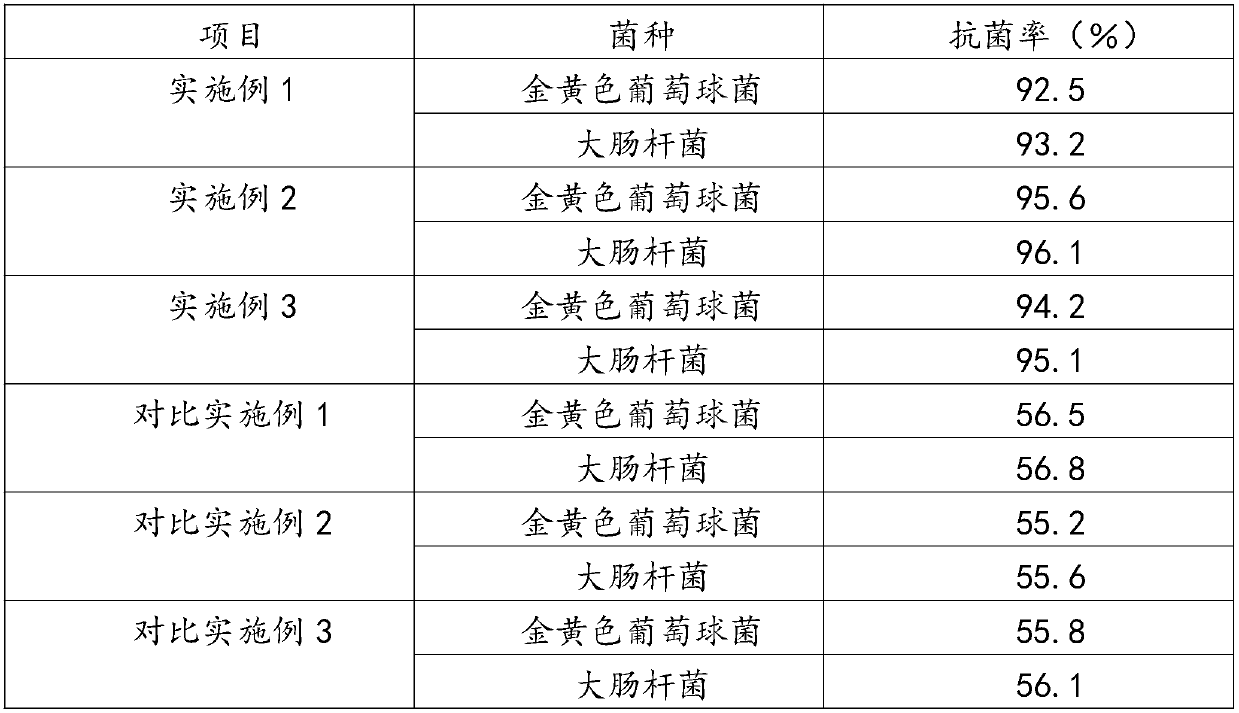

Examples

Embodiment 1

[0028] (1) The antibacterial additive consists of the following components:

[0029] 5wt% nano silver powder;

[0030] 40wt% aluminosilicate;

[0031] 30wt% silane coupling agent;

[0032] 25wt% polyethylene wax;

[0033] Nano silver powder: YFM04-N50, product of Shanghai Yunfu Nano Technology Co., Ltd.;

[0034] Aluminosilicate: 3A molecular sieve, product of Jiangxi Xintao Technology Co., Ltd.;

[0035] Silane coupling agent: SG-Si171, product of Nanjing Shuguang Chemical Group Co., Ltd.;

[0036] Polyethylene wax: PEW-0235, product of Nanjing Tianshi New Material Technology Co., Ltd.;

[0037] The preparation process of the antibacterial auxiliary agent is as follows: dissolve the silane coupling agent in the raw material in water to make a 10% solution, then add the above-mentioned other raw materials, stir for 3-5 hours under the high-speed mixer, mix evenly, filter, and store in a constant temperature box at 100°C Bake for 3-4 hours, pulverize, and pass through a 2...

Embodiment 2

[0056] (1) The antibacterial additive consists of the following components:

[0057] 10wt% nano silver powder;

[0058] 70wt% aluminosilicate;

[0059] 10wt% silane coupling agent;

[0060] 10wt% polyethylene wax;

[0061] Nano silver powder: YFM04-N50, product of Shanghai Yunfu Nano Technology Co., Ltd.;

[0062] Aluminosilicate: 3A molecular sieve, product of Jiangxi Xintao Technology Co., Ltd.;

[0063] Silane coupling agent: SG-Si171, product of Nanjing Shuguang Chemical Group Co., Ltd.;

[0064] Polyethylene wax: PEW-0235, product of Nanjing Tianshi New Material Technology Co., Ltd.;

[0065] The preparation process of antibacterial additives is as follows: dissolve the silane coupling agent in the raw material in water to make a 5% solution, then add the above-mentioned other raw materials, stir for 3-5 hours under a high-speed mixer, mix evenly, filter, and store in a constant temperature box at 100°C Bake for 3-4 hours, pulverize, and pass through a 250-mesh siev...

Embodiment 3

[0084](1) The antibacterial additive consists of the following components:

[0085] 8wt% nano silver powder;

[0086] 60wt% aluminosilicate;

[0087] 16wt% silane coupling agent;

[0088] 16 wt% polypropylene wax;

[0089] Nano silver powder: YFM04-N50, product of Shanghai Yunfu Nano Technology Co., Ltd.;

[0090] Aluminosilicate: 3A molecular sieve, product of Jiangxi Xintao Technology Co., Ltd.;

[0091] Silane coupling agent: SG-Si171, product of Nanjing Shuguang Chemical Group Co., Ltd.;

[0092] Polypropylene wax: PPW-0931, product of Nanjing Tianshi New Material Technology Co., Ltd.;

[0093] The preparation process of the antibacterial auxiliary agent is as follows: dissolve the silane coupling agent in the raw material in water to make a 10% solution, then add the above-mentioned other raw materials, stir for 3-5 hours under the high-speed mixer, mix evenly, filter, and store in a constant temperature box at 100°C Bake for 3-4 hours, pulverize, and pass through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com