Long-acting synthesizing process of heavy sectioned ductile iron

A comprehensive treatment, nodular cast iron technology, applied in the field of cast iron materials, can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

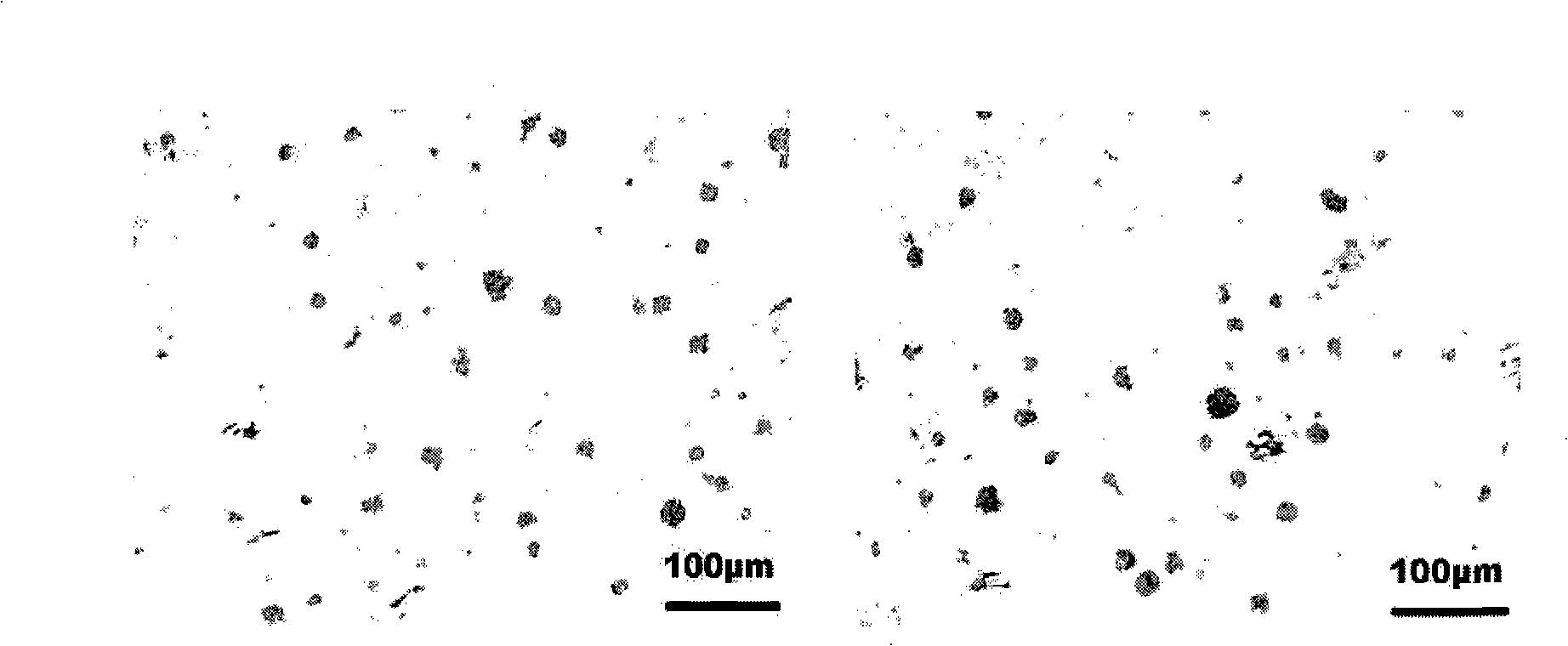

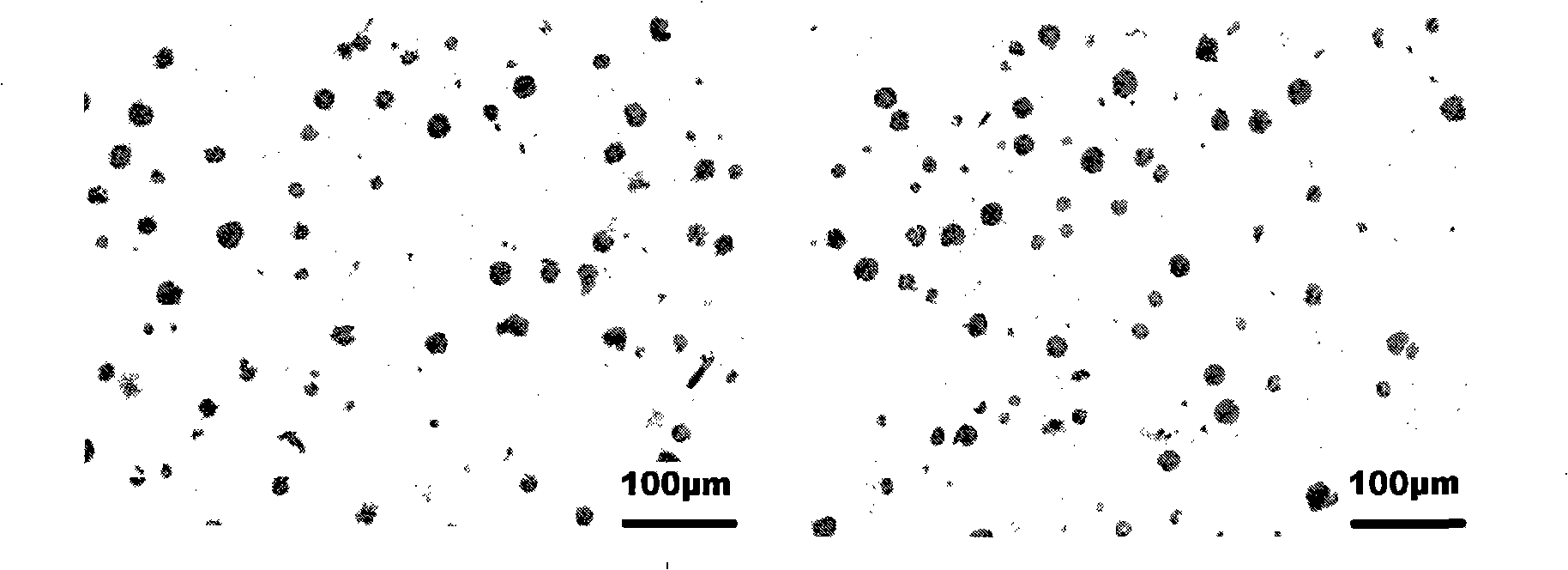

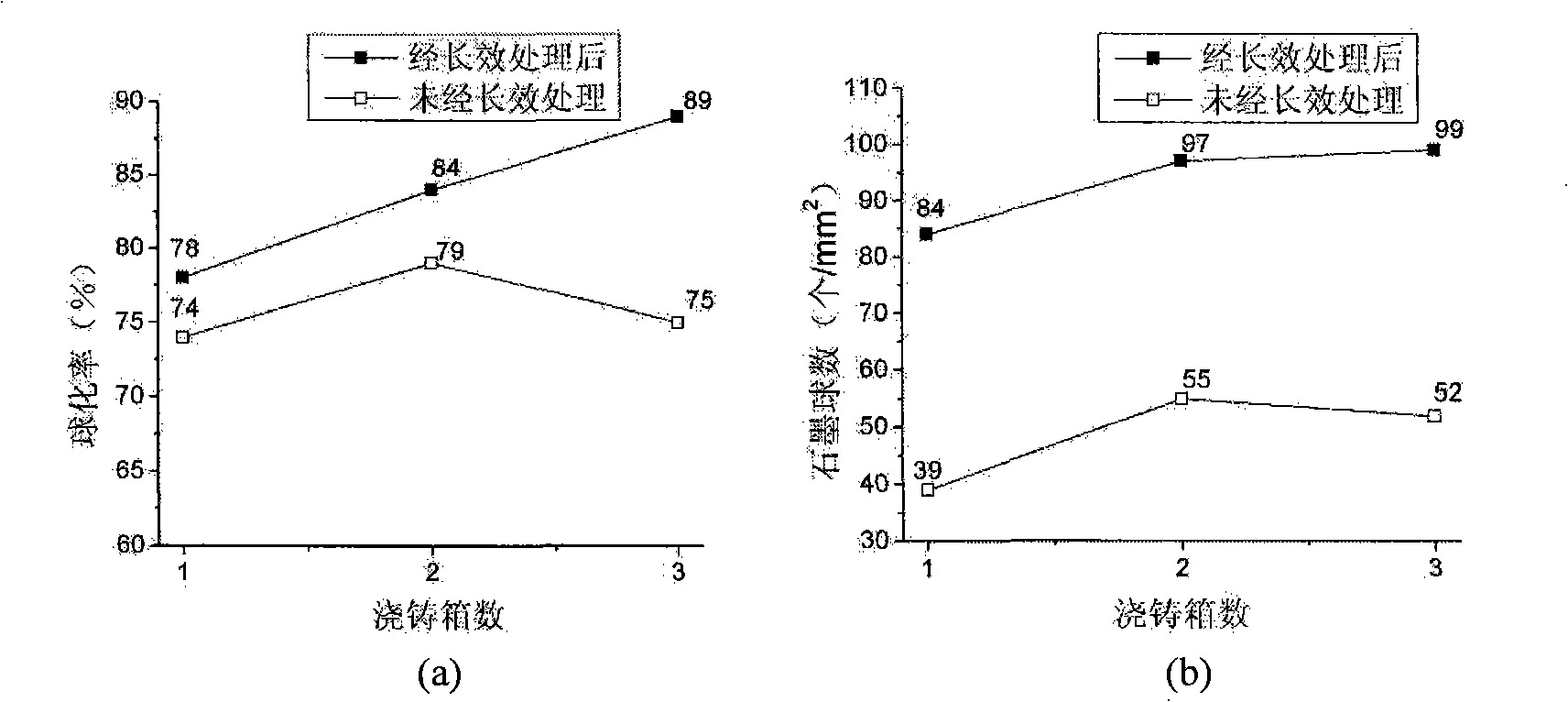

Image

Examples

Embodiment 1

[0020] In this embodiment, under the same casting environment, two kinds of spheroidizing and inoculating agents are used, that is, the spheroidizing inoculating agent sold on the market and the spheroidizing inoculating agent of the present invention, to cast a batch of "steering knuckle" nodular cast iron for automobiles casting. The specific process and steps are as follows:

[0021] Put the special pig iron material for ductile iron and appropriate amount of scrap steel in the medium frequency induction furnace, and smelt it according to the conventional method at 1450°C; when the pig iron and scrap steel are all melted, add Cu, which accounts for 0.2% of the weight of the molten iron, into the molten iron, and wait until the Cu is completely melted. Keep it for one minute after melting to ensure that Cu diffuses evenly in the molten iron.

[0022] Put the spheroidizing agent accounting for 2% of the molten iron weight into the spheroidizing bag. The composition of the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com