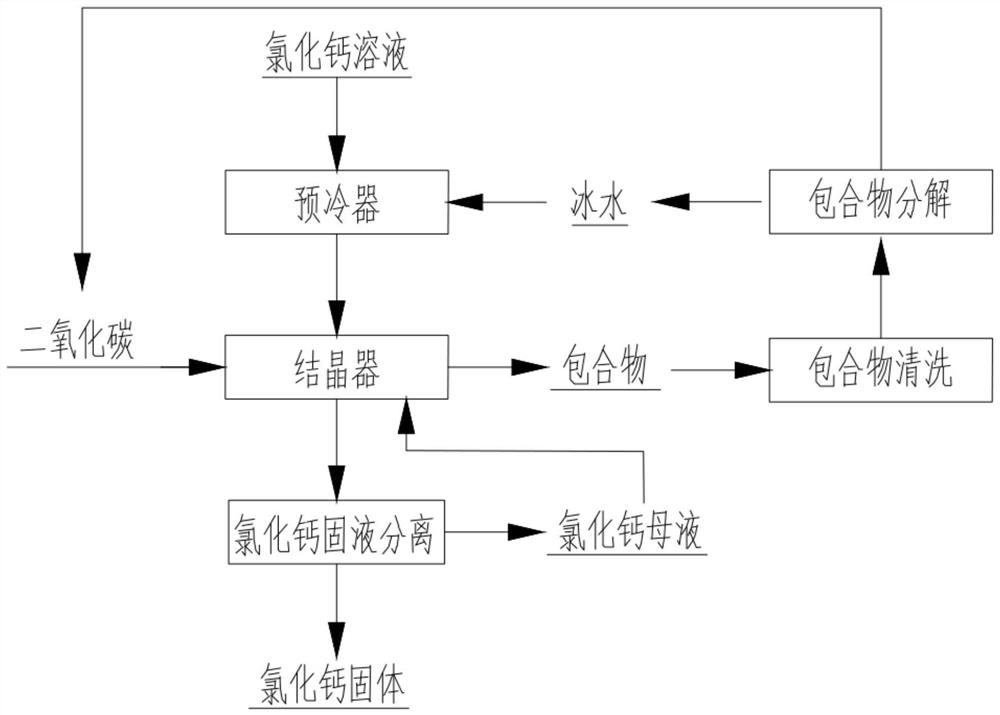

Method for separating water and calcium chloride through eutectic freezing crystallization

A technology of frozen crystallization and calcium chloride, which is applied in the direction of heat exchange cooling crystallization, solution crystallization, calcium/strontium/barium chloride, etc., can solve the problems of high energy consumption, difficult operation, and high operating cost of calcium chloride solids. Achieve the effect of easy operation, simple equipment, and reduced corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare 5L of an aqueous solution with a calcium chloride content of 20%, and use ice water as the cooling medium to pre-cool 5L of the calcium chloride solution to 5°C through a tube-and-tube heat exchanger, and pump the pre-cooled calcium chloride solution into the crystallizer , the crystallizer is stirred to 750rpm, and carbon dioxide is introduced from the bottom of the crystallizer to the inside of the crystallizer. After the pressure shows 1.22Mpa, the carbon dioxide gas is stopped, and the ethylene glycol refrigerant continues to cool down the calcium chloride solution through the jacket of the crystallizer. Stop pre-cooling when the internal temperature of the crystallizer drops to -29°C, at this time the CO 2 , The feed valve is closed.

[0033] Continue to maintain the pressure and temperature for 1.0 hour. It is observed that the salt crystallizes out first, and a carbon dioxide clathrate clathrate is formed on the upper layer of the crystallizer. When the p...

Embodiment 2

[0036] Prepare 5L of an aqueous solution with a calcium chloride content of 20%, and use ice water as the cooling medium to pre-cool 5L of the calcium chloride solution to 5°C through a tube-and-tube heat exchanger, and pump the pre-cooled calcium chloride solution into the crystallizer , the crystallizer is stirred to 750rpm, carbon dioxide is introduced from the bottom of the crystallizer to the inside of the crystallizer, and the pressure shows 1.06Mpa. Stop feeding carbon dioxide gas, and the ethylene glycol refrigerant continues to cool down the calcium chloride solution through the jacket of the crystallizer. Stop precooling when the temperature inside the crystallizer drops to -33°C, at this time the CO 2 , The feed valve is closed.

[0037] Continue to maintain the pressure and temperature for 1.0 hour. It is observed that the salt crystallizes out first, and a carbon dioxide clathrate clathrate is formed on the upper layer of the crystallizer. When the pressure is sli...

Embodiment 3

[0040] Prepare 5L of an aqueous solution with a calcium chloride content of 20%, and use ice water as the cooling medium to pre-cool 5L of the calcium chloride solution to 5°C through a tube-and-tube heat exchanger, and pump the pre-cooled calcium chloride solution into the crystallizer , the crystallizer is stirred to 750rpm, and carbon dioxide is introduced from the bottom of the crystallizer to the inside of the crystallizer. After the pressure shows 1.34Mpa, the carbon dioxide gas is stopped, and the ethylene glycol refrigerant continues to cool down the calcium chloride solution through the jacket of the crystallizer. Stop pre-cooling when the internal temperature of the crystallizer drops to -25°C, at this time the CO 2 , The feed valve is closed.

[0041] The pressure and temperature were maintained for an additional 1.0 hour. It is observed that the salt crystallizes out first, and a clathrate of carbon dioxide is formed on the upper layer of the crystallizer. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com