Austenite nodular cast iron containing carbide and preparing method for austenite nodular cast iron containing carbide

A ductile iron and austenite technology, applied in the field of austenitic ductile iron and its preparation, can solve the problems of not reflecting the superiority of cast steel, inapplicability, etc., achieve good toughness, improve uniformity and stability, improve The effect of graphite morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

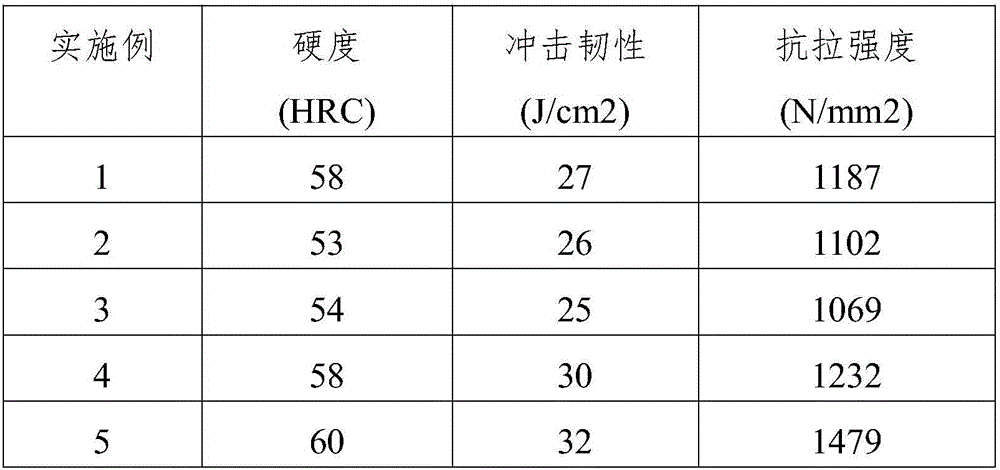

Examples

Embodiment 1

[0019] A carbide-containing austenitic ductile iron, containing the following percentage elements: C 3.5%, Si 3.0%, Mn 1.3%, Nb 0.25%, Ni 0.3%, V 0.25%, Mg 0.03%, RE 0.03 %, the balance is Fe and unavoidable impurities.

[0020] The preparation method of the austenitic nodular cast iron containing carbide comprises the following steps:

[0021] 1) Smelting: Add returned iron, scrap steel, pig iron, recarburizer, and ferronickel into an intermediate frequency induction furnace and raise the temperature to 1230°C, keep it for 6 minutes, then heat up to 1500°C for melting, tempering, to obtain the original molten iron, and take it out of the furnace;

[0022] 2) Spheroidization inoculation: the spheroidization inoculation treatment is carried out by the method of pouring into the bag, the low rare earth magnesium ferrosilicon alloy spheroidizer is placed in the lower layer of the bottom groove of the spheroidized bag, and 1 / 3 of the iron-silicon alloy inoculant is placed in the u...

Embodiment 2

[0026] A carbide-containing austenitic nodular cast iron containing the following elemental components in percentages: C 3.0%, Si 3.2%, Mn 1.0%, Nb 0.3%, Ni 0.2%, V 0.3%, Mg 0.02%, RE 0.045 %, the balance is Fe and unavoidable impurities.

[0027] The preparation method of the austenitic nodular cast iron containing carbide comprises the following steps:

[0028] 1) Smelting: Add returned iron, scrap steel, pig iron, recarburizer, and ferronickel into an intermediate frequency induction furnace and heat up to 1200°C, keep it for 10 minutes, then heat up to 1480°C for melting, quenching and tempering, to obtain the original molten iron, and take it out of the furnace;

[0029] 2) Spheroidization inoculation: the spheroidization inoculation treatment is carried out by the method of pouring into the bag, the low rare earth magnesium ferrosilicon alloy spheroidizer is placed in the lower layer of the bottom groove of the spheroidized bag, and 1 / 3 of the iron-silicon alloy inoculan...

Embodiment 3

[0033] A carbide-containing austenitic nodular cast iron containing the following elements in percentages: C 3.7%, Si 2.7%, Mn 1.5%, Nb 0.2%, Ni 0.4%, V 0.2%, Mg 0.04%, RE 0.02 %, the balance is Fe and unavoidable impurities.

[0034] The preparation method of the austenitic nodular cast iron containing carbide comprises the following steps:

[0035] 1) Smelting: Add returned iron, scrap steel, pig iron, recarburizer, and ferronickel into an intermediate frequency induction furnace and heat up to 1250°C, keep it for 5 minutes, then heat up to 1520°C for melting, tempering, and get the original molten iron, which is released from the furnace;

[0036] 2) Spheroidization inoculation: the spheroidization inoculation treatment is carried out by the method of pouring into the bag, the low rare earth magnesium ferrosilicon alloy spheroidizer is placed in the lower layer of the bottom groove of the spheroidized bag, and 1 / 3 of the iron-silicon alloy inoculant is placed in the upper l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com