Nodular cast iron for automobile braking disc and preparation method thereof

A nodular cast iron and automobile braking technology, which is applied in the field of nodular cast iron, can solve the problems that the performance requirements of nodular cast iron for automobile brake discs cannot be fully met, and the performance of cast iron is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

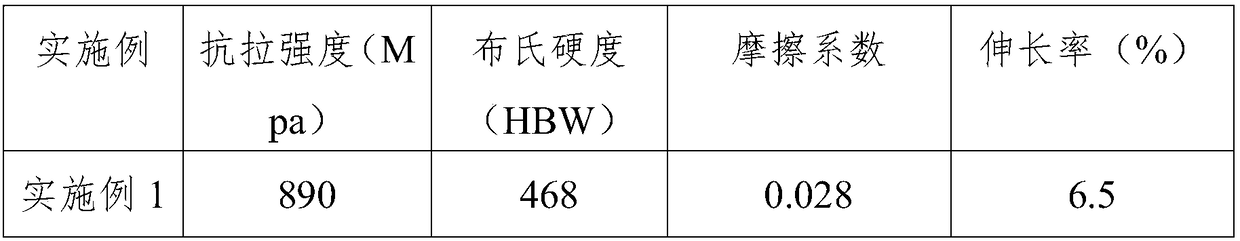

Examples

Embodiment 1

[0022] A kind of nodular cast iron for automobile brake disc, the mass percent of each element composition in the nodular cast iron is: C: 3.4%, Si: 2.9%, Cr: 0.4%, Mn: 0.3%, Al: 0.2%, Ni: 0.6%, Mg: 0.4%, Cu: 0.5%, Mo: 0.3%, Ta: 0.08%, Y: 0.05%, Sb: 0.02%, S≤0.02%, P≤0.04%, the balance is Fe and unavoidable of impurities.

[0023] A method for preparing nodular cast iron for automobile brake discs, comprising the following steps:

[0024] a. Add pig iron, steel scrap and recycled materials into the intermediate frequency induction furnace according to the predetermined formula and smelt them at a temperature of 1500°C. After smelting, detect the content of each element in the molten iron and adjust the content of each element until it meets the formula requirements. When the amount of molten iron in the ladle reaches the required weight, the iron is tapped for spheroidizing inoculation treatment;

[0025] b. Pour the molten iron into the molten iron ladle, add a nodulizer eq...

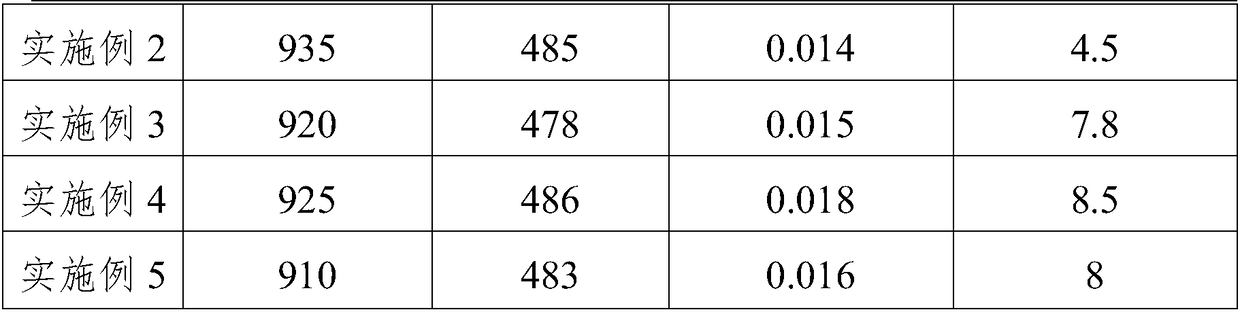

Embodiment 2

[0032]A kind of nodular cast iron for automobile brake disc, the mass percent of each element composition in the nodular cast iron is: C: 3.5%, Si: 3.2%, Cr: 0.8%, Mn: 0.2%, Al: 0.4%, Ni: 0.4%, Mg: 0.2%, Cu: 0.6%, Mo: 0.4%, Ta: 0.10%, Y: 0.04%, Sb: 0.03%, S≤0.02%, P≤0.04%, the balance is Fe and unavoidable of impurities.

[0033] A method for preparing nodular cast iron for automobile brake discs, comprising the following steps:

[0034] a. Add pig iron, steel scrap, and returned materials to the intermediate frequency induction furnace according to the predetermined formula for smelting at a temperature of 1520°C. After smelting, detect the content of each element in the molten iron, and adjust the content of each element until it meets the formula requirements. When the amount of molten iron in the ladle reaches the required weight, the iron is tapped for spheroidizing inoculation treatment;

[0035] b. Pour the molten iron into the molten iron ladle, add a nodulizer equiv...

Embodiment 3

[0042] A kind of nodular cast iron for automobile brake disc, the mass percent of each element composition in the nodular cast iron is: C: 3.2%, Si: 2.7%, Cr: 0.6%, Mn: 0.6%, Al: 0.8%, Ni: 0.2%, Mg: 0.8%, Cu: 0.2%, Mo: 0.4%, Ta: 0.09%, Y: 0.05%, Sb: 0.025%, S≤0.02%, P≤0.04%, the balance is Fe and unavoidable of impurities.

[0043] A method for preparing nodular cast iron for automobile brake discs, comprising the following steps:

[0044] a. Add pig iron, steel scrap, and returned materials to the intermediate frequency induction furnace according to the predetermined formula for smelting at a temperature of 1530°C. After smelting, detect the content of each element in the molten iron, and adjust the content of each element until it meets the formula requirements. When the amount of molten iron in the ladle reaches the required weight, the iron is tapped for spheroidizing inoculation treatment;

[0045] b. Pour the molten iron into the molten iron ladle, add a nodulizer equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com