Nickel-added high-polishing pre-hardened plastic mold steel plate and production method thereof

A technology of plastic mold and production method, applied in the field of plastic mold steel, can solve the problems of difficulty in meeting the hardness requirements of plastic mold steel, reduced polishing performance of mold steel, large difference in surface hardness, etc., and achieve excellent polishing performance of products and improve polishability. , the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

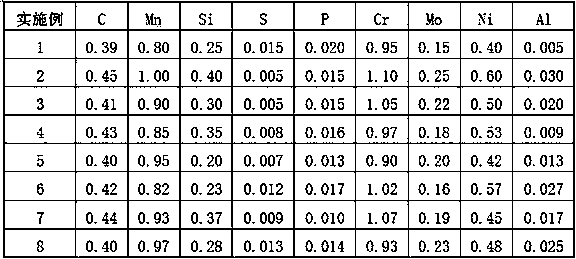

[0019] The thickness of the nickel-added high-polishing pre-hardened plastic mold steel plate in this embodiment is 80 mm, and its chemical composition and mass percentage are shown in Table 1.

[0020] The production method of nickel-added high-polish pre-hardened plastic mold steel plate in this embodiment includes converter smelting, LF furnace refining, RH vacuum refining, continuous casting slab, controlled rolling and controlled cooling, and high-temperature tempering heat treatment processes. The specific process steps are as follows. Said:

[0021] (1) Converter smelting process: the molten iron entering the converter has a sulfur content of 0.050%;

[0022] (2) LF furnace refining and RH vacuum refining process: after LF furnace refining and RH vacuum refining, qualified molten steel is obtained, with Ni element content of 0.40% and H content of 1.2ppm;

[0023] (3) Continuous casting slab process: the thickness of the continuous casting slab is 220mm, and the specif...

Embodiment 2

[0028] The thickness of the nickel-added high-polishing pre-hardened plastic mold steel plate in this embodiment is 150mm, and its chemical composition and mass percentage are shown in Table 1.

[0029] The production method of nickel-added high-polish pre-hardened plastic mold steel plate in this embodiment includes converter smelting, LF furnace refining, RH vacuum refining, continuous casting slab, controlled rolling and controlled cooling, and high-temperature tempering heat treatment processes. The specific process steps are as follows. Said:

[0030] (1) Converter smelting process: the molten iron entering the converter has a sulfur content of 0.042%;

[0031] (2) LF furnace refining and RH vacuum refining process: After LF furnace refining and RH vacuum refining, qualified molten steel is obtained, with Ni element content of 0.60% and H content of 1.5ppm;

[0032] (3) Continuous casting slab process: the thickness of the continuous casting slab is 400mm, and the specif...

Embodiment 3

[0037] In this embodiment, the nickel-added high-polish pre-hardened plastic mold steel plate has a thickness of 120mm, and its chemical composition and mass percentage are shown in Table 1.

[0038] The production method of nickel-added high-polish pre-hardened plastic mold steel plate in this embodiment includes converter smelting, LF furnace refining, RH vacuum refining, continuous casting slab, controlled rolling and controlled cooling, and high-temperature tempering heat treatment processes. The specific process steps are as follows. Said:

[0039] (1) Converter smelting process: the molten iron entering the converter has a sulfur content of 0.046%;

[0040] (2) LF furnace refining and RH vacuum refining process: After LF furnace refining and RH vacuum refining, qualified molten steel is obtained, with Ni element content of 0.50% and H content of 1.0ppm;

[0041] (3) Continuous casting slab process: the thickness of the continuous casting slab is 280mm, and the specifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com