Carbon-modified TiO2/WO3 composite nanofiber photocatalyst, preparation method and application

A technology of composite nanofibers and photocatalysts, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of complex preparation process and achieve simple preparation process. , Enhanced photocatalytic performance, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

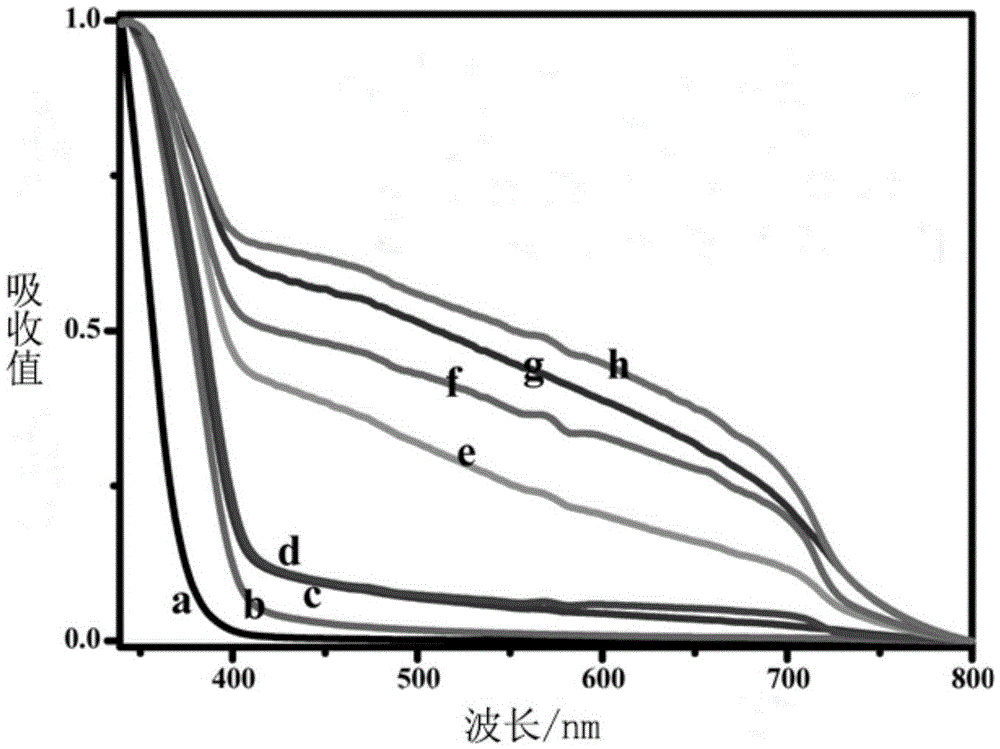

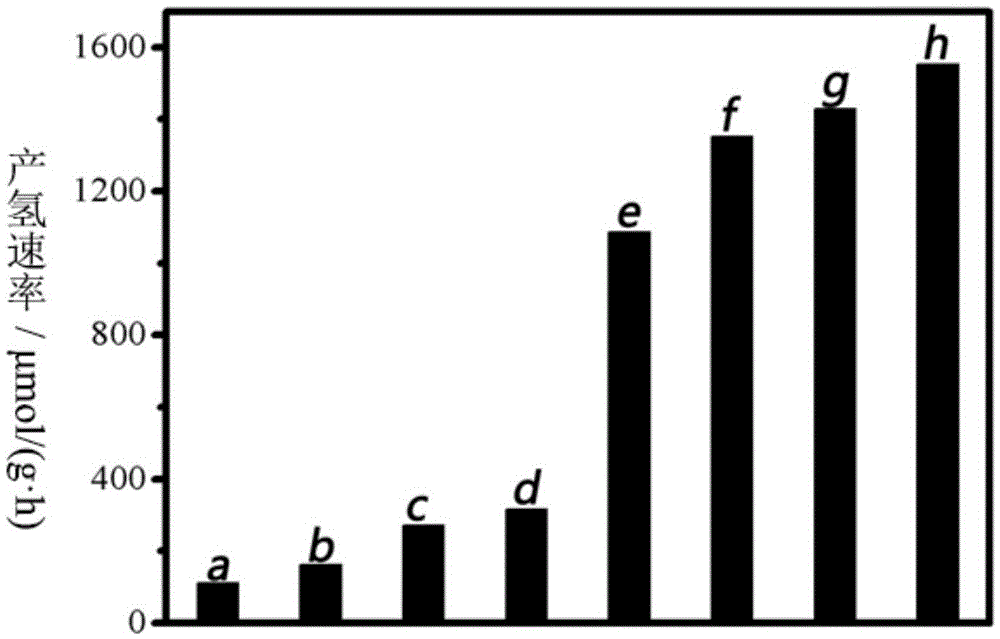

[0037] carbon modified TiO 2 / WO 3 Composite nanofiber photocatalyst, its preparation steps are as follows:

[0038] 1) Add 1.1g polyvinylpyrrolidone to the mixture of 10mL ethanol and 6mL acetic acid, stir well, add 0.05g ammonium tungstate and 2mL tetrabutyl titanate, stir at 600rpm for 12h to get the precursor solution, add it In the electrospinning equipment (Concent 1006 type), the high-voltage electric field voltage is set to 12kV, and the distance from the injector to the receiving plate is 15cm. Under the action of the electric field force, the nanofibers are collected on the receiving device to form a nanofiber mat;

[0039] 2) Take the nanofiber mat and calcinate it at a temperature of 520°C for 30min to obtain TiO 2 / WO 3 Nanofibers;

[0040] 3) 20mgTiO 2 / WO 3 Nanofibers and 0.45g glucose were added to a hydrothermal reaction kettle containing 30mL deionized water, and the hydrothermal reaction was carried out at a temperature of 180°C for 4 hours. After the re...

Embodiment 2

[0043] carbon modified TiO 2 / WO 3 Composite nanofiber photocatalyst, its preparation steps are as follows:

[0044] 1) Add 1.1g polyvinylpyrrolidone to the mixture of 10mL ethanol and 6mL acetic acid, stir well, add 0.1g ammonium tungstate and 2mL tetrabutyl titanate, stir at 600rpm for 12h to get the precursor solution, add it In the electrospinning equipment (Concent 1006 type), the high-voltage electric field voltage is set to 12kV, and the distance from the injector to the receiving plate is 15cm. Under the action of the electric field force, the nanofibers are collected on the receiving device to form a nanofiber mat;

[0045] 2) Take the nanofiber mat and calcinate it at a temperature of 520°C for 30min to obtain TiO 2 / WO 3 Nanofibers;

[0046] 3) 20mgTiO 2 / WO 3 Nanofibers and 0.15g glucose were added to a hydrothermal reaction kettle containing 30mL deionized water, and the hydrothermal reaction was carried out at a temperature of 180°C for 4 hours. After the r...

Embodiment 3

[0049] carbon modified TiO 2 / WO 3 Composite nanofiber photocatalyst, its preparation steps are as follows:

[0050] 1) Add 1.1g polyvinylpyrrolidone to the mixture of 10mL ethanol and 6mL acetic acid, stir well, add 0.15g ammonium tungstate and 2mL tetrabutyl titanate, stir at 600rpm for 12h to get the precursor solution, add it In the electrospinning equipment (Concent 1006 type), the high-voltage electric field voltage is set to 12kV, and the distance from the injector to the receiving plate is 15cm. Under the action of the electric field force, the nanofibers are collected on the receiving device to form a nanofiber mat;

[0051] 2) Take the nanofiber mat and calcinate it at a temperature of 520°C for 30min to obtain TiO 2 / WO 3 Nanofibers;

[0052] 3) 20mgTiO 2 / WO 3 Nanofibers and 0.15g glucose were added to a hydrothermal reaction kettle containing 30mL deionized water, and the hydrothermal reaction was carried out at a temperature of 180°C for 4 hours. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com