Improved roller double-frequently quenching process

A technology of frequency quenching and roll, which is applied in the field of improved dual-frequency quenching process of rolls, can solve the problems of affecting the quenching hardness, short distance, improper cooperation between quenching process and cold treatment, etc., and achieve the effect of improving the quenching hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

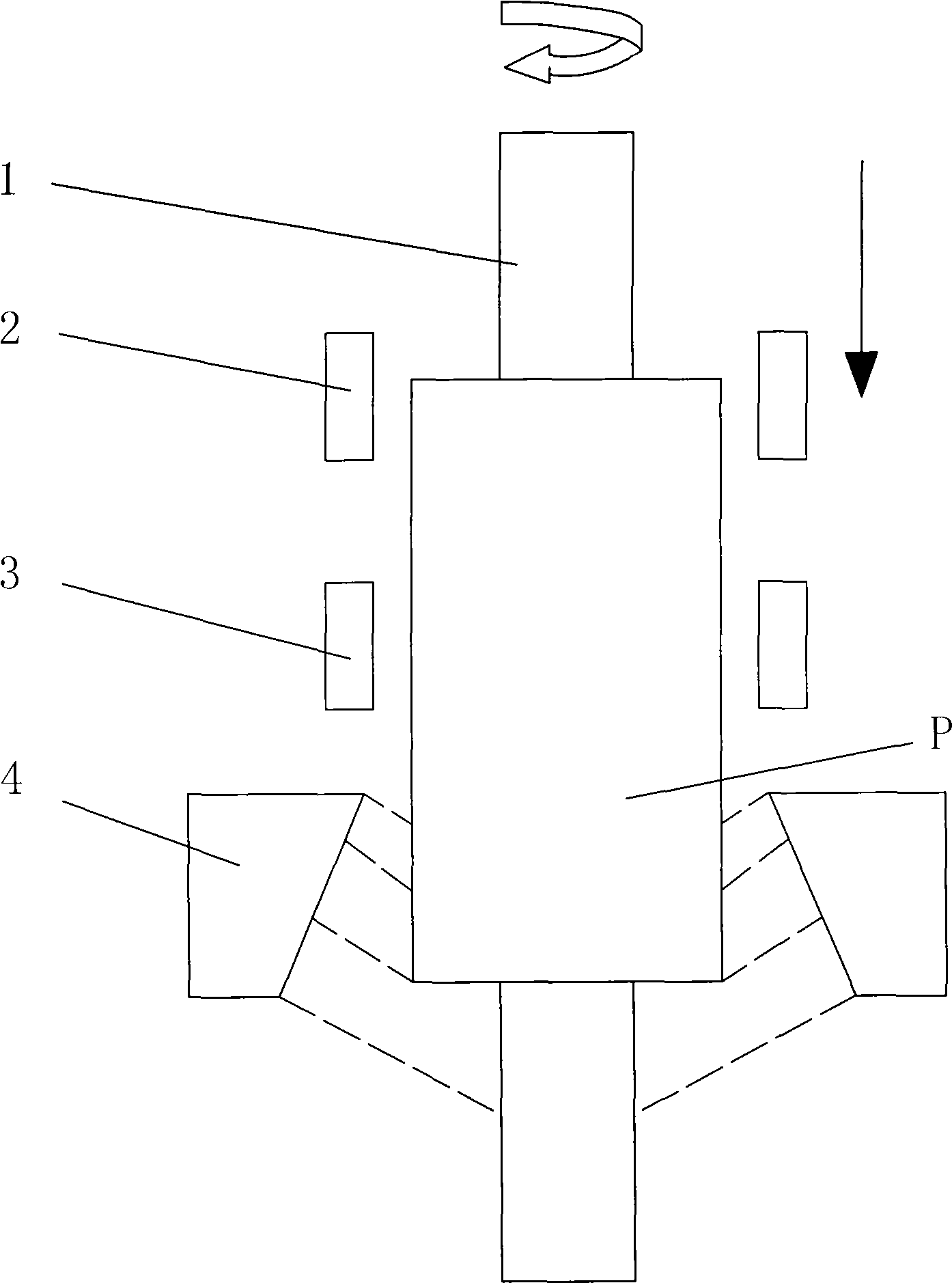

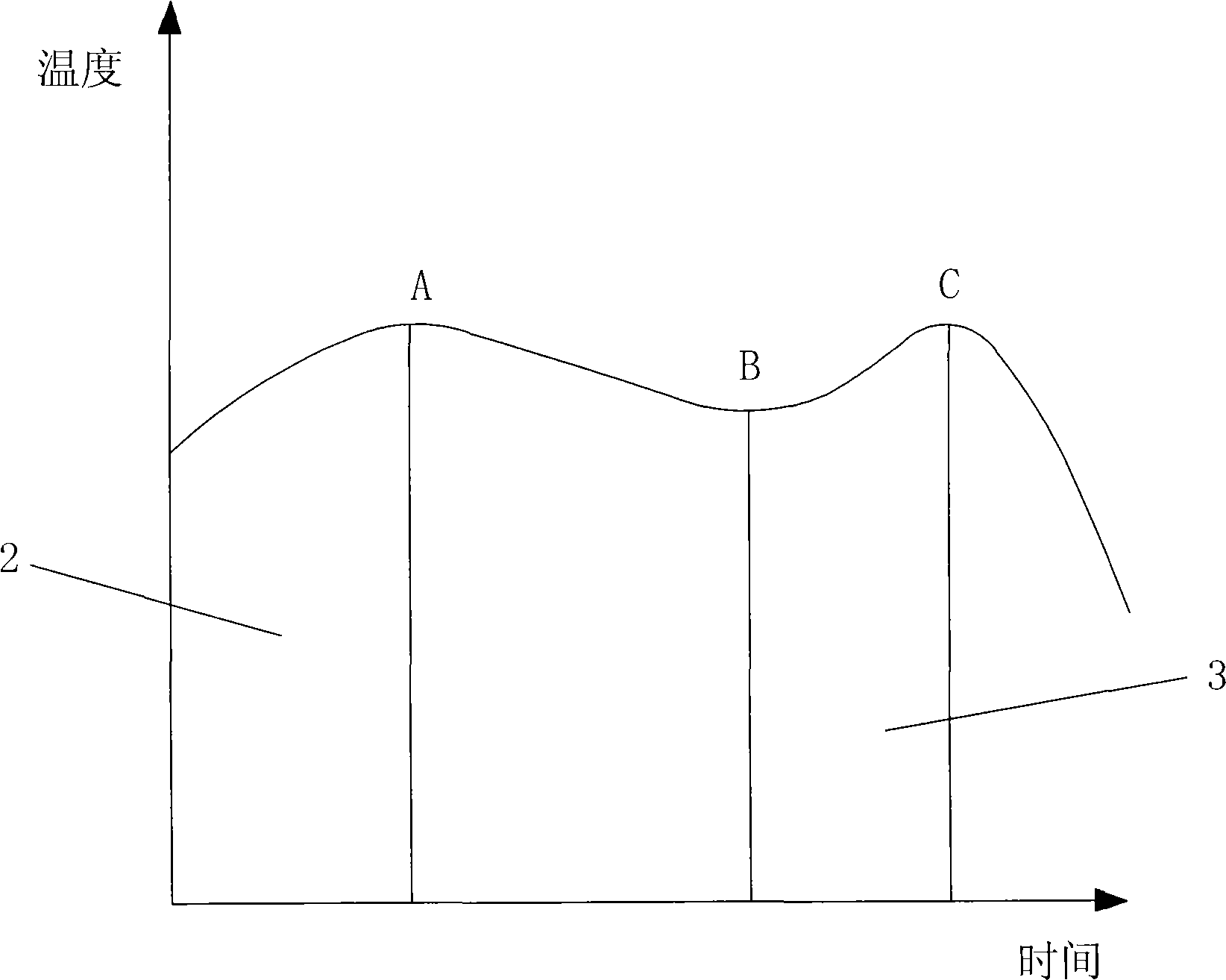

[0024] Example: such as figure 1 and figure 2 As shown, an improved double-frequency quenching process for rolls uses two power supplies to supply power to the upper and lower inductors 2 and 3 respectively, the upper inductor 2 passes a low-frequency current of 50±10HZ, and the lower inductor 3 passes an intermediate frequency of about 200HZ Current, roll 1 is vertically suspended on a special quenching machine, passes through the upper inductor and the lower inductor in sequence from top to bottom, and is heated to the quenching temperature, where the heating temperature (TA) of the upper inductor is slightly higher than that of the lower inductor Heating temperature (TC). Subsequently, the water sprayer 4 located below the inductor quenches and cools the roll 1 . In order to ensure uniform heating, two infrared thermometers are used to monitor the temperature at the outlets of the upper and lower sensors 2 and 3 respectively, and the temperature fluctuation is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com