Food sterilizing device and sterilizing method

A sterilizing device and food technology, applied in food preservation, food science, application, etc., can solve the problems of wasting energy, reducing the taste of food, and taking a long time, and achieve the effects of shortening time, reasonable temperature distribution, and increasing the utilization area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

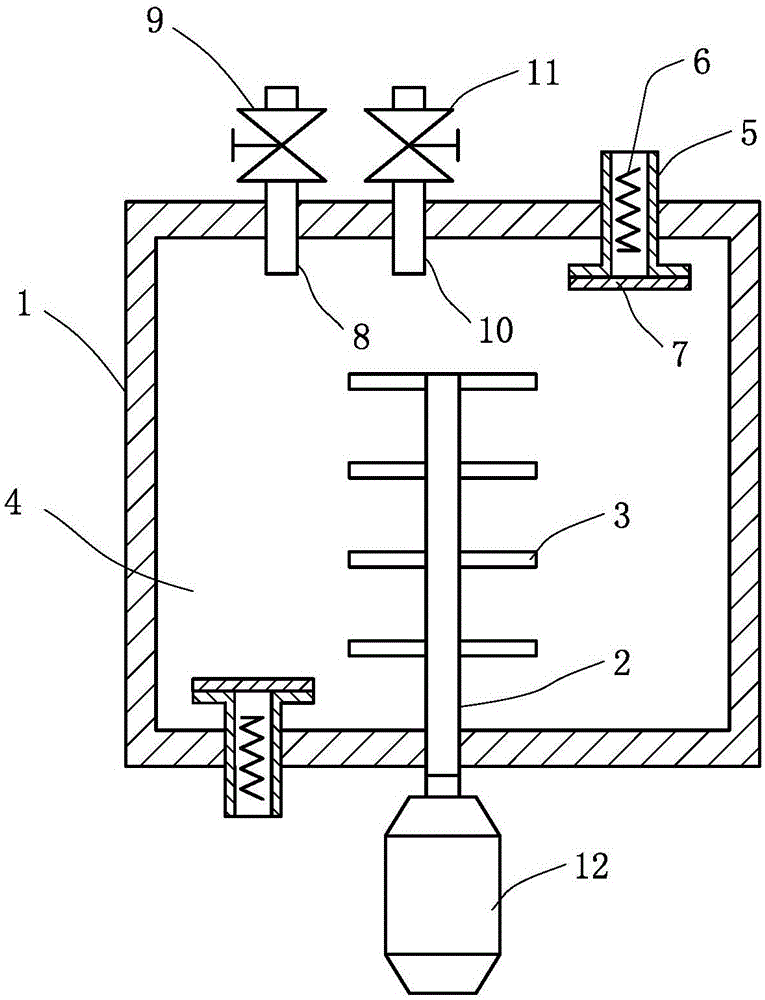

[0022] Such as figure 1 As shown, the present invention provides a food sterilization device, including a pressure vessel 1, the pressure vessel 1 has a closed sterilization cavity 4, the pressure vessel 1 usually includes a box body and a box cover connected together, the box cover can be opened, open the box The food can be put into the sterilization chamber 4 with the lid. The pressure vessel 1 is provided with a non-contact heating mechanism for raising the temperature in the sterilization chamber 4. The pressure vessel 1 is provided with an air inlet pipe 8 and an air outlet pipe 10, and the air inlet pipe 8 is provided There is an inlet valve 9 and an outlet valve 11 on the outlet pipe 10. In order to avoid occupying the volume of the sterilization chamber 4 and to keep the control elements of the inlet valve 9 and the outlet valve 11 away from the high temperature zone, the inlet valve 9 and the outlet valve 11 Usually installed outside the sterilization cavity 4, the ai...

Embodiment 2

[0026] reference figure 1 , The present invention provides a food sterilization method, including the following steps:

[0027] (1) Put food into pressure vessel 1: Pressure vessel 1 has a closed sterilization chamber 4, pressure vessel 1 is rotatably installed with transmission shaft 2 driven by a power device, transmission shaft 2 is provided with tray 3, and tray 3 is located In the sterilization chamber 4, the food is placed on the tray 3. The tray 3 can be provided with several layers to increase the supporting capacity. The power device usually includes a transmission mechanism connected to the motor 12. Of course, the motor 12 can also be directly connected, but it is The direct connection of the motor 12 will have thermal transmission, which will cause the motor 12 to be heated. Therefore, it is recommended to use the motor 12 to connect the sprocket chain or other transmission mechanism;

[0028] (2) Close the pressure vessel 1: make the sterilization chamber 4 a closed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com