Zero cooling air consumption super-strength cooling device for aircraft engine turbine blade

A turbine blade and cooling device technology, applied in the field of turbine blade cooling, can solve the problems of low cooling efficiency per unit air volume and complex cooling structure of gas turbine blades, so as to improve the working environment of the turbine, avoid difficult processing of turbine blades, and improve cycle thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

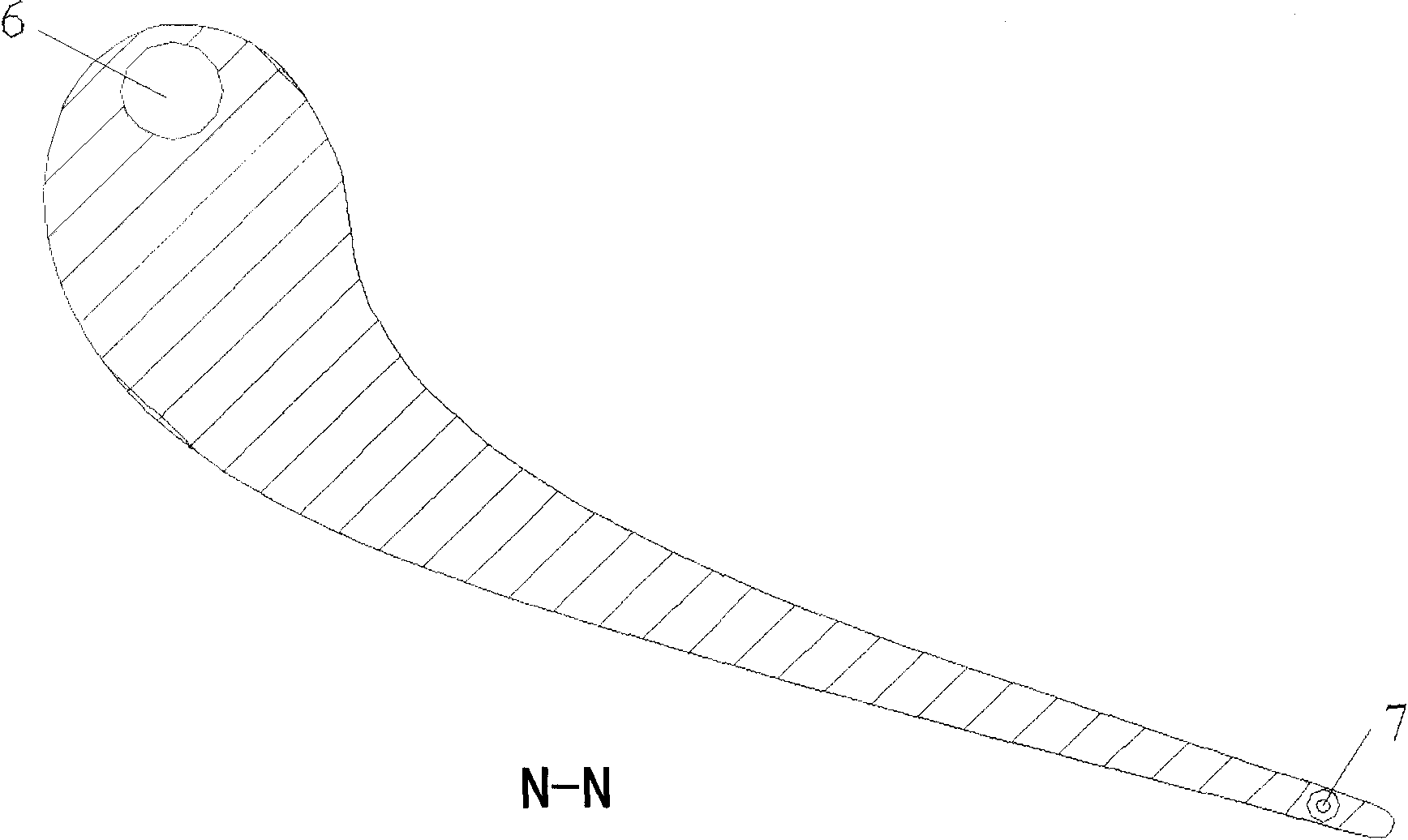

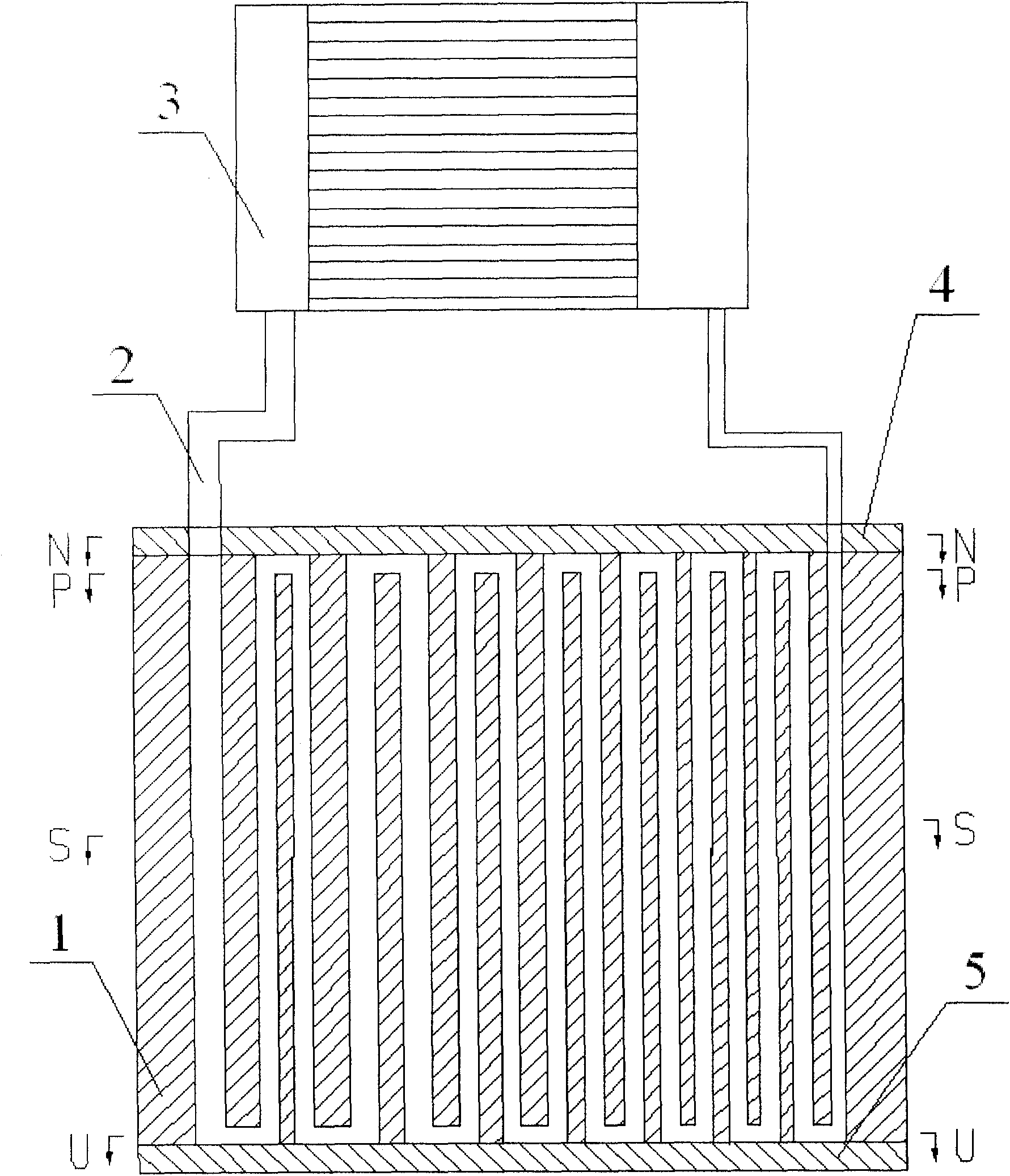

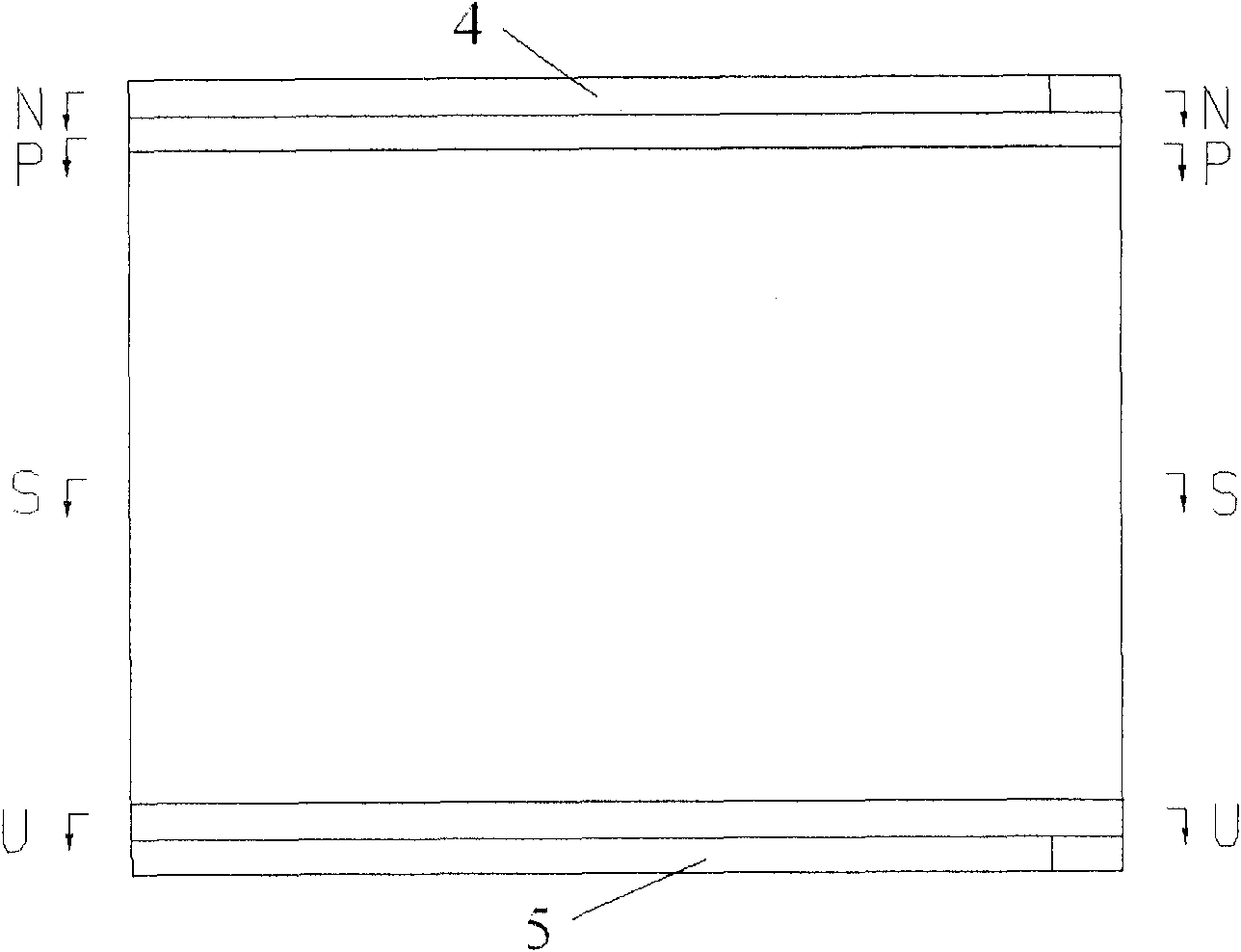

[0028] The zero cold air consumption super-strength cooling device for aeroengine turbine blades of the present invention is to process a plurality of independent circular hole passages transversely within the blade wall thickness (from the leading edge to the trailing edge of the blade), and the circular hole passages are arranged in parallel with each other , the upper end and the upper end of the adjacent round hole channels are connected to each other, and the lower end is connected to the lower end to form a serpentine channel. The inlet and outlet are connected, so that the serpentine channel and the radiator form a closed and connected internal cooling channel, and high-pressure liquid is injected into the channel, and the liquid must fill the channel. When the turbine blades feel the high-temperature gas, driven by the heat of the high-temperature gas, an internal circulation is formed in the internal cooling channel, and the heat in the circulating flow is taken away b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com