Hydraulic type portal frame

A gantry, hydraulic technology, applied in the direction of lifting frame, hoisting device, hoisting equipment braking device, etc., can solve the problems of inconvenient transportation and installation, high manufacturing cost, time-consuming use, etc., and achieve small impact and wear resistance Good, easy to repair and replace parts

Inactive Publication Date: 2011-04-13

SHAOXING UNIVERSITY +2

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the common hydraulic systems or hydraulic machines mostly adopt the structure of three beams and four columns or two beams and four columns. The hydraulic presses or hydraulic systems of this structure mainly have the following disadvantages: 1. The structure is complicated. Due to the use of three beams and four columns or two beams and four columns The structure will bring inconvenience to transportation and installation; 2. The manufacturing cost is high, and the use is time-consuming and laborious; 3. When working, the noise is loud and the environmental protection is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

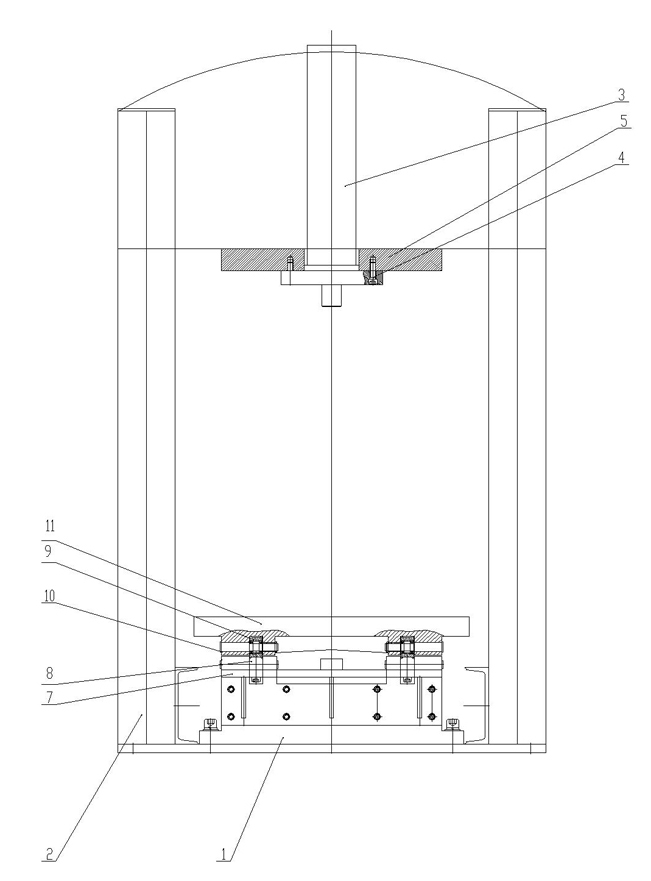

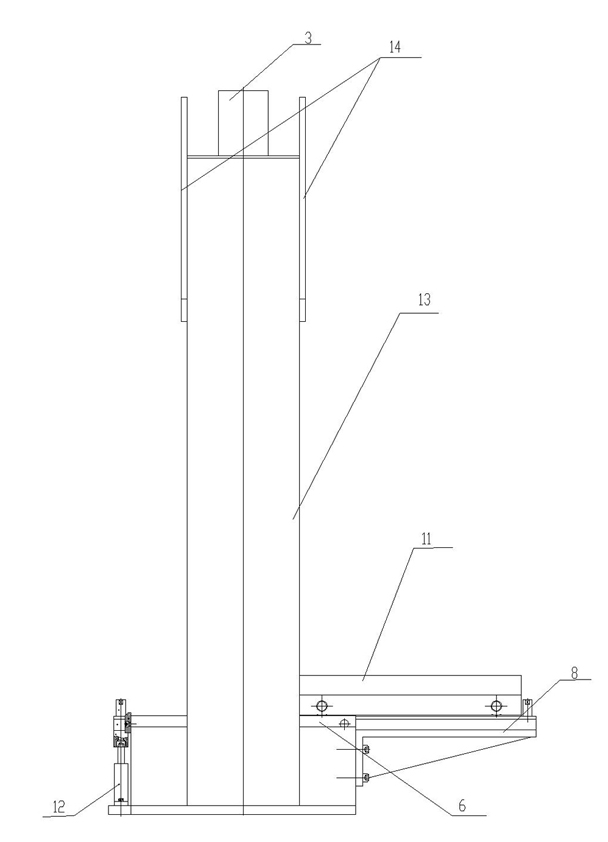

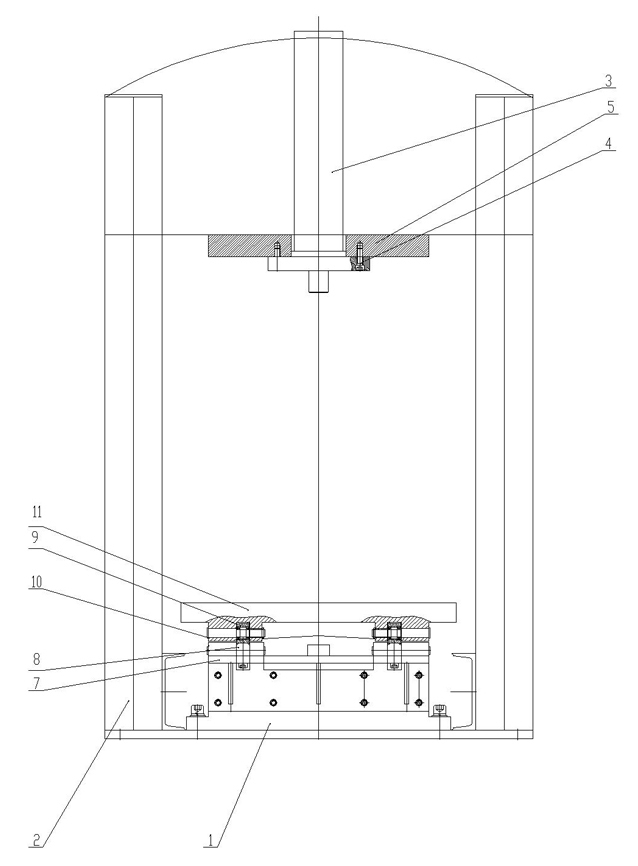

The invention discloses a hydraulic type portal frame which comprises a base and a rack installed on the base, wherein a difunctional hydraulic cylinder is installed on the top of the rack, the bottom of the difunctional hydraulic cylinder is provided with a work platform through a screw, the base is provided with a bracket, a support plate is installed on one side of the bracket, and a guide rail is installed on the support plate, extends into the bracket, and is fixedly connected with the bracket; a guide wheel is movably installed on the guide rail, the guide wheel is provided with a guide wheel shaft, and the guide wheel shaft is installed in a chute on the lower end of a work sliding table; and a single acting hydraulic cylinder is installed on of the base at the other side of the work sliding table. The invention provides a hydraulic machine which has the advantages of reasonable structure and lower production cost, and is lighter and more convenient.

Description

technical field [0001] The invention relates to a hydraulic gantry frame. Background technique [0002] The gantry frame is mainly composed of five parts: beams, columns, chassis, guide beams and fulcrums, which are used as supports for lifting equipment, such as gantry crane supports. The two pillars are like Panlong pillars, and the image is called Longmen frame. Hydraulic transmission began to be used at the end of the eighteenth century, but it was widely used in industry for a relatively short time. The hydraulic system has been greatly developed in recent years because of its small size, light weight, infinitely variable speed, stable movement, and long working life. At present, the common hydraulic systems or hydraulic machines mostly adopt the structure of three beams and four columns or two beams and four columns. The hydraulic presses or hydraulic systems of this structure mainly have the following disadvantages: 1. The structure is complicated. Due to the use of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B66C5/02B66F7/00

Inventor 王文奎俞学人

Owner SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com