Patents

Literature

69results about How to "Guaranteed heat treatment performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

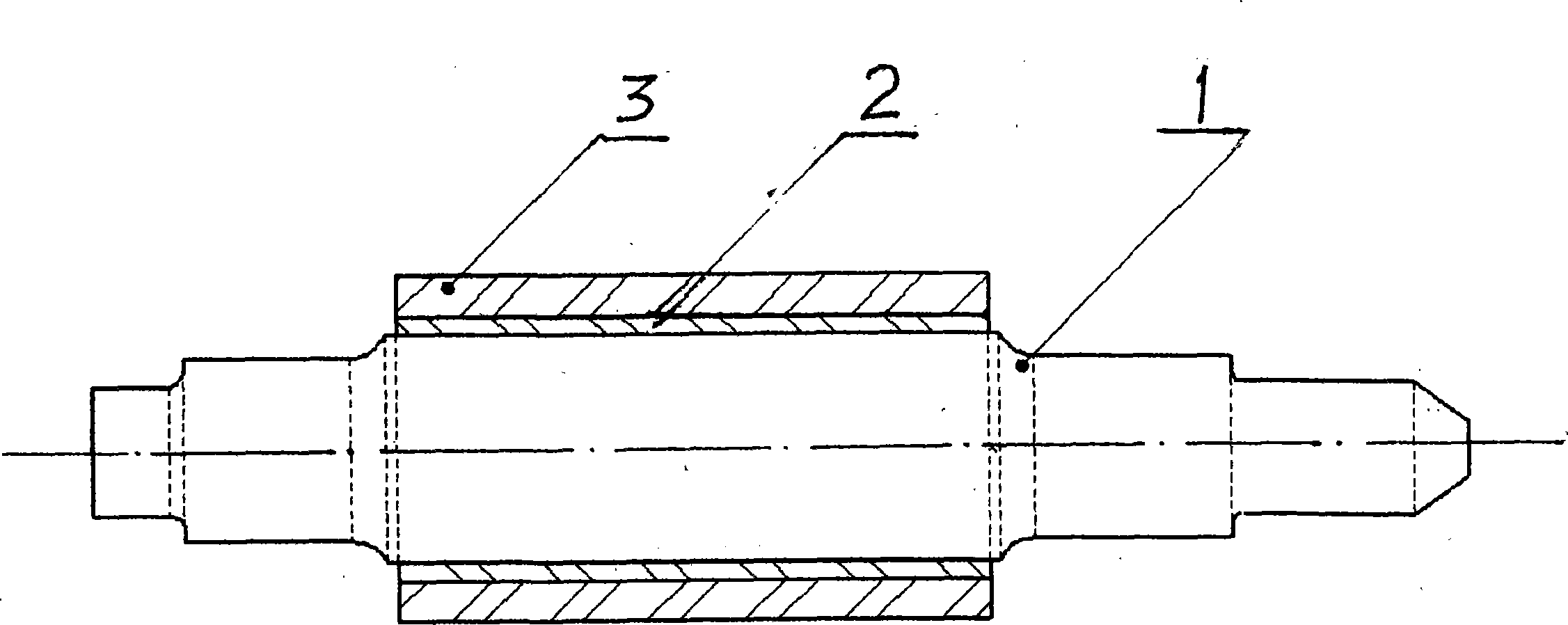

Roll collar roller capable of cyclic utilization and production method

ActiveCN101239359AStable structureImprove securityRollsMetal rolling arrangementsInterference fitIntermediate frequency

The invention discloses a reusable collar roller consisting of a core shaft, an inner ring and an outer ring, and a producing method thereof. A bimetal collar formed by melting the inner ring and the outer ring is disposed at the body part of the core shaft by interference fit. High-speed-steel or high nickel cast iron which is raw material of the outer ring is put into a intermediate frequency stove to be heated and melted to alloy steel fluid with the temperature ranging from 1600 DEG C to 1650 DEG C, the cleaned seamless steel tube or low carbon casting steel tube which is used as the inner ring is preheated to the temperature ranging from 300 DEG C to 800 DEG C, and then is fed into a sand mold, the hyperthermia alloy steel fluid is cast into the sand mold and the casting temperature is held in the range of 1490-1540 DEG C, the inner ring and the outer ring are melt into a bimetal ring during the steel fluid setting process, and the bimetal ring forms a collar roller with the core shaft by interference fit after thermal treatment process. The collar roller is provided with a stable structure and a long life.

Owner:HUNAN 3T NEW MATERIAL

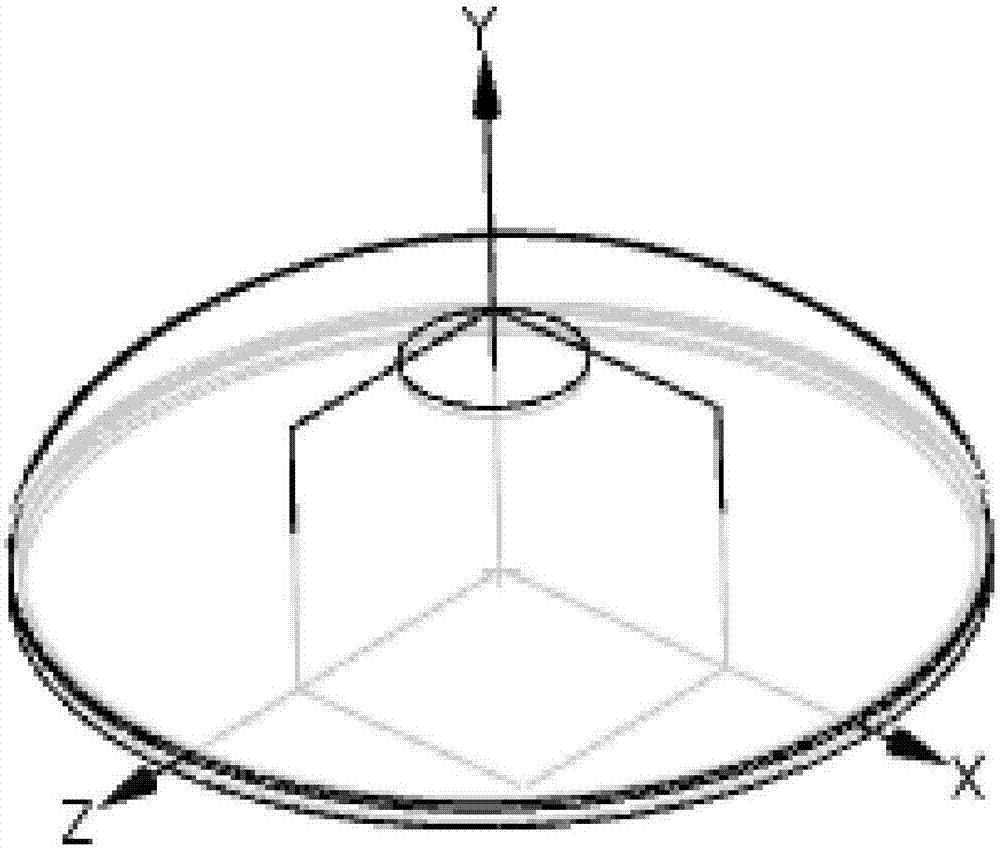

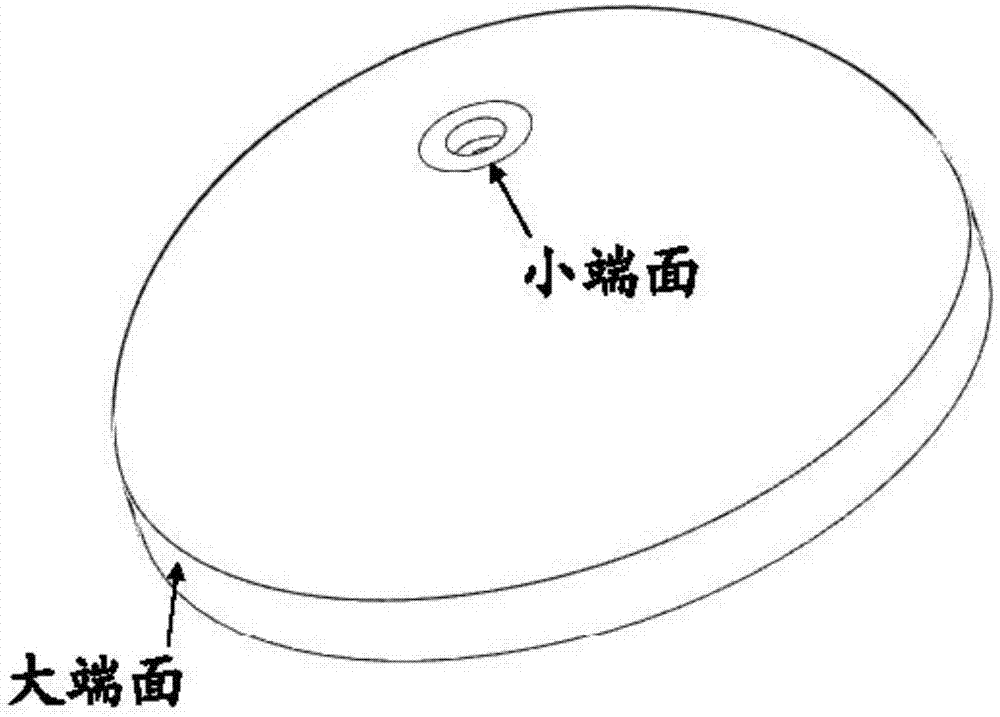

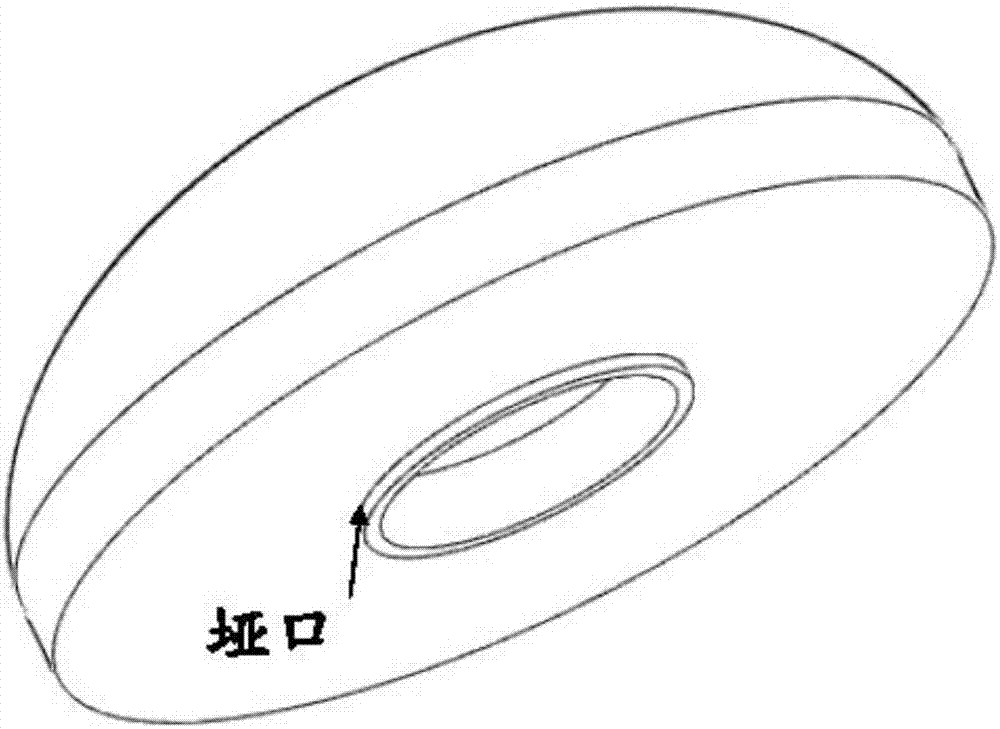

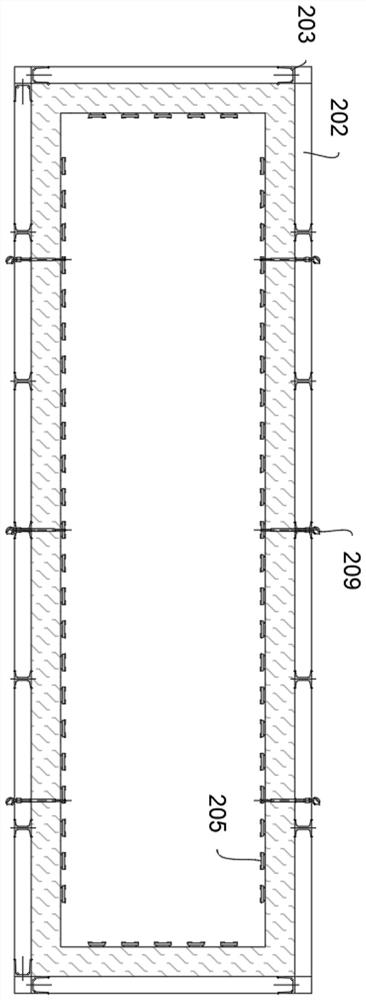

Heat treatment deformation control method for large-diameter and large-modulus elliptical molded surface container semispherical shell

ActiveCN107513677APrevent collapseSmall quenching deformationFurnace typesHeat treatment process controlQuenchingAqueous solution

The invention relates to a heat treatment deformation control method for a large-diameter and large-modulus elliptical molded surface container semispherical shell and belongs to the technical field of container manufacturing. By means of the heat treatment deformation method, due to the fact that an integrated quenching and aging heat treatment tool is designed, the elliptical molded surface container semispherical shell and the heat treatment tool can be tightly matched, the quenching transfer time is shortened, the phenomenon that the top of the shell collapses and pits happen in the circumferential direction of the shell during quenching is avoided, quenching and time aging deformation is reduced, and therefore the heat treatment performance of the elliptical molded surface container semispherical shell can be ensured; and meanwhile, the subsequent machining precision of the shell is also ensured. In addition, a UCON water solution with the concentration ranging from 6% to 10% is adopted in the method to serve as a quenching medium, dynamic flowing of the water solution is maintained, the cooling speed and uniformity of the shell are ensured, meanwhile, quenching deformation is also controlled, and therefore the product precision is ensured.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

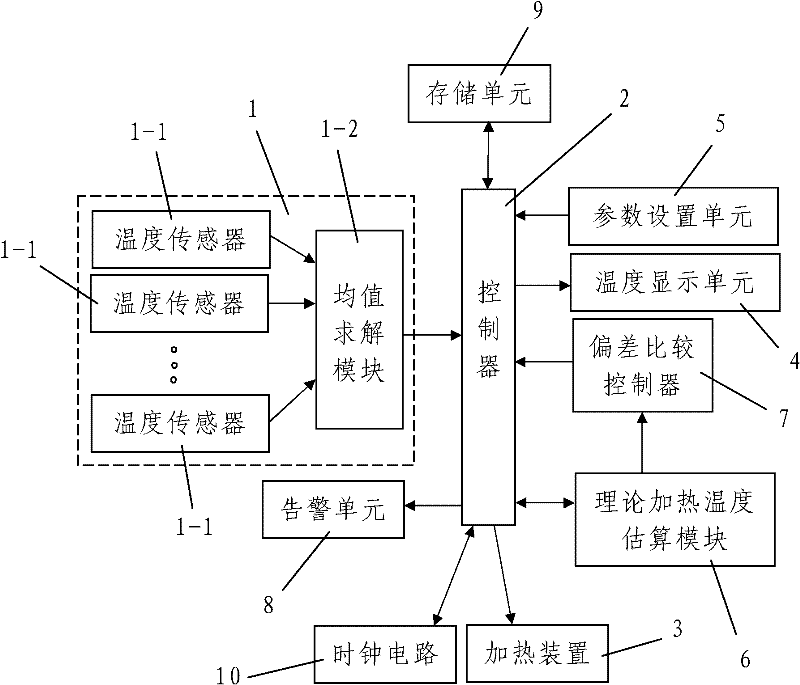

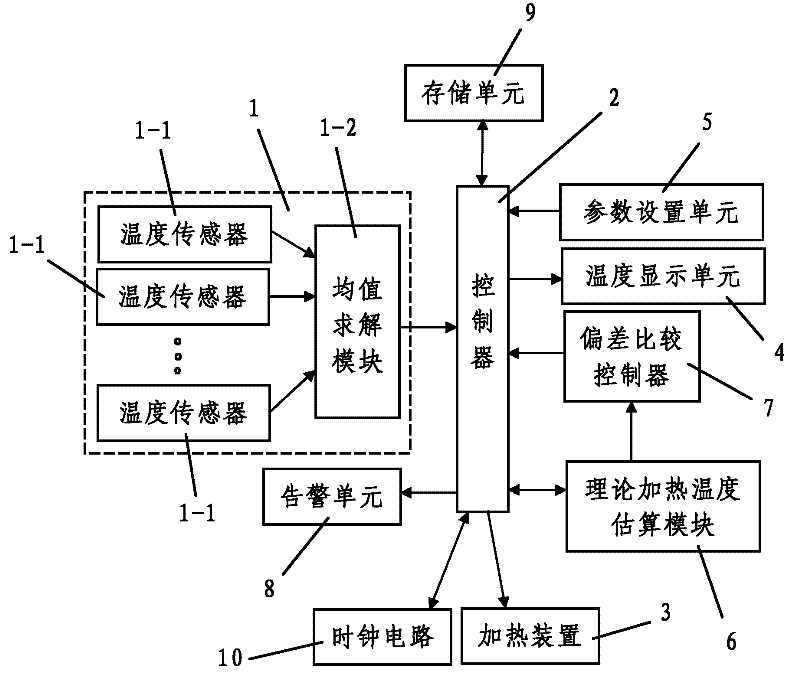

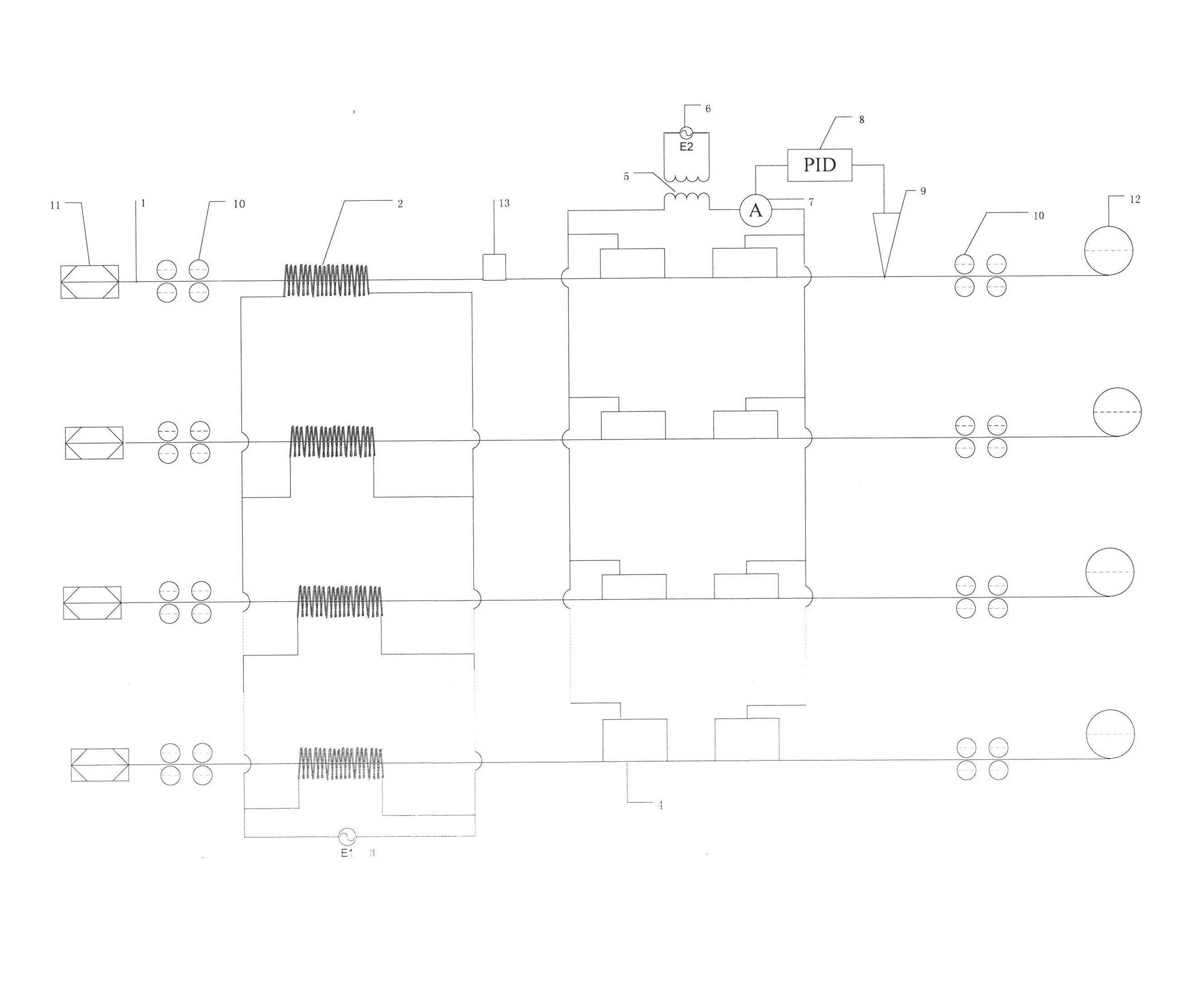

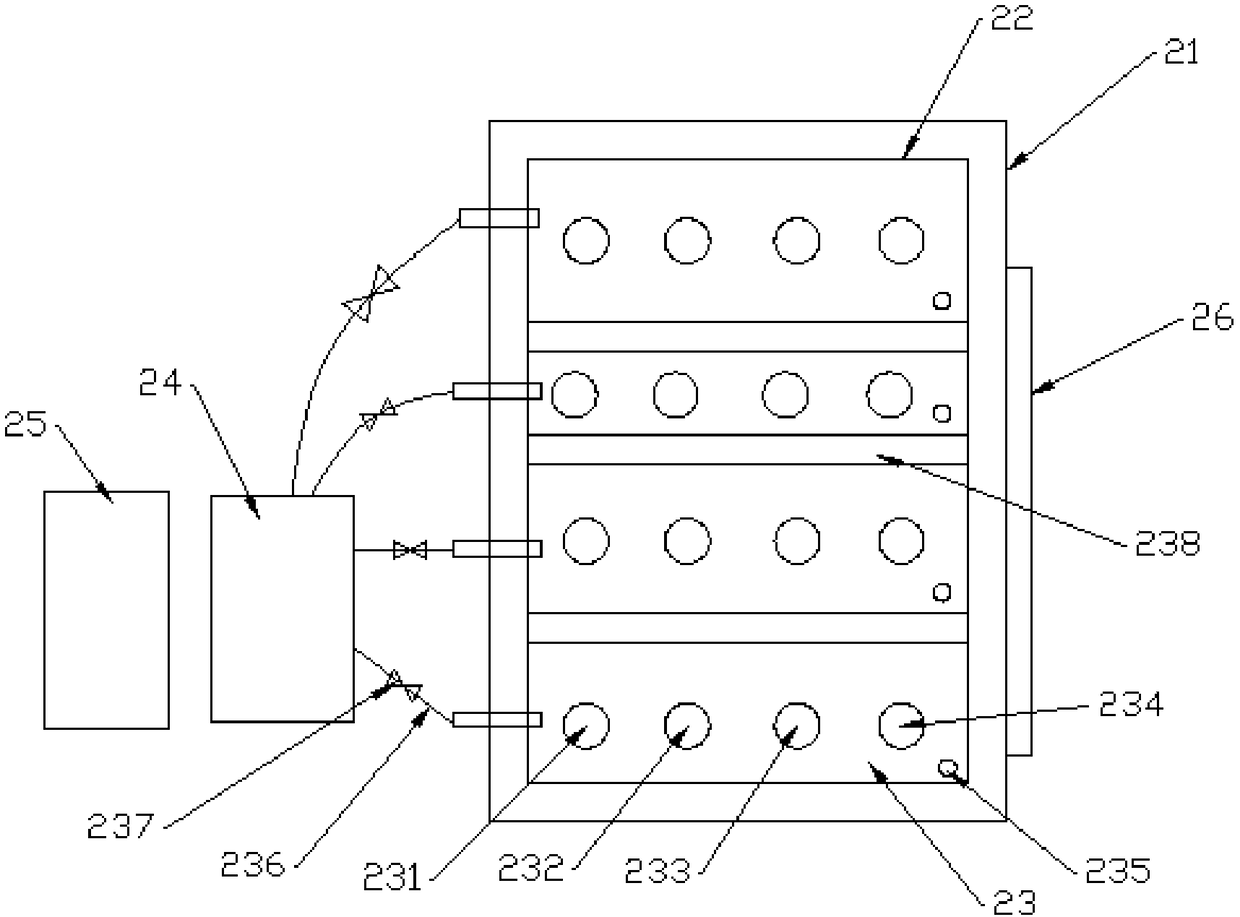

Automatic temperature regulating system for constant temperature furnace

InactiveCN102455134AReasonable designLow costControl devices for furnacesSocial benefitsComputer module

The invention discloses an automatic temperature regulating system for a constant temperature furnace. The automatic temperature regulating system comprises a temperature detection unit, a controller, a temperature display unit, a parameter setting unit, a theoretic heating temperature estimating module, a deviation comparing controller and a warning unit, wherein the controller is used for controlling a heating device of the constant temperature furnace according to the temperature information detected by the temperature detection unit; the deviation comprising controller is used for comparing and analyzing the temperature which is detected by the temperature detection unit in real time with the actual heating temperature calculated by the theoretic heating temperature estimating module; the warning unit is controlled by the controller; the temperature detection unit comprises a plurality of temperature sensors and mean solving modules, wherein the temperature sensors are arranged in the center and a plurality of positions on the inner side of the circumferential wall in the constant temperature furnace; and the mean solving modules are respectively connected with the temperature sensors. The automatic temperature regulating system has the advantages of reasonable design, good use effect and high intelligent degree and is easy and convenient to operate; the detected temperature can accurately reflect the actual temperature in the heating furnace in the current state; the heat treatment effect of processed workpieces can be effectively ensured; and the automatic temperature regulating system has remarkable economic and social benefits.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

Manufacturing method of high-strength aluminum alloy rivet wire for spaceflight

ActiveCN106756333AImprove performanceGuaranteed heat treatment performanceSolution treatmentHigh intensity

The invention discloses a manufacturing method of a high-strength aluminum alloy rivet wire for spaceflight, and relates to a manufacturing method of a novel aluminum alloy rivet wire. The imperious demands of China space industry for high-strength riveting materials, particularly light aluminum alloy rivet materials are met, the material strength is ensured, and meanwhile rivets are required to have certain plasticity. The manufacturing method comprises the first step of alloy solution preparation, the second step of molten aluminum refining treatment, the third step of casting of an alloy cast bar, the fourth step of homogenizing annealing, the fifth step of cast bar sawing, the sixth step of hot extrusion forming, the seventh step of intermediate annealing, the eighth step of cold drawing, the ninth step of solution treatment and the tenth step of aging treatment. According to the aluminum alloy rivet wire manufactured through the manufacturing method, the tensile strength is not smaller than 580 Mpa, the stipulated non-proportional extension strength is not smaller than 500 Mpa, the percentage elongation after fracture is not smaller than 6%, the shear strength is not smaller than 320 Mpa, and application requirements of spaceflight products are met. The manufacturing method can be used for machining and manufacturing spaceflight aluminum alloy rivets.

Owner:NORTHEAST LIGHT ALLOY CO LTD

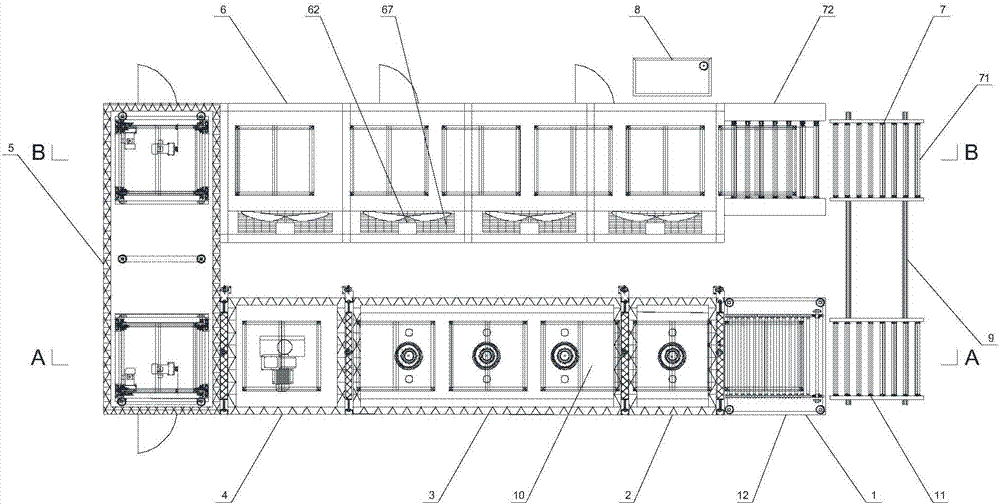

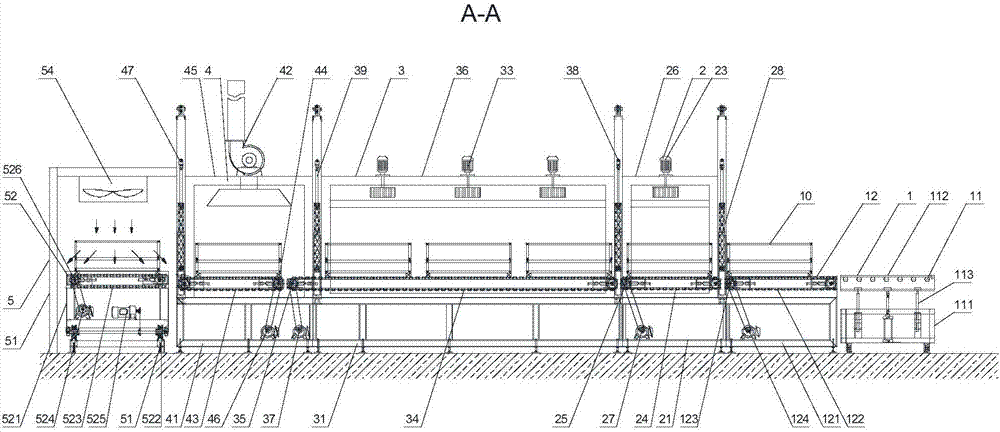

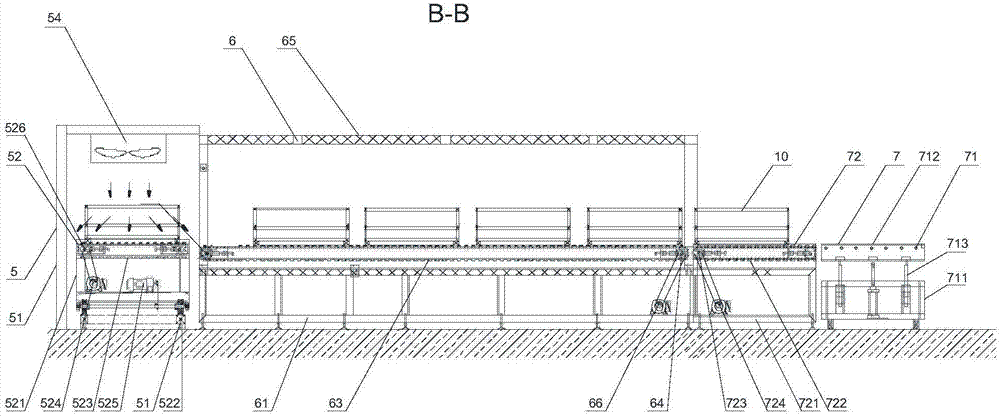

Tunnel furnace and workpiece thermal treatment process

PendingCN106893805AIncrease the level of automationImprove heat treatment effectFurnace typesHeat treatment process controlThermodynamicsHeating effect

The invention discloses a tunnel furnace and a workpiece thermal treatment process. The tunnel furnace comprises a feeding portion for receiving a workpiece, a preheating portion connected with the feeding portion and used for preheating the workpiece, a constant-temperature portion connected with the preheating portion and used for heating the workpiece at the constant temperature, a heat insulation portion connected with the constant temperature portion and used for keeping the temperature of the workpiece, a shock cooling portion connected with a transition portion and used for quickly cooling the workpiece, a cooling portion connected with the shock cooling portion and used for continuously cooling the workpiece and a discharging portion connected with the cooling portion and used for receiving the workpiece. The tunnel furnace and the workpiece thermal treatment process have the beneficial effects that the automatic level of the workpiece thermal treatment and the workpiece thermal treatment effect are improved, the labor is reduced, and accordingly the production cost of enterprises and the occupational injury rate generated in the production process are lowered; and meanwhile, the situation that the workpiece is in contact with the external air in the thermal treatment process is avoided by means of the tunnel furnace, so that the thermal treatment effect of the workpiece is guaranteed greatly, the heating uniformity and the heating effect of the workpiece are improved, and the cooling and shaping effect of the workpiece is improved.

Owner:上海迅美工业设备有限公司

Heat treatment technology of martensite stainless steel workpiece

InactiveCN103627858AMeet the hardness requirements of heat treatmentGuaranteed heat treatment performanceMartensitic stainless steelHardness

The invention discloses a heat treatment technology of a martensite stainless steel workpiece. The technology comprises the steps of annealing, quenching, a primary tempering technology and a secondary tempering technology. By adopting the above mode, the heat treatment technology allows a forged piece to satisfy a heat treatment hardness requirement, guarantees the heat treatment performance, realizes a high quenching hardness, and also realizes alloy uniformization, crystal grain refinement and forging stress elimination.

Owner:SUZHOU BAOFORGING

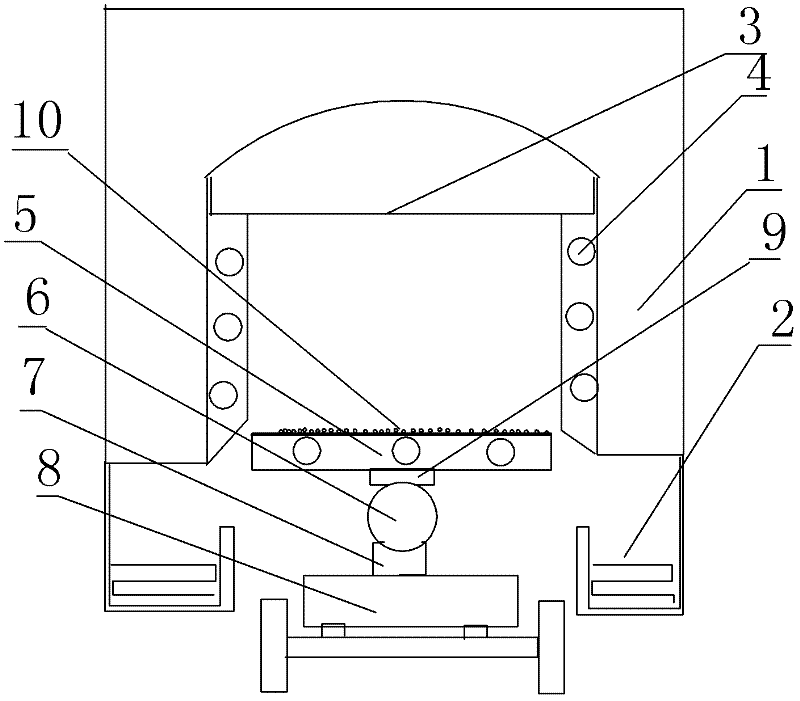

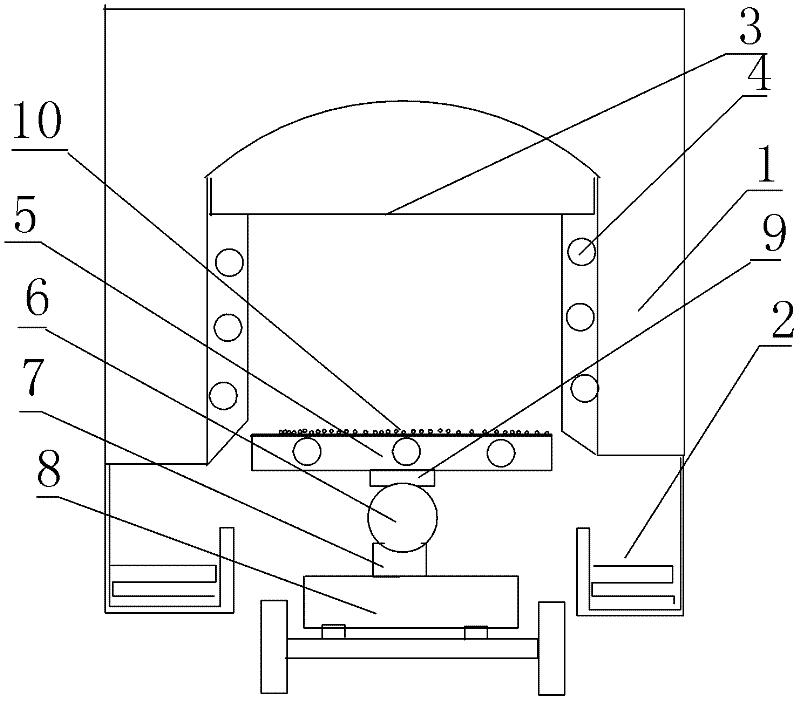

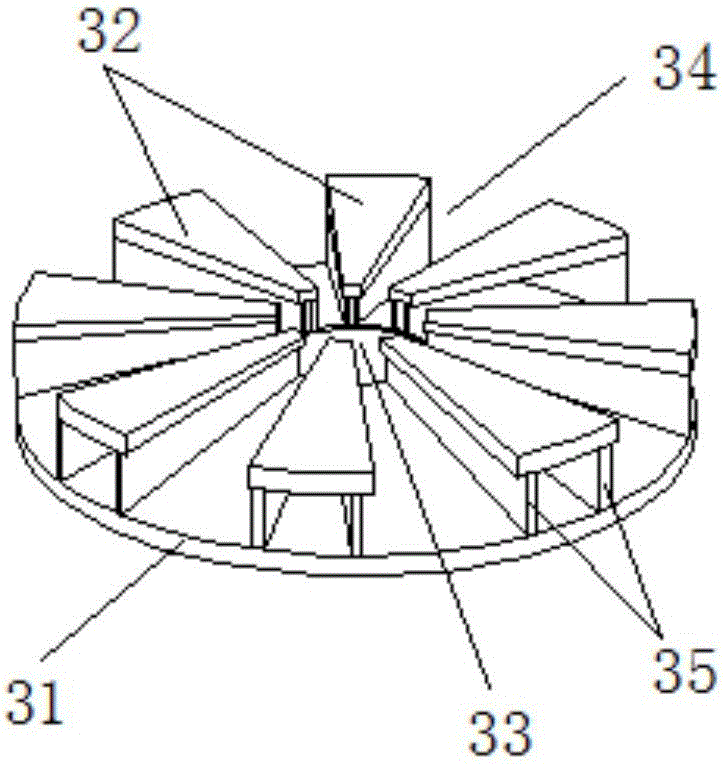

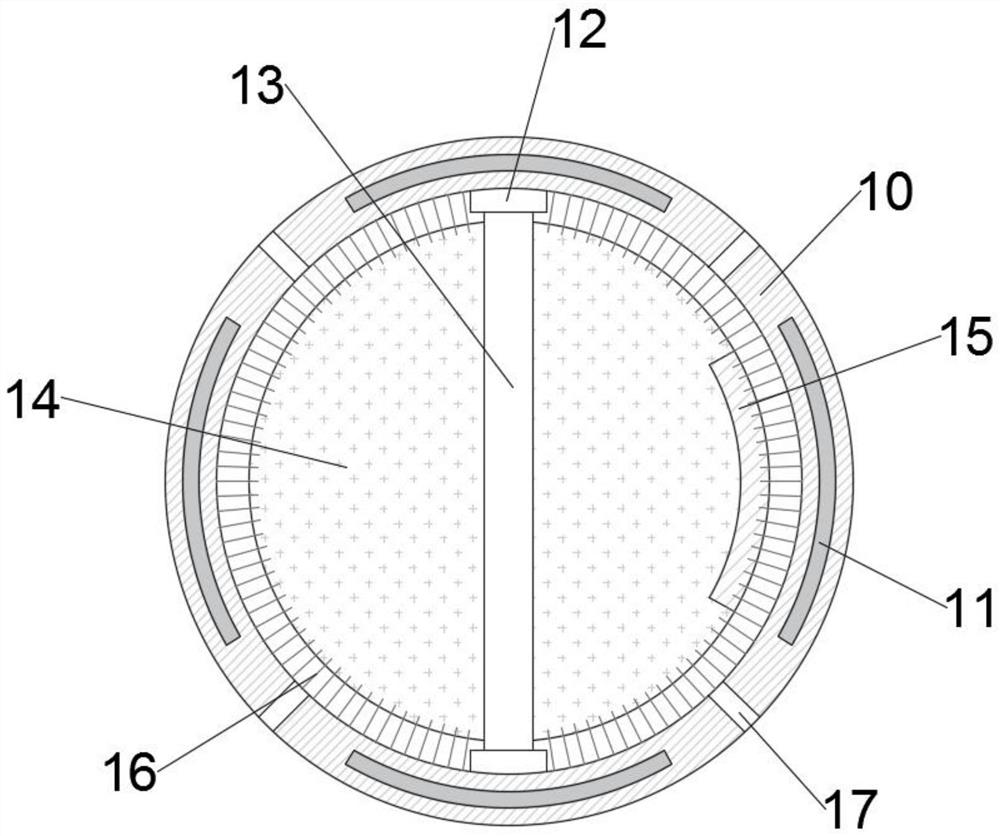

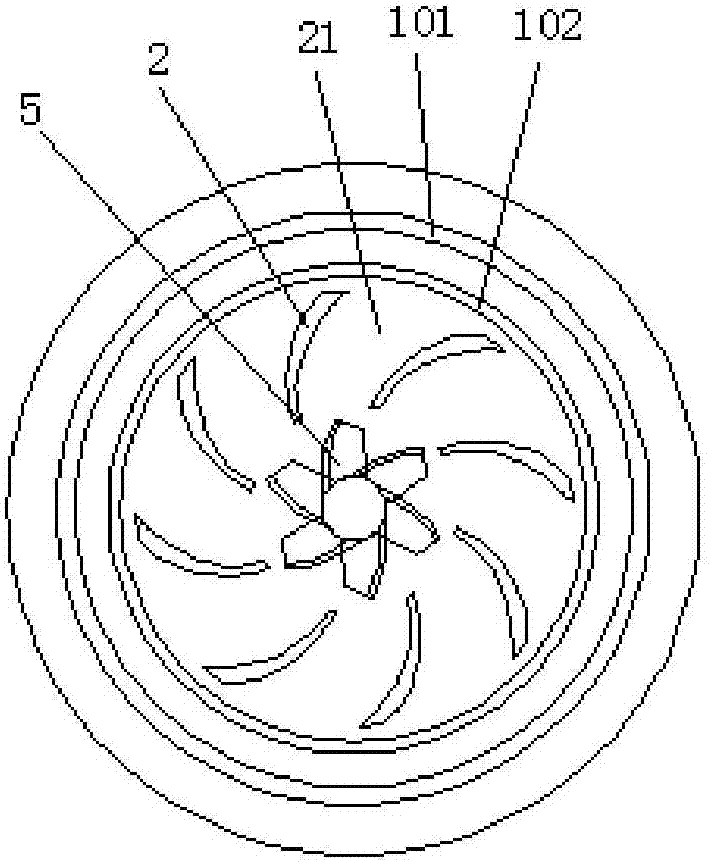

Heat treatment device for rotary support outer ring raceway

ActiveCN109680139AImprove efficiencyGood continuityIncreasing energy efficiencyFurnace typesTreatment effectCooling fluid

The invention discloses a heat treatment device for a rotary support outer ring raceway. The heat treatment device comprises a cooling barrel, the upper end of the cooling barrel is symmetrically provided with two supporting columns, the two supporting columns are provided with a heating unit capable of ascending and descending up and down through a horizontal beam, the cooling barrel is divided into upper and lower two layers, and the upper layer of the cooling barrel contains cooling liquid and is further internally provided with a positioning unit capable of moving up and down and capable of rotating. According to the heat treatment device for the rotary support outer ring raceway, by means of the positioning unit, rotary support outer rings of various sizes can be placed, and heat treatment is performed on these rotary support outer rings at the same time, and the heat treatment efficiency of the rotary support outer ring raceway is greatly improved; and in addition, by means of the heat treatment device for the rotary support outer ring raceway, heating, heat preservation and cooling are concentrated on one device, three heat treatment processes of the heating, the heat preservation and the cooling are made to have good continuity, and the heat treatment effect is guaranteed.

Owner:安徽文君自动化科技股份有限公司

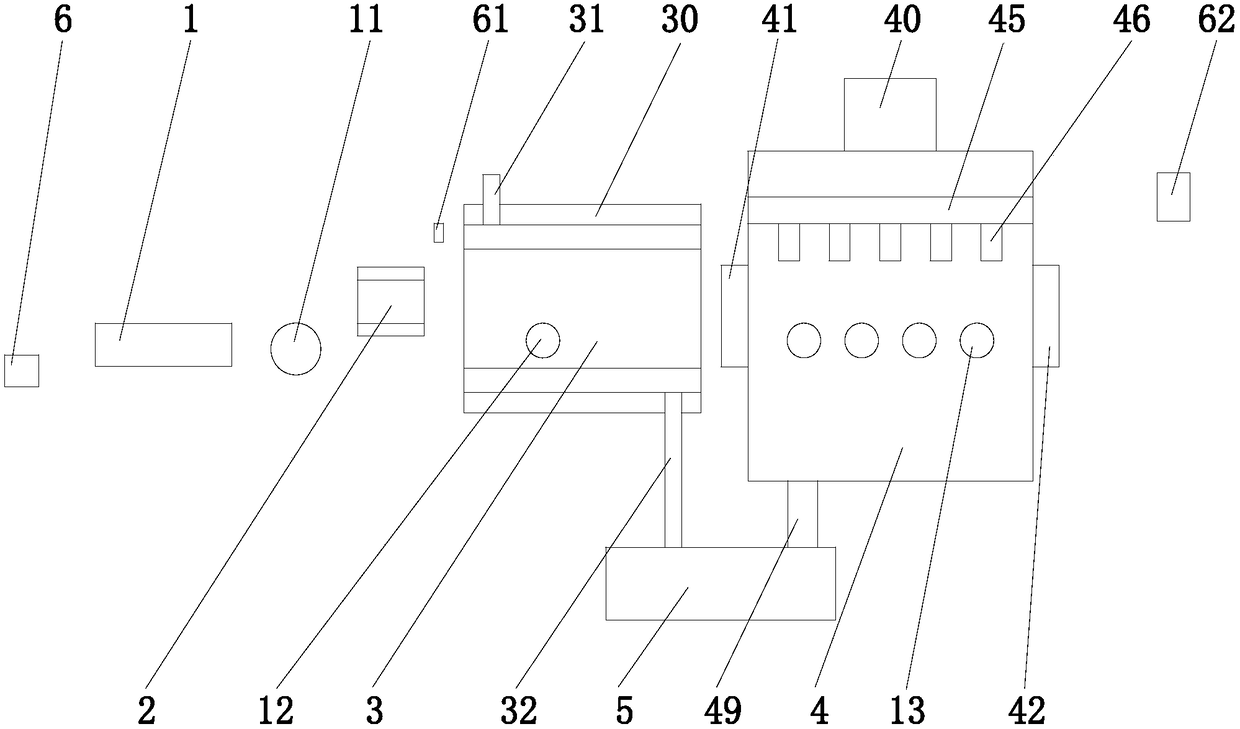

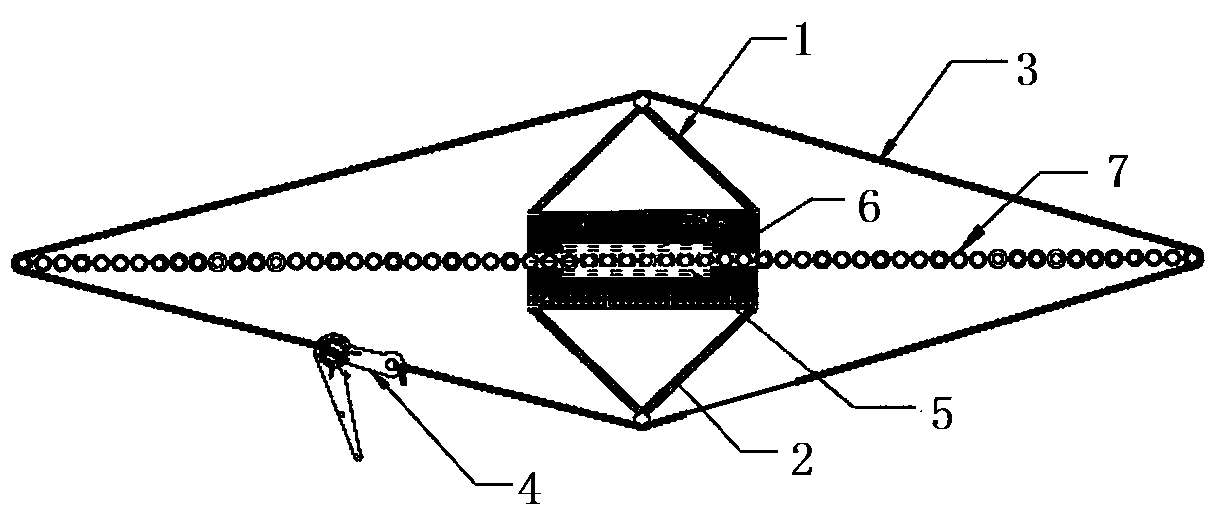

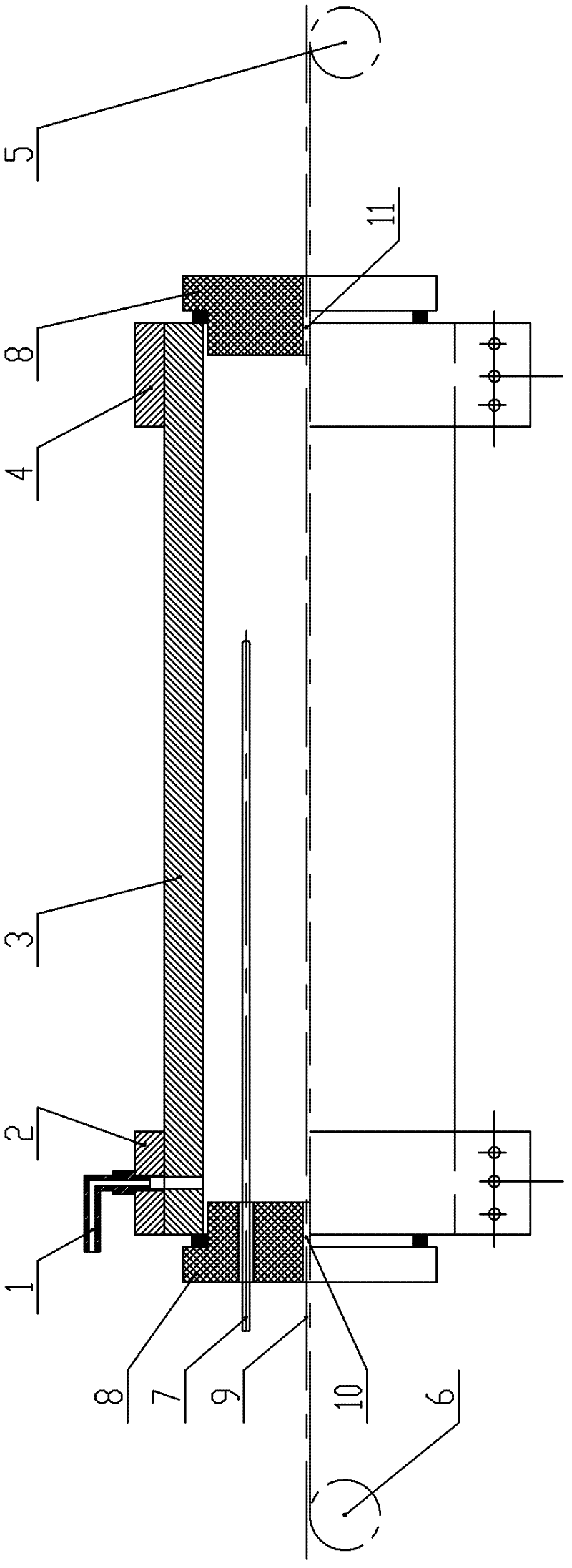

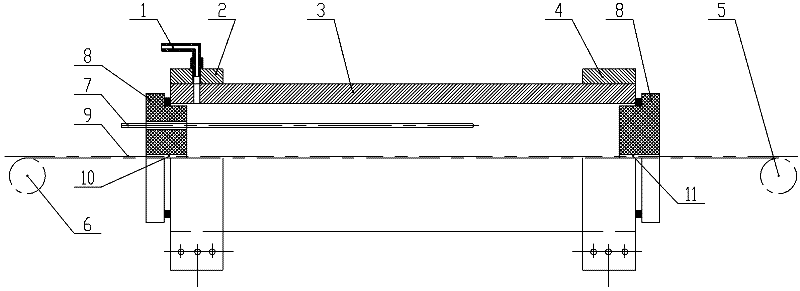

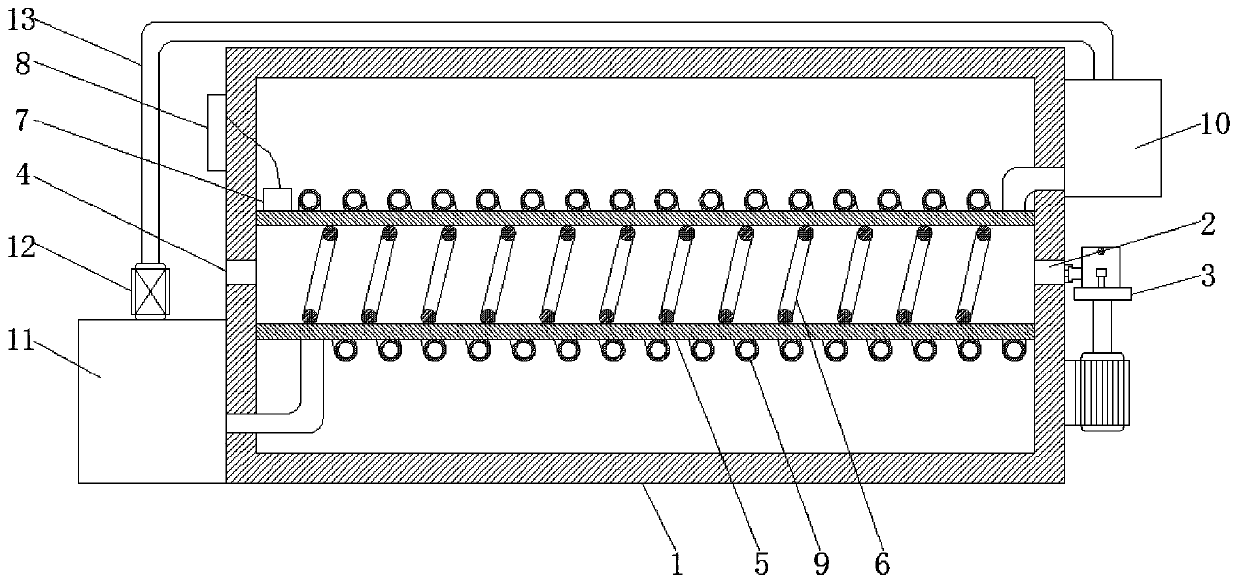

Device for quenching of elongated steel wire

InactiveCN102312076AGuaranteed heat treatment performanceControl the quenching temperatureFurnace typesHeat treatment furnacesQuenchingMaterials science

The invention discloses a device for quenching of an elongated steel wire. The device comprises a quenching furnace. A heating chamber is arranged in the quenching furnace. At least one cooling oil groove is arranged at the bottom of the heating chamber along a length direction of the quenching furnace. The device also comprises a transport mechanism for transporting a steel wire into the heating chamber. The transport mechanism comprises a transport dolly and a support plate. The support plate and the transport dolly are connected by a turnover mechanism. After a steel wire placed on the support plate is heated, the turnover mechanism rotates the support plate so that the steel wire is dumped into the cooling oil groove. The device for quenching of an elongated steel wire has both functions of heating and cooling and is suitable specially for quenching and cooling of a elongated steel wire.

Owner:上海锦荣矿山机械有限公司

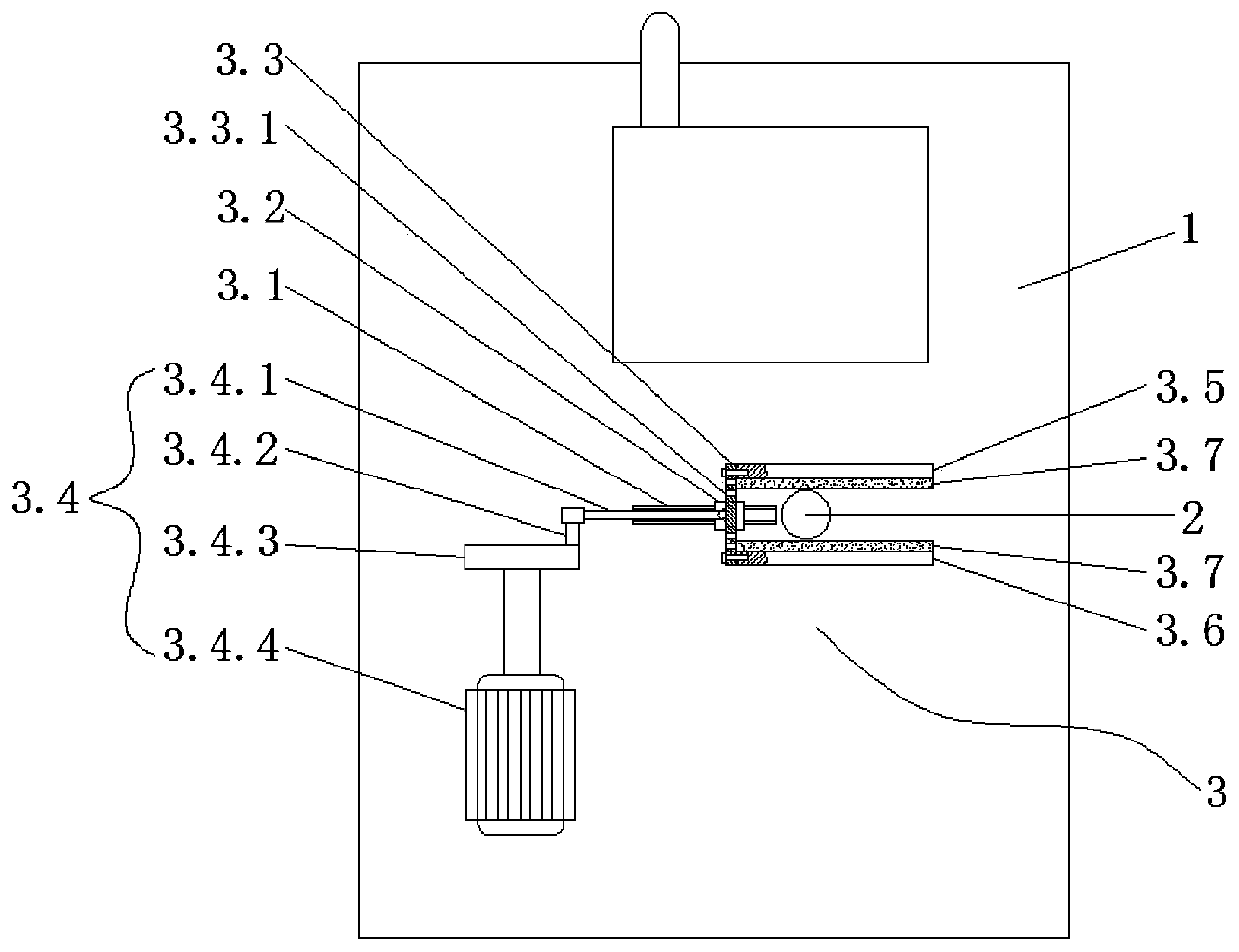

Screw rod heat treatment device safe to use

PendingCN108467932ANot easy to be exposed directlyNot easy to hurtFurnace typesHeat treatment furnacesLight pollutionWastewater

The invention discloses a screw rod heat treatment device safe to use. The screw rod heat treatment device safe to use comprises a feeding mechanism, an eddy current heating pipe, a safety pipe, a cooling tank, a suction fan, a waste water treatment pond and a control device. The feeding mechanism, the eddy current heating pipe, the safety pipe and the cooling tank are sequentially distributed from left to right; a side wall of the safety pipe is hollow; a liquid inlet pipe and a liquid outlet pipe are arranged on the safety pipe and communicate with the hollow part of a side wall of the safety pipe; the liquid outlet pipe is connected with the waste water treatment pond; an inlet is formed in the left side of the cooling tank; an outlet is formed in the right side of the cooling tank; thesuction fan is arranged on the cooling tank; the cooling pipe is arranged in the cooling tank; and a plurality of spray heads for spraying cooling water to a screw rod are arranged on the cooling pipe. According to the screw rod heat treatment device safe to use provided by the invention, the safety pipe is arranged between the eddy current heating pipe and the cooling tank, so that the heated screw rod cannot be directly exposed directly, an operator cannot be hurt easily, and meanwhile, light pollution is further avoided.

Owner:海盐秦山橡胶有限公司

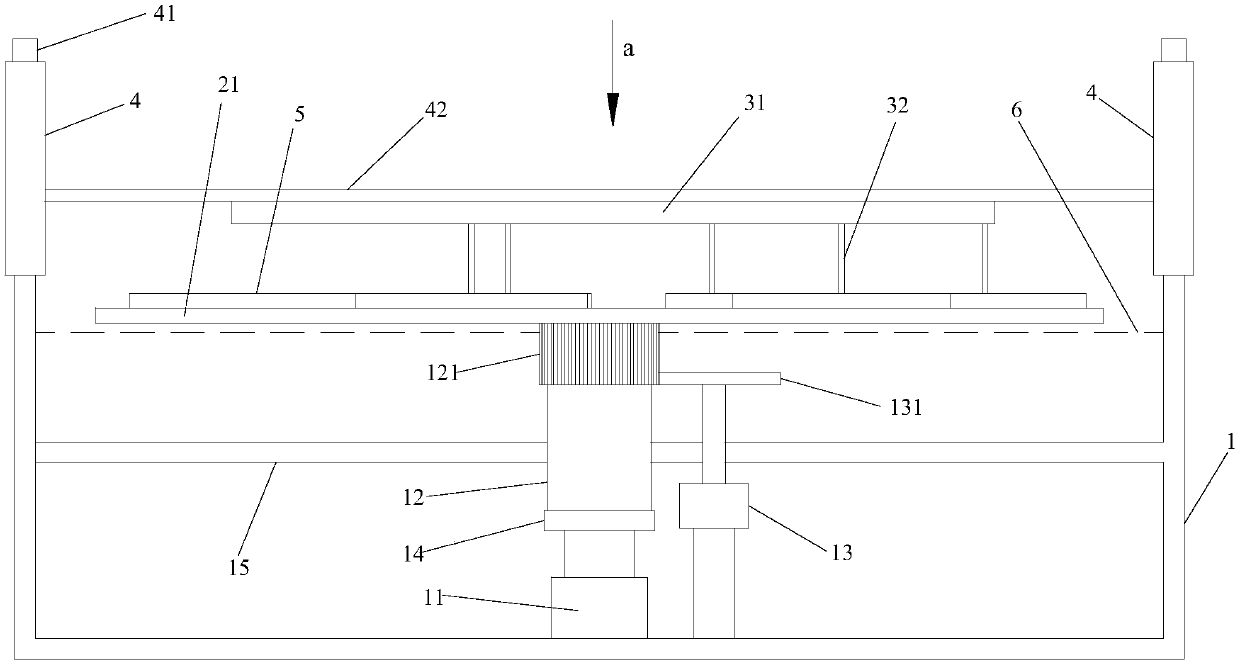

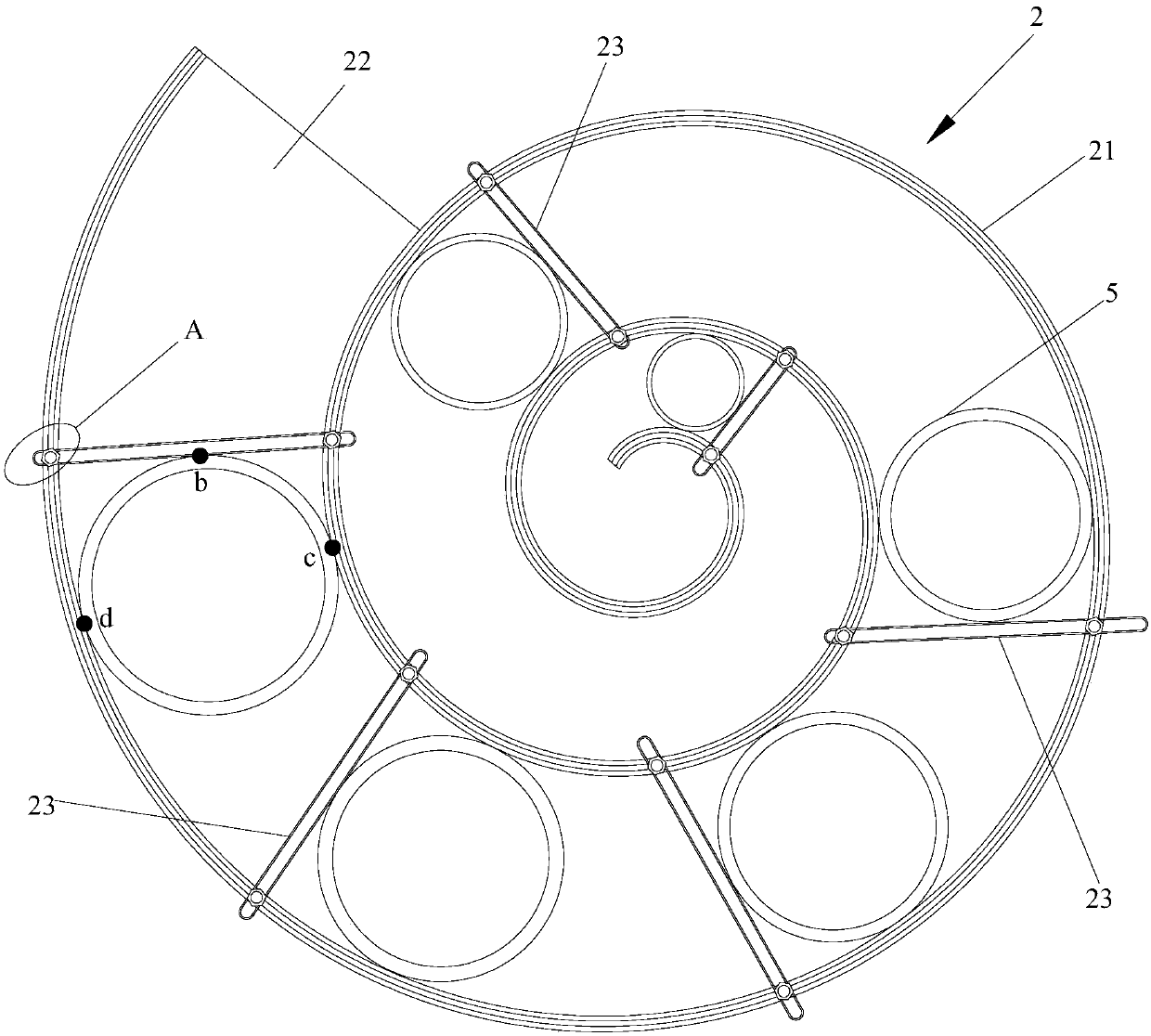

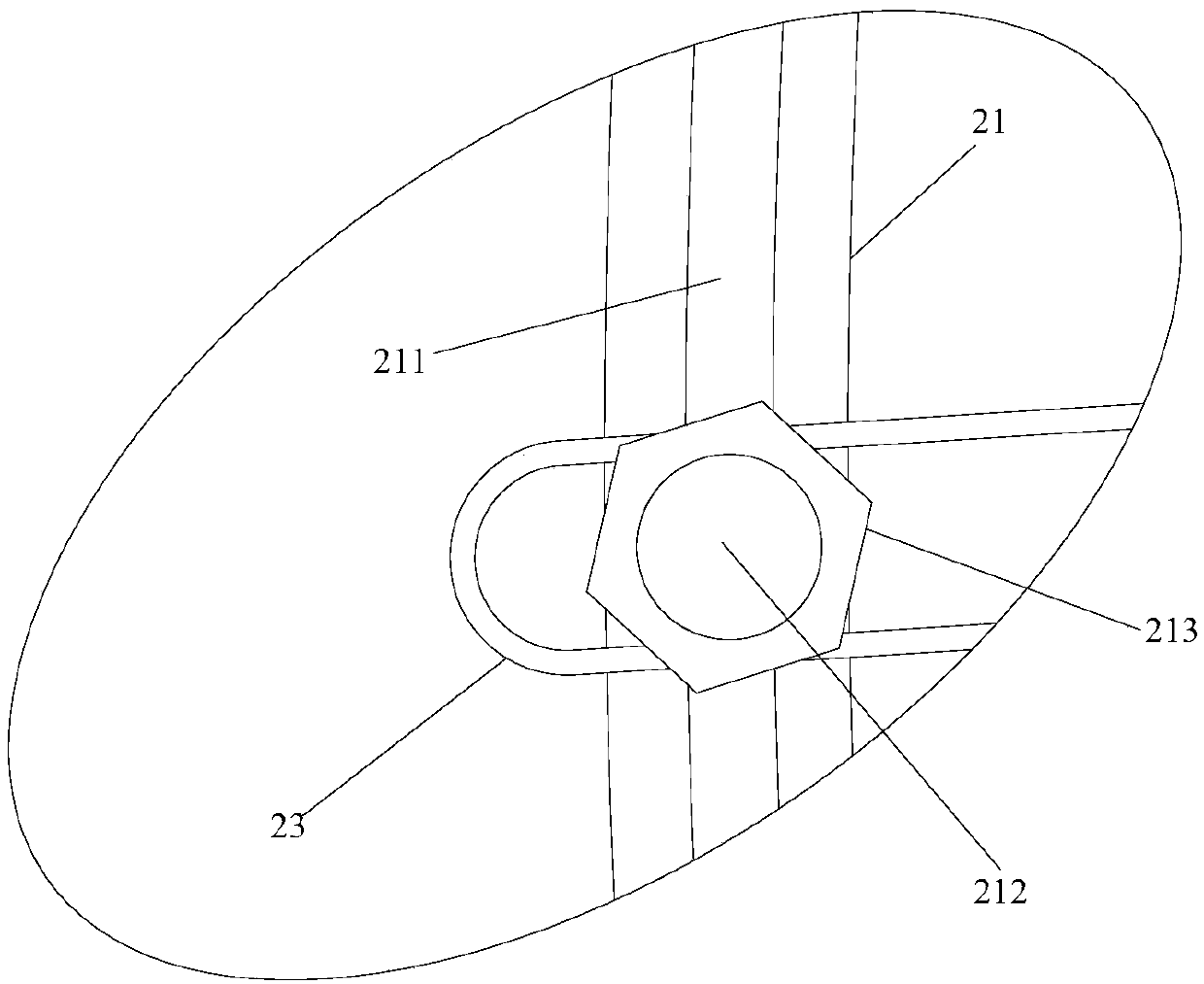

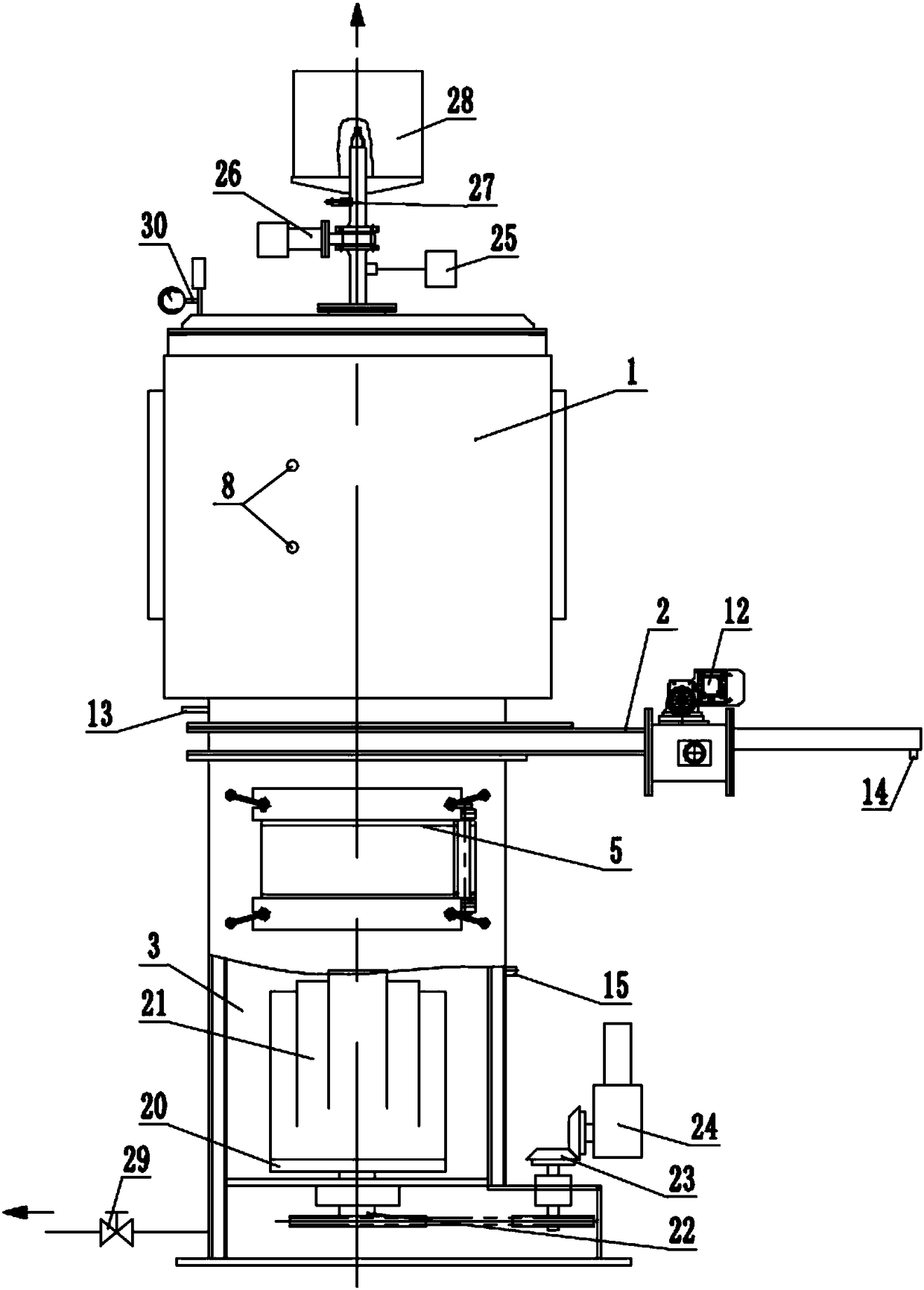

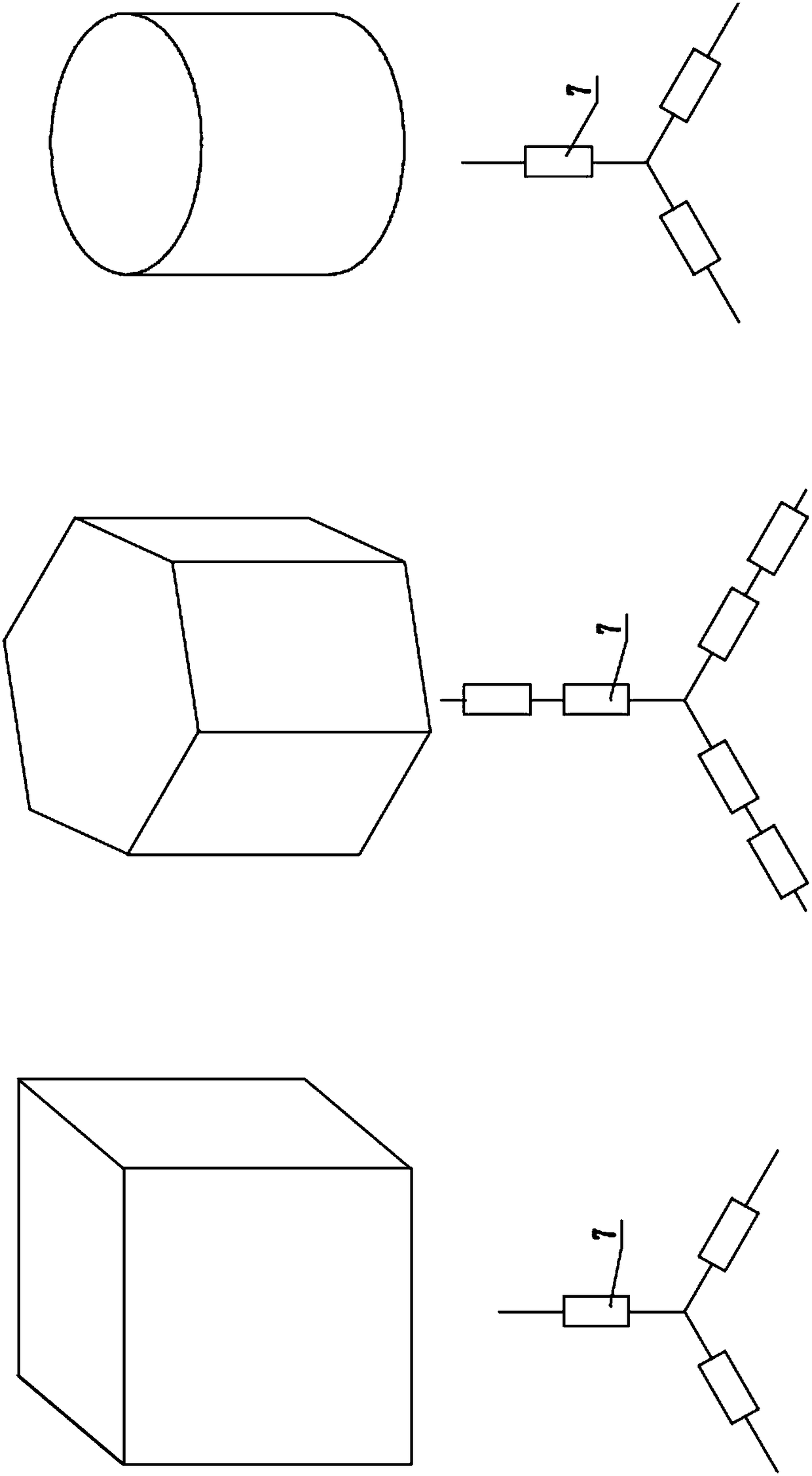

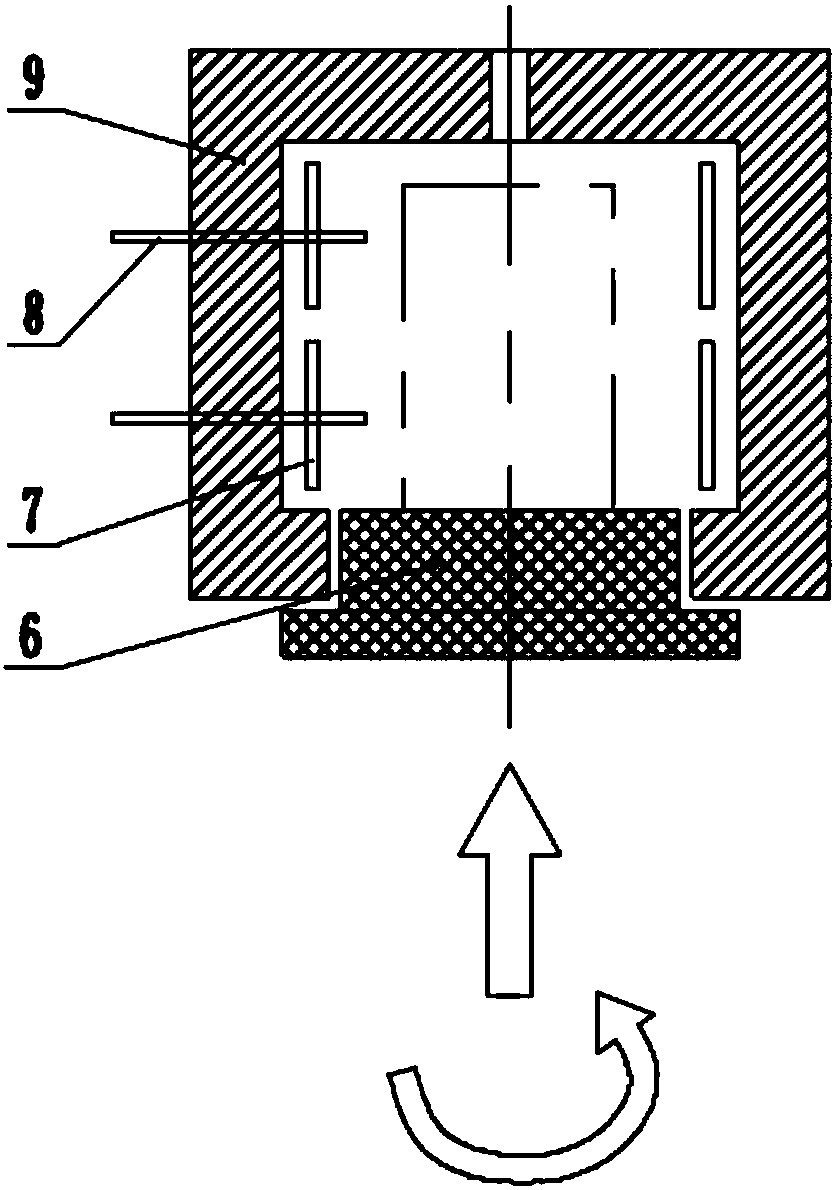

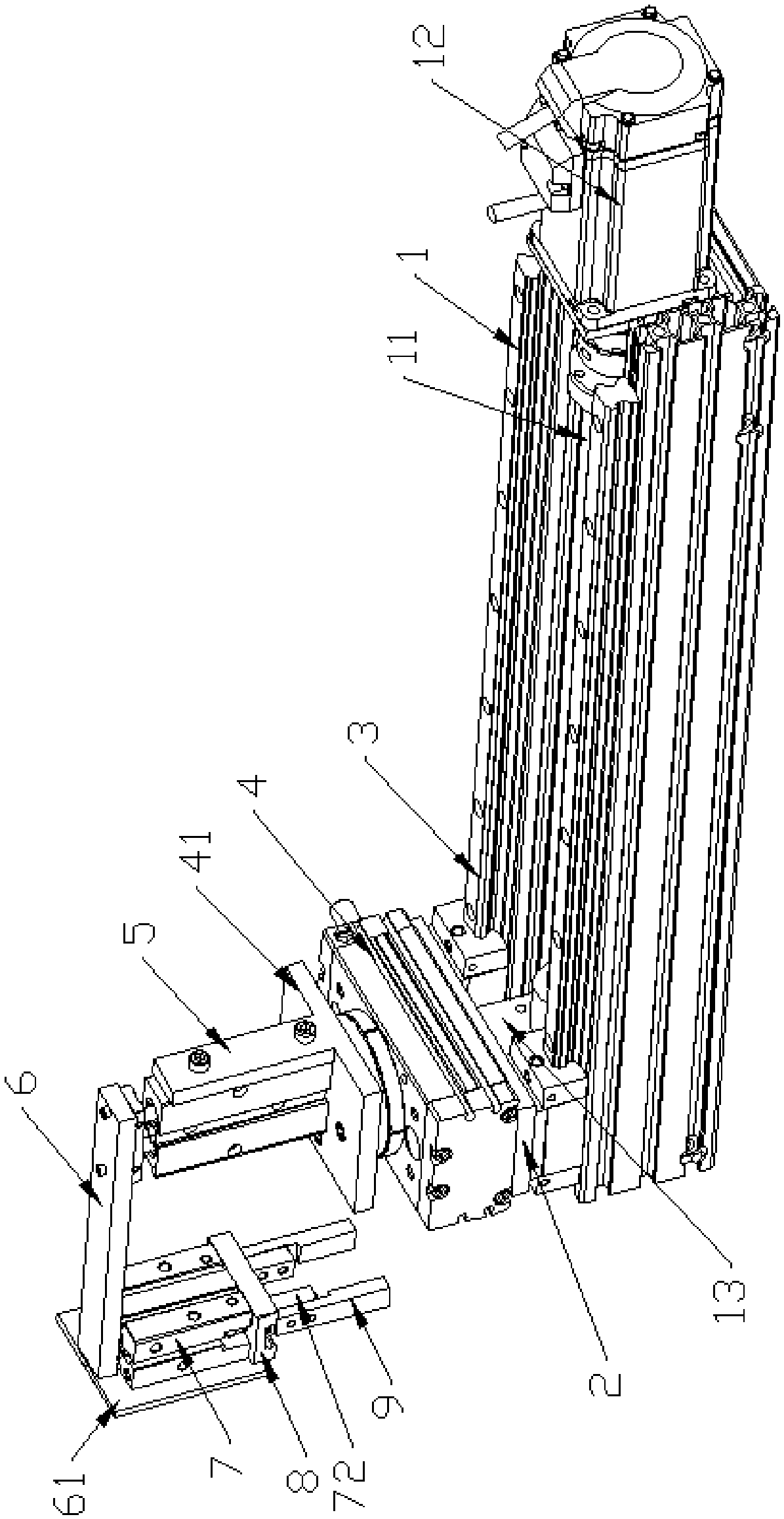

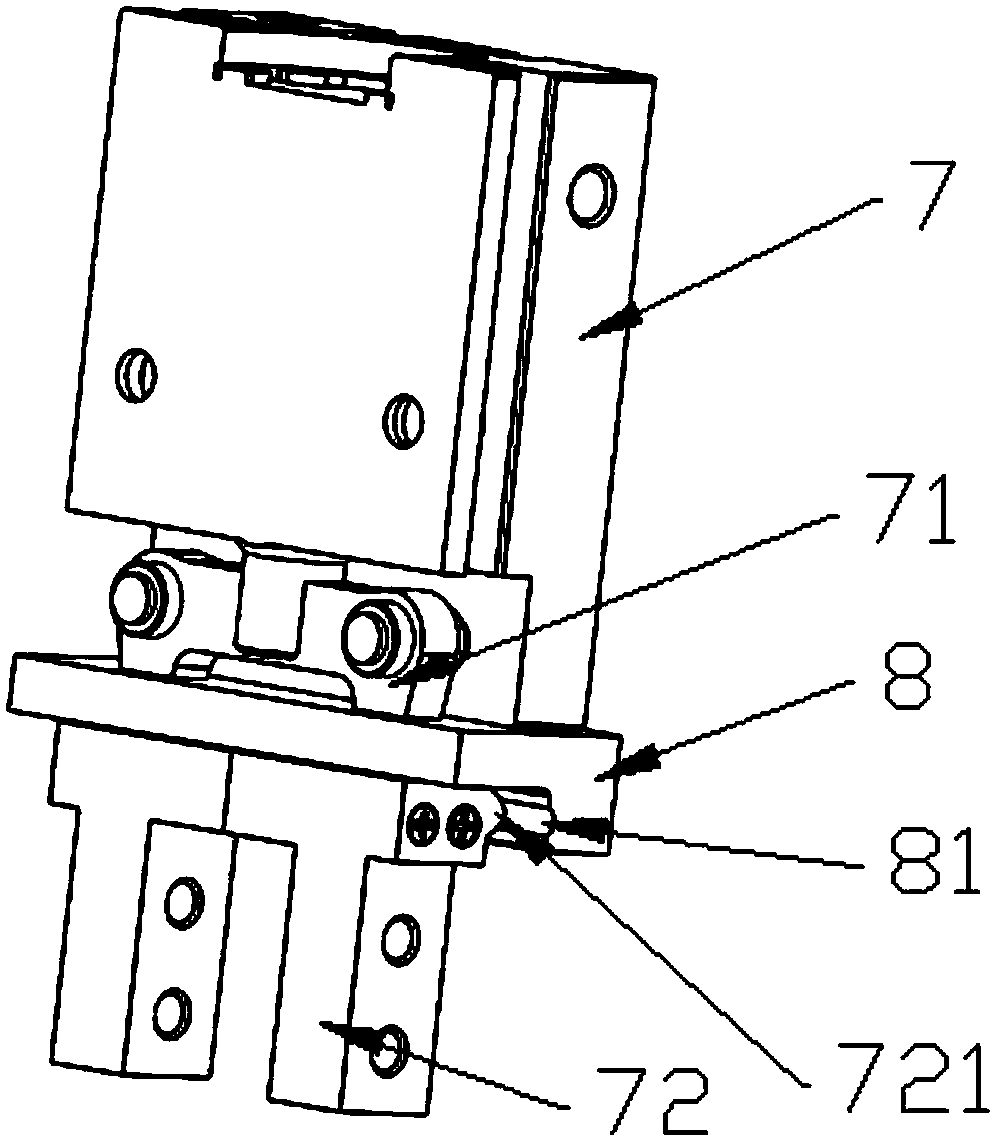

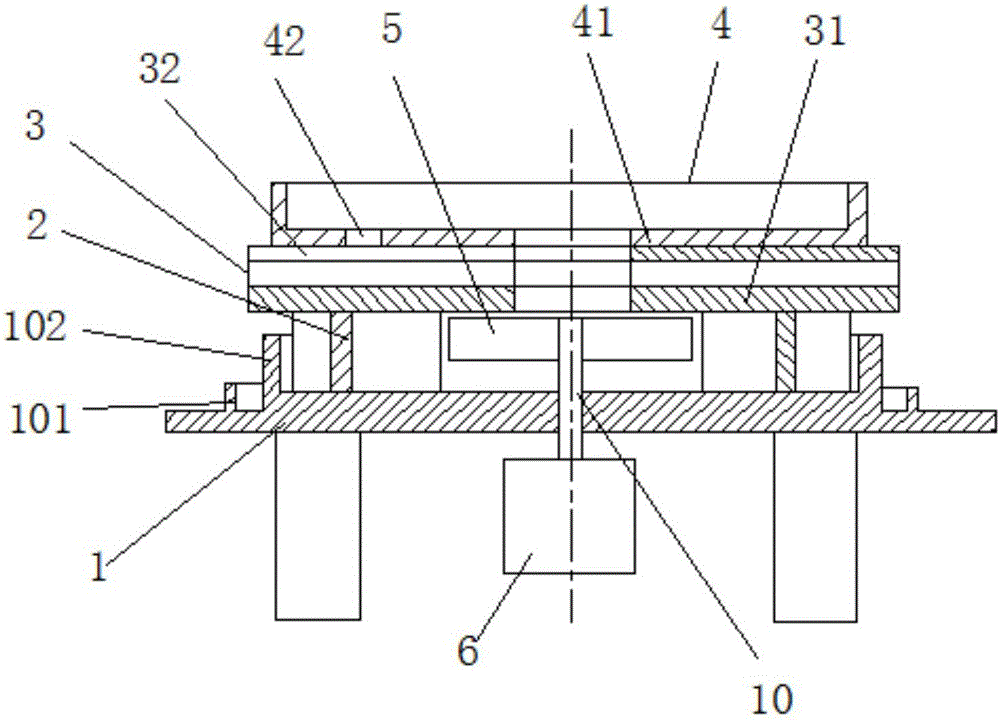

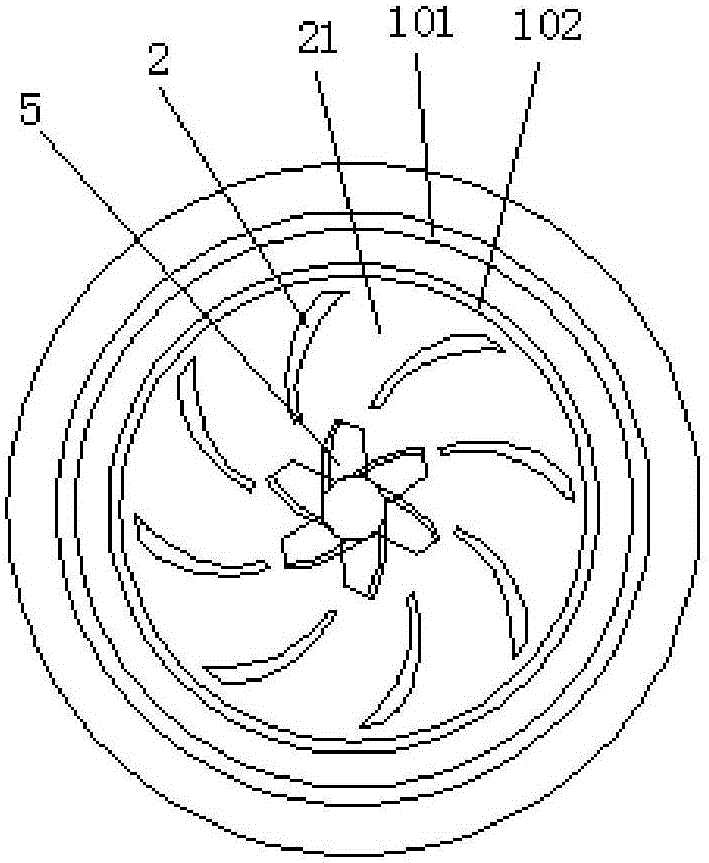

Degreasing sintering furnace for metal powder injection molding

The invention discloses a degreasing sintering furnace for metal powder injection molding. The degreasing sintering furnace comprises a furnace body. The lower portion of the furnace body is connectedwith a lifting rotating device through a gate device, and an outer shell of the lifting rotating device is connected with the gate device. The outer shell is provided with a loading and unloading door, and the outer shell is internally provided with a lifting rotating mechanism. A material placing platform is arranged at the upper end of the lifting rotating mechanism, and a gap is formed betweenthe material placing platform and the furnace body. The material placing platform can enter and exit the furnace body through the gate device under the driving of the lifting rotating mechanism and can rotate in the furnace body. The degreasing sintering furnace for metal powder injection molding can enable products to be heated more uniformly and improves production efficiency.

Owner:NINGBO HIPER VACUUM TECH CO LTD

Thin steel wire secondary heating treatment method and device

InactiveCN102220475ABeneficial technical effectSave energyFurnace typesIncreasing energy efficiencyInduction heaterCurie temperature

The invention discloses a thin steel wire secondary heating treatment method and device, the method comprises the following steps: using an induction heater to heat a thin steel wire in an induction heating coil until the temperature is equal to or slightly lower than the curie point of the thin steel wire; and using a resistance heating device to heat the thin steel wire until the temperature isabove the austenitizing temperature. The method also comprises the following step: cooling the heated thin steel wire. The method provided by the invention can be used for carrying out thermal refining, quenching, normalizing, backfire, isothermal quenching, isothermal annealing, isothermal soxlet process, recrystallization annealing or rapid balling isothermal annealing on the thin steel wire.

Owner:王颖

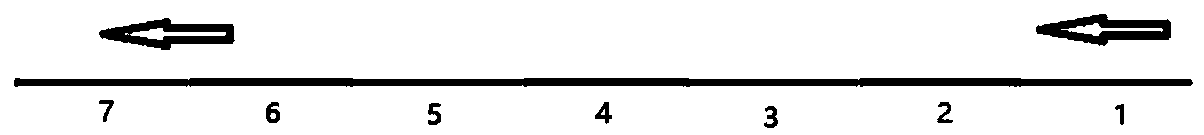

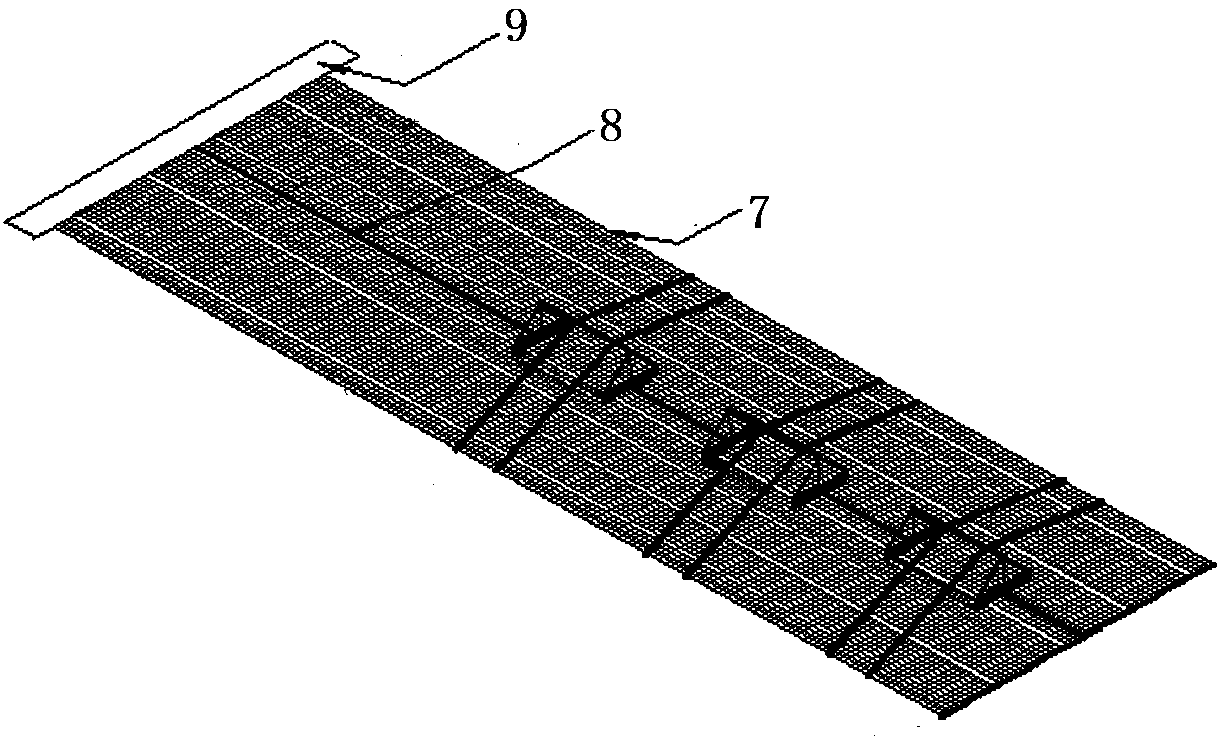

Long seam welding and post-weld heat treatment process for high-alloy heat-resistant steel pipe screen

ActiveCN109465559AImprove construction efficiencyShorten the construction periodWelding/cutting auxillary devicesFurnace typesEngineeringAlloy

In order to solve the problems of poor effect, low construction efficiency, and easy-deformation of a pipe screen in the long seam welding and heat treatment of the tube screen, a long seam welding and post-weld heat treatment process for the high-alloy heat-resistant steel pipe screen is provided. The welding and heat treatment of the long seam of the pipe screen are mainly carried out by adopting the methods of subsection interval skip welding and heat treatment and subsection ladder heat treatment, thereby avoiding the simultaneous heating and cooling of the long seam of the pipe screen, reducing the deformation rate of the seam of the pipe screen, and greatly improving the construction efficiency at the same time.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Single-tubular gas protection fiber thermal treatment device

InactiveCN102382972ASmall tube spaceUniform and easy to control temperatureFurnace typesHeat treatment furnacesFiberShielding gas

The invention relates to a single-tubular gas protection fiber thermal treatment device. The device comprises a heating pipe which is provided with two opening ends and made of high temperature alloy, wherein sealing heads are fixed at the opening positions at the two ends of the heating pipe; the two sealing heads are respectively provided with a feeding port and a discharging port which are corresponding; a left side electrode clamping end and a right side electrode clamping end are respectively fixed on the outer wall of the heating pipe; and the pipe wall of the heating pipe is provided with a protection gas inlet. According to the invention, the heating pipe made of high temperature alloy is adopted; and the heating pipe has small internal space and uniform and controllable temperature, thereby ensuring thermal treatment property and saving energy.

Owner:WUXI BEYOND AOK ELECTRIC

Sealing device for part surface treatment

PendingCN108085472AAvoid spreadingAvoid wastingFurnace typesHeat treatment furnacesThermal insulationSilicone rubber

The invention provides a sealing device for part surface treatment, and belongs to the field of part processing equipment; the sealing device for part surface treatment includes a furnace body arranged at the outermost; the inner wall of the furnace body is provided with a thermal insulation layer, the thermal insulating layer is made of a foam material, and a sealing door is arranged on one sideof the furnace body; a silicone rubber seal ring is arranged between the sealing door and the furnace body, is fixed at the periphery of the sealing door and has an arc shape outwardly raised; the silicone rubber seal ring is arranged in a manner of protruding the height of the sealing door. The sealing device has good sealing performance and high degree of automation.

Owner:TIANJIN KAIDA HEAVY HYDROPOWER EQUIP MFG

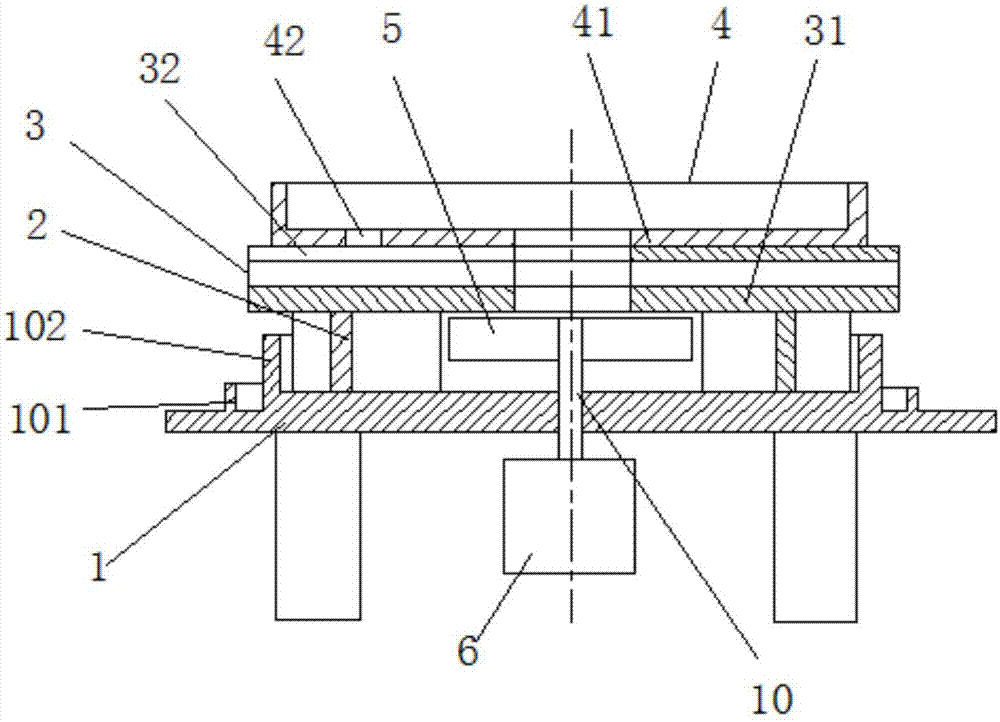

Iron wire heating diversion device

ActiveCN105936973AGuaranteed thermal effectGuaranteed temperature uniformityFurnace typesHeat treatment furnacesThermal energyThermal insulation

The invention provides an iron wire heating diversion device. The device is arranged in the accommodation cavity of a heating furnace and comprises a support seat, a blower fan, a bracket, and a tray, which are arranged from bottom to top. The blower fan is rotatingly arranged on the support seat through a rotation shaft. The top surface of the support seat is provided with a plurality of baffle plates. The baffle plates are evenly arranged around the blower fan. The center of the bracket is provided with a first air hole. The center of the tray is provided with a second air hole. The bottom surface of the bracket and the top surface of the support seat form a first air channel. Two neighbored baffle plates form a first air channel. In the provided iron wire heating diversion device, the support seat is provided with an air blower and first air channels, the bracket is provided with a first air hole, the tray is provided with a second air hole, the first air hole and the second air hole are opposite to the blower fan; when the blower fan rotates, hot air goes through the second air hole and the first air hole and is discharged from the first air channels, thus thermal energy circulation is formed, the uniformity of temperature in a thermal insulation box can be guaranteed, and the iron wire heating effect is ensured.

Owner:TIANJIN HUAYUAN WIRE PROD

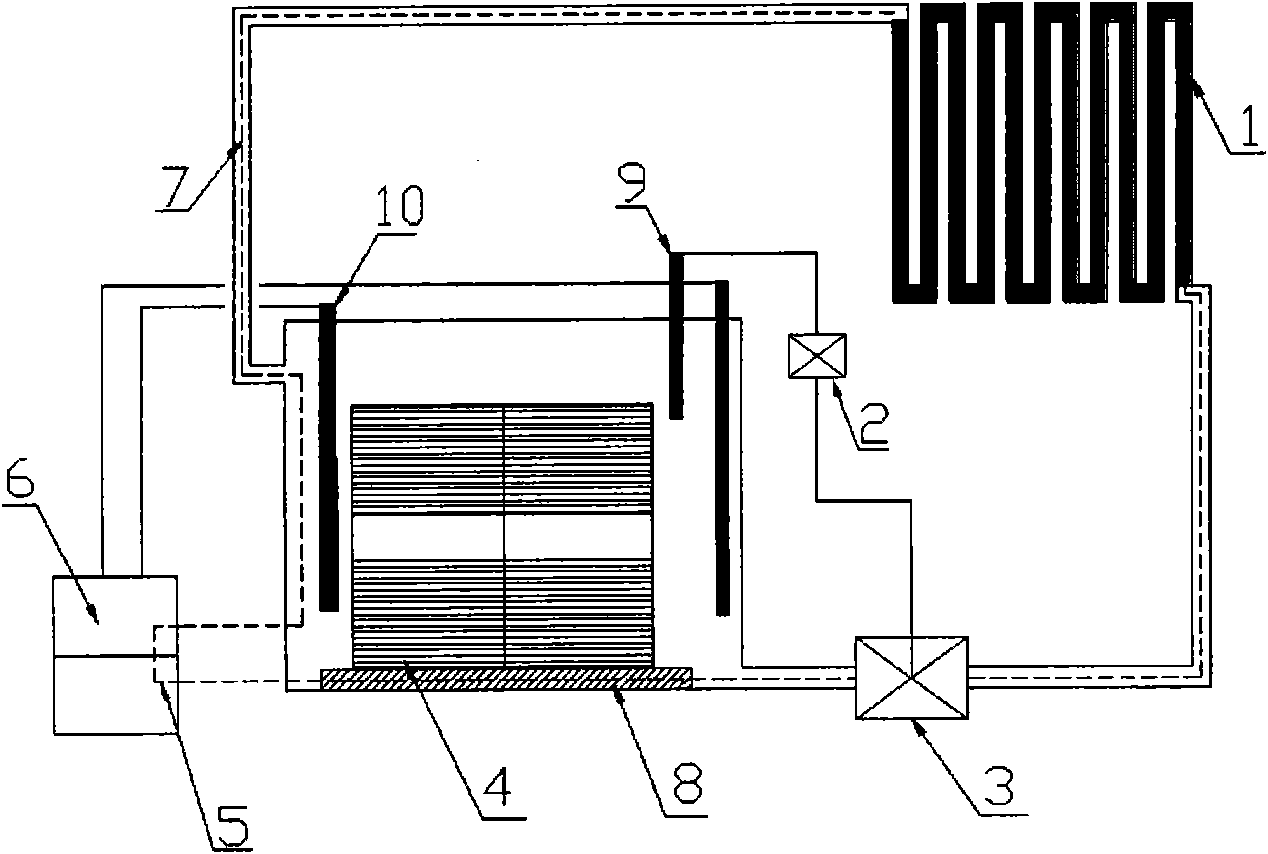

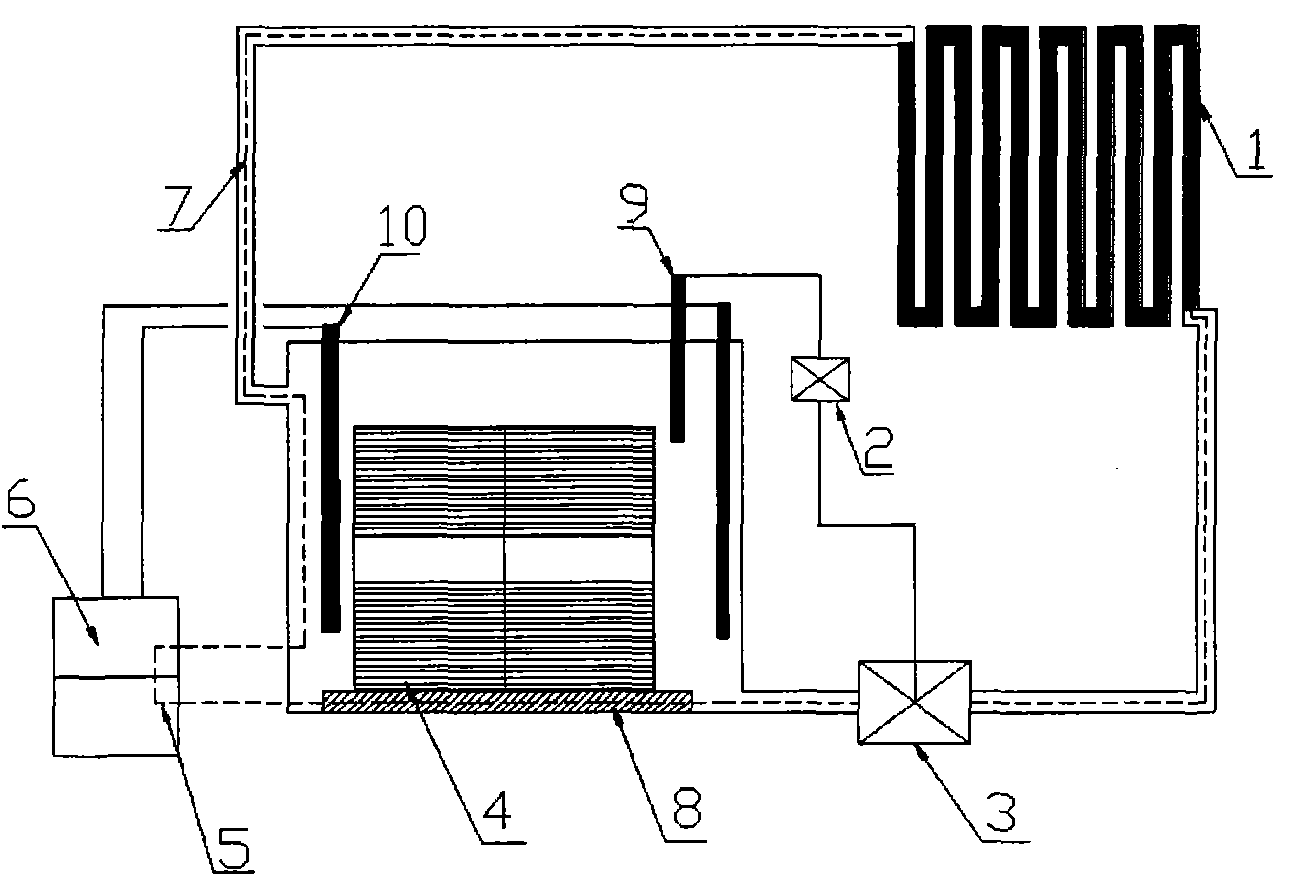

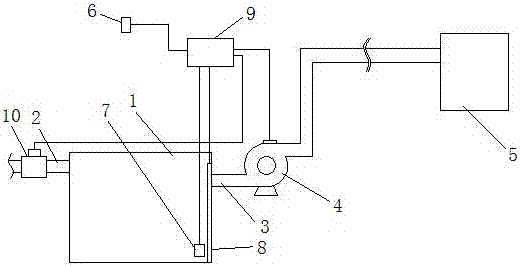

Solar-powered constant-temperature salt bath system

InactiveCN102002564ASolve wasteSave electricityHeat treatment bathsComputer control systemMolten salt

The invention provides a solar-powered constant-temperature salt bath system. The system comprises a solar-powered vacuum tube heater, a salt bath furnace, a temperature sensor, a fused salt pump and a computer control system, wherein the solar-powered vacuum tube heater absorbs the radiation of sunlight through a coating of a vacuum tube so as to heat fused salt; the salt bath furnace consists of a salt bath container and the fused salt in the salt bath container; the temperature sensor is arranged in the salt bath furnace and used for detecting the temperature of the fused salt in the salt bath furnace and providing a temperature signal; the fused salt pump is used for providing power for the flow of the fused salt; the computer control system controls the stop and operation of the fused salt pump according to a preset program command through the temperature signal provided by the temperature sensor; the two ends of the solar-powered vacuum tube heater are connected to the salt bath furnace through pipelines respectively; and the fused salt pump is arranged between the solar-powered vacuum tube heater and the salt bath furnace. The solar-powered constant-temperature salt bath system of the invention performs thermal treatment by using solar energy, so that a large amount of electric energy can be saved; moreover, the thermal treatment temperature can be kept stable by the computer control system, so that thermal treatment effect is ensured.

Owner:KUNMING IRON & STEEL

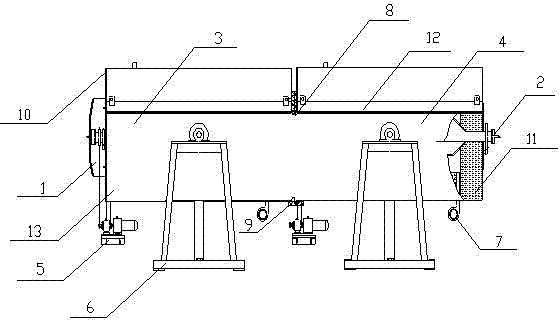

Double-roller furnace

InactiveCN103486848AMeet the requirements of industrializationGuaranteed heat treatment performanceRotary drum furnacesControl systemMetallurgy

Provided is a double-roller furnace. The body of the double-roller furnace comprises a first processing furnace and a second processing furnace, the first processing furnace and the second processing furnace are connected through a bolt, dismounting and maintaining of the first processing furnace and the second processing furnace can be achieved conveniently, the rear end of the second processing furnace is supported through a bearing seat, the processing furnaces can be expanded and shrunk freely due to variation of temperatures, heat treatment of the two processing furnaces is conducted on a workpiece, products which are not well processed by the second processing furnace can be processed again in the first processing furnace, independent control systems are used in the two processing furnaces, and all indexes in the processing furnaces can be absolutely guaranteed.

Owner:JIANGSU GAOHAO IND FURNACE

Bulge type titanium alloy self-plugging rivet manufacturing technology

ActiveCN111571142AImprove corrosion resistanceIncrease usageManufacturing technologyHeat conservation

The invention discloses a bulge type titanium alloy self-plugging rivet manufacturing technology. The technology comprises rivet body manufacturing, rivet sleeve manufacturing and driving ring manufacturing. The rivet body manufacturing includes the following steps of 1, preparing a blank; 2, performing tampering to obtain a semi-finished product; 3, cleaning and removing surface dirt and raw material coatings formed by tampering; 4, performing thermal treatment, wherein a, first-time thermal treatment is performed, the cleaned semi-finished product is placed into a thermal treatment furnace under the temperature of 680-720 DEG C for production, the temperature is kept for 10-20 min, and then post-air-cooling is performed; b, secondary thermal treatment, the semi-finished product obtainedafter air cooling is placed into a thermal treatment furnace under the temperature of 450-500 DEG C for heat preservation for 8-10 h, and then post-air-cooling is performed; 5, performing centerless grinding, wherein the semi-finished product obtained after thermal treatment is placed into a centerless grinding machine for rod diameter grinding; 6, rolling threads, wherein the ground semi-finishedproduct is rolled to obtain a thread and a ring groove; 7, performing surface treatment. The machining efficiency and the yield are high, the product corrosion resistance, structural strength, surface hardness, the tissue uniformity and other properties are excellent, the mass is low, and the product usage rate is increased.

Owner:王丽

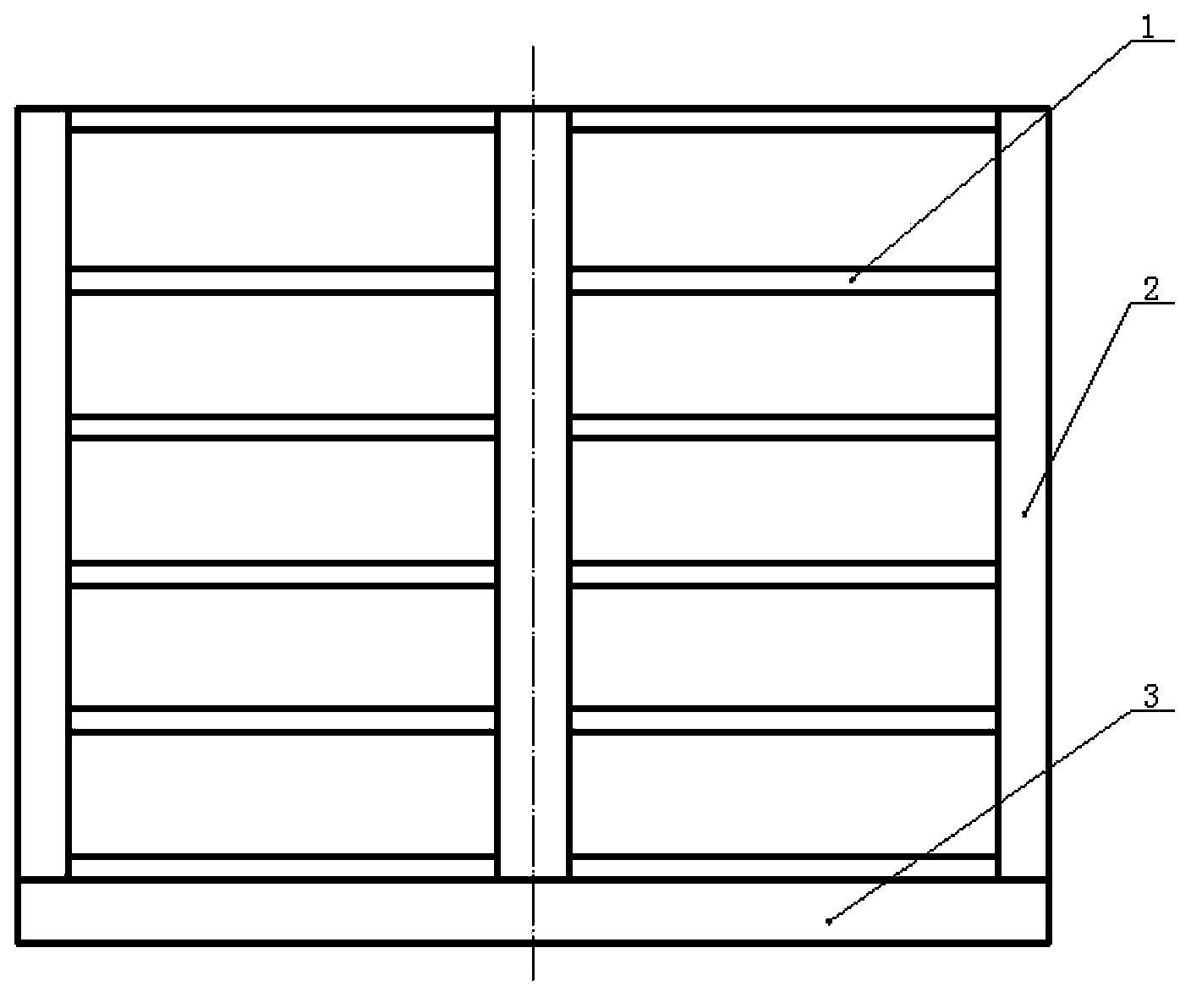

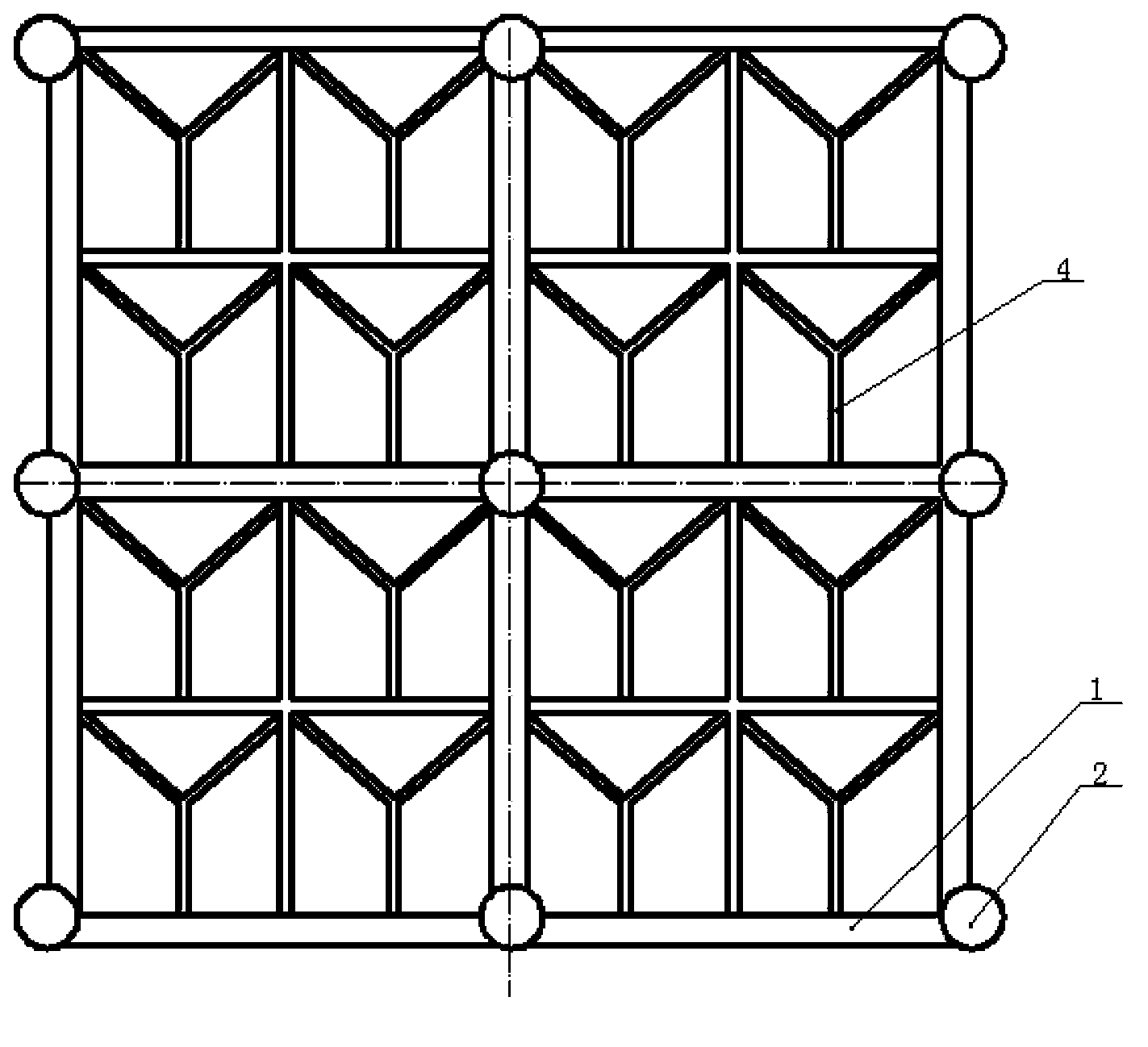

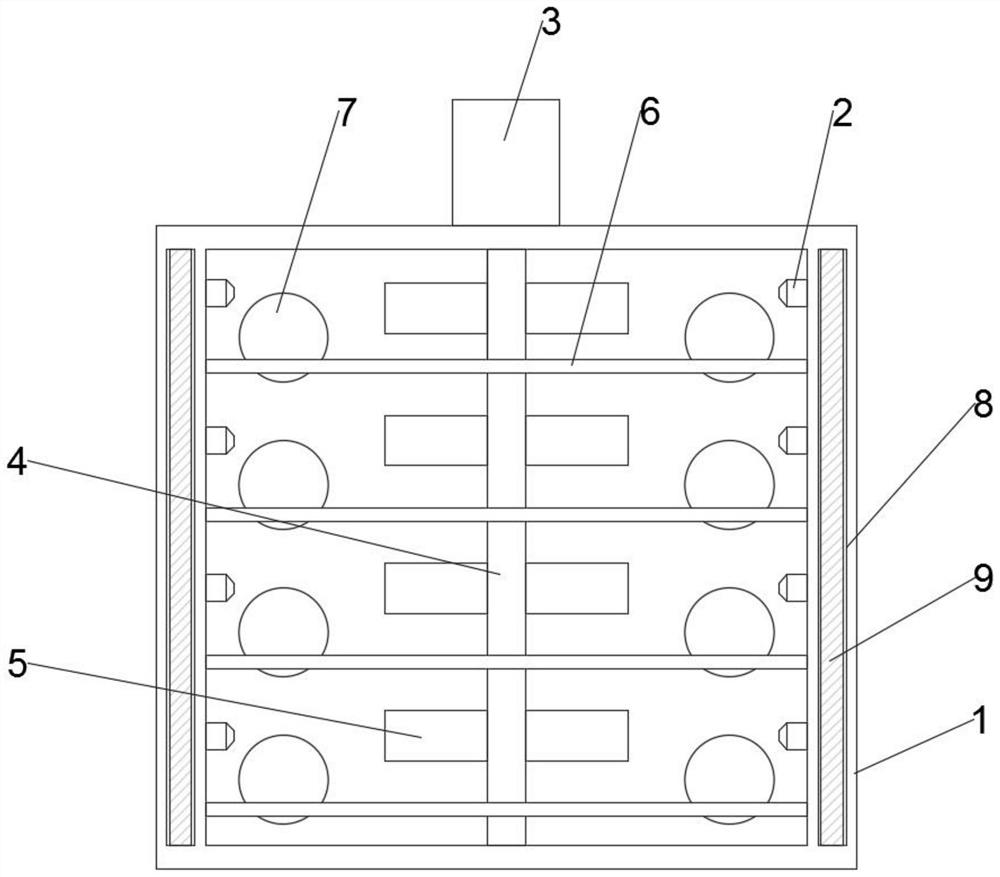

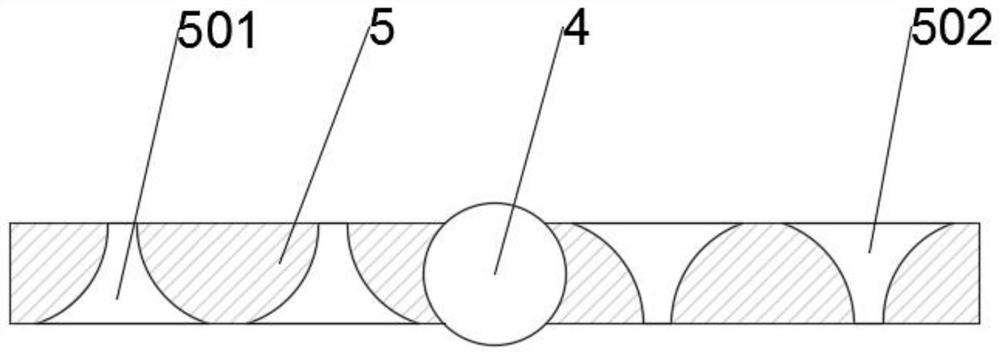

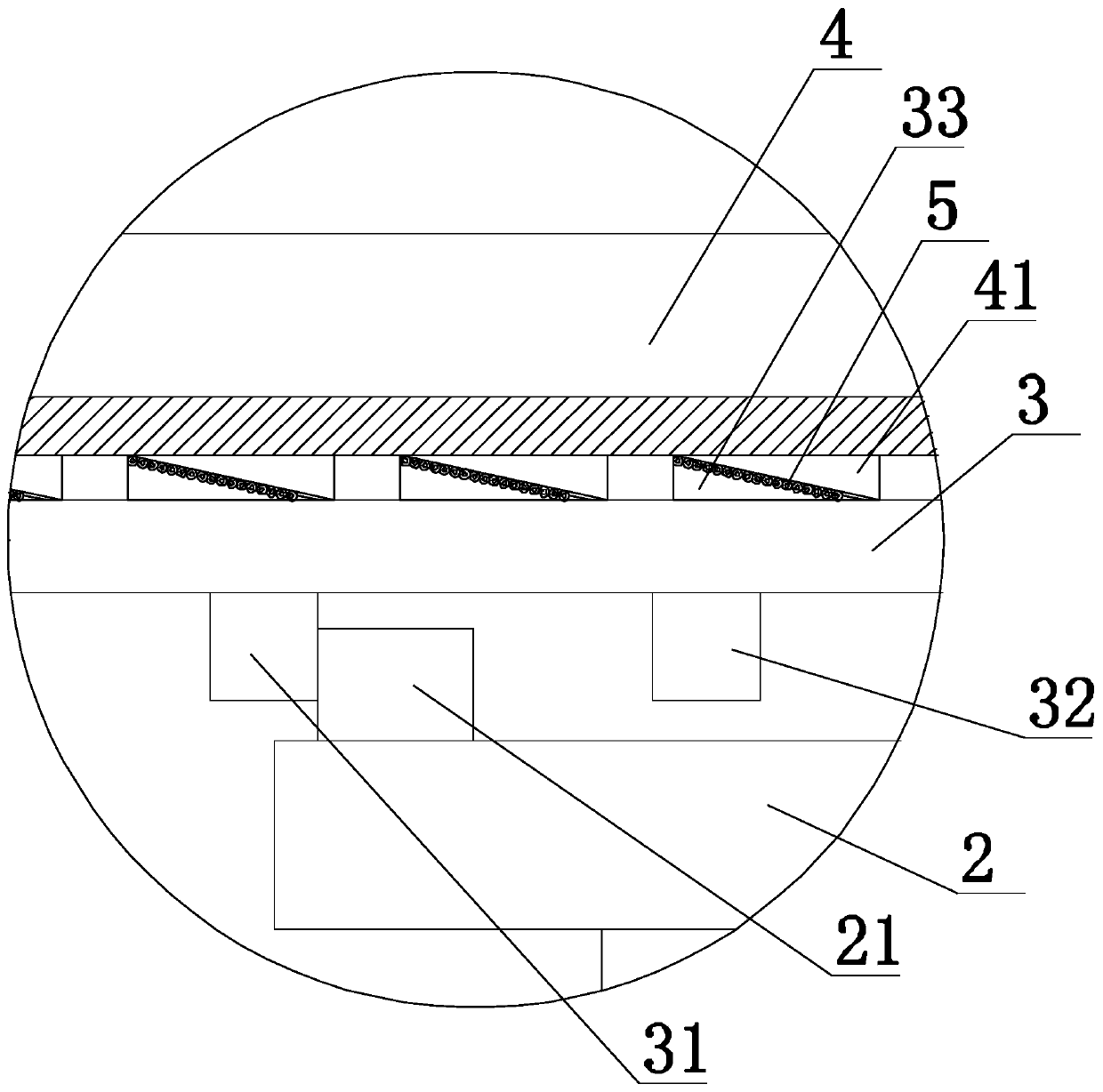

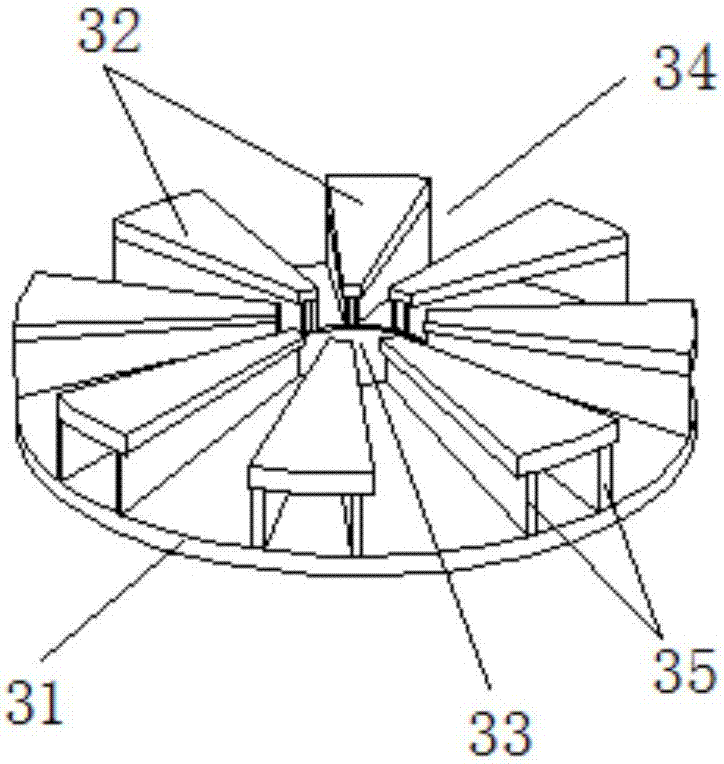

Layered wheel hub blank heat-treatment material rack

InactiveCN103898309AAvoid deformationExtended service lifeFurnace typesHeat treatment furnacesEngineeringMechanical engineering

The invention relates to a layered wheel hub blank heat-treatment material rack. The layered wheel hub blank heat-treatment material rack comprises a base, stand columns and crossbeams. The base, the stand columns and the crossbeams form a cubical frame. The multiple stand columns are vertically, uniformly and fixedly arranged on the base. Multiple layers of the staggered crossbeams are uniformly and fixedly distributed between each two adjacent stand columns, and each layer of the crossbeams form a uniform horizontal grid. The layered wheel hub blank heat-treatment material rack has a scientific design and a simple structure, is firm and durable, can be moved conveniently, has a long service life and saves a production cost. The layered wheel hub blank heat-treatment material rack can receive more wheel hub blanks thereby improving production efficiency, guarantee workpiece heating uniformity, and effectively reduce deformation shrinkage of the wheel hub blank in heating treatment.

Owner:TIANJIN DAIKA WHEEL HUB MFG

Thermal treatment method of MgYNdZr alloy

InactiveCN104109826AGuaranteed heat treatment performanceUniform furnace temperatureRoom temperatureTherapeutic effect

The invention relates to a thermal treatment method of an MgYNdZr alloy. A uniform furnace temperature in a furnace is ensured by utilizing a fan through regulating thermal treatment parameters, heating and uniformly cooling are carried out twice, thereby ensuring that elements such as strengthening phases zirconium, yttrium are sufficiently dissolved in a matrix, so that effects of the strengthening phases are brought into play to the greatest extent. The thermal treatment method disclosed by the invention guarantees thermal treatment effects of the MgYNdZr alloy, so that after the material thermal treatment, room-temperature mechanical performances meet the following requirements: sigma b is not less than 250MPa, sigma 0.2 is not less than 185MPa, and sigma 4 is not less than 4%, and an qualification rate is over 80%; and moreover, performances of the MgYNdZr alloy are stable, and application requirements of casting pieces under a great-load condition are satisfied.

Owner:HARBIN DONGAN ENGINE GRP

Tank-cover-free type forevacuum heat treatment furnace

PendingCN114410905AAchieve heat treatmentImprove uniformityMaintainance of heating chambersSolid state diffusion coatingExhaust valveEngineering

The invention belongs to the field of metallurgical equipment, and particularly relates to a tank-cover-free type forevacuum heat treatment furnace. Comprising a furnace bottom and a furnace cover detachably mounted on the furnace bottom, and a closed space is formed after the furnace cover covers the furnace bottom; the furnace bottom is composed of a substrate and a furnace lining which is arranged above the substrate and completely located within the range of the substrate, a heating body is arranged on the furnace lining, and a supporting bottom is further arranged on the periphery of the substrate; the furnace cover is composed of an outer cover and a lining, a heating piece is arranged on the inner side wall of the lining, and after the furnace cover is closed, the outer cover is buckled downwards to abut against the supporting bottom. The furnace cover is provided with an exhaust valve used for vacuumizing, and the exhaust valve is externally connected with a vacuum pump to work, so that vacuumizing treatment of the heat treatment furnace is achieved. According to the invention, large-batch plate heat treatment can be quickly and efficiently realized, the size of the furnace body can be adjusted according to actual use requirements, and heat treatment of materials with different specifications and sizes can be realized.

Owner:浙江精瑞工模具有限公司

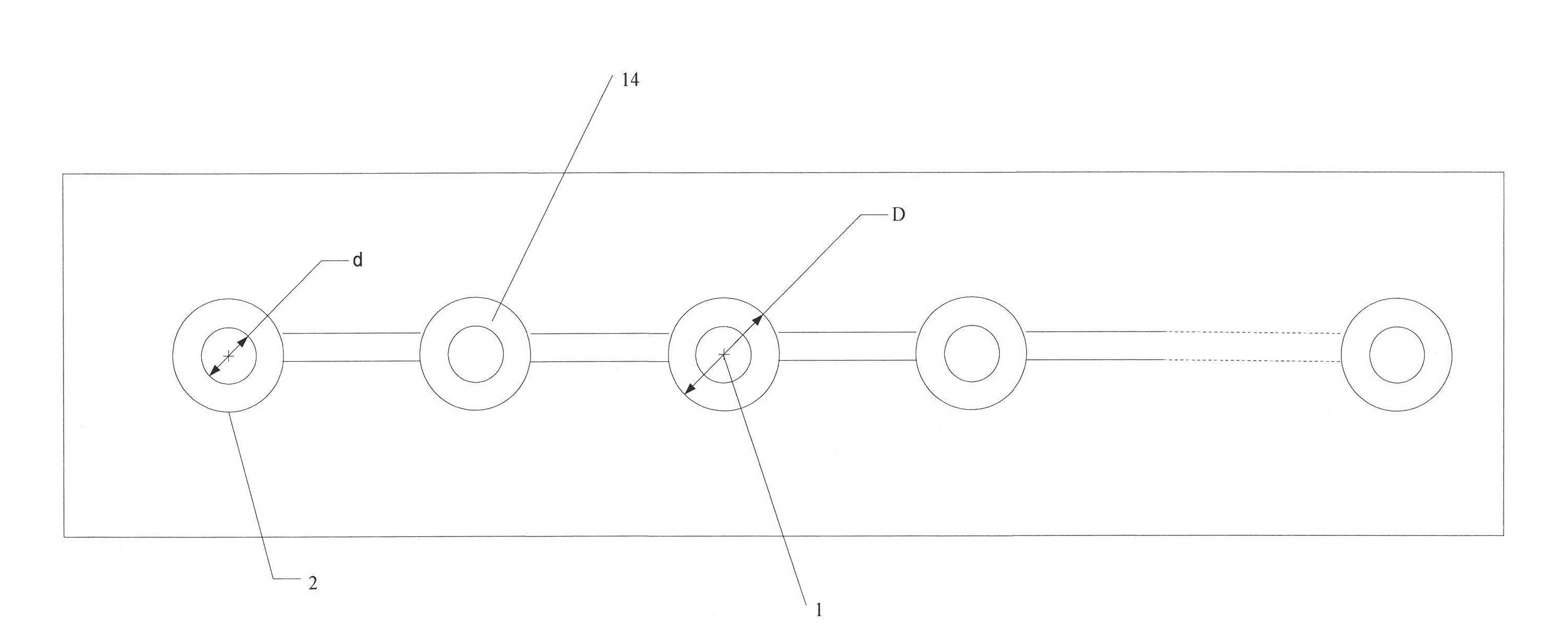

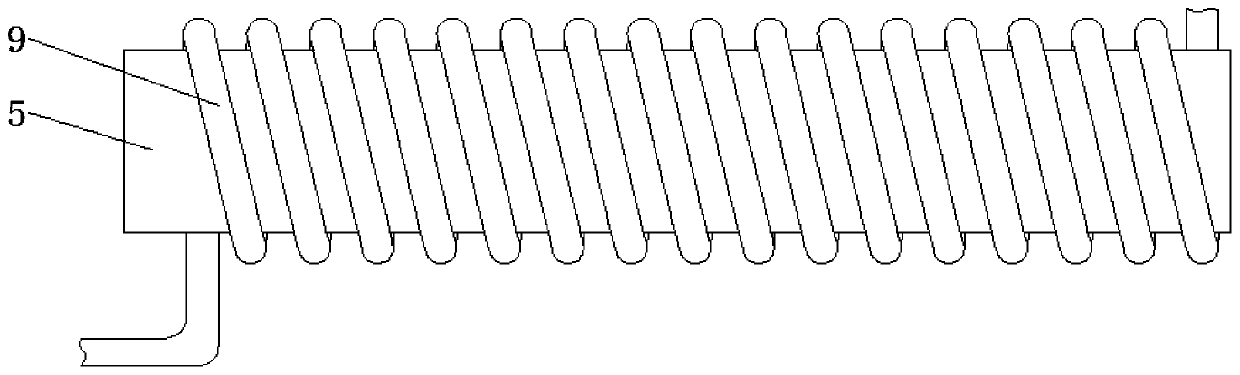

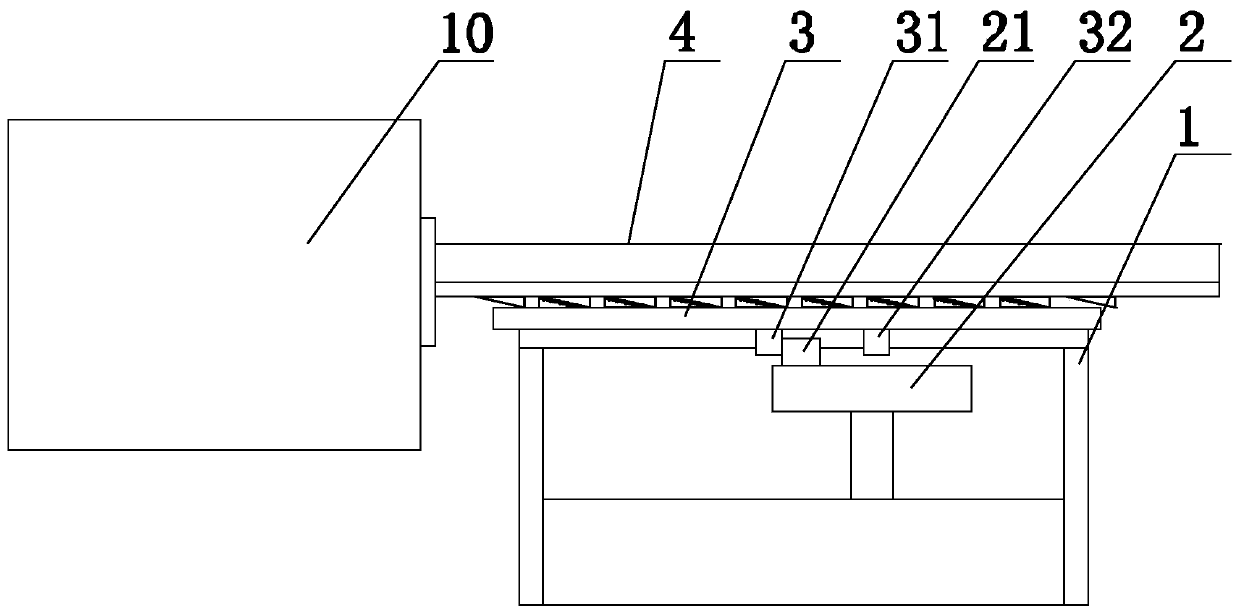

Electromagnetic induction medium-frequency furnace and high-strength prestress steel strand production process

PendingCN110306022AGuaranteed heat treatment performanceImprove molding qualityFurnace typesIncreasing energy efficiencySurface cleaningPre stress

The invention discloses an electromagnetic induction medium-frequency furnace and a high-strength prestress steel strand production process, and relates to the technical field of steel strand production. The electromagnetic induction medium-frequency furnace comprises a furnace box, wherein an inlet is formed in one side end of the furnace box, a surface cleaning device is arranged on the side wall, close to the inlet, of the furnace box, the surface cleaning device comprises a horizontal sliding rail arranged on the furnace box, a sliding block is arranged on the horizontal sliding rail, thesliding block is connected with a vertical mounting plate, the upper end and the lower end of the vertical mounting plate are detachably connected with a horizontal mounting plate A and a horizontal mounting plate B which are located on the upper side and the lower side of the inlet respectively, and the side, close to the inlet, of the horizontal installation plate A and the side, close to the inlet, of the horizontal installation plate B are respectively provided with a wiping layer. According to the high-strength prestress steel strand production process, chlorohydric acid pickling, water washing, phosphorization and saponification are sequentially carried out, corresponding steel wires are and drawn out through a wire drawing machine, stranding of the steel wires are performed througha stranding machine, the steel strand is treated by adopting the electromagnetic induction medium-frequency furnace, and finally water cooling treatment is carried out. The steel strand prepared by the production process has the advantages that the strength is high, and the tensile strength can reach more than 2200 MPa.

Owner:兰州斯凯特路桥预应力技术开发有限公司

Hardening and tempering treatment technology for roll

InactiveCN107177725AGuaranteed heat treatment performanceEasy to shapeFurnace typesHeat treatment furnacesQuenchingHardness

The invention discloses a hardening and tempering treatment technology for a roll. The hardening and tempering treatment technology particularly comprises the steps that crack detection is conducted on the roll, and the qualified roll is put into a preheating pipeline for preheating treatment and preheated till the temperature reaches 80-120 DEG C; the preheated roll is put into a quenching furnace for quenching treatment, specifically, the temperature is heated to 560-640 DEG C, heat preservation is conducted for 1-2 h, the temperature is heated to 940-980 DEG C, and heat preservation is conducted for 2-4 h; the roll is taken out, and the temperature is lowered to 460-500 DEG C through air cooling and then lowered to room temperature through water cooling; the roll is put into a tempering furnace for tempering treatment, specifically, the temperature is increased to 260-300 DEG C, heat preservation is conducted for 0.5-1.5 h, the temperature is increased to 620-660 DEG C, and heat preservation is conducted for 2-3 h; finally the tempering furnace is opened, the roll is cooled to 360-400 DEG C along with the furnace and then put into a cooling water pool to be water-cooled to room temperature, and then the hardening and tempering treatment technology is completed. In this way, the hardening and tempering effect can be significantly improved, the roll achieves the higher shaping, strength and hardness properties, and the product quality is high.

Owner:太仓市钧胜轧辊有限公司

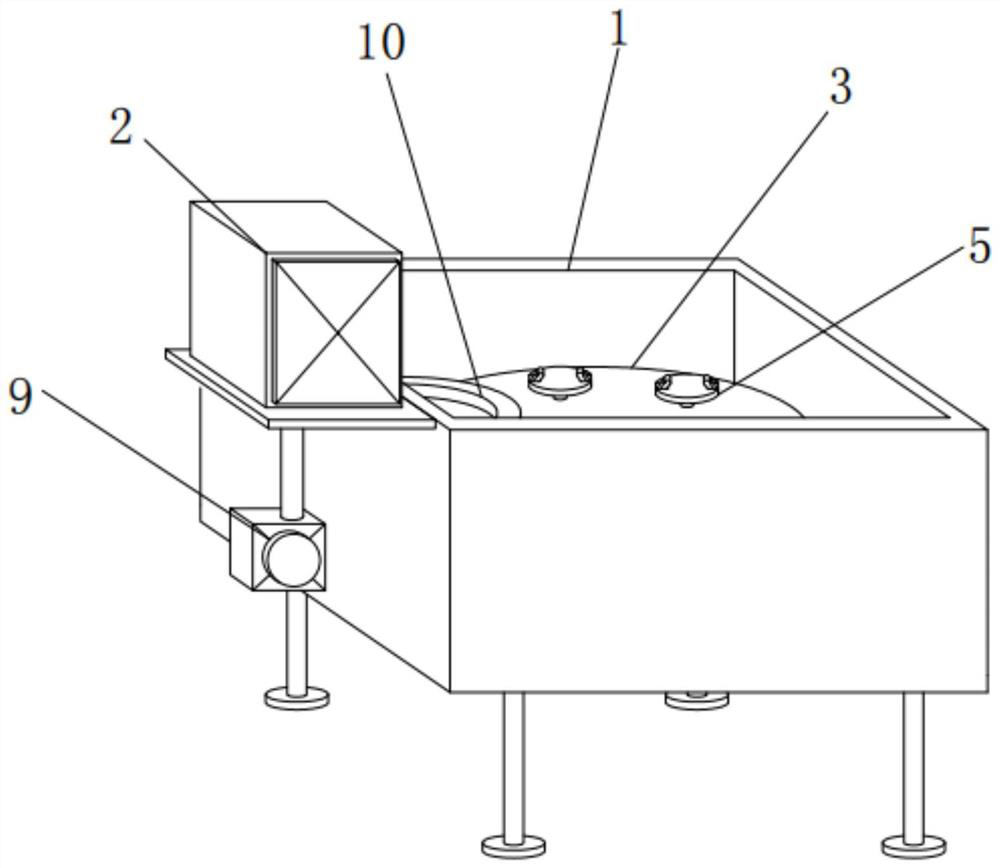

Kitchenappliance glass tempering heat treatment device and process

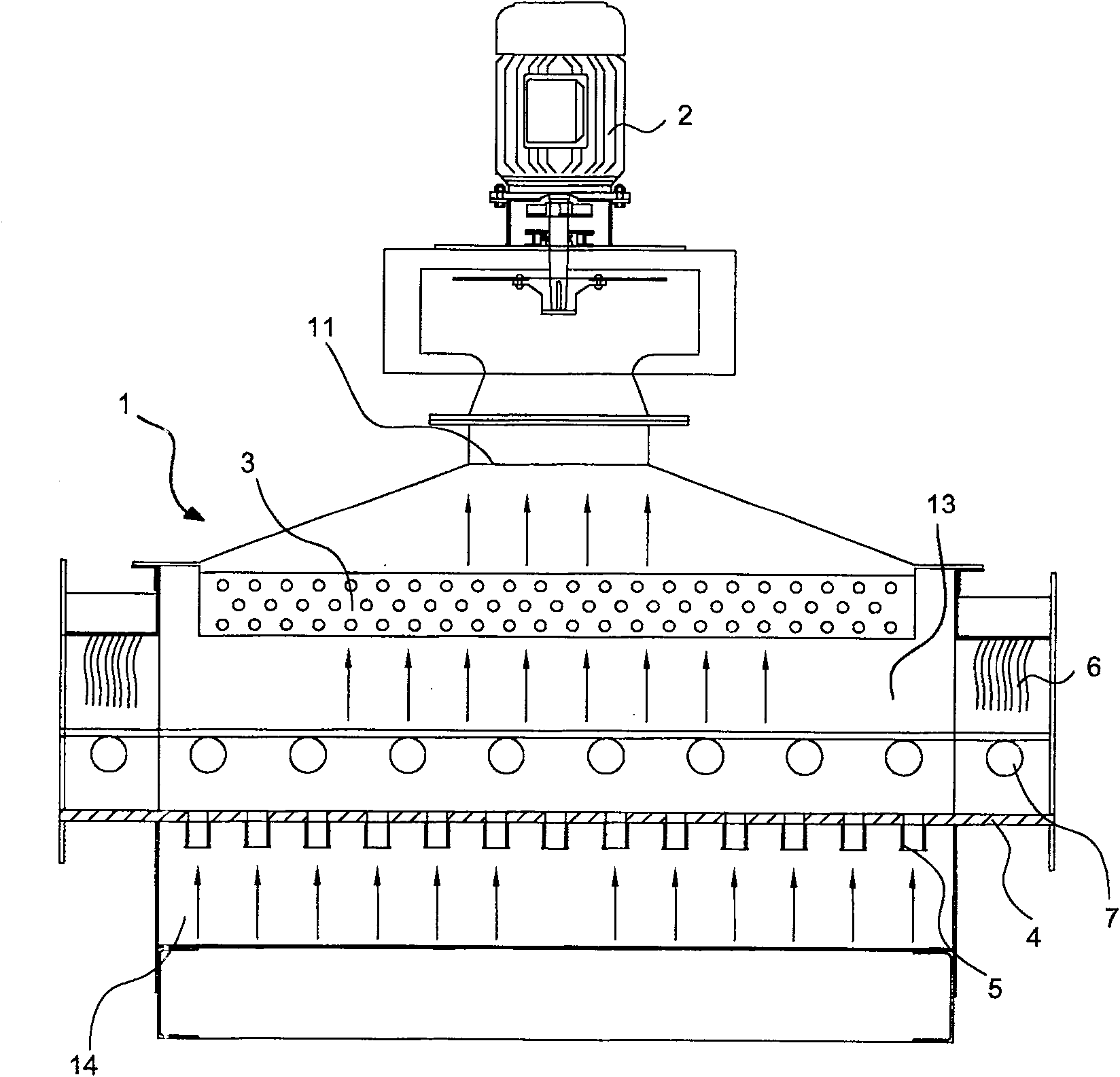

ActiveCN112851101AFully uniform temperatureGuaranteed heat treatment performanceGlass tempering apparatusGlass productionElectric machineEngineering

The invention discloses a kitchen appliance glass tempering heat treatment device and process, and belongs to the technical field of glass processing. The kitchen appliance glass tempering heat treatment device comprises a heating furnace, a glass heat treatment working area is arranged in the heating furnace, a plurality of evenly-distributed heating furnace nozzles are arranged on the inner wall of the heating furnace, a driving motor is fixed to the upper surface of the heating furnace, a rotating shaft is vertically arranged in the center of the interior of the heating furnace, the top end of the rotating shaft penetrates through the upper surface of the heating furnace and is connected with the output end of the driving motor, multiple sets of symmetrically-arranged air guide plates are fixed to the outer wall of the rotating shaft, air guide holes are formed in the air guide plates, and the movement of a rolling temperature balance ball in the furnace body of the heating furnace can be utilized to accelerate the temperature in the heating furnace to rapidly reach a balance state, so that the temperature in the heating furnace is fully uniform, the glass heat treatment effect is ensured, the phenomenon that the heat treatment quality is influenced by non-uniform temperature distribution is effectively avoided, and energy is effectively saved.

Owner:浙江银升新材料有限公司

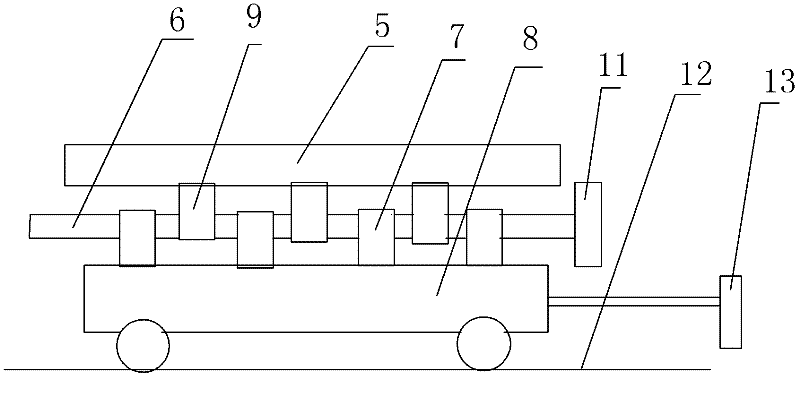

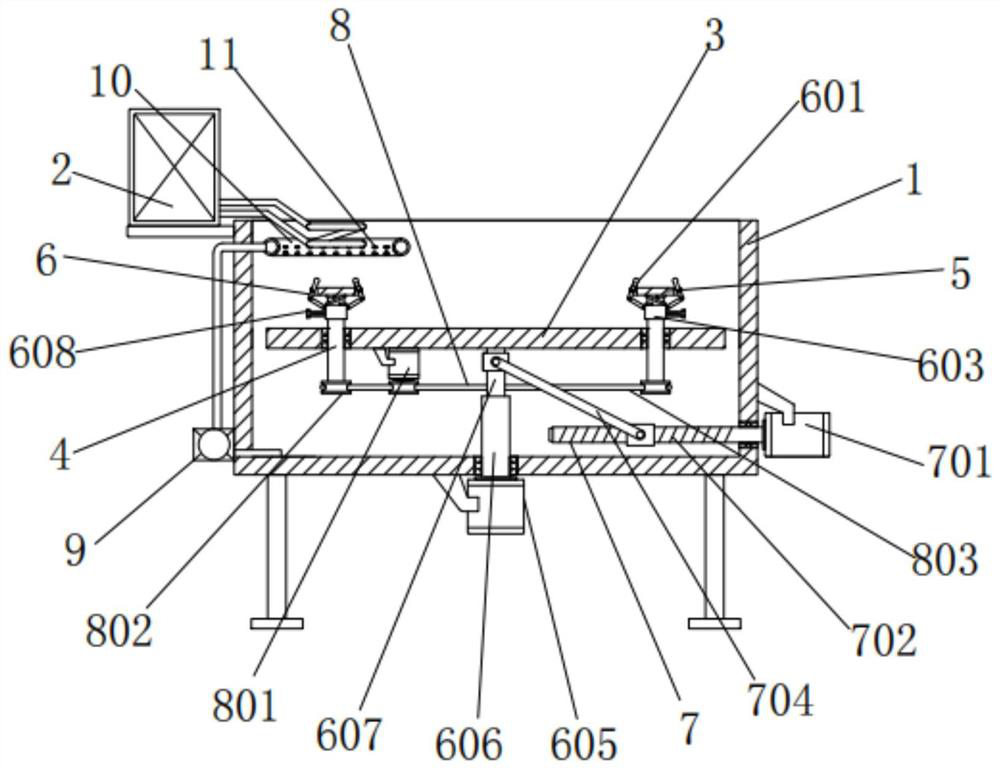

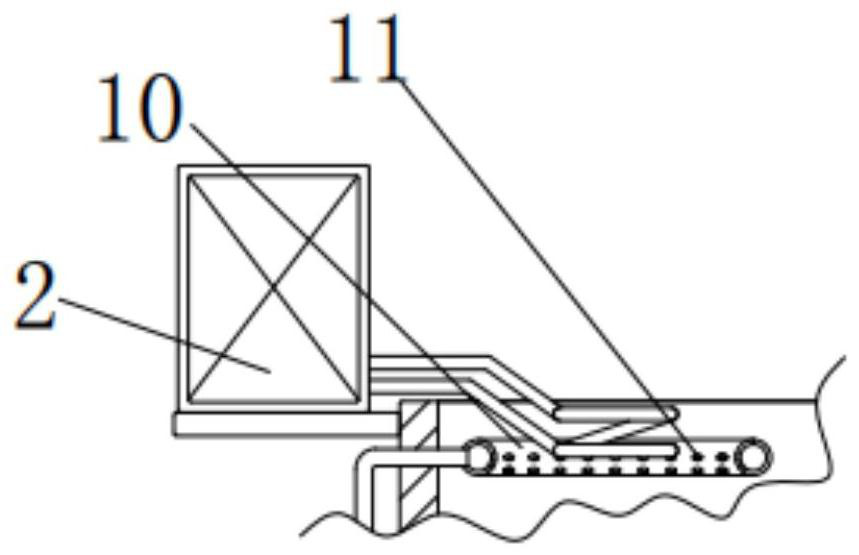

Supporting plate type feeding tool for isothermal heat treatment process

PendingCN110983015AAvoid stackingExtend heat treatment timeFurnace typesHeat treatment furnacesReciprocating motionEngineering

The invention discloses a supporting plate type feeding tool for isothermal heat treatment process. The supporting plate type feeding tool is characterized in that a pushing bracket is slidably installed on a sliding rail, a first stop block and a second stop block are arranged at the bottom of the pushing bracket, a plurality of pushing blocks are sequentially arranged at the top of the pushing bracket in the feeding direction, a material conveying tray is located above the pushing bracket, a plurality of feeding blocks corresponding to the pushing blocks are arranged at the bottom of the material conveying tray, a driving rotary disc is horizontally arranged below the pushing bracket, an eccentric pushing shaft is arranged at the top of the driving rotary disc, and the eccentric pushingshaft is located between the first stop block and the second stop block of the pushing bracket. According to the optimally-designed supporting plate type feeding tool for the isothermal heat treatmentprocess, the driving rotary disc drives the pushing bracket to reciprocate through the eccentric pushing shaft, and then the material conveying tray is driven to conduct feeding at a low speed, so that parts slowly enter a heat treatment furnace along with the material conveying tray, part stacking is prevented, the part heat treatment time is prolonged, and the heat treatment effect is guaranteed.

Owner:ANHUI NINGGUO DONGBO FASTENER

Self-plugging rivet manufacturing process

ActiveCN111571143AImprove structural strength and surface hardnessImprove product performanceHeat conservationManufacturing engineering

The invention discloses a self-plugging rivet manufacturing process. The self-plugging rivet manufacturing process comprises rivet body manufacturing and rivet sleeve manufacturing, wherein the rivetbody manufacturing process comprises the following steps of 1, preparation of rivet body blanks: selecting an A286 raw material with the appropriate specification and mass; 2, upsetting forming: conducting upsetting on the selected A286 raw material through molds with the corresponding specifications in a cold upsetting machine 2-3 times to form heads, steps and rod parts of rivets to obtain semifinished rivet bodies; 3, cleaning: feeding the semifinished rivet bodies onto a corresponding cleaning line to remove oil dirt and blasted surface sand generated after upsetting; 4, heat treatment: feeding the cleaned semifinished rivet bodies into a heat treatment furnace of 650-700 DEG C for production heat preservation for 8-10 h, and then conducting air-cooling; 5, thread rolling: conducting thread rolling on the semifinished rivet bodies subjected to heat treatment to form knurls, threads and grooves; and 6, surface treatment: conducting surface treatment on the semifinished rivet bodiessubjected to thread rolling to obtain finished products. The self-plugging rivet manufacturing process is simple in working procedure, high in machining efficiency and qualified rate of the products and good in quality.

Owner:王丽

Hardware heat treatment system

InactiveCN113337687APrevent accidental fall offImprove stabilityFurnace typesIncreasing energy efficiencyComputer hardwareEngineering

The invention discloses a hardware heat treatment system, which comprises a box body, wherein a circular plate is arranged in the box body; and positioning mechanisms are arranged on the upper side and the lower side of the circular plate correspondingly. According to the hardware heat treatment system, a lantern ring is stressed upwards to drive an ejector rod to rotate inwards through a supporting rod and abut against hardware, and at the moment, the hardware can be fastened by tightening a bolt, so that the heat treatment stability is improved, and the hardware is prevented from accidentally falling off; multiple supporting plates can be sequentially arranged below an annular pipe and a heating coil, so that rapid switching heat treatment is achieved, and the heat treatment efficiency is improved; a screw rod rotates to drive a vertical rod to slide up and down, and then a circular plate and hardware fixed above the circular plate are driven to simultaneously slide into the annular pipe and the heating coil, so that the hardware can be directly and uniformly cooled after precise heat treatment, and the heat treatment effect is improved; and the hardware can axially rotate during heat treatment and cooling, so that the heat treatment and cooling uniformity is improved, the heat treatment effect is further guaranteed, and the hardness of the hardware is greatly improved.

Owner:孙华伟

Aluminum alloy wheel hub heat treatment quenching heat energy recycling system

InactiveCN107227396AReduce water temperatureReduce energy consumptionFurnace typesHeat treatment process controlThermal energyThermal water

The invention discloses a quenching water heat recovery system for heat treatment of aluminum alloy wheels, which comprises a quenching tank in which a water supply pipe is communicated, and a water delivery pipeline extending to a painting and cleaning reservoir is also arranged in the quenching tank. The water delivery pipeline is provided with a water pump. The hot water in the quenching tank is sent to the painting and cleaning reservoir, which can not only reduce the water temperature in the quenching tank by timely replenishing water, so as to improve the heat treatment effect, but also reduce the energy consumption of heating the cleaning water before painting, killing two birds with one stone .

Owner:鄢贵龙

A wire heating guide device

ActiveCN105936973BGuaranteed thermal effectGuaranteed temperature uniformityFurnace typesHeat treatment furnacesThermal energyThermal insulation

The invention provides an iron wire heating diversion device. The device is arranged in the accommodation cavity of a heating furnace and comprises a support seat, a blower fan, a bracket, and a tray, which are arranged from bottom to top. The blower fan is rotatingly arranged on the support seat through a rotation shaft. The top surface of the support seat is provided with a plurality of baffle plates. The baffle plates are evenly arranged around the blower fan. The center of the bracket is provided with a first air hole. The center of the tray is provided with a second air hole. The bottom surface of the bracket and the top surface of the support seat form a first air channel. Two neighbored baffle plates form a first air channel. In the provided iron wire heating diversion device, the support seat is provided with an air blower and first air channels, the bracket is provided with a first air hole, the tray is provided with a second air hole, the first air hole and the second air hole are opposite to the blower fan; when the blower fan rotates, hot air goes through the second air hole and the first air hole and is discharged from the first air channels, thus thermal energy circulation is formed, the uniformity of temperature in a thermal insulation box can be guaranteed, and the iron wire heating effect is ensured.

Owner:TIANJIN HUAYUAN WIRE PROD

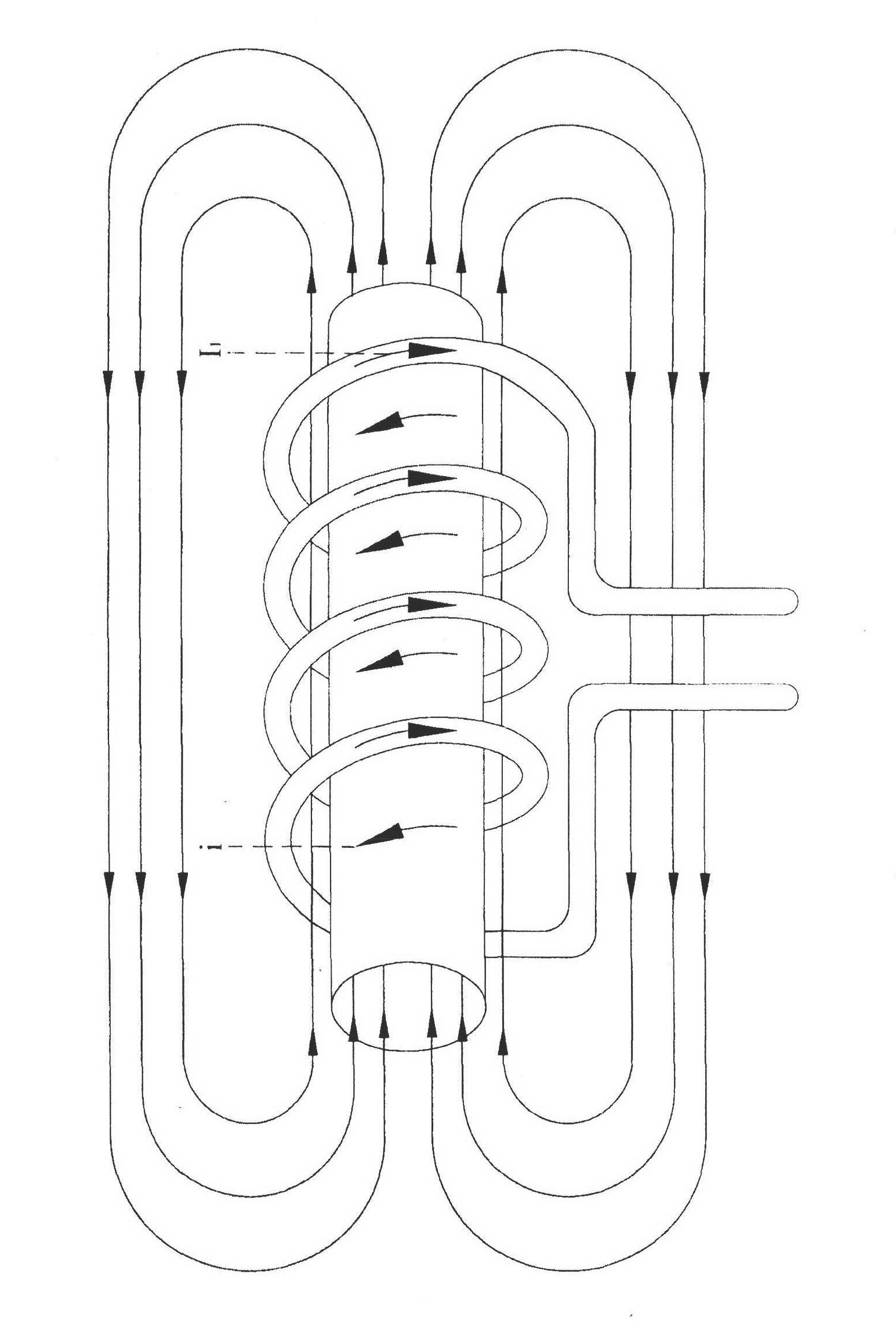

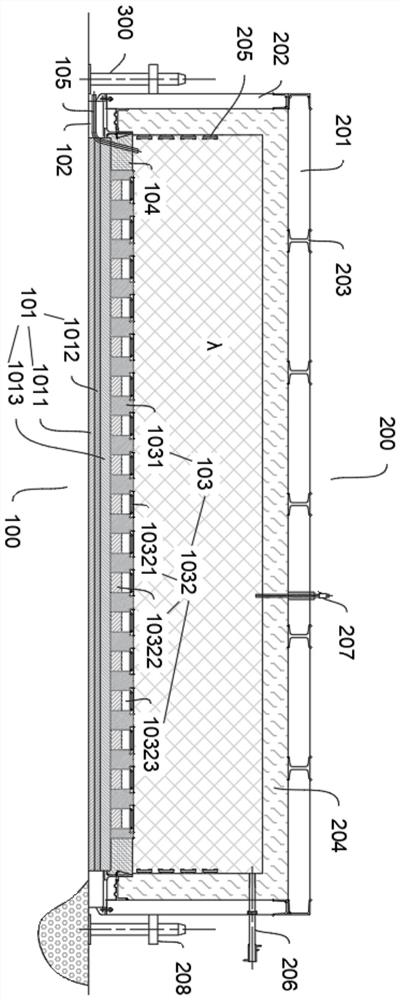

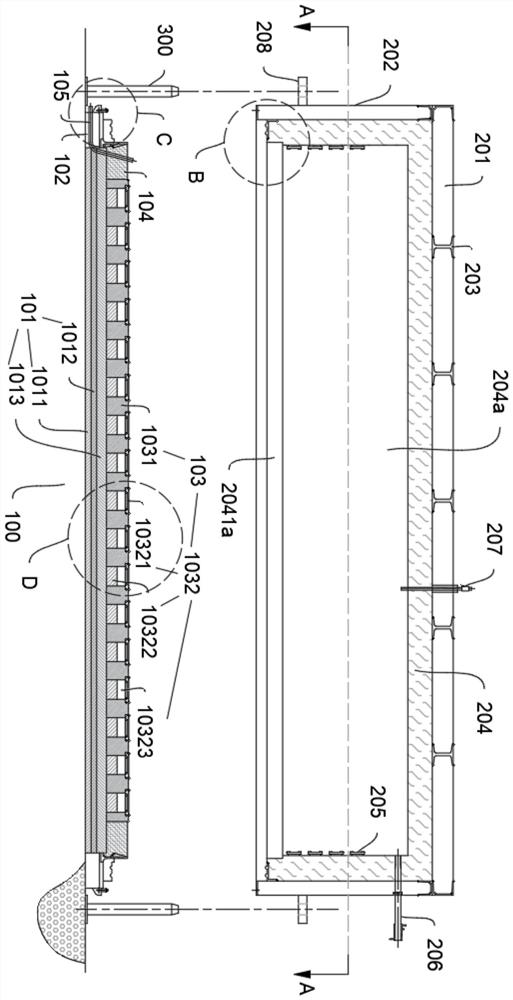

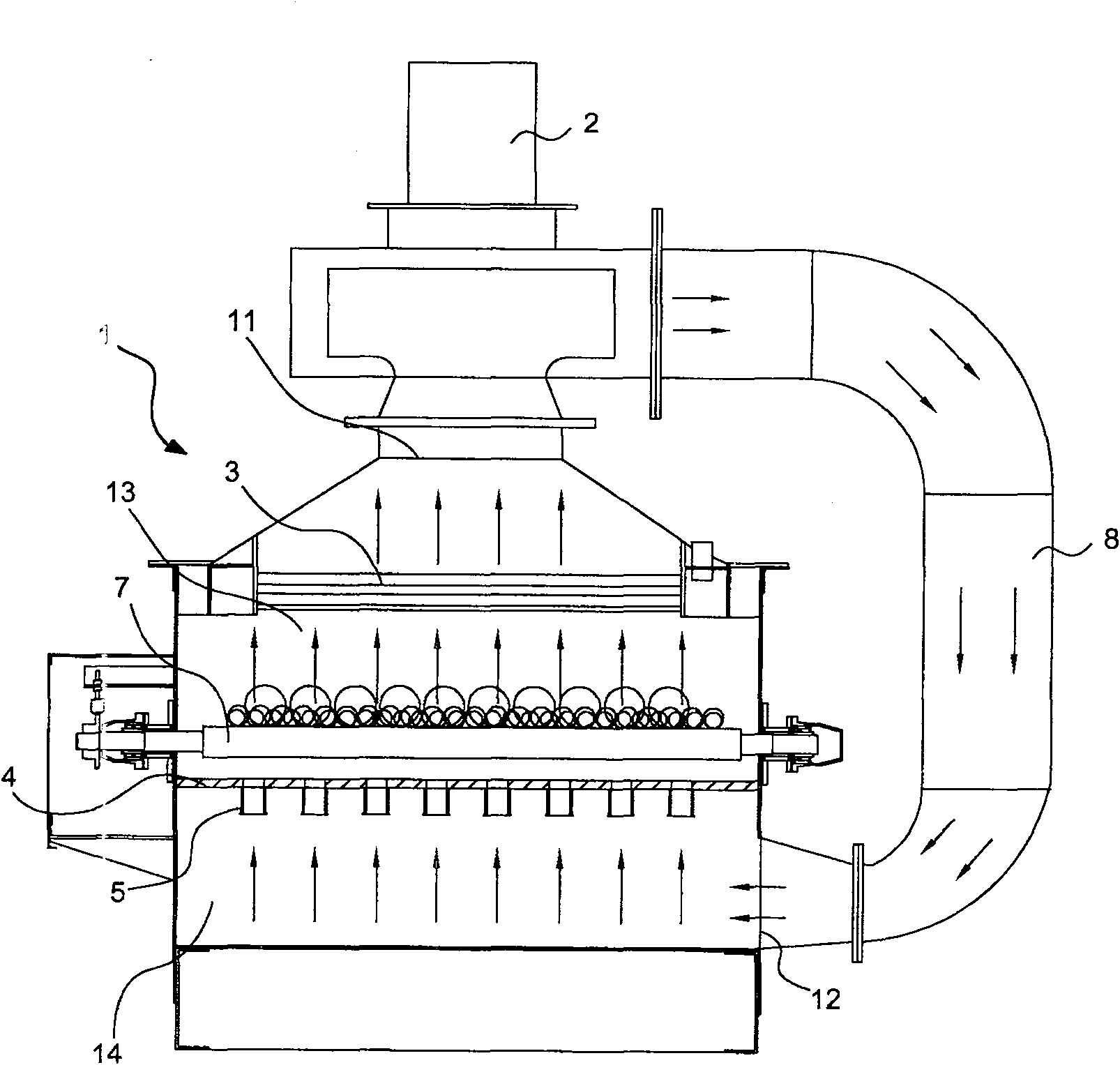

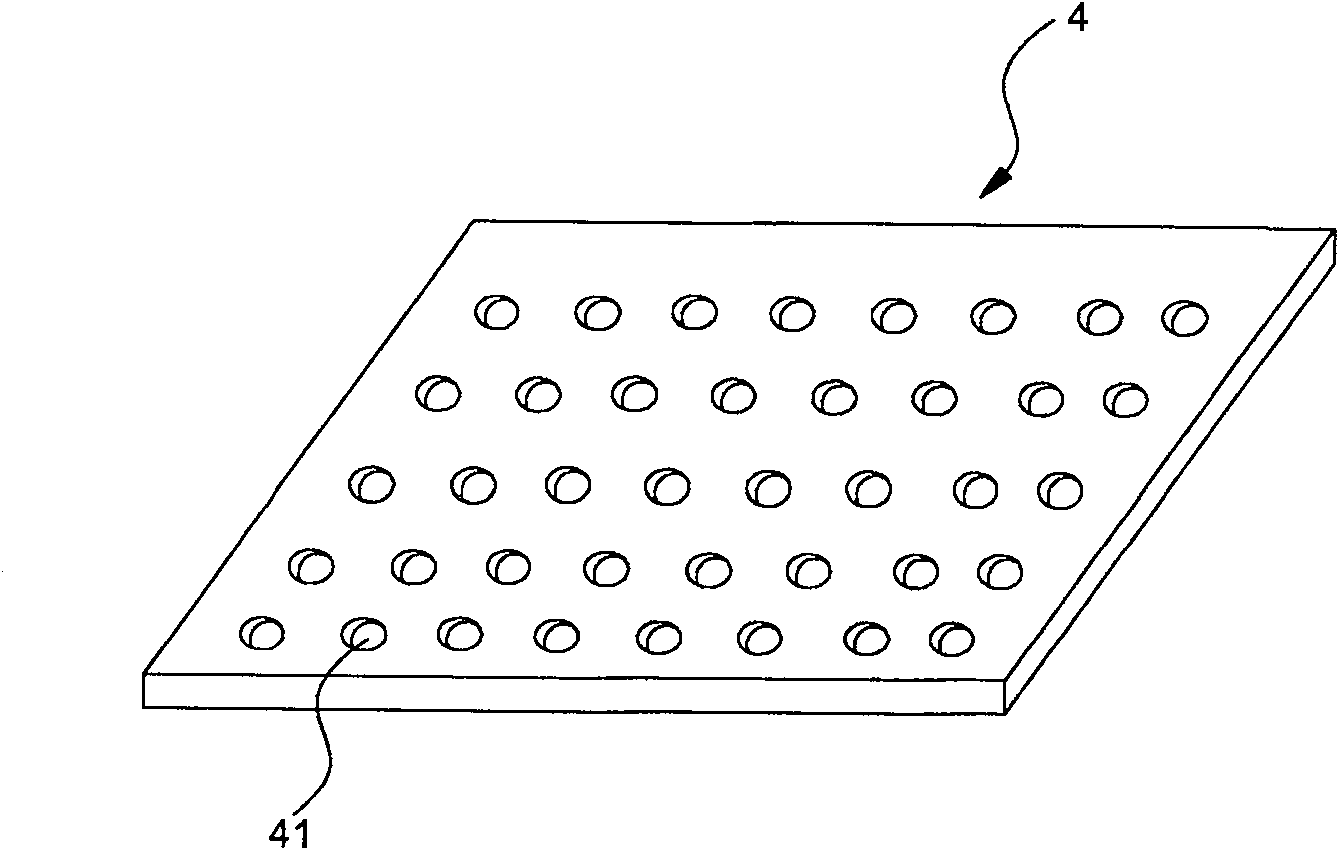

Severe-convective cooling system for low-pressure continuous protective atmosphere heat treatment furnace

ActiveCN100577824CImprove cooling efficiencyGuaranteed heat treatment performanceFurnace coolingCooling chamberCooling effect

The invention relates to a strong convection cooling system of a continuous passing protective atmosphere annealing oven with low furnace pressure, which comprises a cooling chamber with a built-in work rest, a strong convection circulating fan, a heat-cold exchanger and a circulating air channel, wherein an air return is arranged on the top portion of the cooling chamber, an air supply outlet is arranged on the bottom of the cooling chamber, the air return is communicated with the air inlet of the circulating fan, the air supply outlet is communicated with the air outlet of the strong convection circulating fan through the circulating air channel, a baffle is arranged in the cooling chamber, the baffle which is located on the low portion of the work rest separates the cooling chamber into an upper cavity chamber and a lower cavity chamber, a plurality of diversion channels are arranged on the baffle, the upper cavity chamber and the lower cavity chamber are communicated through the diversion channels, air flow forms laminar flow when air flow flows into the upper cavity chamber after flowing through the diversion channels, protective air flow enters into the cooling chamber through the air supply outlet, and is sprayed on the surface of a work-piece in the laminar flow way after flowing through an air flow channel, thereby achieving the purpose of evenly cooling the work-piece, and largely increasing the cooling effect.

Owner:SUZHOU ZHONGMENZI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com