Layered wheel hub blank heat-treatment material rack

A wheel hub blank, layered technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of short service life, easy deformation and bending of cantilever beams, etc., and achieve long service life, small deformation, and easy movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

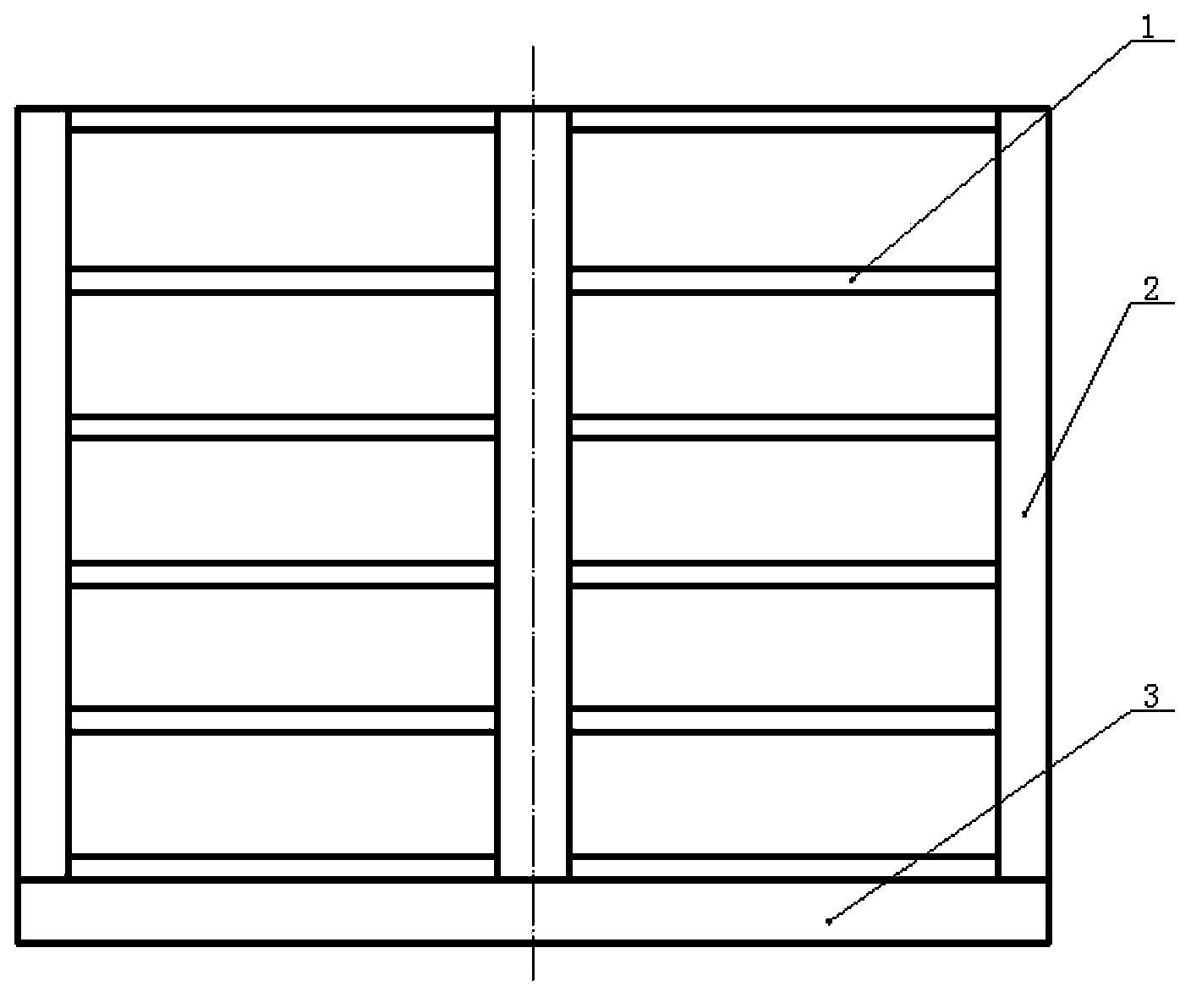

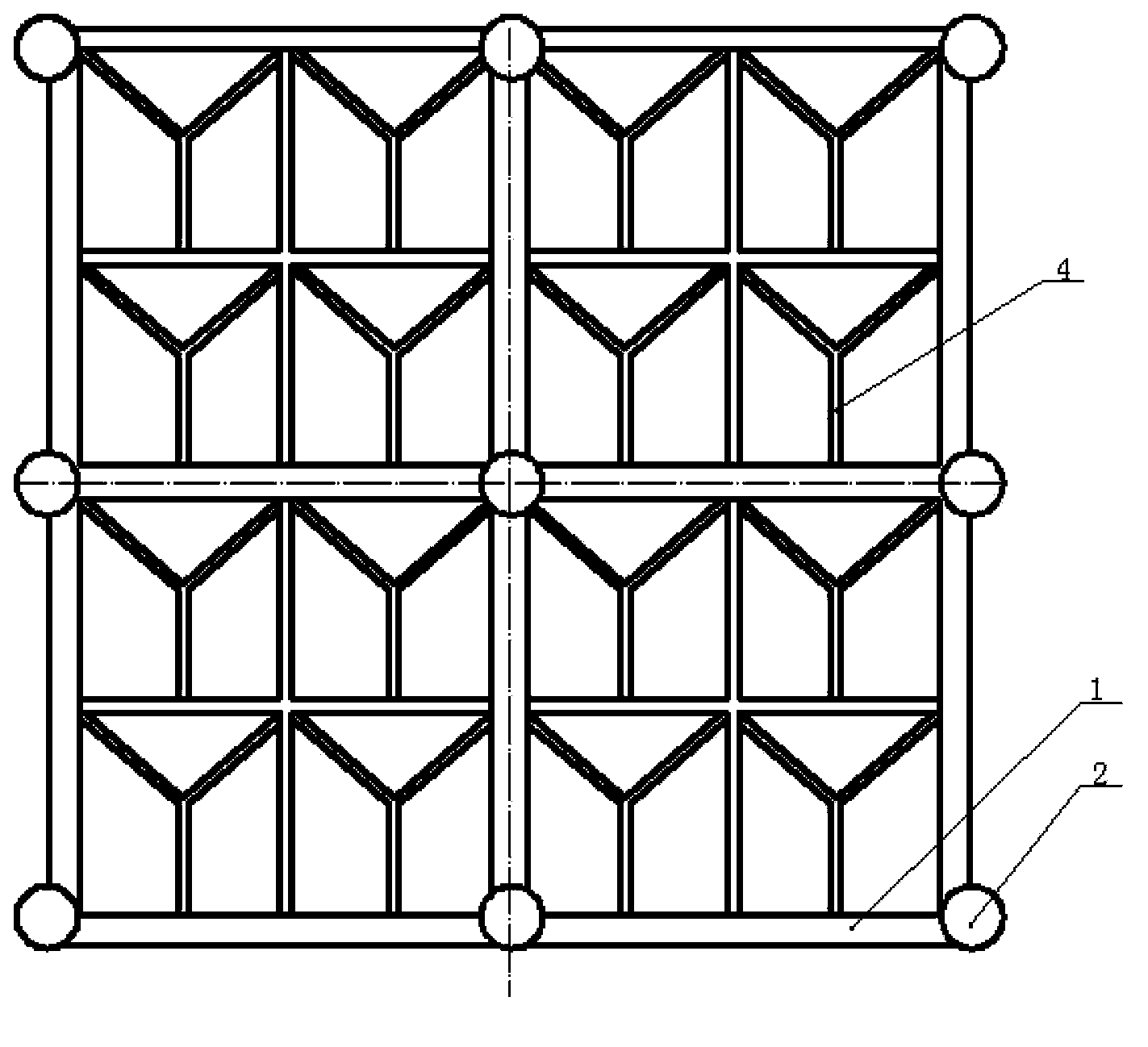

[0016] A layered hub blank heat treatment rack, including a base 3, a column 2 and a beam 1, the base, the column and the beam constitute a cube-shaped frame, and its specific structure is: vertically and evenly distributed on the base A plurality of uprights are installed, and multiple layers of horizontal and vertical intersecting beams are evenly distributed and fixed between adjacent uprights, and the beams of each layer form a uniform horizontal grid.

[0017] In order to strengthen the supporting force of each layer of material rack, the hub support frame 4 is fixedly installed in the horizontal grid formed by the beam.

[0018] In this embodiment, nine upright columns are fixed vertically and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com