Heat treatment device for rotary support outer ring raceway

A technology of heat treatment device and slewing bearing, used in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve problems such as discounting treatment efficiency, and achieve the effect of improving efficiency, ensuring effect and good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

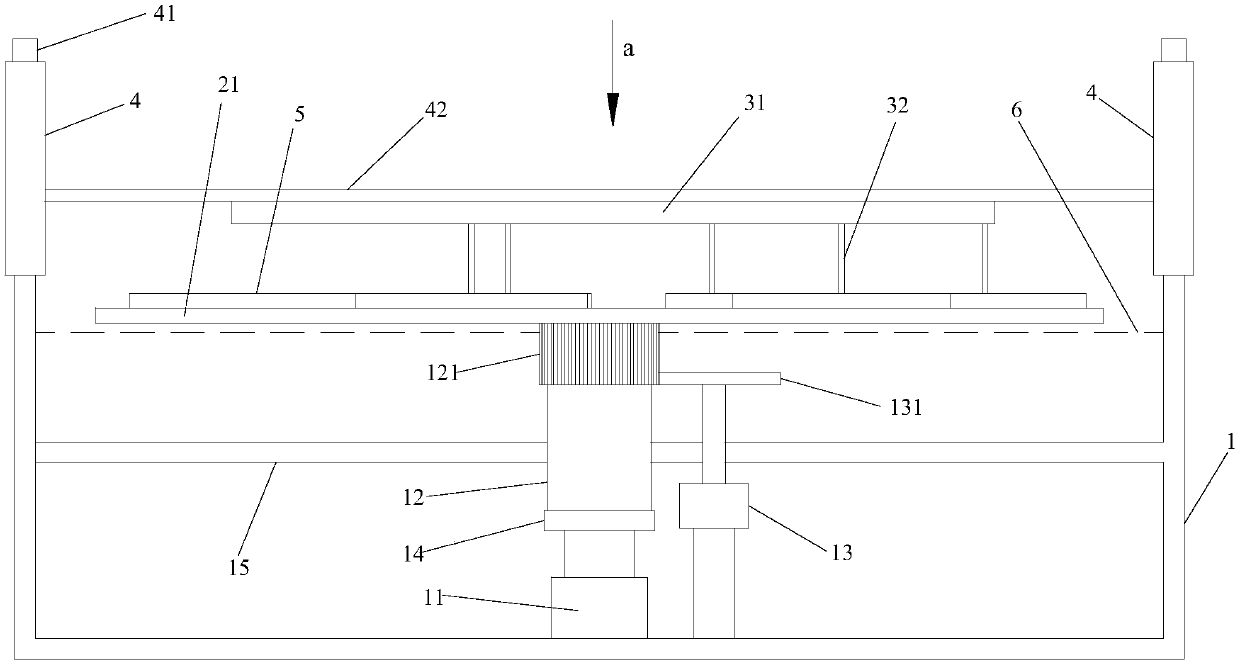

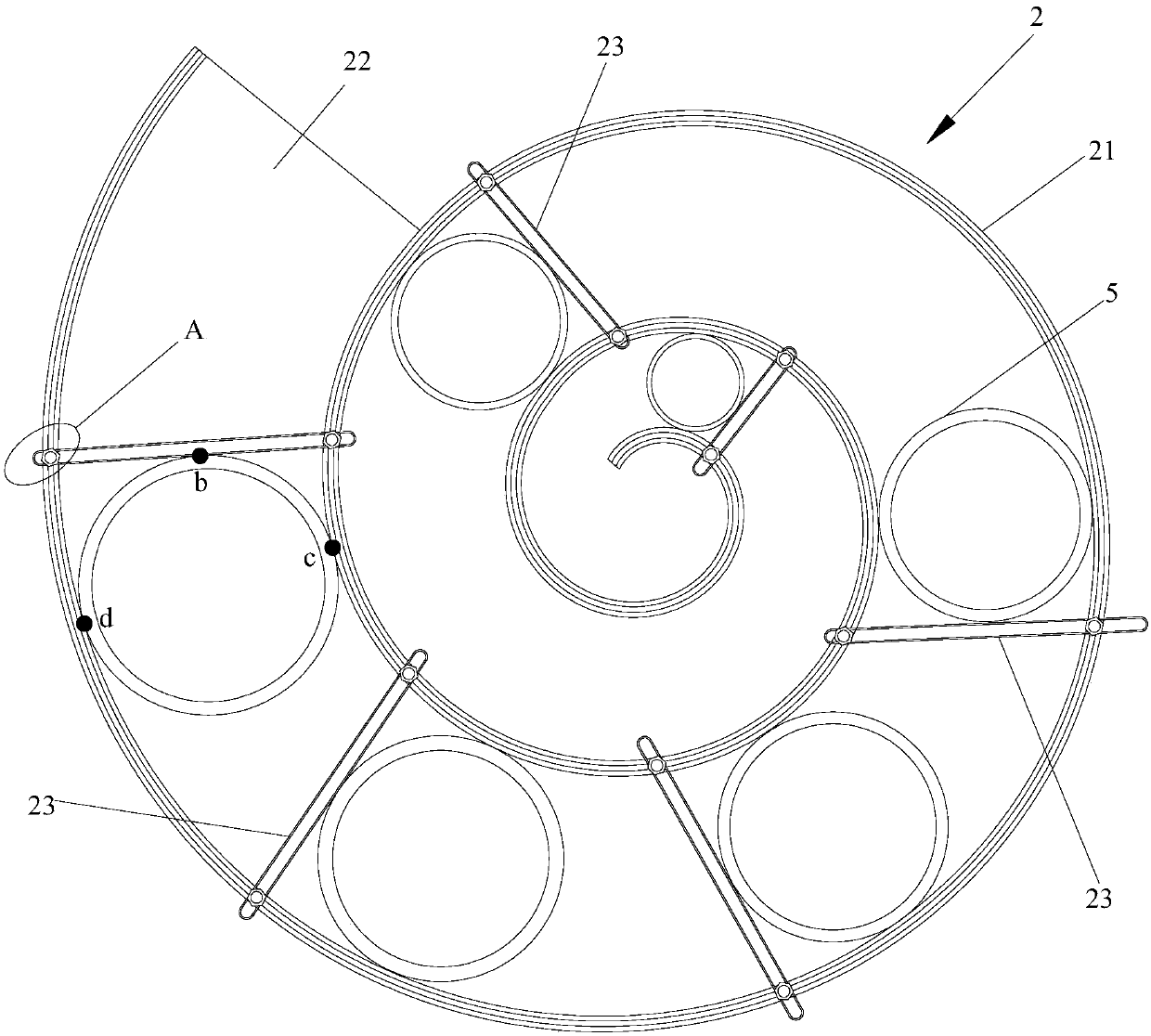

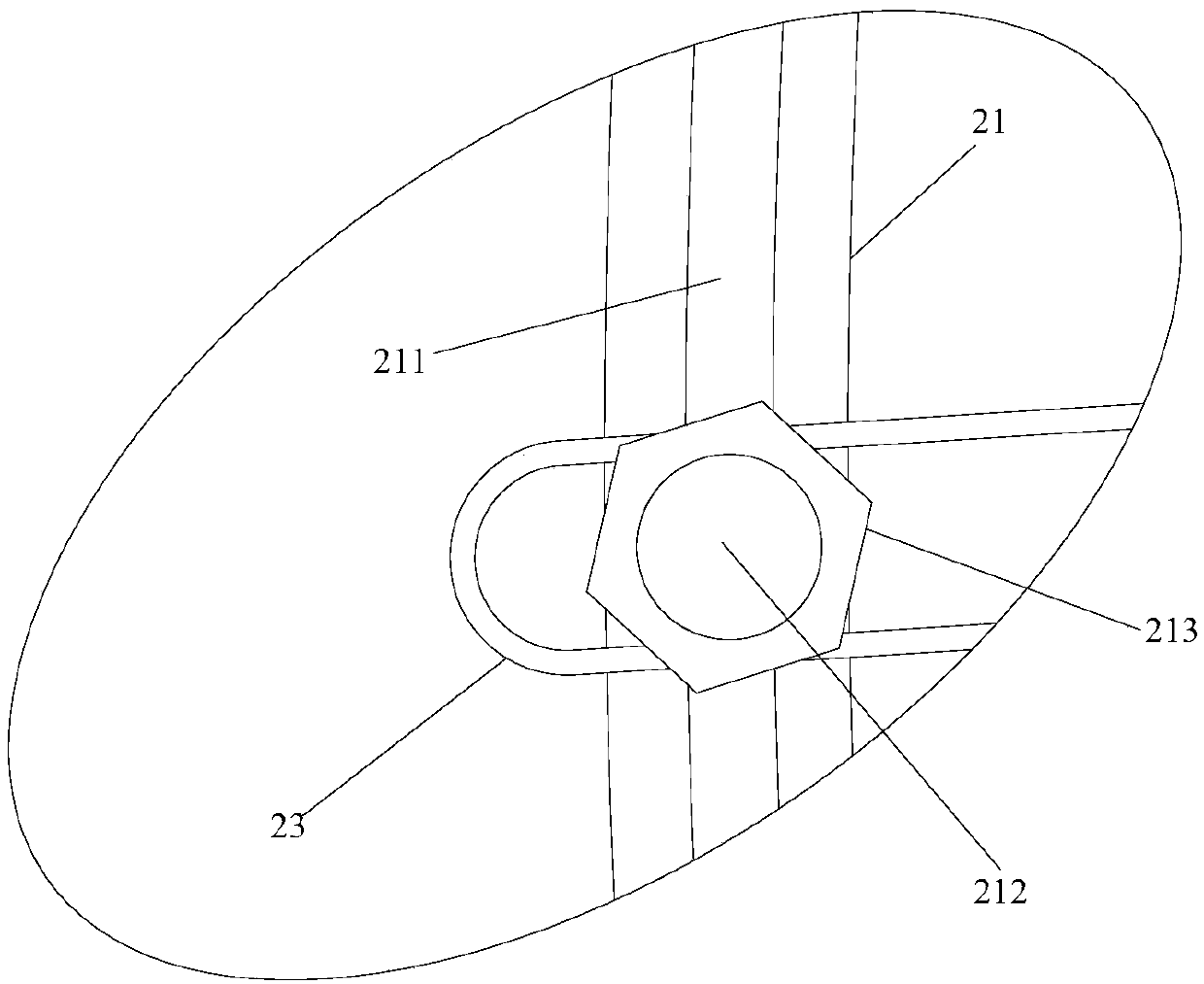

[0024] Such as figure 1 As shown, the present invention provides a heat treatment device for the raceway of the outer ring of the slewing bearing, which includes a cooling cylinder 1, two support columns 4 are symmetrically arranged on the upper end of the cooling cylinder 1, and there is a vertical lift between the two support columns 4. The beam 42 is fixed with the heating unit 3 on the beam 42; Figure 7 , the supporting column 4 is provided with a rotatable leading screw 43, the top of the supporting column 4 is fixedly provided with a stepper motor 41 for driving the rotating screw 43, and the two ends of the beam 42 are connected with the leading screws in the two supporting columns 4 respectively. 43 threaded assembly, two stepping motors 41 drive the electric heating unit 3 to move up and down; the cooling cylinder 1 is provided with a partition 15, and the partition 15 divides the cooling cylinder 1 into upper and lower layers, and the upper layer is used to hold the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com