Severe-convective cooling system for low-pressure continuous protective atmosphere heat treatment furnace

A technology of protective atmosphere and heat treatment furnace, which is applied in the field of strong convection cooling system, can solve the problems of increased manufacturing cost, difficult control of gas flow in the cooling chamber, and low cooling efficiency, so as to improve cooling efficiency and production efficiency, ensure heat treatment effect, improve The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

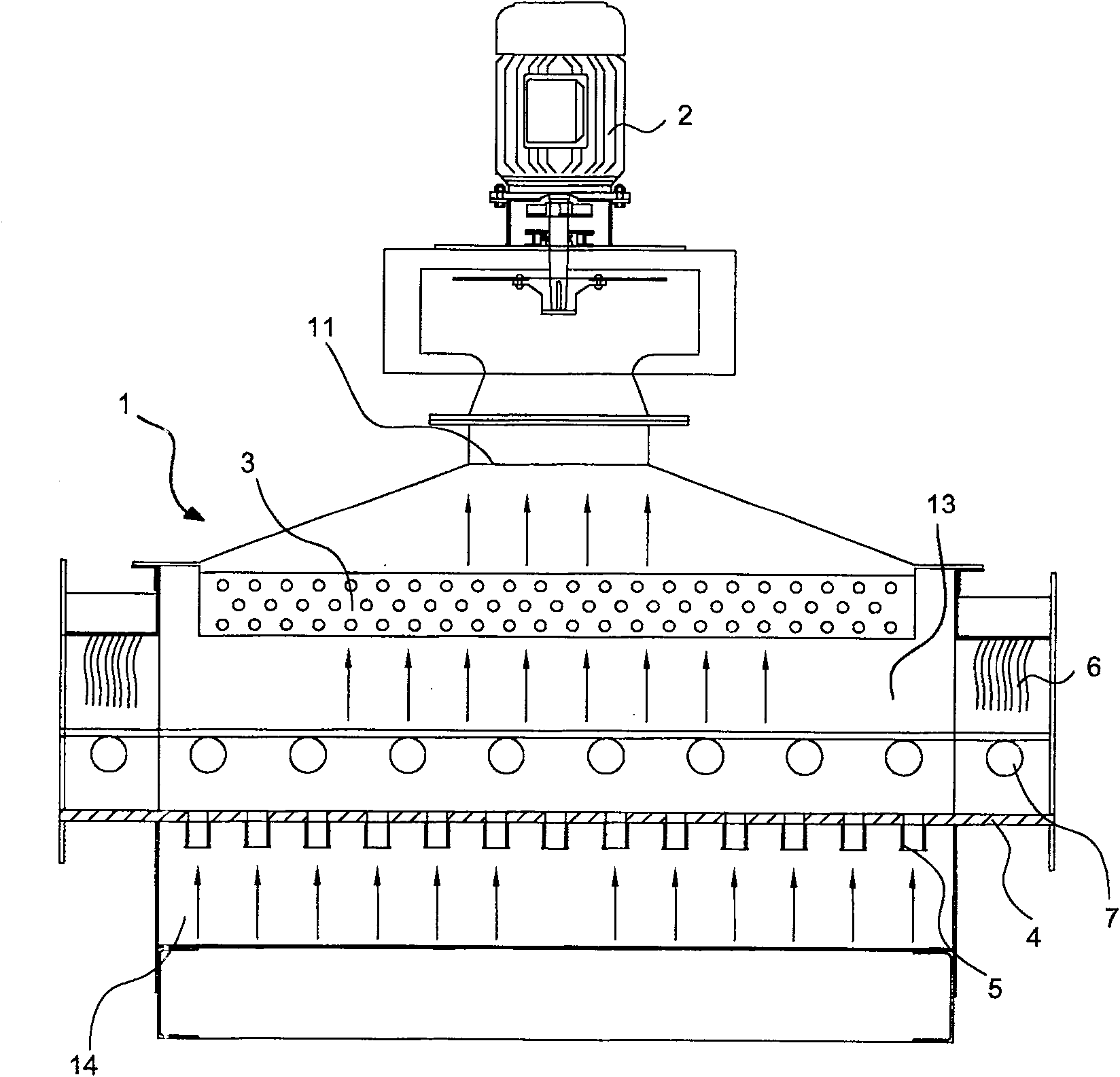

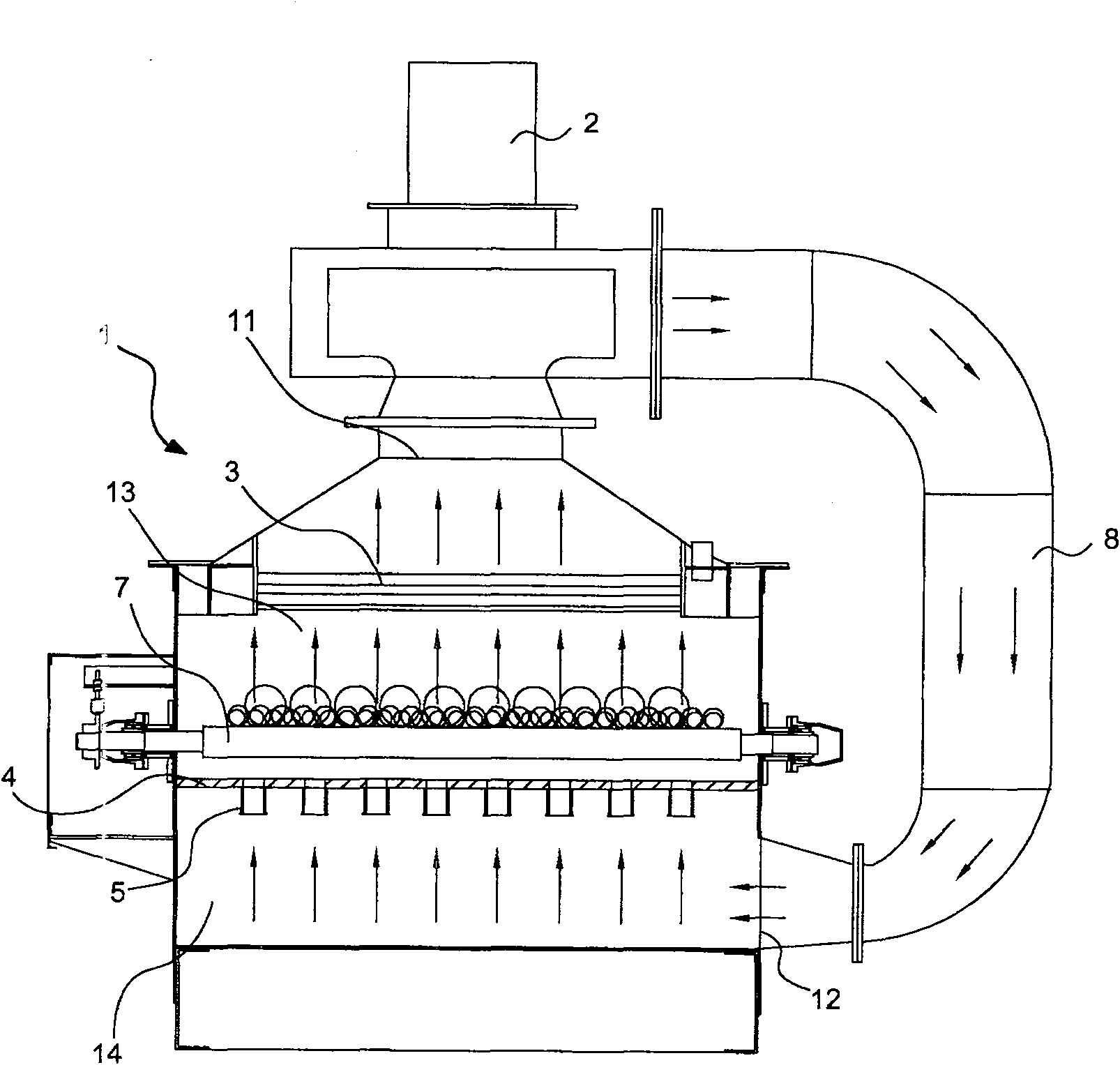

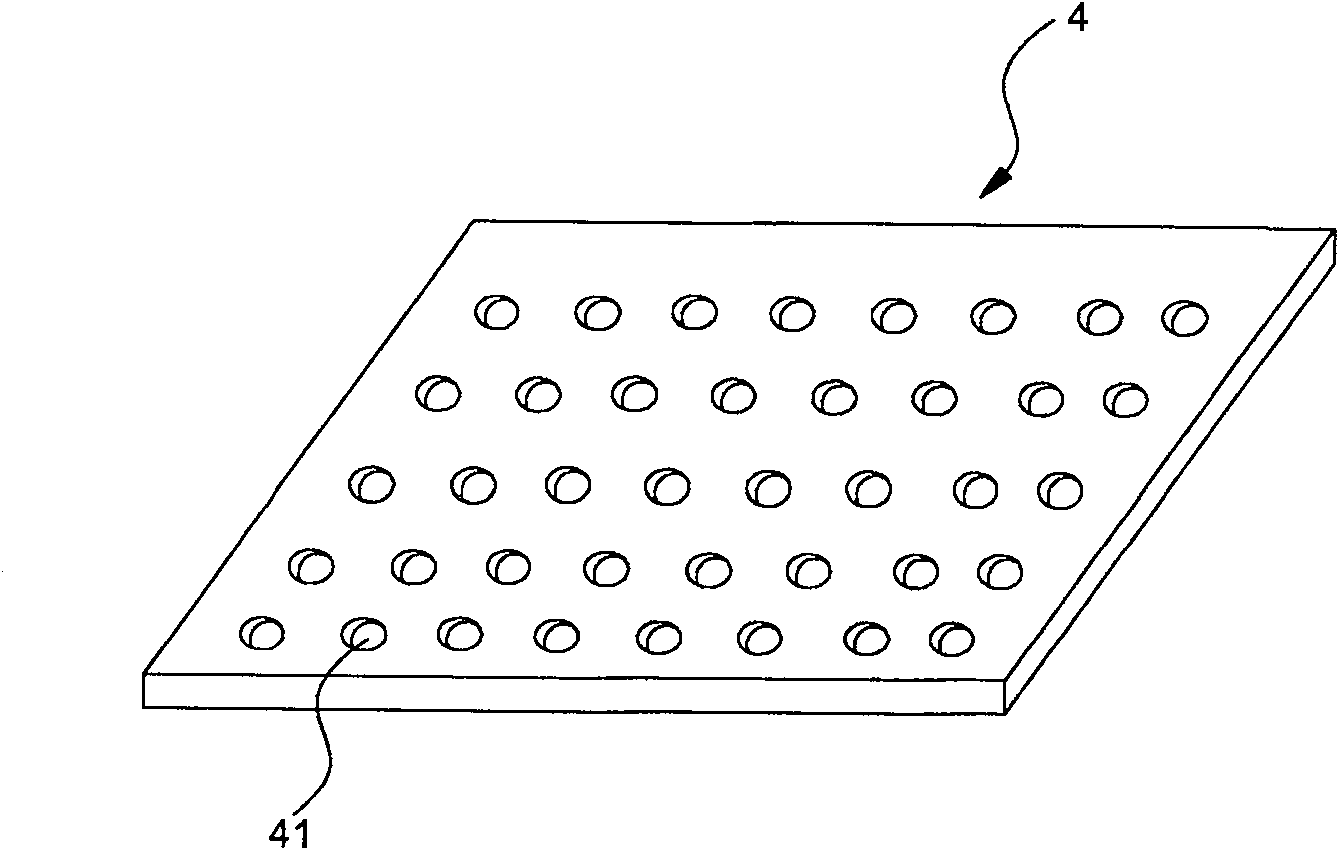

[0017] See attached Figure 1~2 The strong convection cooling system shown includes a cooling chamber 1 with a workpiece rack 7 inside, a strong convection circulating fan 2, a heat exchanger 3, and a circulating air duct 8. The top and bottom of the cooling chamber 1 are respectively provided with return air outlets 11 and The air supply port 12 and the air return port 11 communicate with the air inlet of the strong convection circulating fan 2 , and the air supply port 12 communicates with the air outlet of the circulating fan 2 through the circulating air channel 8 . Also be provided with dividing plate 4 (structure such as image 3 shown), a plurality of hollow draft tubes 5. The partition plate 4 is located below the workpiece frame 7 and divides the cooling chamber 1 into two parts, the upper chamber 13 and the lower chamber 14. The partition plate 4 is provided with several holes 41, and a plurality of hollow guide tubes 5 are corresponding to each other. Installed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com